-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2019; 9(1): 1-11

doi:10.5923/j.ep.20190901.01

Hybrid Oven (Solar + Biomass) for Cooking. Design, Construction and Thermal Evaluation

Quiroga N. V.1, Esteves A.2, 3, Bailey J.2, Esteban S.4

1Facultad de Ciencias Agrarias, UNCUYO - Almirante Brown 500, Chacras de Coria, Luján de Cuyo, Mendoza, Argentina

2Environmental, Habitat and Energy Institute, INAHE – CONICET. Av. Ruiz leal s/n, 5500 Mendoza, Argentina

3Facultad de Arquitectura, Urbanismo y Diseño, Universidad de Mendoza, Mendoza, Argentina

4Non Conventional Energy Research Institute INENCO – CONICET – UNSa Av. Bolivia 5150 – 4400, Salta, Argentina

Correspondence to: Esteves A., Environmental, Habitat and Energy Institute, INAHE – CONICET. Av. Ruiz leal s/n, 5500 Mendoza, Argentina.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

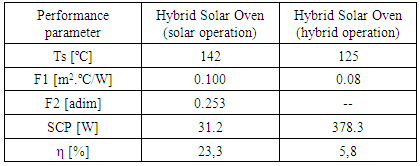

Solar energy for cooking is an interesting option to achieve energy efficient cooking, while reducing environmental impact and facilitating nutritious cooking on a daily basis, especially to provide nutrition for young children. Solar oven delivers high thermal performance running on solar energy alone on clear days. On cloudy days, the amount of solar energy is not enough to use the solar oven. Therefore, it is necessary to cook with electricity, gas or firewood, which breaks the continuity of the use of the solar oven. Then, when it is possible to use the solar oven again (on the subsequent clear day), it is difficult because of the habit established of fuel use. The hybrid oven (solar + biomass) allows for cooking every day of the year (clear or cloudy), with the same device, even at night. This paper presents the design, construction and thermal evaluation of a hybrid solar oven with biomass as an auxiliary source of energy. The basis is the drum solar oven, widely used for its characteristics: easy to build, efficient performance and optimum cooking capacity. It incorporates a specially designed appliance which takes advantage of the biomass and generates energy efficient cooking. Thermal tests are carried out to determine the characteristic parameters: figures of Merit F1 =0.100; F2 =0.253, standardized cooking power for 50°C, 31.2 W, and cooking efficiency 23.3% for operation only with solar energy and standardized cooking power for 50°C, 378.3W and cooking efficiency 5.8% for the oven with hybrid operation. Temperatures reached by the absorber plate are 120°C for solar-only energy operation and 173°C for hybrid operation. These temperatures do not endanger the integrity of the materials used. Only a minimum amount of energy is needed to reach the necessary temperature and power for cooking. It is therefore an interesting and economical solution for all communities of any climatic condition, especially those that are isolated from energy supply networks.

Keywords: Hybrid oven, Energy efficient cooking, Solar Oven, Biomass oven

Cite this paper: Quiroga N. V., Esteves A., Bailey J., Esteban S., Hybrid Oven (Solar + Biomass) for Cooking. Design, Construction and Thermal Evaluation, Energy and Power, Vol. 9 No. 1, 2019, pp. 1-11. doi: 10.5923/j.ep.20190901.01.

Article Outline

1. Introduction

- Access to energy resources is a problem in vulnerable sectors of the world population. According to the Intergovernmental Panel on Climate Change (IPCC), 56% of the world’s renewable energy is made up of firewood and vegetable carbon (bioenergy), which is mainly utilized for cooking in developing countries [1]. In this context, providing a cooking device that has high performance and low environmental impact would be of immense and immediate benefit for theses vulnerable communities.In Argentina the energy matrix is made up primarily of fossil fuel consumption, particularly natural gas [2]. With regards of fuel utilized for cooking food, only 56.2% of homes have access to natural gas, while it 37.5% use LPG - Liquefied Petroleum Gas (10kg propane tanks), many of which also use firewood (when they finish the 10kg tank) and 2.65% use only firewood [3]. The costs of fuels are variable for 10,000 kcal: natural gas $Ar 6.00 (U$S 0.157); LPG $Ar 31.25 (u$s 0.822); firewood $Ar 22.80 (U$S 0.60). Due to the high cost of LPG and electricity, and the inability to use natural gas (because of the non-existence of pipelines), people in remote rural areas, mostly use biomass (firewood) as an easily accessible, cheap fuel. [4].A family that uses biomass daily for cooking can have problems associated with its collection and use: injuries, tears, lacerations, sores, lumbar injuries during gathering; asphyxia, eye irritation and allergies caused by exposure to smoke, burns from hot water or caused by direct contact during cooking, etc. [5]. In the central-western region of Argentina this activity took up to 2 hours daily. Additionally, people choose to avoid preparing energy intensive foods such as meats, cereals and legumes that are rich source of proteins, vitamins and minerals essential for the daily diet, especially for children.Also in this region of the country, the extraction of firewood from the native forests peripheral to communities in non-irrigated areas is one of the causes of desertification, with the rate of regeneration lower than the rate of exploitation [6, 7]. Over time, these forests become scarce, due to an increase in consumption or an increase in consumers, because firewood is cut from the native forests by those who need a quick solution to their energy needs. As a result greater distances have to be covered to obtain firewood. In oasis areas where irrigated water is available, firewood can be obtained from pruning trees on public streets or from windbreak barriers. In a global context, people below the poverty line are dependent on biomass as a source of energy for cooking and other uses [8].In this context, solar energy for cooking is an interesting option to achieve energy efficient cooking, while reducing environmental impact and facilitating nutritious cooking on a daily basis, especially to provide nutrition for young children. Solar cooking can be done without the use of other fuels. The only requirement is to have sufficient solar radiation. This occurs on clear or partly cloudy days (In the central-western part of Argentina, approximately 300 days/year are measured). Cooking can be completed in about 2 hours [5, 9].On cloudy days, solar energy is not enough to use the solar cooker (in the central-western part of Argentina, approximately 65 days/year are computed). On such days it is necessary to cook with electricity, gas or wood stoves. In this way, the continuity of the use of the solar oven is lost and return to the use of solar cooking is difficult once the sun shines again. A possible solution would be a hybrid oven that uses another source of auxiliary energy in addition to solar energy, allowing it to work on cloudy or clear days. There are different types of hybrid ovens that have been designed for cooking. Saxena and Agarwal design a new hybrid solar cooker with air duct and halogen lamp and low power fan in it. These help to reduce the cook time. They present tested for thermal performance evaluation in climatic condition of western Uttar Pradesh, India. The parameters calculated are: F1 = 0.12 m2.°C/W, F2 = 0.46, thermal efficiency = 45.11%, cooking power = 60.20 W and overall heat loss coefficient is 6.01 W/m2 °C with minimum consumption of only 210W [10].Saxena and Karakilcik present a solar box cooker (SBC) with low cost heat storage material composed of sand (40%) and carbon (60%). With this SBC it is possible to cook during the off-sunshine hours. They indicate the figures of merit F1 = 0.13 m2.ºC/W and F2 = 0.44 and thermal efficiency of 37.1% were estimated [11]. Another system is an SBC with phase change materials (PCM) such as stearic acid, found to have good latent heat storage to combine with solar cooking [12]. Nandwani designed and tested a hybrid solar system that allows, in addition to cooking, to dehydrate and purify water, using electric power on cloudy days or partially cloudy days in addition to solar energy. Effective thermal efficiency is from 23% to 32%, depending on the mode of operation. Nandwani indicates that electric power consumption is minimal because it is used only to complete cooking when solar energy is insufficient [13].Prasanna and Umanand utilize a hybrid solar cooking system with use of LPG too. The solar energy is collected in a paraboloid dish concentrator and heats oil that transports energy to an intermediate tank. Later when cooking is required the energy stored in the intermediate tank is used to generate heat. If the temperature is not enough, liquefied gas is used to supplement [14].Arunachala designed a hybrid cooker for night cooking, using cylindrical parabolic concentrator-CPC that heats oil with solar energy. Later, at night, the temperature of the oil is enough to heat the food. Temperatures of 110°C are reported for this cooker [15].Another hybrid solar oven was presented by Joshi [16]. It uses solar thermal and photovoltaic energy, enhancing the work the oven and, at the same time, reducing the weight of the appliance with respect to other solar ovens.Fonseca presented a high capacity hybrid cooker for use in industrial kitchens [17]. This oven consists of a cooking chamber and a combustion chamber. The latter is attached to the outside of the oven. This model reduces wood consumption and its performance is 21% higher than traditional non-solar ovens. The energy consumed in hybrid solar-biomass cooking to reach a difference in temperature of 50°C is: 80W when the test is carried out with orientation and 58 W without orientation. This is according to the protocol of the Red Iberoamericana de Cocción Solar de Alimentos (RICSA-CYTED, or Iberoamerican Network of Food Solar Cooking) [18]. Among the advantages is that the quantity of biofuel used, 1 kg of coal and 3.7 kg of firewood, can maintain the temperature of 7.2 kg of water above 80°C for a five hour period. The disadvantages are that the equipment is too big and would be onerous for family use. Buigues analyses the possibility of combining a solar oven with electricity to make it viable for cloudy day use [19]. On those days, the temperature of the absorber plate remained between 120°C and 140°C with electric power.Quiroga has designed a solarelectric oven that allows for cooking on cloudy days, as well as at night. The disadvantage of this type of hybrid solar oven is that it requires a source of electrical power that does not exist in many isolated rural communities [20].This paper presents the design, construction and thermal evaluation of a hybrid solar oven with biomass as an auxiliary source of energy. The basis is the drum solar oven, widely used by its ease of construction, efficient performance and optimum cooking capacity. It incorporates a specially designed appliance which takes advantage of biomass and generates energy efficient cooking.

2. Construction of the Oven

2.1. Design Objectives

- The design of the hybrid solarbiomass oven requires meet certain objectives:1. The cooking power of the auxiliary fuel must be equal to or exceed the cooking power of the system when it is operated with only solar energy2. Take only one to two hours for cooking.3. The materials used (thermal insulation and transparent materials) should maintain their physical properties over time, because biomass combustion generates higher temperatures than the solar energy process. 4. The combustion chamber should be able to hold the quantity of biomass required in order to reach and maintain the cooking temperatures during the period of time required.5. The oven should be made with available materials, such as those that can be found in local hardware stores, as much as possible. 6. The design must be easy to assemble, be easily replicated and economic.

2.2. Drum Solar Oven

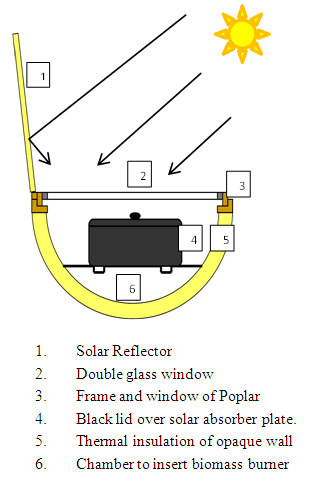

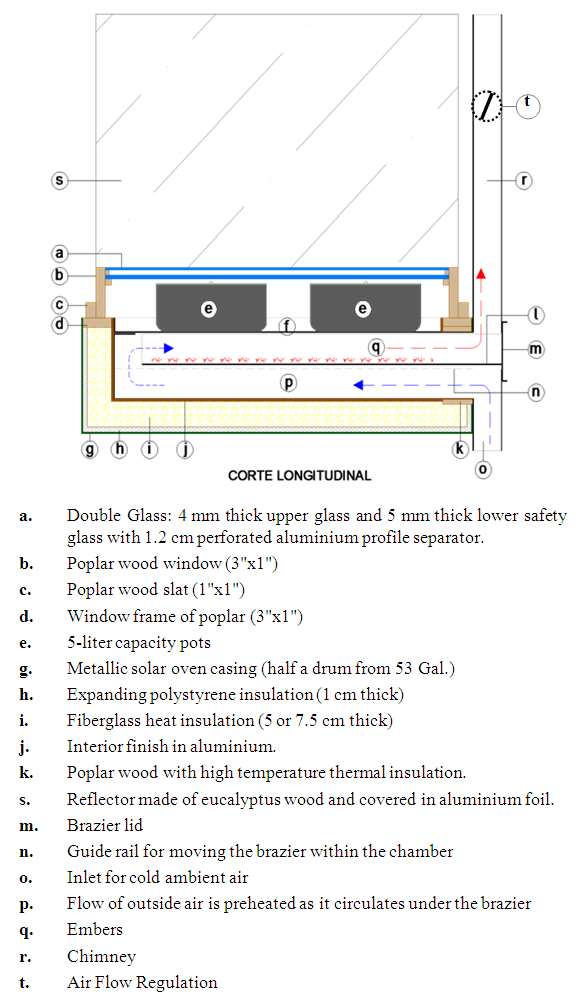

- The drum solar oven was developed by Hobbs in Australia [21], and later introduced in Argentina by Saravia [22] who made a replica in Salta, Argentina. Subsequently Esteves made his own version in the central-western region of Argentina [23]. Figure 1 shows Esteves version of drum solar oven and Figure 2 shows transversal section of the oven, showing different elements.

| Figure 1. Drum solar oven with mobile stand |

| Figure 2. Transversal section of the drum solar oven |

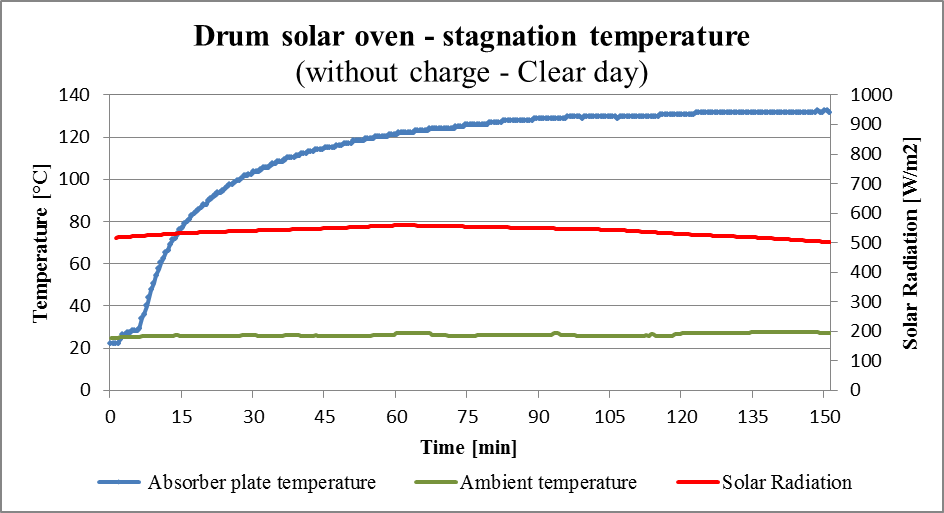

| Figure 3. Stagnation temperature without charge, on clear day |

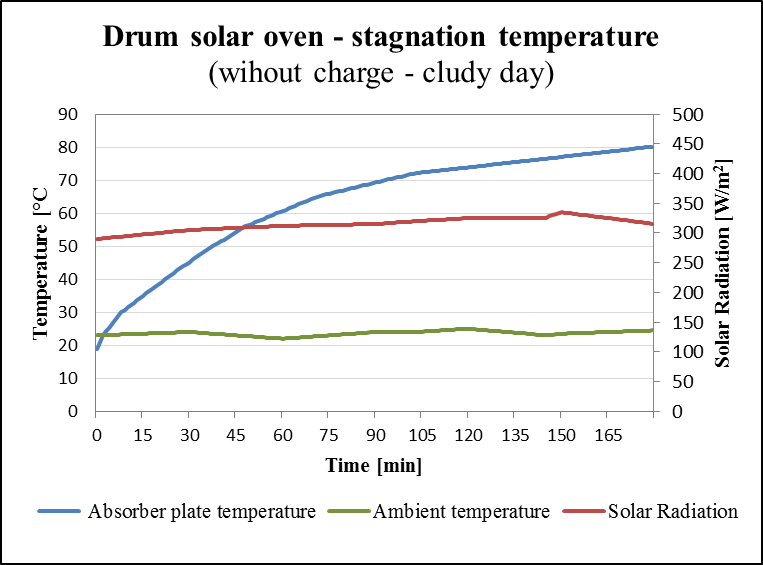

| Figure 4. Stagnation temperature without charge, on cloudy day |

2.3. Composition of Biomass for Use as Fuel

- Combustion is a process of rapid oxidization with a release of heat. Firewood as fuel contains carbon (C) hydrogen (H), oxygen (O) nitrogen (N) and other elements, which combine with oxygen (O2) of the air. With the correct combination, ignition ensues, which in turn maintains the temperature that allows the reaction to continue.The cells of wood have cellulose, hemicellulose and lignin as their main components (99%). Nitrogen (N) content is about 0.75%, while the sulfur content is very low [24].In general, firewood has an initial combustion temperature of around 300°C, this being the temperature at which the energy generated in the reaction is greater than the energy lost to the atmosphere, thus maintaining combustion. Ignition temperature depends on the atmospheric pressure, combustive agent (air) and used combustible [25].The moisture content of freshly cut firewood varies between 40 and 50%; after being left exposed in dry weather protected from rain, the average moisture content drops by approximately 25%.The biomass available in any given area depends on the native species and exotic species planted by previous generations. The area that concerns us in this work comprises the province of Mendoza in the central-western region of Argentina, that is south latitude between 31° and 36°; west longitude, between 66° and 69°; altitudes between 400 and 900 m.a.s.l.

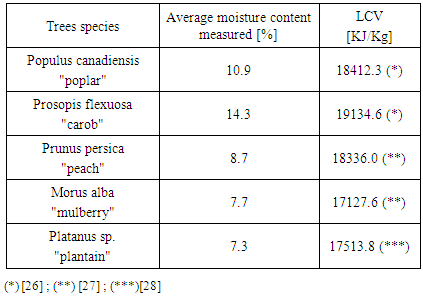

2.4. Measuring the Water Content of the Wood

- The low calorific value (LCV) of biomass is affected by moisture content because evaporating water requires more energy during the combustion process [24, 25].To determine the average moisture content (%) of the biomass used in the tests, measurements were taken with a resistive hygrometer made by Delmhorst Instrument, which has a sensitivity of +/ 1%. The wood used in the tests have been air dried for a minimum of 1 year, and protect from rain.Table 1 indicates the LCV and percentage of moisture of the firewood used in the thermal tests. The five species listed are common in Mendoza [26]. Of these, the only native species is Prosopis flexuosa, or carob, while the others are exotic. Mulberry and plantain are frequently present in urban spaces, peach and poplar are found in the gardens of suburban housing as well as in cultivated rural areas, while the carob is present in the dry lands of Mendoza province.

|

|

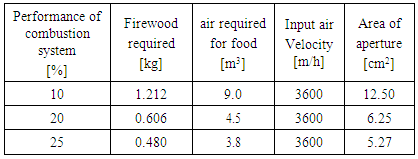

2.5. Sizing of the Combustion Chamber

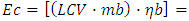

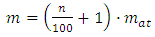

- Since the temperature of the flame is much higher than the temperature reached using only solar energy, the combustion chamber of the oven is projected taking into account the incorporation of hot embers as an auxiliary source of energy. These have a lower temperature than a flame. The combustion chamber must, in this case, hold the temperatures generated by the embers without damaging other parts of the oven. Therefore an appropriate container is designed to hold hot embers and, at the same time, to deliver the heat generated to the cooking chamber. It should also be large enough to hold the amount of biomass that needs to be loaded.The amount of energy Ec, necessary to cook any given meal made by combustion of mass of biomass (mb) is obtained from Eq. 1:

| (1) |

| (2) |

2.6. Necessary Air for Combustion

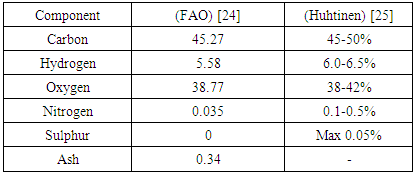

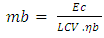

- The chemical composition of the firewood used in the combustion system depends on its moisture content. Table 2 indicates moisture content in several wood samples after 1 year in open air and protected from rain. The value is around 10%, its chemical composition of C, H, O, N and S is very similar for different woods [27, 28, 30].The theoretical amount of air required for complete combustion, is computed from the proportion of each chemical compound present in the wood, according to Eq. 3.

| (3) |

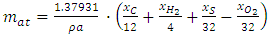

= theoretical air mass required [m3 air/kg of firewood]ρa = air density [kg/m3]XI = % of each chemical compound (from Table 2)The air density is calculated from the equation recommended by the International Organization of Legal Metrology (OIML), according to Picard [31].In the case of Mendoza, Argentina there is relative humidity of 49% average, ambient temperature 27°C (January), and air density resulting in 1,1068 kg/m3. For chemical composition indicated by FAO [25] (Table 2) and replacing the values in Eq. 3, theoretical amount of air is 4.93 m3 per kg of firewood for total combustion is required.It is important to ensure that the entire mass of wood utilized completes the combustion process; for this purpose, excess air must be considered. Solid fuels require the most excess air, that is, from 30 to 50% more than the theoretical value calculated from Eq. 3. When working with fluidized bed, the excess air mass can be less 20 to 25% [32]. Air mass required it is calculated with Eq. 4 [25].

= theoretical air mass required [m3 air/kg of firewood]ρa = air density [kg/m3]XI = % of each chemical compound (from Table 2)The air density is calculated from the equation recommended by the International Organization of Legal Metrology (OIML), according to Picard [31].In the case of Mendoza, Argentina there is relative humidity of 49% average, ambient temperature 27°C (January), and air density resulting in 1,1068 kg/m3. For chemical composition indicated by FAO [25] (Table 2) and replacing the values in Eq. 3, theoretical amount of air is 4.93 m3 per kg of firewood for total combustion is required.It is important to ensure that the entire mass of wood utilized completes the combustion process; for this purpose, excess air must be considered. Solid fuels require the most excess air, that is, from 30 to 50% more than the theoretical value calculated from Eq. 3. When working with fluidized bed, the excess air mass can be less 20 to 25% [32]. Air mass required it is calculated with Eq. 4 [25]. | (4) |

|

2.7. Design and Construction of the Combustion Chamber with Air Circulation

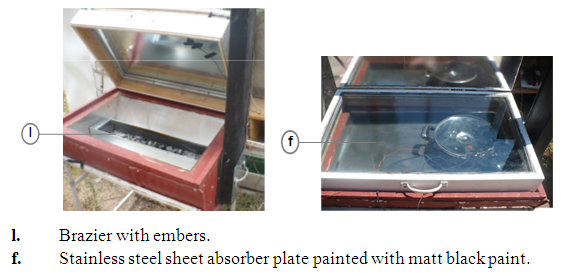

- An appropriate device is designed to allow both the solar gain on the top of the absorber plate and the heat transfer from biomass combustion in the bottom of it. It consists of a container that holds the embers, and at the same time, allows an air stream to flow in order to provide the necessary oxygen to complete the combustion of the embers (Figures 5 and 6).

| Figure 5. Longitudinal cross section of hybrid solar oven |

| Figure 6. View of the oven without absorber plate (upper); and with absorber plate (lower) |

| Figure 7. View of the oven with the open brazier ready to place the embers |

3. Thermal Test for Determining oven Performance

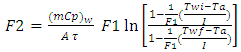

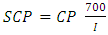

- A Labjack U3LV data acquisition system was used to measure the temperatures of the oven components. It is programmed with Daqfactory software to collect data every minute. This is connected to a PC to record the data. The temperature measurements were made with type K, J and T self-compensated thermocouples, connected to data acquisition system. Solar radiation was recorded using a Kipp and Zonen sensor, model CM5, connected to a Datalogger HOBO. The weight of the mass of water and biomass used is measured using an electronics scale Systel Bumer with +/- 5g precision.The first factor of merit F1 takes into account the relationship between the optical efficiency of the oven and the heat it loses to the outside from the absorber plate [33, 34]. Its mathematical expression is indicated in Eq. 5 and its value should be greater than 0.12 m2.ºC/W but, depending on the climate of the place and the stagnation temperature. This should be equal or exceed 111ºC [33].

| (5) |

| (6) |

= time interval between Twi and Twf [sec]Twi = initial water temperature [°C]Twf = final water temperature [°C]Ta = ambient temperature [°C]I = solar radiation [W/m2]Another figure that is interesting to evaluate in solar ovens is the standardized cooking power SCP. The Eq. 5 is used to calculate it [34], [36].

= time interval between Twi and Twf [sec]Twi = initial water temperature [°C]Twf = final water temperature [°C]Ta = ambient temperature [°C]I = solar radiation [W/m2]Another figure that is interesting to evaluate in solar ovens is the standardized cooking power SCP. The Eq. 5 is used to calculate it [34], [36]. | (7) |

| (8) |

| (9) |

= time it takes to heat from Ti to Tf [s]Iavg = average solar radiation in interval of time [W/m2]Aa = aperture area [m2]mb = mass of biomass [kg]LCV = Lower calorific value of biomass [J/kg]When it is operated with only solar energy, mb = 0, and the second term of the denominator is zero, what is left is the equation for the efficiency of the solar-only oven.Thermal test has been done in order to determine: figures of merit F1 and F2; the standardized solar power of the oven [18], [35], [36] and its thermal efficiency.

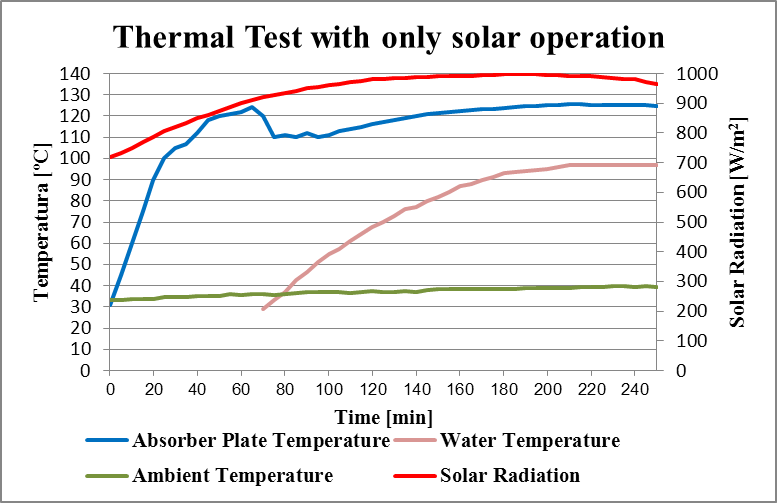

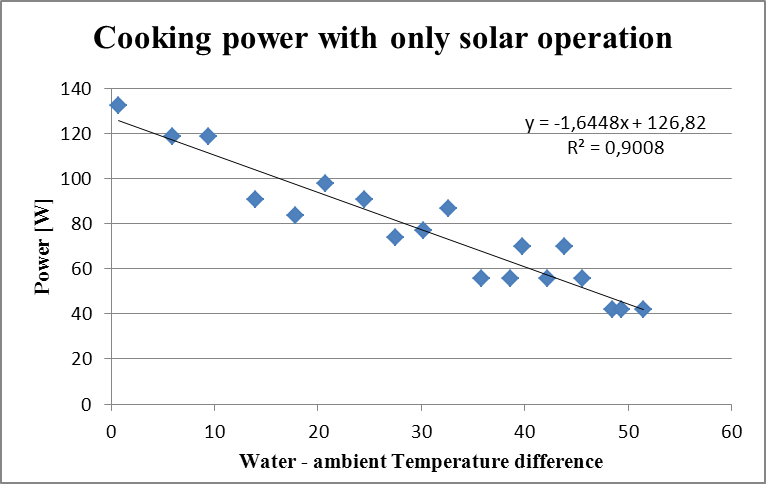

= time it takes to heat from Ti to Tf [s]Iavg = average solar radiation in interval of time [W/m2]Aa = aperture area [m2]mb = mass of biomass [kg]LCV = Lower calorific value of biomass [J/kg]When it is operated with only solar energy, mb = 0, and the second term of the denominator is zero, what is left is the equation for the efficiency of the solar-only oven.Thermal test has been done in order to determine: figures of merit F1 and F2; the standardized solar power of the oven [18], [35], [36] and its thermal efficiency.3.1. Thermal Test with only Solar Energy Operation

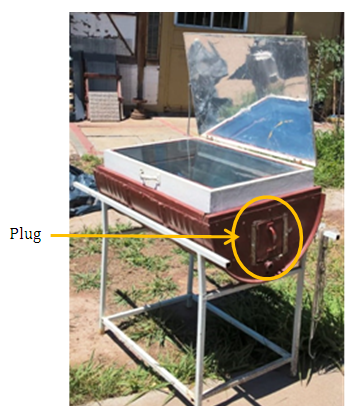

- To operate the oven exclusively with solar energy (on clear days), it is appropriate to disassemble the biomass combustion chamber. Figure 8 shows the oven with the “plug” utilized when it is operating only with solar energy (on clear days).

| Figure 8. Oven with the “plug” utilized when operates only with solar energy (on clear days) |

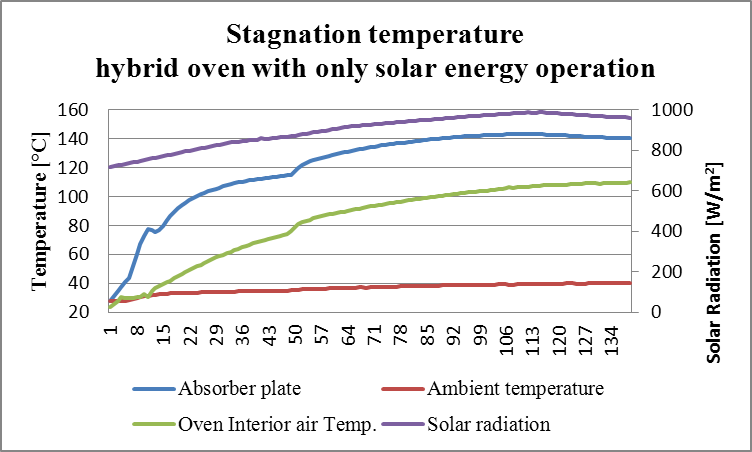

| Figure 9. Stagnation temperature with only solar energy operation |

| Figure 10. Thermal test results with only solar energy operation |

| Figure 11. Cooking power with only solar energy |

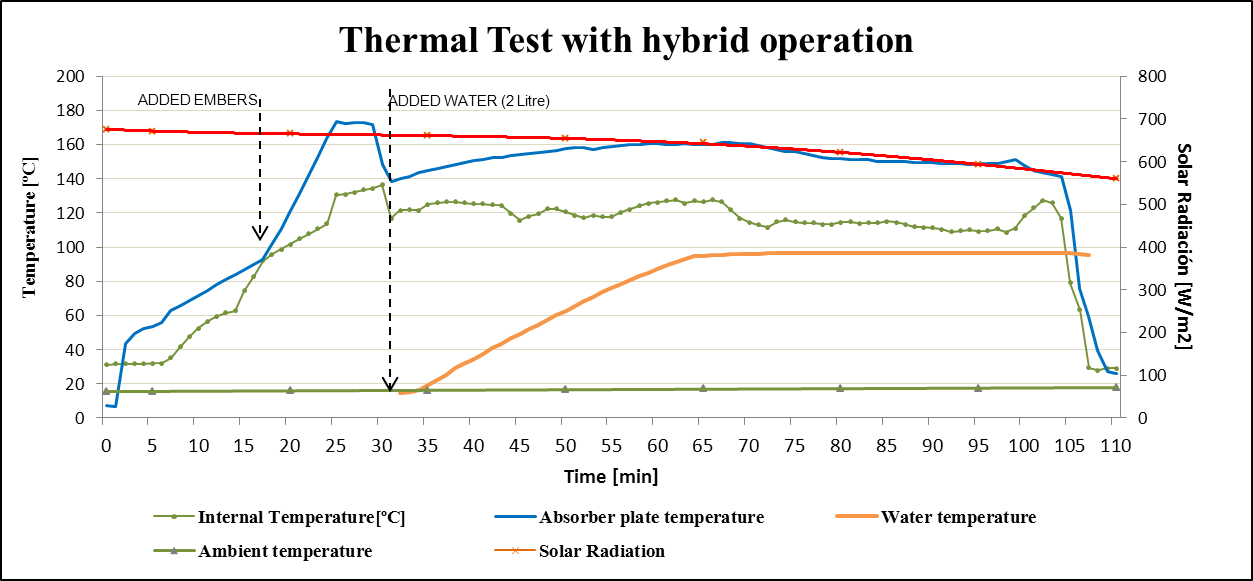

3.2. Thermal Test with Hybrid Operation

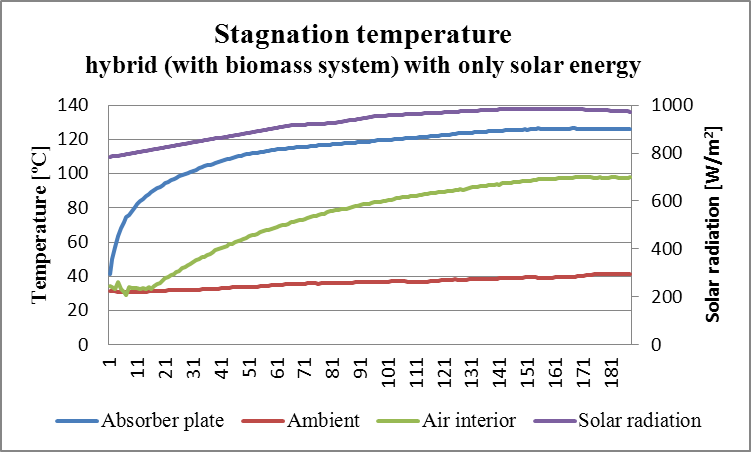

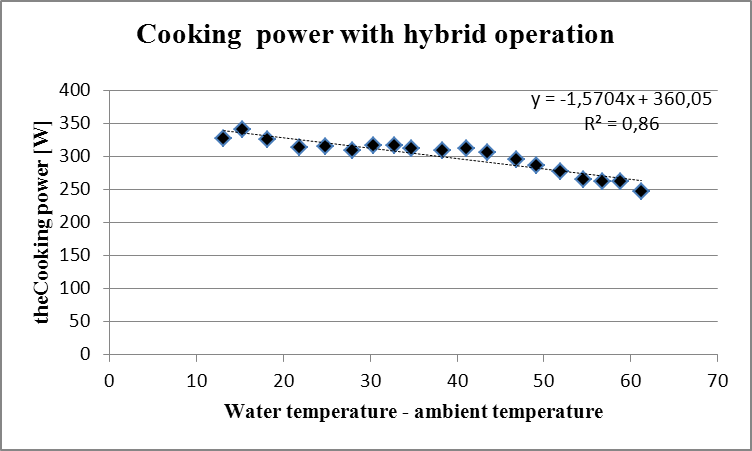

- Fig. 12 show the stagnation temperature and it is possible to obtain F1, in this case: F1=0.085 m2.°C/W. This test is carried out with the biomass system assembled on the oven.

| Figure 12. Stagnation temperature with only solar energy operation but with biomass system incorporated (see Fig. 7) |

| Figure 13. Oven temperatures with hybrid operation |

| Figure 14. Cooking power for hybrid operation |

4. Results

- The results of the two oven operations: hybrid solar oven with only solar operation and hybrid solar oven with hybrid operation are included in Table 4.

|

5. Conclusions

- Observing the starting objectives of the research and the results obtained from the thermal tests with the oven in operation mode only with solar and with hybrid energy, the following conclusions can be reached:- The oven’s capacity in hybrid and solar mode does not change.- The oven’s power in hybrid mode is such that the cooking of meals is carried out in less time than in solar-only energy mode.- The temperatures reached by the absorber plate and the interior of the oven are not hazardous to material deterioration.- The material used for the biomass heating system (steel sheet) is easily obtainable in local hardware stores, which allows it to be easily and cheaply replicated.Some additional advantages to be considered are: The combustion chamber is closed off from the cooking chamber, i.e., the combustion gases do not mix with the food but allow heat transfer towards the absorber plate before being expelled.Temperatures reached for the absorber plate are around 120°C and 173°C in solar-only mode and hybrid mode respectively. The standardized cooking power in the solar-only operation is 31.2W, while in hybrid mode it is 378.3W, resulting in lower cooking times. One of the greatest advantages of the hybrid solar design is that can be used consistently for cooking every day, regardless of climatic conditions. This kind of oven has sufficient thermal power to be useful in places with a high proportion of cloudy or partially cloudy days, and even at night. Another notable advantage of this design is that it is an adaptation of the drum solar oven, which is cheap and simple to build, as well as easy to operate. It is therefore an economical solution that could be of significant benefit for all communities isolated from the energy supply networks.

ACKNOWLEDGEMENTS

- The authors acknowledge the contributions of Fernando Buenanueva for the constructive face of the oven and also to CONICET for partially funding this research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML