| [1] | International Energy Agency. Africa Energy Outlook 2019 World Energy Outlook Special Report. 2019 Available from: www.iea.org/t&c/ [accessed on 20 November 2020]. |

| [2] | Obi OF, Adeboye BS, Aneke NN. Biomass Briquetting and Rural Development in Nigeria. Int J Sci Environ Technol. 2014; 3(3): 1043–1052. |

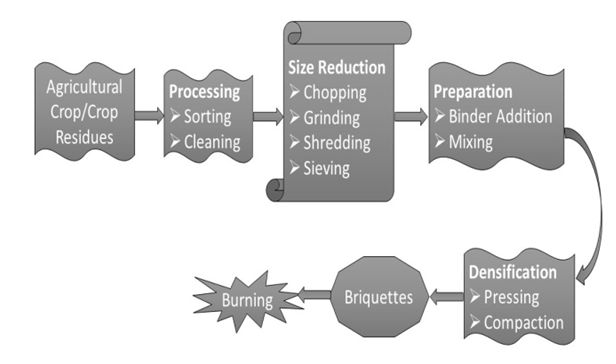

| [3] | Katimbo A, Kiggundu N, Kizito S, Kivumbi HB, Tumutegyereize P. Potential of densification of mango waste and effect of binders on produced briquettes. Agric Eng Int CIGR J. 2014; 16(4): 146–155. |

| [4] | Gujba H, Mulugetta Y, Azapagic A. The Household Cooking Sector in Nigeria: Environmental and Economic Sustainability Assessment. Resources. 2015; 4(2): 412–133. |

| [5] | Weinhold B. Indoor PM pollution and elevated blood pressure: cardiovascular impact of indoor biomass burning. Vol. 119, Environmental health perspectives. 2011. |

| [6] | Barnes BR. Behavioural Change, Indoor Air Pollution and Child Respiratory Health in Developing Countries: A Review. Int J Environ Res Public Health. 2014 25; 11(5): 4607–4618. |

| [7] | Smith KR, Mehta S. The burden of disease from indoor air pollution in developing countries: Comparison of estimates. Int J Hyg Environ Health. 2003; 206: 279–289. |

| [8] | Ritchie H, Roser M. Indoor Air Pollution - Our World in Data. 2019 Available from: https://ourworldindata.org/indoor-air-pollution [accessed on 22 November 2019]. |

| [9] | Watts N, Amann M, Arnell N, Ayeb-Karlsson S, Belesova K, Boykoff M, et al. The 2019 report of The Lancet Countdown on health and climate change: ensuring that the health of a child born today is not defined by a changing climate. Lancet. 2019; 394: 1836–1887. |

| [10] | World Health Organization. Indoor air Pollution: National Burden of Disease Estimates 2007. Available from: http://www.who.int/indoorair/publications/fuelforlife/ [accessed on 22 November 2019]. |

| [11] | Balmes JR. Household air pollution from domestic combustion of solid fuels and health. J Allergy Clin Immunol. 2019; 143(6): 1979–1987. |

| [12] | Felfli FF, Mesa P JM, Rocha JD, Filippetto D, Luengo CA, Pippo WA. Biomass briquetting and its perspectives in Brazil. Biomass and Bioenergy 2011; 35(1): 236–242. |

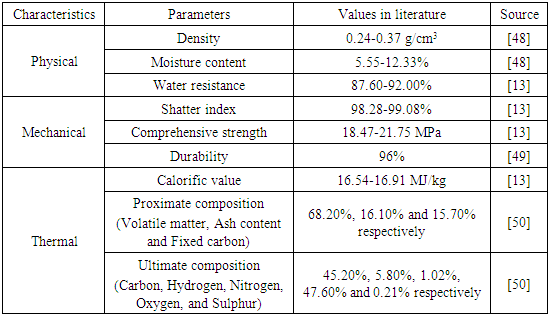

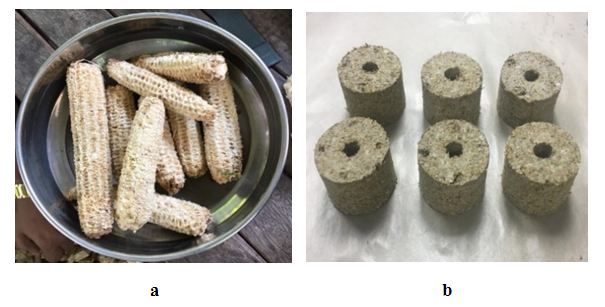

| [13] | Kpalo SY, Zainuddin MF, Manaf LA, Roslan AM. Production and Characterization of Hybrid Briquettes from Corncobs and Oil Palm Trunk Bark under a Low Pressure Densification Technique. Sustainability. 2020; 12(6): 1–16. |

| [14] | United Nations. UN Sustainable Development Goals. 2015 Available from: https://sustainabledevelopment.un.org/?menu=1300 [accessed on 26 September 2019]. |

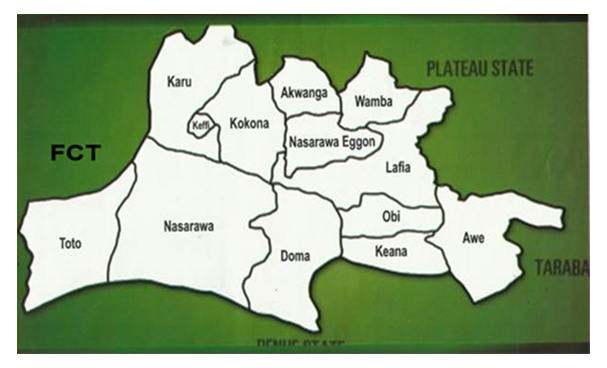

| [15] | Nasarawa State Government. About Nasarawa State].. Available from: http://www.nasarawastate.gov.ng/about.php [accessed on 13 February 2019] |

| [16] | Weather Spark. Average Weather in Nasarawa, Nigeria, Year-Round. Available from: https://weatherspark.com/y/55086/Average-Weather-in-Nasarawa-Nigeria-Year-Round [accessed on 19 May 2020]. |

| [17] | Aboki MP, Mailafiya MA, Osabo PA. Vegetation and Forest Resources of Nasarawa State. In: Geographic Perspective on Nasarawa State. Keffi: Onaivi printing and publication company; 2005. |

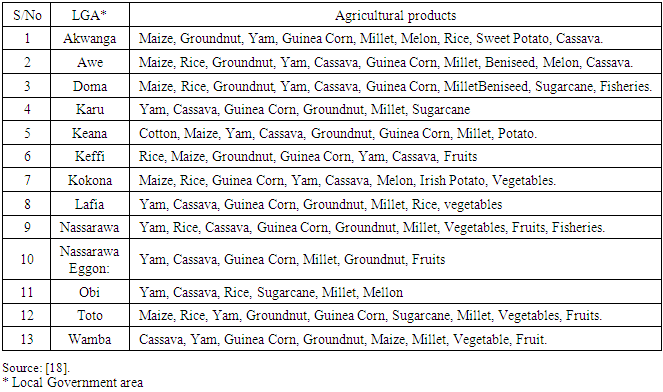

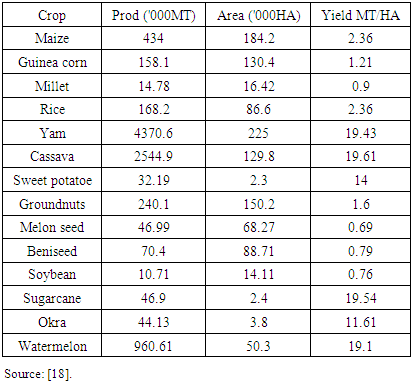

| [18] | Nasarawa Agricultural Development Programme (NADP). Distribution and Yield of Agricultural Crops in Nasarawa State. Available from: http://www.nasarawastate.gov.ng/about.php [accessed on 13 February 2019]. |

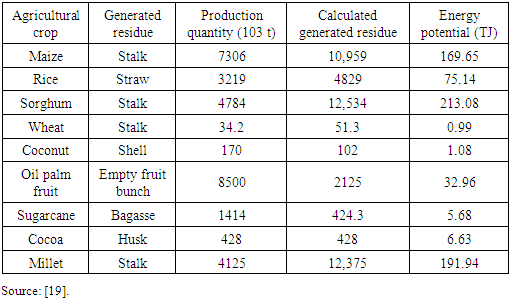

| [19] | Mohammed YS, Mustafa MW, Bashir N, Ogundola MA, Umar U. Sustainable potential of bioenergy resources for distributed power generation development in Nigeria. Renew Sustain Energy Rev. 2014; 34: 361–370. |

| [20] | Cooper CJ, Laing CA. A macro analysis of crop residue and animal wastes as a potential energy source in Africa. J Energy South Africa. 2007; 8(1): 10–19. |

| [21] | Agbro EB, Ogie NA. A comprehensive review of biomass resources and biofuel production potential in Nigeria. Res J Eng Appl Sci. 2012; 1(3): 149–155. |

| [22] | Hu J, Lei T, Wang Z, Yan X, Shi X, Li Z, et al. Economic, environmental and social assessment of briquette fuel from agricultural residues in China – A study on flat die briquetting using corn stalk. Energy. 2014; 64: 557–566. |

| [23] | Muazu RI, Stegemann JA. Effects of operating variables on durability of fuel briquettes from rice husks and corn cobs. Fuel Process Technol. 2015; 133: 137–145. |

| [24] | Shuma R, Madyira DM. Production of Loose Biomass Briquettes from Agricultural and Forestry Residues. Procedia Manuf. 2017; 7: 98–105. |

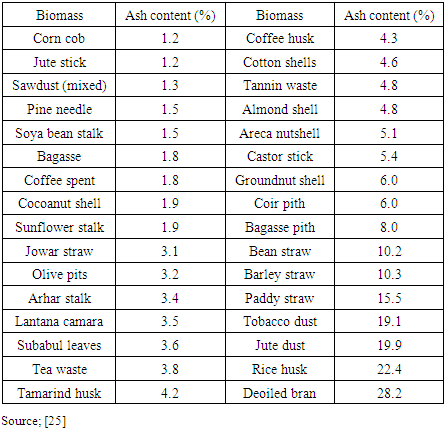

| [25] | Grover PD, Mishra SK. Biomass Briquetting: Technology and Practices. Regional Wood Energy Development Programme In Asia. Field Document No 46, Food and Agriculture Organization; 1996. |

| [26] | Kaliyan N, Vance Morey R. Factors affecting strength and durability of densified biomass products. Biomass and Bioenergy. 2009; 33: 337–359. |

| [27] | Oladeji J. Theoretical Aspects of Biomass Briquetting: A Review Study. J Energy Technol Policy. 2015; 5(3): 72–82. |

| [28] | Asamoah B, Nikiema J, Gebrezgabher S, Odonkor E, Njenga M. A Review on Production, Marketing and Use of Fuel Briquettes. 2016 Available from: http://www.iwmi.cgiar.org/Publications/wle/rrr/resource_recovery_and_reuse-series_7.pdf [accessed on 18 October 2018]. |

| [29] | Kristoferson LA, Bokalders V. Renewable Energy Technologies-their applications in developing countries. Pergamon Press, Oxford; 1986. 319 p. |

| [30] | Wang Z, Lei T, Yang M, Li Z, Qi T, Xin X, et al. Life cycle environmental impacts of cornstalk briquette fuel in China. Appl Energy. 2017; 192: 83–94. |

| [31] | Bhattacharya SC, Leon MA, Rahman MM. A study on improved biomass briquetting. Energy for Sustainable Development. 2002. |

| [32] | Dinesha P, Kumar S, Rosen MA. Biomass Briquettes as an Alternative Fuel: A Comprehensive Review. Energy Technol. 2018; 1(11): 1–21. |

| [33] | Kaur A, Roy M, Kundu K. Densification of Biomass by Briquetting: A Review. Int J Recent Sci Res. 2017; 8(10): 20561–20568. |

| [34] | Surendra KC, Khanal SK, Shrestha P, Lamsal B. Current status of renewable energy in Nepal: Opportunities and challenges. Renew Sustain Energy Rev. 2011; 15: 4107–4117. |

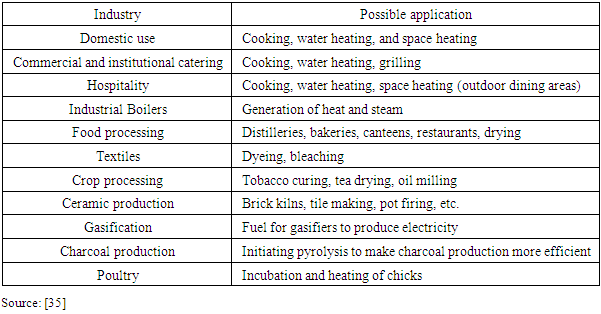

| [35] | Mwampamba TH, Owen M, Pigaht M. Opportunities, challenges and way forward for the charcoal briquette industry in Sub-Saharan Africa. Energy Sustain Dev. 2013; 17: 158–170. |

| [36] | Tripathi AK, Iyer PVR, Kandpal TC. A Techno-economic evaluation of biomass briquetting in India. Biomass and Bioenergy. 1998; 14(5/6): 479–488. |

| [37] | Chen L, Xing L, Han L. Renewable energy from agro-residues in China: Solid biofuels and biomass briquetting technology. Renew Sustain Energy Rev. 2009; 13(9): 2689–2695. |

| [38] | Rousset P, Caldeira-Pires A, Sablowski A, Rodrigues T. LCA of eucalyptus wood charcoal briquettes. J Clean Prod. 2011; 19(14): 1647–1653. |

| [39] | Pallavi H V, Srikantaswamy S, Kiran BM, Vyshnavi DR, Ashwin CA. Briquetting Agricultural Waste as an Energy Source. J Environ Sci Comput Sci Eng Technol. 2013; 2(1): 160–172. |

| [40] | Olorunnisola A. Production of Fuel Briquettes from Wastepaper and Coconut Husk Admixtures. CIGR Ejournal. 2007; IX: 1–11. |

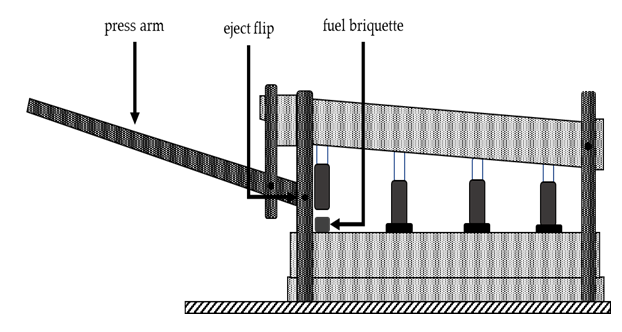

| [41] | Obi, O.F, Akubuo, C.O, Nwankwo V. Development of an Appropriate Briquetting Machine for Use in Rural Communities. Int J Eng Adv Technol. 2013; 2(4): 578–582. |

| [42] | Ajieh MU, Igboanugo AC, Audu TOK. Design of grass briquette machine. Niger J Technol. 2016; 35(3): 527–530. |

| [43] | Dairo OU, Adeleke AE, Shittu T, Ibrahim NA. Development and Performance Evaluation of a Low-Cost Hydraulic-Operated Biomass Briquetting Machine 1*. FUOYE J Eng Technol. 2018; 3(1): 1–6. |

| [44] | Legacy Foundation. Fuel Briquette Press Kit – A Construction Manual. 2003. |

| [45] | Tumuluru SJ, Christopher WT, Kenny KL, Hess JR. A Review on Biomass Densification Technologies for Energy Application. Idaho; 2010. |

| [46] | Stolarski MJ, Szczukowski S, Tworkowski J, Krzyzaniak M, Gulczyński P, Mleczek M. Comparison of quality and production cost of briquettes made from agricultural and forest origin biomass. Renew Energy. 2013; 57: 20–26. |

| [47] | Arewa ME, Daniel IC, Kuye A. Characterization and comparison of rice husk briquettes with cassava peels and cassava starch as binders. Biofuels. 2016; 7(6): 671–675. |

| [48] | Kpalo SY, Zainuddin MF, Halim HBA, Ahmad AF, Abbas Z. Physical characterization of briquettes produced from paper pulp and Mesua ferrea mixtures. Biofuels. 2019; 1–8. https://doi.org/10.1080/17597269.2019.1695361. |

| [49] | Tumuluru JS. Effect of pellet die diameter on density and durability of pellets made from high moisture woody and herbaceous biomass. Carbon Resour Convers. 2018; 1(1): 44–54. |

| [50] | Efomah AN, Gbabo A. The Physical, Proximate and Ultimate Analysis of Rice Husk Briquettes Produced from a Vibratory Block Mould Briquetting Machine. IJISET-International J Innov Sci Eng Technol. 2015; 2(5): 814–822. |

| [51] | Eriksson S, Prior M. The Briquetting of agricultural wastes for fuel. Rome, Italy: Food and Agricuture Organization; 1990. 131 p. |

| [52] | Bajwa DS, Peterson T, Sharma N, Shojaeiarani J, Bajwa SG. A review of densified solid biomass for energy production. Renew Sustain Energy Rev. 2018; 96: 296–305. |

| [53] | Lyheang C, Limmeechokchai B. The role of renewable energy in CO2 mitigation from power sector in Cambodia. Int Energy J. 2018; 18(4): 401–408. |

| [54] | International Energy Agency. CO2 emissions from fuel combustion - Highlights. 2019 Available from: www.iea.org/t&c/ (accessed on 20 November 2019). |

| [55] | Tursi A. A review on biomass: importance, chemistry, classification, and conversion. Biofuel Res J. 2019; 22: 962–979. |

| [56] | Kumar D, Singh B. Role of biomass supply chain management in sustainable bioenergy production. Biofuels. 2017; 1–11. https://doi.org/10.1080/17597269.2017.1368060. |

| [57] | Kuhe A, Ibiang FA, Igbong DI. Potential of low pressure agricultural waste briquettes: An alternative energy source for cooking in Nigeria. J Renew Sustain Energy. 2013; 5(1): 1–8. |

| [58] | Singh RM, Kim HJ, Kamide M, Sharma T. Biobriquettes-an Alternative Fuel for Sustainable Development. Nepal J Sci Technol. 2010 Apr 16; 10: 121–127. |

| [59] | Chen H. Lignocellulose biorefinery product engineering. In: Lignocellulose Biorefinery Engineering. 1st ed. Cambridge, UK: Woodhead Publishing Limited; 2015. p. 125–165. |

| [60] | Romallosa A, Kraft E. Feasibility of Biomass Briquette Production from Municipal Waste Streams by Integrating the Informal Sector in the Philippines. Resources. 2017; 6(12): 2–19. |

| [61] | Njenga M, Karanja N, Prain G, Malii J, Munyao P, Gathuru K, et al. Community-based energy Briquette production from urban organic waste at Kahawa Soweto Informal Settlement, Nairobi. Urban Harvest Working Paper Series No. 5. International Potatoe Center, Lima, Peru; 2009. |

| [62] | Jingura RM, Musademba D, Kamusoko R. A review of the state of biomass energy technologies in Zimbabwe. Renew Sustain Energy Rev. 2013; 26: 652–659. |

| [63] | Popp J, Lakner Z, Harangi-Rákos M, Fári M. The effect of bioenergy expansion: Food, energy, and environment. Renew Sustain Energy Rev. 2014; 32: 559–578. |

| [64] | Portugal-Pereira J, Soria R, Rathmann R, Schaeffer R, Szklo A. Agricultural and agro-industrial residues-to-energy: Techno-economic and environmental assessment in Brazil. Biomass and Bioenergy. 2015; 81: 521–533. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML