-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2018; 8(2): 46-50

doi:10.5923/j.ep.20180802.02

Experimental Investigation on the Performance of Novel Stove for Use with Vegetable Oil

1M.Tech Student, Energy Systems Engineering, NMAM Institute of Technology, Nitte, India

2Department of Mechanical Engineering, NMAM Institute of Technology, Nitte, India

Correspondence to: Sudesh Bekal, Department of Mechanical Engineering, NMAM Institute of Technology, Nitte, India.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Most of the families in rural areas depend upon kerosene stove for their household purposes. The shortage of kerosene fuel will cause a severe problem for their daily life. Since the vegetable oil can be produced abundantly, an attempt needs to be made to use vegetable oil as fuel for cooking. Since the conventional Kerosene stove cannot function well with vegetable oil, in this work an attempt has been made to develop a novel stove designed for use with vegetable oil. Two types of oil were tested on the developed stove, namely Pongamia oil and Neem oil, by varying the secondary air supply (by varying the throat length). A comparison of thermal efficiency, fire power, and specific fuel consumption has been made. The novel stove is found to work well with both types of vegetable oil with Pongamia oil producing marginally better efficient than Neem oil.

Keywords: Novel cooking stove, Neem oil, Pongamia oil, Fire power

Cite this paper: Arvind, Sudesh Bekal, Experimental Investigation on the Performance of Novel Stove for Use with Vegetable Oil, Energy and Power, Vol. 8 No. 2, 2018, pp. 46-50. doi: 10.5923/j.ep.20180802.02.

Article Outline

1. Introduction

- Kerosene is extensively used in stoves for cooking purpose in villages. India’s kerosene consumption is approximately 12 million kilo litre per annum. Approximately 72% of the population of India as well as several African countries continue to rely on kerosene as fuel for cooking, heating and lighting. Electrified households in rural areas also use kerosene as a backup fuel due to the poor electricity supply.Because of limited supply of kerosene, its depletion and many kitchens born respiratory diseases from kerosene, a means should be found out for replacing it by renewable fuels. Considering the success associated with replacement of diesel with vegetable oil and their esters, it is conceivable that even kerosene can be replaced by such vegetable oil fuels.Generally, for cooking purpose either pump or wick stove is used. When wick stove is used, the working of stove is based on capillary action which causes fuel to move to the tip of the wick; Kerosene being a fuel with high capillary action can easily rise up through the wick. The kerosene burning pump stoves and their imitators are made of brass burners and are a significant advance over stove designs which used wick. The burner vaporized the fuel in a loop of pipe which rose up from the fuel tank at the base of the stove, and Initial pressure is provided by a small, hand operated pump integrated into the stove's fuel tank. The flame in the burner is adjusted by using the pump to increase the pressure in the tank to make the flame larger, or by venting the tank to reduce the pressure and make the flame smaller. Later models use a separate valve to adjust the flame.Any vegetable oil has viscosity nearly fifteen times more than kerosene. Therefore if vegetable oil is used in straight form it may not be able to rise through the wick, thus resulting in poor or no flame formation. Therefore, the goal of this work is to design a Bio-stove to work on vegetable seed oil.Research on the use of vegetable oil in I.C engines has been extensive and good results have been obtained. However the use of vegetable oil in household stove for reducing indoor air pollution and saving kerosene fuel find no extensive work by the researchers.Verendra [1] used a mixture of raw Pongamia/esterified pongamia and kerosene mixture in different proportions for comparing the operational characteristics like efficiency, firepower, specific fuel consumption and various emission characteristics used to determine appropriate fuel variant. The two stoves namely wick stove and pump stove were used. The various blends of fuel are 10, 20, 30, 40, 50, 60, 70, 80, 90%.From the experiment it was found that the use of Pongemia oil-kerosene blend beyond 50P-60P result in inefficient burning in a wick stove and beyond 80P while working with pump stove. Further based on study, use of pump stove is recommended for both combinations of blend and esterified Pongamia. Further, use of wick stove with ester/oil is beneficial over pump stove on the basis of emission. Rao et al [2] carried out investigation of Pongamia, Jatropa and Neem methyl esters as bio-kerosene on stoves. Investigations have been carried out to examine properties, performance and emission of different blends. Pongamia methyl esters gave better performance compared to jatropa and neem methyl esters.In their paper Rubab and Kandapal [3] mention about use of bio-fuel mix for cooking in rural areas, implications for financial viability of improved cooking stove, an attempted to study financial implications of replacing a traditional bio-fuel cook stove with an improved one has been made. The capital cost of a popular portable metallic cook stove designs and fuel savings have been quantified in terms of two performance indicators-overall thermal efficiency pot-cook stove combination and specific fuel consumption of a cook stove. In his paper, Singh [4], mentioned about having worked on SVO (Straight Vegetable oil) of Jatropha was de-waxed and de-gummed as per the standard procedure, and was tested in irrigation pump set, kerosene cook stove and kerosene lamp. Trials taken with kerosene stove and kerosene lamp also reveals that Jatropha oil could be used as cooking fuel in pressurized stoves with a blend of 30% Jatropha oil and 70% kerosene without any problems. In their paper, Bhattacharya and Mishra [5], work on different stove found that higher moisture content reduces the efficiency, increase in the emission factor of CO and decrease in the emission factor of NOx, a slight decrease in CO2 emission factor was also observed.In their work, Natrajan et al [6], an attempt has been made to use waste vegetable oil as a fuel for a cooking stove. Suitable modifications have been made in the kerosene stove for use with vegetable oil as fuel. The efficiency of the stove using vegetable oil as fuel is observed to be increased by 14% as compared with that of a conventional stove when a flat copper bottom vessel is used.In their study, Kratzien and muller [7], mentioned about having working on influence of calcium and magnesium content of coconut oil on deposit and performance of plant oil pressure stove found that deposits increased as the level of calcium in the fuel blends increased. The same was also valid for magnesium enriched fuel blend.In their paper, Victer et al [8], working on energy performance of wood cooking stoves in Mexico found that energy evaluation of cook stove and efficient burning cook stove developed showed energy savings of 66% for fuel wood and 64% for LPG in households using mixed fuels.Divakar [9] in his work wanted to see the possibility of using pongemia oil in kerosene stoves. In order to improve the capillary action, kerosene has been mixed with vegetable oil for experimentation on two type stoves namely wick stove and pump stove. From the experiment it was found that the use of pongemia oil-kerosene blends beyond 50-60% (by volume) of pongamia-Kerosene mixture result in inefficient burning in a wick stove and beyond 80P while working with pump stove.In the light of above literature survey in which most of the work is associated with use of vegetable oil-Kerosene blend in conventional Kerosene stove, and none on new type of stove, in this work a novel type of Bio-stove was developed which is found to work well with any type of vegetable oil. Basically two types of oils namely [1] Pongamia oil and [2] Neem oil have been tried. Experiments were conducted for both oils, and it is found from the experiments that the use of Pongamia oil results in better efficiency than Neem oil.

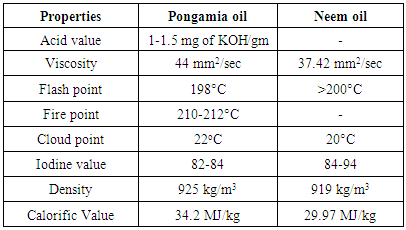

2. Characteristic and Parameters of Pongamia & Neem Seed Oil

- In this work, pongamia and Neem seed oil has been chosen as the vegetable oil. The non-edible oil is known for its medicinal properties. There is a long history of using the oil as a fuel for lamps and cooking stoves. The pressed cake is used as an insect repellent and as an organic fertilizer because it contains fixed Nitrogen (4%), Phosphorus (1%) and Potassium (1%).All properties of plant oils are close to diesel except the viscosity. High viscosity of the plant oils is considered to be the major constraint although high acid value and presence of wax/gums etc. also adversely affects the engine performance. To reduce the viscosity number of method has been tried by researcher such as; cracking of plant oil, blending of the plant oil with appropriate additives like alcohol, chemically transforming the plant oils to convert them into esters (bio-diesel) by alcoholises and de-waxing, de-gumming and heating the plant oils before injecting them into the combustion chamber.Pongamia is one of the forest based trees bearing non-edible oil with a production potential of 13,500 metric tons per year in India. It has seeds containing 30-40% oil. Pongamia tree is cultivated for two purposes: As an ornamental tree in gardens along avenues and road sides and as a host plant for lace insects. Bone-dry pongamia seed having typically 19% moisture, 27.5% fatty oil, 17.4% proteins, 6.6% starch, 7.7% crude fibre and 2.4% ash. The fatty acid composition and structure of pongamia oil is shown in table 1. A single tree gives yield 9-90 kg seed per year, indicating a yield potential of 900-9000 kg seed/ha. It is possible to extract 25% of oil using a mechanical expeller. The Properties of pongamia oil is shown in Table 1.Neem oil is a vegetable oil pressed from the fruits and seeds of the neem (Azadirachta indica), an evergreen tree which is endemic to the Indian subcontinent and has been introduced to many other areas in the tropics. It is the most important of the commercially available products of neem for organic farming and medicines.Neem oil is not used for cooking purposes. In India, it is used for preparing cosmetics (soap, hair products, body hygiene creams, hand creams) and in Ayurvedic, Unani and folklore traditional medicine, in the treatment of a wide range of afflictions. The most frequently reported indications in ancient Ayurvedic writings are skin diseases, inflammations and fevers, and more recently rheumatic disorders, insect repellent and insecticide effects. The Properties of Neem oil is shown in Table 1.

|

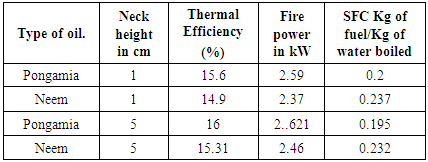

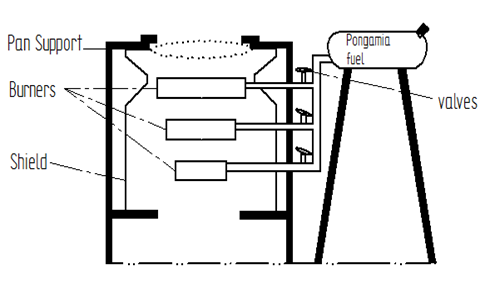

3. General Description of the Novel Stove

- Vegetable oil if used in conventional wick stove would not be able to support the flame as it may not be able to rise up because of its poor capillary action. Hence a novel stove has been developed which uses gravity instead of capillary action to ensure passage of oil to the tip of the wick. This section gives an account of the stove.In the novel bio-stove three burners of different sizes are used. Figure 1 shows the schematic diagram of burners. These burners are fixed one above the other, 3 cm apart. The fuel is supplied to the burners from fuel tank through separate pipe lines each provided with a valve for controlling fuel over flow from the top of the burner holes. Neck of the stove provides secondary air supply. In this work, experiments have been conducted with two neck heights. Figure 2 is the photographic snapshot of the novel stove.

| Figure 1. Schematic Diagram of the Novel Stove |

| Figure 2. Photograph of the Novel stove |

4. Experimental Methodology

- The objective of this work is to design a novel stove for household cooking to work on vegetable seed oil. The investigations were carried out to examine the effectiveness of the stove when using Pongamia and neem seed oil. The standard water boiling test (WBT) was conducted to evaluate the performance.The firing of the stove is ensured by filling the burner with oil by controlling the valves. The wicks are adjusted to 1cm height. The wicks are lighted and then shield is placed. The shield reduces the heat loss and also provides opening for secondary air. To determine the performance of the stove, like thermal efficiency, fire power and specific fuel consumption, the beaker is filled with 500ml of water and is heated in the stove. The time required for vaporizing 100ml of water is noted. The fuel consumed is determined by comparing the quantity of fuel remaining in the stove tank with original fuel taken. The data thus obtained are used for determining performance parameters. The procedure is repeated for different heights of the neck, burner to burner distance, and wick heights.

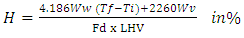

4.1. Determination of Thermal Efficiency

- The thermal efficiency is the ratio of energy consumed to energy supplied and is calculated by Thermal Efficiency,

| (1) |

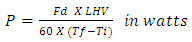

4.2. Determination of Fire Power

- Fire power is the ratio of wood energy consumed by stove per unit time (in W) during each phase of the test. It is given by

| (2) |

4.3. Specific Fuel Consumption (SFC)

- It is the ratio of amount of fuel wood consumed to the amount of water vaporised at the end of the trial and can be defined for any number of cooking tasks. SFC basically represents fuel wood required to produce the unit output, whether the output is the boiling water, cooked beans or leaves of bread. In this case specific fuel consumption refers to a measure of the amount of wood required to produce one kg of boiling water.SFC = Fd/ (Ww-v) in Kg of fuel / Kg of water boiledWhere,Ww-v = mass of water boiled (kg)

5. Results and Discussion

- The experiment was carried out on the novel stove fuel with pongamia and Neem oil as fuel. The main objective is to compare the performance of stove for different oils, various neck height and distance between burners. The comparison is based on performance parameters like thermal efficiency, fire power, specific fuel consumption, and flame observation. This section gives the results of the experimentation and a discussion was carried out.

5.1. Comparison of Thermal Efficiency of Novel Stove for Pongamia and Neem Oil for Various Neck Heights

- The thermal efficiency of Bio-stove operating on pongamia and Neem oil for both 1cm and 5 cm neck height is shown in Table 2. It is seen that the thermal efficiency is found to be marginally better for Pongamia oil for both 1 cm and 5 cm neck height than that of Neem oil.

|

5.2. Comparison of Fire Power of Bio-stove for Pongamia and Neem oil with 1cm and 5cm Neck Height

- The values of Fire power for different combination of oil and neck height has been shown in Table 2. The fire power depends on the calorific value and fuel consumed per unit time during evaporation of definite mass of water.In the Table it is seen that the fire power is found to be better for Pongamia oil. The combination of Pongamia oil and 5cm neck height together has a 10.59% more fire power than the combination with the least fire power.

5.3. Comparison of Specific Fuel Consumption of Bio-stove for Pongamia and Neem Oil with 1cm and 5cm Neck Height

- The Specific fuel consumption of Bio-stove operating on pongamia and Neem oil for both 1cm and 5cm neck height has been shown in Table 2. The Specific fuel consumption depends on the calorific value and fuel consumed per unit time during evaporation of definite mass of water.In the Table it is seen that the Specific fuel consumption is found to be better for Pongamia oil with 5cm neck height. For the combination of Pongamia oil and 5cm neck height the specific fuel consumption is less by 21.53% over the combination with the highest specific fuel consumption.

5.4. Comparison of Performance of Proposed Novel Stove with Kerosene Stove Working on Raw Pongamia Oil

- The author learned from his earlier work on use of Pongamia oil (raw) in kerosene stove [10], that the stove did not produce a steady flame when pongamia oil(raw) was tried. Because of high viscosity and low capillary action, oil could not be replenished to the tip of the wick. The author’s effort resulted in burnt wick(tip) and no steady flame was established. Hence, the novel stove developed in this work, is considered to be of enormous value.

6. Conclusions

- A novel bio-stove was built and performance test was carried out to determine the appropriate oil and certain design aspect like neck height for the stove. Based on the result and discussion carried out the following conclusions have been drawn.1. The novel cooking stove works well the pongamia and neem oil2. The operation with Bio-stove of 5 cm neck height gives better thermal efficiency, fire power and specific fuel consumption for Pongamia oil than that for neem oil.3. From the water boiling test, use of Neem oil takes 2 min more time for boiling 500 ml of water than Pongamia oil.4. The combination of Pongamia oil and 5 cm neck height improves thermal efficiency by 7.38 %, fire power by 10.59%, and reduces SFC by 21.3%.5. The novel stove developed in this work for use with raw vegetable oil can produce a steady flame, which was not possible with kerosene stove.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML