-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2017; 7(4): 99-104

doi:10.5923/j.ep.20170704.02

Effect of Copperoxide Nanoadditives on the Performance and Emissions Characteristics of a C.I. Engine

Rolvin D’Silva1, Mohammed Hafeez1, Joyal Fernandez1, Faheem Paloth1, Ibrahim Abdul Rahiz1, Binu K. G.1, Raju K.1, Thirumaleshwara Bhat2

1Department of Mechanical Engineering, St Joseph Engineering College - Vamanjoor, Mangaluru, India

2Department of Mechanical Engineering, Shree Madhwa Vadhiraja Institute of Technology, Udupi, India

Correspondence to: Rolvin D’Silva, Department of Mechanical Engineering, St Joseph Engineering College - Vamanjoor, Mangaluru, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

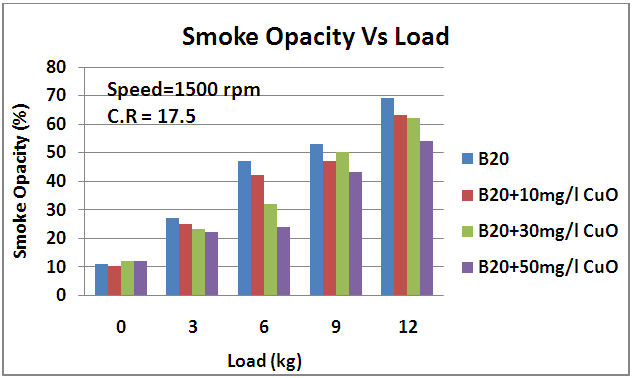

In this paper, the performance and emission characteristics of a C.I. Engine are studied using a fuel additive in a biodiesel blend. Biodiesel used for the present work is pongamia pinnata and fuel additive used is Copper oxide nanoparticles (CuO). The concentration of CuO nanoparticles used are 10mg/l, 30mg/l and 50mg/l. The property sudy of the fuel samples show that there is increase in the Fire point, Viscosity, Density and Calorific Value. The fuel samples are then tested in a diesel engine test rig at various loads. It is observed that that performance and emission characteristics can be increased with increase in concentration of CuO nanoparticle in B20 blend. The brake thermal efficiency (BTE) increased by 2.75% for B20+50mg/l CuO when compared to B20 blend without nanoparticles. Among all the blends, we note that B20+50 mg/l CuO reduces BSFC by 4.85% compared to B20 blend. It is noted that addition of nanoparticles to biodiesel decreases the NOx emissions. At maximum load, B20+50 mg/l CuO shows 2.63% less NOx when compared to the B20 blend. When compared with B20 sample, all other blends have slightly higher HC emissions at different loads. The CO emissions for all blends are slightly decreasing at same load. B20+50mg/l CuO blend has lower CO emission compared to other blends. Smoke emission is all most 20% less in B20+50mg/l CuO as compared to B20 blend. Smoke can be reduced with increase in the concentration of CuO nanoparticle in B20 blend. Hence B20+50mg/l CuO gives better performance and emission characteristics among the three blends tested.

Keywords: Performance and Emission of C. I. Engine, Copperoxide nanoparticles, NOx

Cite this paper: Rolvin D’Silva, Mohammed Hafeez, Joyal Fernandez, Faheem Paloth, Ibrahim Abdul Rahiz, Binu K. G., Raju K., Thirumaleshwara Bhat, Effect of Copperoxide Nanoadditives on the Performance and Emissions Characteristics of a C.I. Engine, Energy and Power, Vol. 7 No. 4, 2017, pp. 99-104. doi: 10.5923/j.ep.20170704.02.

Article Outline

1. Introduction

1.1. Biodiesel – An Alternate Fuel

- The diesel engine, also known as compression ignition engine, is an internal combustion engine that uses the heat of compression to initiate and burn the fuel that has been injected into the combustion chamber. Diesel engine works on diesel cycle which is also referred to as constant pressure cycle. The air is compressed in the cylinder during the compression stroke and the fuel is atomized and sprayed into the cylinder. The spraying is considered to be under constant pressure. Diesel engines are the important power systems for on road and off road vehicles. Most of the heavy duty trucks and buses are powered by diesel engines for their known reliability and economy. The increasing modernization of world has led to increased consumption of fuels that has now led to depletion of oil resources and thus have made the fuels expensive. This has led the current world to research for alternate fuels to power diesel engines. Biodiesel, as an alternative fuel of diesel, is described as fatty acid methyl ester or ethyl esters from vegetable oils or animal fats [1].Biodiesel is renewable, biodegradable and oxygenated fuel. Research has proved that blending of biodiesel with diesel enhances the property as well as the performance of diesel engines. Biodiesel produced from the biomass is becoming cost competitive with fossil fuels due to the wide spread availability of biomass resources. Currently various products are being used to extract biodiesel. Thus, at a time when conventional energy resources are under a constant threat of extinction, biodiesel is emerging as one of the most promising environmentally friendly renewable energy options.Biodiesel refers to a vegetable oil or animal fat-based diesel fuel consisting of long chain alkyl esters. Biodiesel is basically made by chemically reacting lipids with an alcohol producing fatty acid esters. A single step base transesterification process is adopted for the production of biodiesel [2]. Biodiesel can be used alone, or blended with diesel in various proportions. For example, B20 means 20% biodiesel and 80% diesel, B30 means 30% biodiesel and 70% diesel. Studies have shown that the engine power of a diesel engine reduces with increase in content of biodiesel. Hence, efforts have been made by many of the researchers to improve the properties of biodiesel and make it similar to diesel without diminishing the existing required properties of biodiesel. Many researches have widely investigated and improved the properties of various kinds of biodiesel such as viscosity, density and flash point in order to be similar to those of diesel fuels [3, 4]. The biodiesel have a higher viscosity, a bit higher density and extremely higher flash point compared to the properties of the diesel fuel. The higher density and viscosity of bio-fuel can affect the volatility and atomization of the fuel spray and, subsequently, less accurate operation of the fuel injectors [5]. Ultimately, the combustion suddenly deteriorates in the chamber. The most abundant non edible oil sources for biodiesel production in India are Sal, Neem, Pongamia and Jatropha oil. Among these, Sal and Neem have medicinal uses and so we have to work with the remaining two oils, i.e. Pongamia and Jatropha.

1.2. Fuel Additives

- Considerable amount of research has been carried out in the field of additives for fuel. Among the fuel additives the ethers used were monoethylene glycol ethyl ether (EGEE), monoethylene glycol butyl ether (EGBE), diethylene glycol ethyl ether (DEGEE). The addition of DEGEE enhances cetane number of base diesel fuel, but addition of EGEE and EGBE decreases the cetane number. These compounds have a positive effect on diesel fuel lubricity, and also slightly decrease its viscosity [6]. Generally, all the compounds listed above help in reducing CO and hydrocarbon emissions, but not smoke. The organic compounds of Mn, Mg, Cu and Ca metals are also used as Diesel fuel additive. The organic based manganese drops the viscosity and flash point, and also improves the contents of the exhaust gases [7].Cerium oxide (CeO2) nano additive blended with jatropha biodiesel in a diesel engine showed a major reduction in the hydrocarbon (HC) and NOx emissions and a development in the brake thermal efficiency, due to the catalytic activity of the CeO2 nanoparticles [8]. The aluminum nanofluid additive blended with diesel fuel increased the exhaust emission concentration and reduced the fuel consumption considerably [9]. Alumina nano additive (25 and 50 ppm) blended biodiesel fuel with 5% of water content by volume in a diesel engine resulted in a major improvement in the performance and reduction in dangerous emissions, such as NOx and smoke [10]. Experiments on ceria nanoparticles dispersed with biodiesel-ethanol blends have shown improved brake thermal efficiency (BTE) and reduction in the ignition delay and hazardous emissions [11].In this work Copperoxide nanoparticles are used with pongamia pinnata methyl ester. Copper oxide nanoparticles appear as brownish black powder. Metal oxides such as CuO, have attracted attention mostly because of their anti microbial and biocide properties and they may be used for biomedical applications. Copper oxide is a semiconductor metal, which has a unique optical, electrical and magnetic properties and it has been used for various applications, such as super capacitors, near infrared filters, magnetic storage media, sensors, catalysis, semiconductors. However, their heat carrying capacity was most helpful in completing this investigation. Being a transition metal oxide, it helps in carrying out the heat from the engine to the exhaust, thereby reducing the NOx emissions.

2. Experimental Setup

2.1. Preparation of Nanofuel

- An Ultrasonic Bath Sonicator is used to disperse the nanoparticles in the fuel. The fuel for investigation is a B20 blend of diesel and biodiesel (80% of diesel and 20% of biodiesel). The biodiesel used is Pongamia Pinnata, commonly known as Honge biodiesel. The fuel additive used are Copper Oxide nanoparticles of <50nm in size. The dosage of the nanoparticles is varied from 10mg/l to 50mg/l. The required quantity of the nanoparticle for each sample is accurately measured using a precision electronic balance. The modified fuel is utilized immediately after preparation, in order to avoid any settling or for sedimentation to occur.

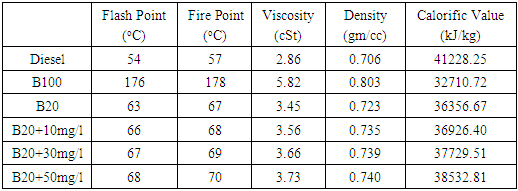

2.2. Measurement of Properties of Nanofuel

- The fuel samples are tested for their physiochemical properties like viscosity, fire point, density and calorific value following the ASTM methods. These properties affect the performance and emission features of an engine. Redwood viscometer is used for viscosity measurement, Penksy Martin apparatus is used for measurement of fire point. Calorific value is found out using bomb calorimeter.

2.3. Performance and Emission Testing

- A computerized single cylinder four-stroke, naturally aspirated, Direct Injection and water-cooled, variable compression ratio diesel engine test Rig of 3.5 kW rated power is used to conduct the test. The compression ratio of the engine can be varied from 12:1 to 18:1.It is directly coupled to an eddy current dynamometer. The setup has standalone type independent panel box consisting of air box, fuel tank, manometer, fuel measuring unit, transmitters for air flow and fuel flow measurements, process indicator and engine indicator. For measurement of water flow rate for engine cooling and exhaust gas calorimeter, rotameters are provided. An AVL Digas 444 five gas Exhaust gas analyzer, is used to measure the NOx (ppm), CO (%), CO2 (%) and HC (ppm) emissions in the exhaust. Smoke meter is used to measure the smoke opacity. The compression ratio is fixed at 17.5 and injection pressure at 200 bar. The load is varied from 0 kg to 12kg in steps of 3 kg increment and the readings of speed, fuel consumption and emission readings are noted down.

3. Results and Discussion

- The experiments are carried out for different loads at constant speeds of 1500 rpm for the different blends. The fuel samples used are, B20, B20+10 mg/l CuO, B20+30 mg/l CuO and B20+50 mg/l CuO at compression ratio of 17.5:1. Readings of mass flow rate is noted down manually. The exhaust emissions are recorded by an AVL di gas exhaust gas analyser and the smoke opacity is measured using an AVL smoke meter.

3.1. Test Results

- From these results it is observed that the viscosity of the fuel samples increase with the addition of nanoparticles. Literatures have been showing similar inference when nanoparticles are dispersed in a base fluid [12, 13]. Also the calorific value is observed to be higher in the presence of nanoparticles.

|

3.2. Performance Study of C. I. Engine

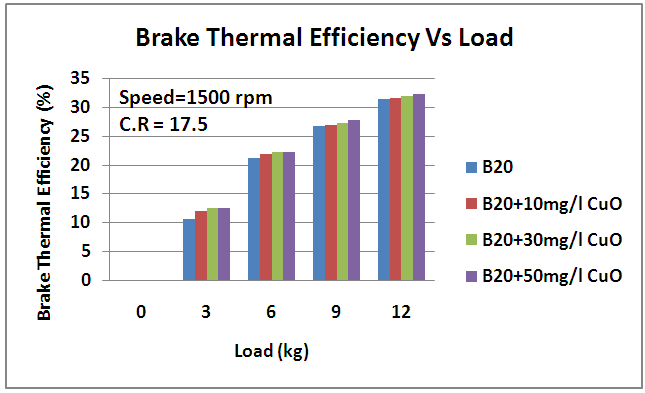

- Fig 1 shows the variation of Brake Thermal Efficiency Vs load for different blends. It is clear that brake thermal efficiency (BTE) increases with increase in load and also among the various blends, B20+50mg/L of CuO has the highest brake thermal efficiency, when compared with other blends. With the addition of CuO nanoparticles, the BTE has increased marginally compared to the same of biodiesel. At maximum load, the increase in BTE is found to be 0.63%, 1.59% and 3.19% for B20+10 mg/l CuO, B20+30 mg/l CuO and B20+50 mg/l CuO respectively when compared with B20 blend.

| Figure 1. Variation of Brake Thermal Efficiency Vs Load for different fuel samples |

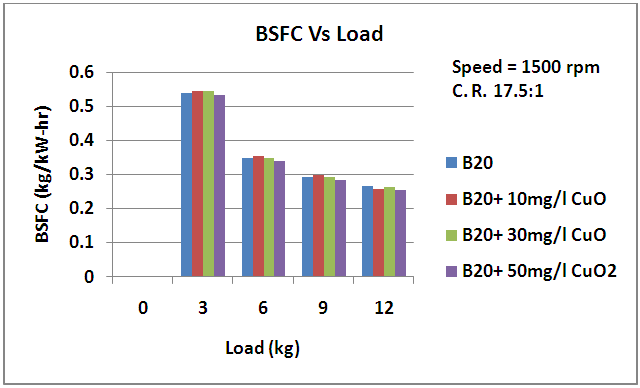

| Figure 2. Variation of Brake Specific Fuel Consumption Vs Load for different fuel samples |

3.3. Emissions Study of C. I. Engine

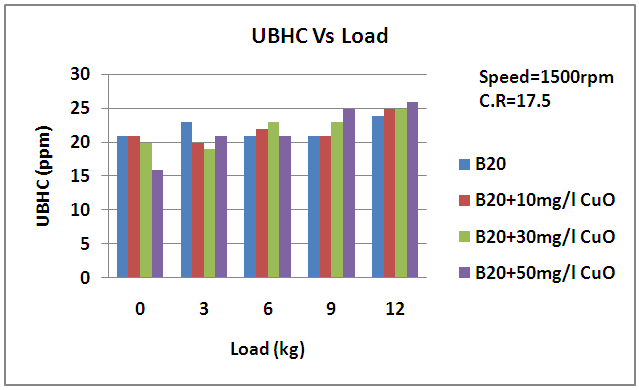

- From Fig 3, we note that increase in load causes an increase in hydrocarbon (HC) emissions. It is to be noted, at 12 kg load the HC emissions for all blends is relatively much higher compared to the emission of the blends at 0, 3, 6 and 9 kg loads. At maximum load, the increase in HC is found to be 4.16%, for B20+10 mg/l CuO, B20+30 mg/l CuO and 8.33% for B20+50 mg/l CuO respectively when compared with B20 blend.

| Figure 3. Variation of Unburnt Hydrocarbons Vs Load for different fuel samples |

| Figure 4. Variation of Nitrogen Oxides Vs Load for different fuel samples |

| Figure 5. Variation of Smoke Opacity Vs Load for different fuel samples |

4. Conclusions

- The dispersion of CuO nanoparticles in the base fuel B20 blend of Pongamia Pinnata biodiesel is successfully carried out using bath sonicator. The physiochemical properties of fuel samples are studied. The viscosity and density of the fuel sample is found to increase with addition of nanoparticles. The brake thermal efficiency (BTE) increased with the addition of CuO nanoparticles to biodiesel. At maximum load B20+10 mg/l CuO gives the maximum BTE when compared with B20 blend. Among all the blends, it is noted that B20+50 mg/l CuO has the least BSFC compared to other blends. It is noted that addition of nanoparticles to biodiesel decreases the NOx emissions. At maximum load, B20+50 mg/l CuO emits least NOx when compared to the other blends. When compared with B20 sample, all other blends have slightly higher HC emissions at different loads. The CO emissions for all blends are slightly decreasing at same loads.B20+50mg/l CuO blend has lower CO emission compared to other blends. As a result CO emissions can be reduced by increasing the CuO nanoparticle concentration in B20 blend. Smoke emission is less in B20+50mg/l CuO as compared to other blends. Smoke can be reduced with increase in the concentration of CuO nanoparticle in B20 blend. It can be concluded that performance and emission characteristics can be increased with increase in CuO nanoparticle in B20 blend.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML