-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2017; 7(4): 105-110

doi:10.5923/j.ep.20170704.03

A Study on Effect of Injection Pressure on the Performance and Emission of CI Engine with B20 and B30 Blends of Mahua Methyl Ester

Prashanth Kumar1, Rithesh1, Preetham1, Melrick1, Joel1, Peter Fernandes2, Raju K.1

1Department of Mechanical Engineering, St Joseph Engineering College, Mangalore, India

2Department of Mechanical Engineering, AIET, Mangalure, India

Correspondence to: Prashanth Kumar, Department of Mechanical Engineering, St Joseph Engineering College, Mangalore, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Mahua is the second largest available natural source of feedstock for biodiesel in India. Biodiesel is not just only a substitute fuel to the diesel engines but also plays a crucial role in protecting environment, enhancing economy and also leads the challenge in exploiting the best way to be used in CI (compression ignition) engine. The present research paper studies the performance and emission characteristics of CI engine with 20% and 30% blend of mahua methyl ester with diesel (B20MOME and B30MOME) are carried on a single cylinder diesel engine at 200bar, 220bar and 240 bar fuel injection pressure. The study shows that the increased blend has deteriorating effect on brake thermal efficiency (BTE) of CI engine. BTE of B20MOME is better than BTE of B30MOME. At higher injection pressure the performance of the B20 blend is better compared with at lower injection pressure. The brake thermal efficiency of 30.09% is obtained at B20MOME at 240 bar injection pressure. NOx (Oxides of Nitrogen) emission of blended B20MOME and B30 MOME is higher than with diesel as fuel. HC (unburned Hydrocarbon) and CO (carbon monoxide) emission of blended MOME is lower than diesel.

Keywords: B20 MOME, Injection pressure, Performance, Emission

Cite this paper: Prashanth Kumar, Rithesh, Preetham, Melrick, Joel, Peter Fernandes, Raju K., A Study on Effect of Injection Pressure on the Performance and Emission of CI Engine with B20 and B30 Blends of Mahua Methyl Ester, Energy and Power, Vol. 7 No. 4, 2017, pp. 105-110. doi: 10.5923/j.ep.20170704.03.

Article Outline

1. Introduction

- Global warming and increased pollution due to combustion of fossil fuels in CI engines (compression ignition engines) is the major threat to the environment. The application of CI engine is widely used in different sectors such as transport, agriculture and power sector due to high thermal efficiency. Large number of studies has been carried out for in the last decade to find alternative fuels to CI engine. Biodiesel is considered as a suitable alternative to the fossil fuel due similar properties and renewability. Among the different sources of biodiesels, jatropha, cotton seed, mahua are largely available in India. The study on use of biodiesel in CI engine ensured that biodiesel can be blended with diesel at any proportion without aid of any special mixing process. Biodiesel can be used at lower blends without any modification in the engine. The performance and emission of the engine are affected by the biodiesel proportion in the blend. At standard operating condition B20 blend of biodiesel is considered to be optimum. Many researchers have studied about the performance of biodiesel blends in CI engine and reported increased emission of NOX and decreased emission of HC and CO when compared with fossil fuels.Many factors contribute for the performance and emission characteristics of the engine. Among them major parameters are injection pressure, injection timing, properties of fuel, compression ratio, type of injector and type combustion chamber etc. Different authors studied performance of CI engine at different injection pressure with biodiesel from different feedstock such as cotton seed oil methyl ester, pongamia methyl ester jatropha methyl ester etc. Rizwanul Fattah et al. [1] reported the BTE for JB20 (jatropha biodiesel) and CB20 (coconut biodiesel) blends is lower by 2.60% and 1.30%, respectively, than diesel. They reported that with increase in injection pressure the performance of the engine increases.Heywood [2] explained effect of spray characteristics; spray angle, injection pressure and injection timing also have a significant role in diesel engine combustion. Yamane et al. [3] reported the properties of bio-diesel are not the same as diesel fuels especially their high viscosity and low volatility. These properties strongly affect injection pressure injection timing and spray characteristics.Mohan et al. [4] conducted study on performance of CI engine at elevated injection pressure and reported that increasing injection pressure to 275 bars and retarding injection timing to 21° BTDC, the BTE increased about 10% and BSFC reduced about 8% on full load compared to that with diesel fuel. Along with BTE and BSFC, NOx emission also increased by 6%, which was accounted as adverse effect.Gumus et al. [5] studied the effect of injection pressure on the increased injection pressure gave the better results for BSFC, BSEC and BTE compared to that of original injection pressure. Finer fuel droplets obtained with increased injection pressure provided more surface area and better mixing with air. This resulted in better combustion, HC, and CO emissions decreased and NOx emissions increased with the increase in injection pressure for the all test fuel blends.Jindal et al. [6] studied the performance of Jatropha Methyl ester as a fuel in CI engine with increase in compression ratio and injection pressure, reported improved performance of the engine. The highest performance is delivered by the engine at 250 bar injection pressure and compression ratio of 18.5 at which BSFC improves by 10% and BTE improves by 8.9% than that with diesel at full load condition.Puhan et al. [7] reported performance and emission of a high linolenic linseed oil methyl ester at constant speed, DI diesel engine with varied fuel injection pressures (200, 220 and 240 bars). The test results showed that the optimum fuel injection pressure is 240 bars with linseed methyl ester. At this optimized pressure the thermal efficiency is similar to diesel and a reduction in carbon monoxide, unburned hydrocarbon and smoke emissions with an increase in the oxides of nitrogen was noticed compared to diesel. Metin Gumus et al. [8] Studied the performance of engine fueled with biodiesel–diesel blends when running the engine at four different fuel injection pressures (18, 20, 22, and 24 MPa) and four different engine loads in terms of mean effective pressure (12.5, 25, 37.5, and 50 kappa) and reported increased injection pressure caused to decrease in BSFC of high percentage biodiesel–diesel blends (such as B20, B50, and B100), smoke opacity, the emissions of CO, UHC and increased the emissions of CO2, O2 and NOx. The increased or decreased injection pressure caused to increase in BSFC values compared to original (ORG) injection pressure for diesel fuel and low percentage biodiesel–diesel blends. Anbarasu & Karthikeyan et al. [9] studied the effect of injection pressure on the performance and emission characteristics of CI engine using canola emulsion fuel and reported that the BTE has increased and when the injection pressure has risen from 200 to 240 bar and found to be maximum28.48% at 240 bar. Balaji Mohan et al. [10] conducted the performance and emissions of B20 blend of MME was investigated using a single cylinder diesel engine at various nozzle opening pressures (NOP) (225, 250, 275 bar) and static injection timings (19°, 21°, 23°, 25°, 27° bTDC) . The performance of B20 mahua bio-diesel was compared with diesel at manufacturers’ default NOP of 225 bar and 23° bTDC static injection timing. The results show that by either increasing the NOP to 275 bar or by retarding the static injection timing to 21° bTDC, the stringent emission norms of Central Pollution Control Board (CPCB) stage I can be met with B20 mahua bio-diesel without compromising the performance against diesel. Eventually, on varying NOP and static injection timing, it was found that obtained emissions were lesser than CPCB limits by maximum of 5.7% and 11.8% for NOx, 91.5% and 90.0% for HC, 15.7% and 11.1% for CO, and 21.4% and 5.7% for smoke respectively. Nanthagopal et.al [11] presented the effect of Calophyllum inophyllum methyl ester on diesel engine performance, emission and combustion characteristics at different injection pressures. Experimental investigations with varying injection pressures of 200 bar, 220 bar and 240 bar revealed that brake specific fuel consumption of C. inophyllum methyl ester fuelled engine has been reduced to a great extent with higher injection pressure.R. Kannan et al. [12] studied the effect of biodiesel derived under optimum conditions for investigating the effect of injection pressure and timing on performance, emission and the combustion characteristics of single cylinder, four-stroke direct injection diesel engine at a constant speed of 1500 rpm. On varying the injection pressure and timing, it was found that the combined effect of higher injection pressure of 280 bar and an advanced injection timing of 25.5°bTDC had significant improvement in the brake thermal efficiency, cylinder gas pressure and heat release rate. Many researchers were studied the effect of different blends on performance of engine. Comparative performance of B20MOME and B30MOME at different injection pressure with mahua methyl ester is discussed in this paper.

2. Experimental Set up and Fuel Used

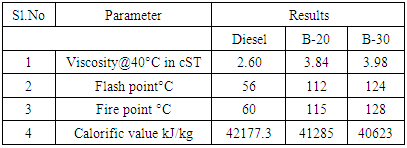

- Mahua biodiesel procured from a local biodiesel supplier and its required blend with diesel (B20 and B30) were prepared. The relevant physico chemical properties are determined as per relevant ASTM standards. The properties of the different blends of fuels are detailed in table 1.

|

| Figure 1. Different sample of blends of mahua biodiesel |

|

3. Results and Discussion

3.1. Performance Characteristics

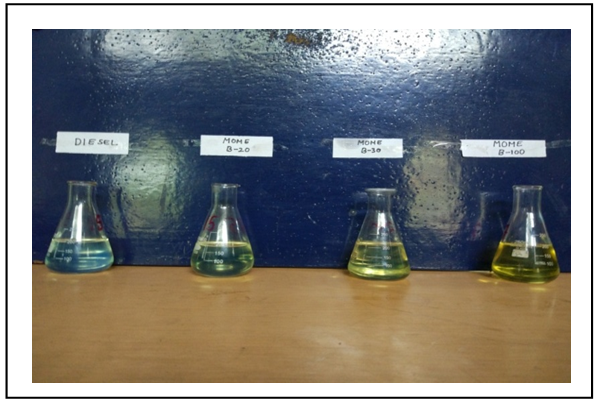

- Performance characteristics are measured in terms of brake thermal efficiency and brake specific energy consumption. Brake thermal efficiency indicates the loss of energy without utilising for the conversion when used in the engine.Brake thermal efficiency increases with increase in engine load. Higher thermal efficiency obtained at maximum load on the engine. Figure 2 shows the effect injection pressure and blends on brake thermal efficiency of the engine. The brake thermal efficiency with diesel and B20MOME at 200, 220 and 240 bar injection pressure are 30.23%, 30.01%, 30.04 and 30.09% respectivly. The increased biodiesel content in the blend reduced the brake thermal efficiency. For B30 MOME the brake thermal efficiency are 28.89%, 29.4% and 29.6% at 200,220 and 240 bar injection pressure respectivly. The maximum brake thermal efficiency obtained with B30MOME is 2.08% lower than that of diesel at standard operating conditions. Increased injection pressure resulted in better atomisation of injected fuel resulted in better mixing and enhanced combustion efficiency of the engine. Higher blend of biodiesel at normal injection pressure resulted in lower brake thermal efficiency.

| Figure 2. Effect of injection pressure and blends on brake thermal efficiency |

3.2. Emission Characteristics

- Emission characteristics are studied in terms of emission of HC, CO, and NOX.

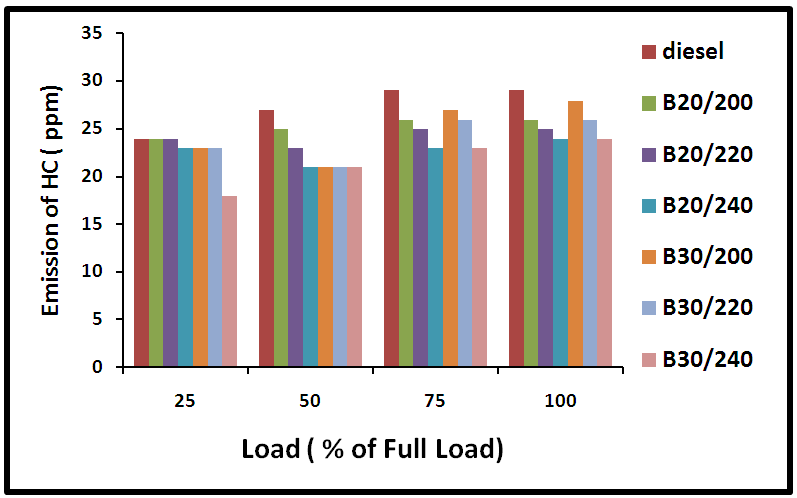

3.2.1. Emission of HC

- Figure 3 shows the effect of injection pressure and biodiesel blend on emission of HC the engine.

| Figure 3. Effect of injection pressure and blends on Emission of NOx |

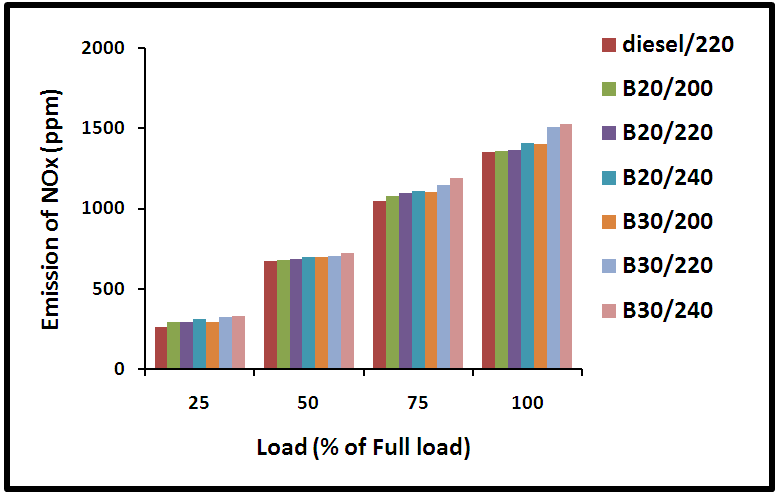

3.2.2. Emission of NOX

- Higher burned gas temperature in the combustion chamber and available of oxygen and residual time during combustion is the main reason for the formation of NOX. With B20 blend the NOX emission increased with increase in injection pressure. NOX emission increases with increase in load on the engine.Figure 4 shows effect of injection pressure and biodiesel blend on the emission of NOX. Emission of NOX found maximum at maximum rated load. The NOX for B20MOME at maximum load are 1358ppm, 1362ppm and 1411 ppm at 200, 220 and 240 bar injection pressure respectively. For B30MOME emission of NOx are, 1403 ppm, 1505ppm and 1527ppm at 200 bars, 220bar and 240 bar injection pressure respectively. Emission of NOx is lower with diesel and is found to be 1352ppm which lower compared with blends of biodiesel. Higher amount of oxygen present in the B30 blend may be the main contributor for the increased NOX.

| Figure 4. Effect of injection pressure and blends on Emission of NOx |

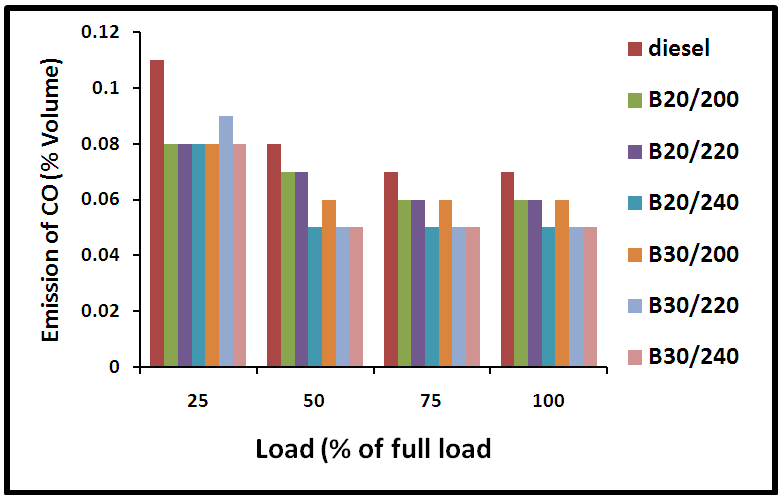

3.2.3. Emission of CO

- Emission of carbon monoxide is mainly due to improper air fuel ratio in some part of the combustion chamber due to improper mixing of air and fuel. B20 blend is shows better combustion efficiency at higher injection pressure. The CO emission is lower for B30 blend compared with B20 blend. Higher oxygen content of B30 blend and higher injection pressures may be the cause for reduction of CO. Fig.5 shows the effect of injection pressure and B20MOME and B30MOME blends on emission of CO.

| Figure 5. Effect of injection pressure and blends on emission of CO |

4. Conclusions

- Performance and emissions of diesel engine fuelled with B20 and B30 blends of mahua biodiesel with diesel fuel are experimentally investigated. The results of the study may be summarized as follows:The brake thermal efficiency increases with increase in injection pressure. The brake thermal efficiency of blend B20MOME at 240 bar injection pressure is marginally lower than that of diesel.As the load increases, NOx emissions for B-30 blend is higher when compared to B-20 blend at higher injection pressure. Increased CO emission at higher biodiesel blend with lower injection pressure. HC emission is lower than diesel. At higher blend and lower injection pressure HC emission is higher compared with other conditions. For different Injection pressures the NOx is higher than diesel and, CO, & HC emissions of B-20 & B-30 blends are lower compared to diesel.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML