-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2017; 7(5): 149-151

doi:10.5923/j.ep.20170705.05

Aero-Blending of Ethanol for Internal Combustion Engine

Joseph Gonsalvis, Rohan Manuel D’Souza, Roydon Manvel D’Souza, Stephen Eric Madtha, Sheldon Wilbert D’Souza

Department of Mechanical Engineering St. Joseph Engineering College, Mangalore, India

Correspondence to: Joseph Gonsalvis, Department of Mechanical Engineering St. Joseph Engineering College, Mangalore, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Diesel engines are used most widely among the internal combustion engines for generation of power. With the depleting mineral oils efforts are made to find alternative energy sources. Different methods proposed have attained 10% fuel savings with marginal decrement of pollutants produced. Sugar is produced in large quantities in our country and ethanol is also produced as a bi-product that can be effectively blended with mineral fuels. Currently in our country 5% of ethanol is blended with petrol as well as diesel oil. Certain other countries permit higher level of blend to substitute import of petroleum although it is not efficient. A novel method is developed in this work to blend ethanol known as aero-blending, in this method the ingoing air of the engine is allowed to aerate through a column of ethanol in a container. Low pressure created in the induction manifold helps ethanol to evaporate at a faster rate and blend with the in- going air of the engine. The homogeneous mixture of air and ethanol produced is used in running a 3.75 kW diesel governor controlled engine that runs at constant speed 1500 RPM. Performance tests have been carried out under various loads. Results obtained are promising saving diesel oil by 16.25% and increase in power production by 6% giving rise to overall improvement in performance by 22% and exhaust gas emissions like nitrous oxides (NOx) have reduced by 71.42%, Carbon dioxide has decreased by 6.06% and Carbon monoxide has decreased by 33.3%. The results obtained from this study are highly encouraging which suggests the use of ethanol in engines to substitute diesel oil. Further study is essential to enhance the evaporation rate of ethanol so that the amount diesel oil consumed can be reduced thus meeting the objective of this work.

Keywords: Ethanol, Blend, Atomization

Cite this paper: Joseph Gonsalvis, Rohan Manuel D’Souza, Roydon Manvel D’Souza, Stephen Eric Madtha, Sheldon Wilbert D’Souza, Aero-Blending of Ethanol for Internal Combustion Engine, Energy and Power, Vol. 7 No. 5, 2017, pp. 149-151. doi: 10.5923/j.ep.20170705.05.

Article Outline

1. Introduction

- Germen inventor Rudolf Diesel invented the diesel engine in the year1893, this is also known as compression ignition engine that uses the heat of compression to initiate ignition and burn the fuel injected into the combustion chamber. Diesel engines play a vital role in the field of locomotive, construction equipment, automobiles, agriculture and countless industrial applications. Diesel engines are more efficient since they use higher compression ratios unlike petrol engines, resulting in lower fuel consumption. In diesel engines, conditions in the engine differ from the spark –ignition engine, since power is directly controlled by the quality of air fuel mixture, rather than by controlling the quantity of air fuel mixture. Thus when the engine runs at low power, there is enough oxygen present to burn the fuel, and diesel engines only make significant amounts of carbon monoxide when running under a load. The most efficient direct injection Diesel engine can reach an efficiency of about 40%.

2. Literature Review

- The diesel engine dominates the field of commercial transportation and agricultural machinery due to its ease of operation and higher fuel efficiency. Due to the shortage of petroleum products and its increasing cost, efforts are on to develop alternate fuels, especially diesel oil, for partial or full replacement. Internal combustion engines generate undesirable emissions during combustion process. The emissions exhausted in to the surroundings pollute the atmosphere and causes several problems. The emissions of concern are: Unburned hydrocarbon (HC), oxides of carbon, and oxides of nitrogen (NOx). It is recognised that the engine, lubricants and fuel after treatment and the engine application must be integrated into a system to maximize the control of emissions. Recent engine work focuses on improvements or incorporation of new technologies to the air delivery, cylinder, fuel management, and electronic systems. These improvements typically satisfy the emission requirements of new engines. Advanced diesel fuel formulations offer significant emission reductions to new and older in-use engines every time the fuel tank is filled. To meet the air quality objectives in many regional areas, reductions in emissions will need to be derived from the in-use, mobile-source engine population.

3. Objective of the Work

- The objective of this work is to develop a simple and low cost method to use ethanol as an alternative fuel for diesel powered engines. In achieving this bubbler carburettor (Aero-Blender) is developed for a Compression ignition (CI) engine. Since ethanol is a volatile fuel using this method of carburetion a highly homogeneous mixture of fuel and air is produced by the aero-blender, which helps in improving combustion efficiency, lowering fuel consumption and emissions both in the form of carbon monoxide (CO) and Oxides of Nitrogen (NOx)

4. Methodology

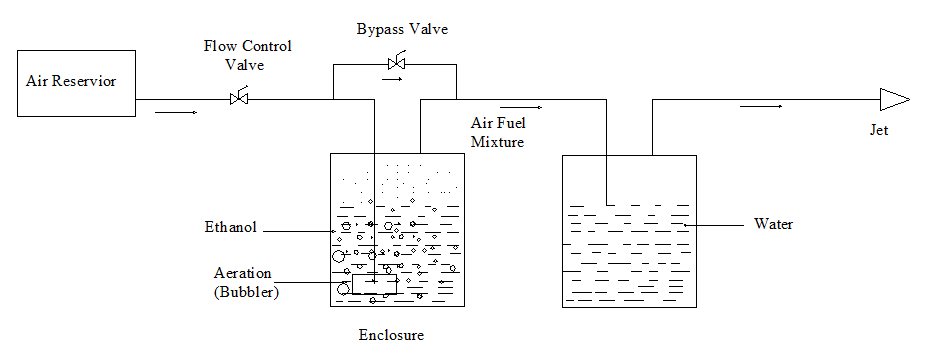

- A bubbler carburettor is a simple device in which the in going air of an engine is made to bubble through a column of ethanol (fuel) maintained in an enclosure. The air, as it rises from the bottom of the container vapourizes the fuel and a near saturated mixture of air and ethanol is formed in the bubble. This bubble rises to the top surface of the fuel and breaks releasing the mixture which then gets sucked into the intake manifold of the engine.

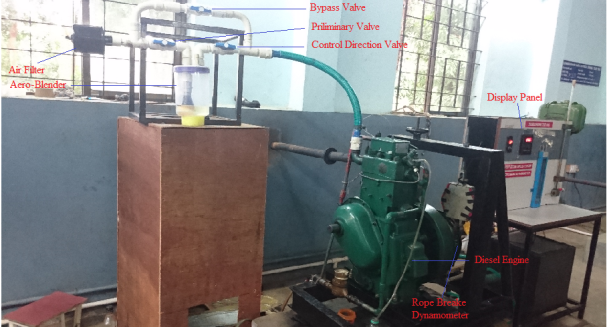

| Figure 1. Experimental Setup |

| Figure 2. Schematic Layout of the Bubbler Carburettor |

5. Results

- The concept of running the engine by admitting ethanol vapour along with the fresh charge of air at the inlet has been successfully realised. The performance of the engine has been measured under various loads using a diesel engine test rig. • At maximum load the consumption of diesel oil has been lowered by 16.25% while using the blend of ethanol with air. • The use of air ethanol blend has lowered the presence of NOx by 71.42% under maximum load compared to when the engine run with only diesel oil. The presence of Carbon monoxide is lowered by 33.3% at maximum load when the engine is run with air/ethanol blend, compared with the engine run with diesel oil. This indicates better combustion of fuels (diesel oil and ethanol).Ÿ The presence of Carbon dioxide has decreased by 6.06% at maximum load when the engine is run with ethanol/air blend. Ÿ Interesting result is observed at elevated temperature of evaporation of ethanol, in which HC (HydroCarbon) in the exhaust gases decreased from 234 ppm to 135 ppm. This change is observed due to the increased rate of evaporation of ethanol. Since ethanol as it evaporates looses the heat which lowers the rate of evaporation. This also suggests that experiments are necessary to study the performance at elevated temperature of vaporizing ethanol.

6. Conclusions

- Ÿ Combustibility test of air/ethanol mixture has been done in order to ensure the formation of an effective air /ethanol blend. The flame test conducted has produced blue flame indicating proper combustion. The air-ethanol mixture is produced by evaporation of ethanol developing a bubbler carburettor which receives air from an air reservoir.Ÿ Ensuring the flammability of the air ethanol mixture, the mixture is sent along with the ingoing air of a diesel engine and performance has been measured. The study conducted using ethanol as an alternative fuel has produced the following interesting results;Ø At normal operating conditions the net amount of diesel oil saved is to an extent of 6%. Ø The noxious NOx gases have reduced by 68%.Ÿ Realizing the need for improving rate of evaporation ethanol in the container of the bubbler carburettor is heated which has yielded better results by way of saving diesel by an extent of 16% and enhancement of power production by 6%. With this the overall performance has enhanced by 22%. More tests have to be conducted using evaporation of alcohol at higher temperatures which might give much better results leading to increased savings in diesel oil.Ÿ Experiments are conducted limiting the load applied to 50% of full load capacity. If tests are conducted using a good engine which could be run at full load is expected to yield much better results promising ethanol to be used as an viable alterative.

7. Scope for Future Work

- The present study to use ethanol as an alternative fuel has been successful and interesting. The study conducted has given promising results to take the work forward considering the following parameters:Ÿ The aeration chamber employed in this work is large size which requires downsizing in order to facilitate the same for commercial viability.Ÿ Studies have to be made in improving rate of evaporation of ethanol by elevating the temperature of ethanol in the container.Ÿ Similar studies can also be extended to spark ignition engines (petrol engines), where it is expected to produce much better results.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML