-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2017; 7(4): 119-122

doi:10.5923/j.ep.20170704.05

Effect of Biodiesel-Ethanol Fuel on the Performance and Emission Characteristics of a CI Engine

Vinoothan Kaliveer, Sandeepa Shetty K., Sujay Shetty, Manish S., Sandeepa M. M., Rolvin S. D’Silva

Department of Mechanical Engineering, St Joseph Engineering College, Mangalore, India

Correspondence to: Vinoothan Kaliveer, Department of Mechanical Engineering, St Joseph Engineering College, Mangalore, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In this present work, waste cooking oil methyl ester, diesel oil and ethanol are blended to be used as fuel sample. Various physio-chemical properties of these fuel samples are determined. It has been observed that the calorific value is lower for blends as compared to diesel oil. The performance and emission characteristics were studied using variable compression ratio engine test rig at the injection pressure of 200 bar and compression ratio of 17.5 by varying the load. From the experimental results it is observed that B15E5 has a better performance and emission characteristics compared to B20. Brake Thermal efficiency (BTE) for B15E5 blend is 1.12% higher compared to B20 at full load. BSFC decreases by 3.5% for B15E5 compared to B20 at full load. CO emission for B15E5 decreases by 20% compared to that of B20. NOx emission decreases by 4.1% for B15E5 compared to B20. UBHC emission increases by 45% for B15E5 compared to B20 at full load.

Keywords: Waste cooking oil Methyl Ester, Ethanol, Performance and emission characteristics

Cite this paper: Vinoothan Kaliveer, Sandeepa Shetty K., Sujay Shetty, Manish S., Sandeepa M. M., Rolvin S. D’Silva, Effect of Biodiesel-Ethanol Fuel on the Performance and Emission Characteristics of a CI Engine, Energy and Power, Vol. 7 No. 4, 2017, pp. 119-122. doi: 10.5923/j.ep.20170704.05.

Article Outline

1. Introduction

- In this challenging world of industrialisation, depleting of petroleum products has become a major problem and also it affects global warming and increase in fuel prices. In this regard the use of alternative fuel is preferable and eco-friendly. Biodiesel is an alternative fuel similar to conventional or ‘fossil’ diesel. Biodiesel has plenty of advantages over diesel. Biodiesel has many environmentally beneficial properties. The main benefit of biodiesel is that it can be described as ‘carbon neutral’ fuel. This means that the fuel produces no net output of carbon in the form of carbon dioxide [1].Biodiesel is defined as fatty acid methyl or esters derived from vegetable oils or animal fats and it is used in diesel engine and heating systems. Thus, this fuel could be regarded as mineral diesel substitute with advantage of reducing greenhouse emissions because it is renewable resource. Biomass sources, particularly vegetable oils have attracted much attention as an alternate energy source. They are renewable, nontoxic and can be produced locally from agriculture and plant resources. Their utilization is not associated with adverse effects from the environment because they emit less harmful emissions and greenhouse gases. Vegetable oils have been promoted as possible alternatives for diesel [2]. The mineral diesel fuel is a complex mixture with carbon atoms ranging between 12 and 18, whereas vegetable oils are a mixture of organic compounds ranging from simple straight chain compounds to complex structures of proteins and fat soluble vitamins and are commonly referred to as triglycerides. Vegetable oils are usually triglycerides, generally with a number of branched chains of different lengths and different degrees of saturation. The vegetable oil is modified to reduce viscosity and to increase volatility. This method employed includes pre heating the oil, pyrolysis, micro emulsion, blending and transesterification. From the various studies it was found that the best way to make vegetable oil compatible with existing engines is to convert it into ester (biodiesel) [3]. In comparison to mineral diesel, biodiesel has a more favourable combustion and emission profile. Emissions of CO and particulate matter, hydrocarbon (HC) emissions decrease but NOx increase with biodiesel [4].

2. Fuel Sample Used for CI Engine

2.1. Biodiesel from Waste Cooking Oil

- Biodiesel is a renewable, biodegradable, environment friendly fuel for diesel engines. It can be produced from renewable sources such as vegetable oils or animal fats. Although this fuel is more expensive than petroleum diesel, waste cooking oil may be used to improve the economy of biodiesel. Thus, this fuel could be regarded as mineral diesel substitute with advantage of reducing greenhouse emissions because it is renewable resource. Biodiesel from waste cooking oil is a promising alternative to vegetable oil due to its reduced raw mineral cost. Waste oils from restaurants are less expensive than food grade oils. The use of waste cooking oil as a biodiesel source as the potential to reduce CO, particulate matter and other greenhouse gases, as the carbon contain in biomass derived fuel is largely bioorganic and renewable [5]. Since one of the major concerns on biodiesel production is the price of the feedstock, utilization of waste cooking oil significantly enhances the economic viability of biodiesel production. Huge quantities of waste cooking oil and animal fats are available throughout the world, especially in the developed countries. Management of such oils and fats pose significant challenge because of their disposal problems and possible contamination of the water and land resources. In India some of the hotels and restaurants are having the good practice of disposing off the used oil after reaching the degradation level. Some of these hotels and restaurants are ready to use biodiesel from the waste cooking oil which they produce for their stationary engines and generator sets. Many others are unaware of the potential of waste cooking oil they dispose. So technology has to be evolved for mass production of biodiesel and awareness has to be created regarding the usage and benefits of biodiesel. Biodiesel can be blended with diesel, and can be used in IC engines without any modifications [6-8].

3. Experimental Details

- Waste cooking oil was collected from various sources like restaurants, mess and canteens. The oil was filtered to remove the solid food contents and other impurities. The filtered oil is transesterified to get methyl ester which is known as biodiesel. Three fuel samples are prepared B20, B15E5 and B10E10. B20 consists of 80% Diesel and 20% Biodiesel. B15E5 consists of 15% Biodiesel, 5% Ethanol and remaining 80% Diesel. B10E10 contains 10% Biodiesel, 10% ethanol and 80% Diesel. The physiochemical properties of these samples are measured using ASTM methods. For engine study the speed is kept constant at 1500rpm and compression ratio is set to 17.5. The specification of the Diesel engine test rig used for the present work is given in the Table 1. The experiments were carried on direct injection, compression ignition engine for various loads, with injection pressure of 200 bar with different blends B20, B20 with E10, B15 with E5 and diesel. The load on the engine was varied from 0 kg to 12 kg. The speed, fuel consumption, exhaust gas temperature readings were noted down for all the trials. The emission readings like, CO, CO2, HC and NOx was recorded by an AVL di gas exhaust gas analyser.

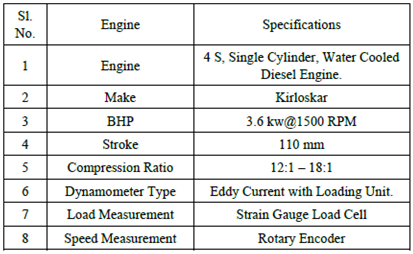

|

4. Results and Discussion

4.1. Performance Parameters

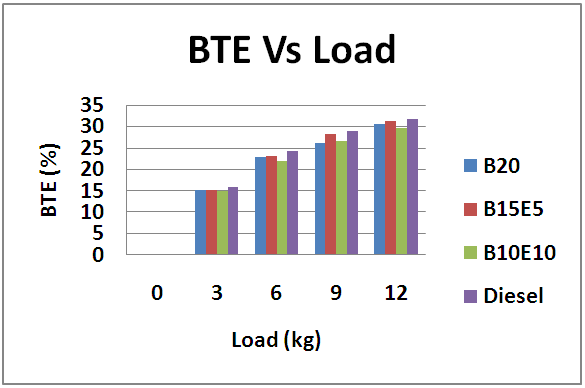

4.1.1. Brake Thermal Efficiency (BTE)

- Fig.1 shows the variations of Brake thermal efficiency for different fuel samples tested. BTE is a measure of the performance of an engine considering the heat input and work output. BTE increases as the load increases. BTE of B20 blend is lesser than the BTE value of diesel fuel due to the lower calorific value. By adding ethanol which is a volatile fluid, it is observed that when 5% Ethanol in the blend gives better BTE than B20. This can be attributed to the rapid premixed combustion part possessed by ethanol blends because of improved mixing during ignition delay, oxygen enrichment, leading to higher percentage of combustion [9]. B15E5 shows 1.12% relative increase in the BTE compared to B20.

| Figure 1. Variation of brake thermal efficiency with load for various fuel blends |

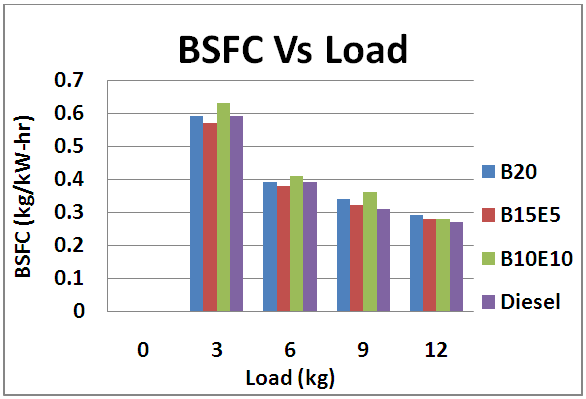

4.1.2. Brake Specific Fuel Consumption (BSFC)

- Brake specific fuel consumption is a measure of fuel consumption to produce a known quantity of power. Fig.2 shows the variations of Brake Specific Fuel Consumption for different fuel samples tested. For all fuels tested, BSFC is found to decrease with increase in load. BSFC reduces due to the reduction in the viscosity of the oil. Comparing the Ethanol blends B15E5 is showing 3.5% decrease in the BSFC compared to the B20 fuel sample.

| Figure 2. Variation of BSFC with load for various fuel blends |

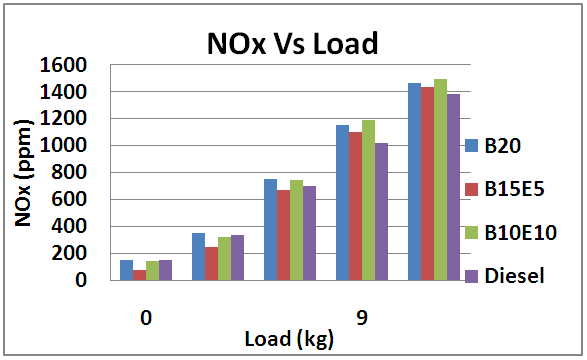

4.2. Emission Characteristics

- The emissions reading are recorded for 0, 3, 6, 9 and 12 kg load. The Emissions are recorded by using an AVL di-gas exhaust gas analyser.

4.2.1. NOx Emission

- Fig 3 shows the variation of nitrogen oxide emission versus load. It is observed from the figure as the load increases NOX emission also increases. This is expected because with increasing load, the temperature prevailing in combustion chamber increases and NOX formation is a strongly temperature dependent phenomenon [10-13]. At full load condition NOX emission is lower for diesel compared to other blends. NOX emission is high for the blend B10 with E10 at higher loads. NOx emission for B15E5 is 4.1% lesser compared to B20 blend.

| Figure 3. Variation of NOx with load for various fuel blends |

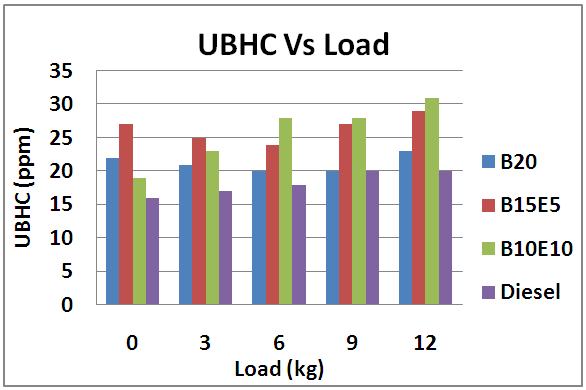

4.2.2. Unburnt Hydrocarbon (UBHC)

- Figure 4 shows the variation of Unburnt Hydrocarbon versus load. Figure shows that by addition of ethanol there is an increase in UBHC. For B15E5 there is a 45% relative increase in UBHC emissions compared to B20.

| Figure 4. Variation of UBHC with load of various fuel blends |

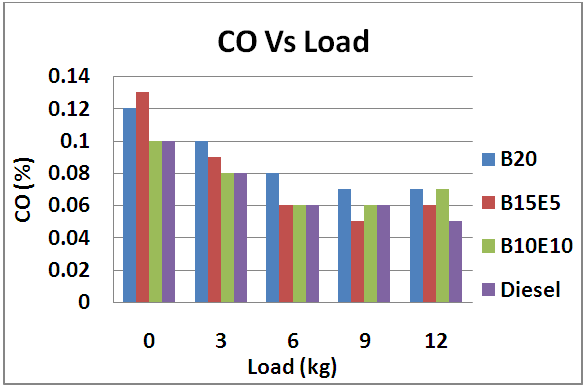

4.2.3. CO Emissions

- Figure 5 shows the variation of Carbon monoxide versus load. The results showed that the CO emissions are higher at lower loads and decreases slightly at higher loads for the blends compared to diesel fuel. CO emissions of the blends are higher than the CO emissions of Diesel. B15E5 is showing 20% relative lesser CO emission compared to B20.

| Figure 5. Variation of Carbon monoxide with load of various fuel blends |

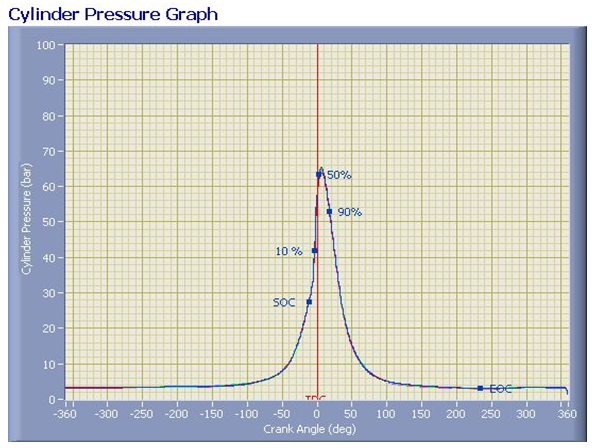

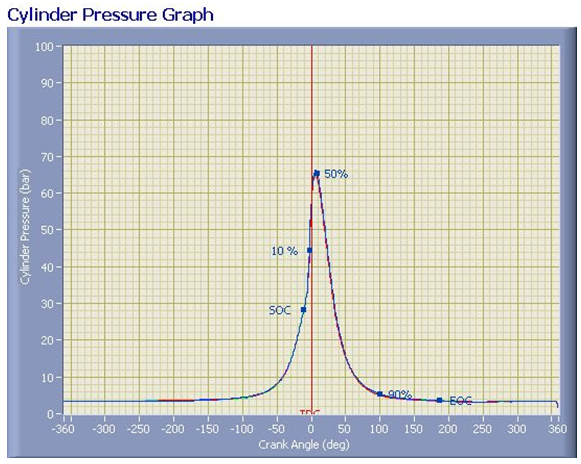

4.3. Combustion Characteristics

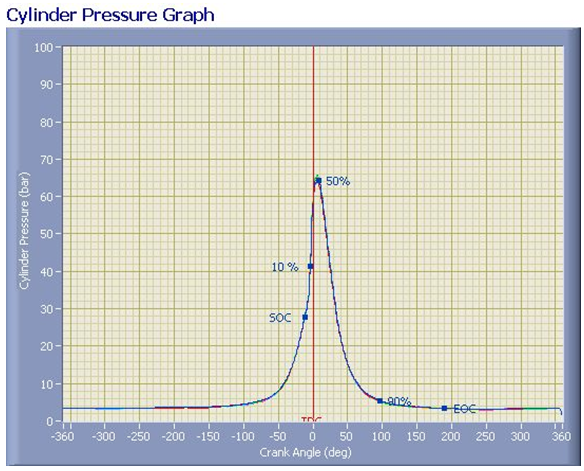

- Figure 6-8 shows the Pressure-Crank angle diagram for B20, B15E5 and B10E10 fuel samples. It is observed that the maximum pressure rise occurs when engine is fuelled with B15E5 fuel sample. In B20 sample 90% of combustion occurs by 25 deg crank angle rotation, whereas in ethanol added fuel samples 90% combustion of fuel samples completes after a 90 deg rotation of crank.

| Figure 6. Pressure V/s Crank Angle diagram for B20 |

| Figure 7. Pressure V/s Crank Angle diagram for B15E5 |

| Figure 8. Pressure V/s Crank Angle diagram for B10E10 |

5. Conclusions

- The objective of this study is to investigate the engine performance and emission of diesel engine operating on ethanol biodiesel-diesel blends and compare these results with those operating on neat diesel oil and B20. The experimental results have shown that Brake Thermal efficiency (BTE) for B15E5 blend is 1.12% higher compared to B20 at full load. BSFC decreases by 3.5% for B15E5 compared to B20 at full load. CO emission for B15E5 decreases by 20% compared to that of B20. NOx emission decreases by 4.1% for B15E5 compared to B20. UBHC emission increases by 45% for B15E5 compared to B20 at full load. B15E5 fuel samples shows a better performance than B20 blend.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML