Joynel Pinto, Aldrin J. Nazareth, Anston C. Pais, Jayadev P. Y., Sushanth H. G., K. Raju, Joseph Gonsalvis

Department of Mechanical Engineering, St. Joseph Engineering College, Mangaluru, India

Correspondence to: K. Raju, Department of Mechanical Engineering, St. Joseph Engineering College, Mangaluru, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

In the present work, B10 blends of biodiesels were prepared from Vateria Indica and Honge oils and their properties have been evaluated. A comparative study on the performance and emission characteristics has been carried out using a 4-stroke single cylinder diesel engine. The performance and emission test results indicate that B10 blends of biodiesels can be used directly without any modification in the CI engine. Among the B10 blends, the performance of Honge Oil Methyl Ester was slightly better than that of Vateria Indica Oil Methyl Ester. It has been observed that the brake thermal efficiency of Honge Oil and Vateria Indica Oil Methyl Esters was found to be less than that of neat diesel at full load condition by 7% and 9% respectively. Also the CO, CO2 and HC emissions were found to be less for Vateria Indica and Honge Methyl Esters as compared to that of neat diesel.

Keywords:

Vateria Indica Oil Methyl Ester (VIOME), Honge Oil Methyl Ester (HOME), Transesterification, Brake thermal efficiency, Diesel engine

Cite this paper: Joynel Pinto, Aldrin J. Nazareth, Anston C. Pais, Jayadev P. Y., Sushanth H. G., K. Raju, Joseph Gonsalvis, A Comparative Study on the Performance and Emission Characteristics of B10 Blends of Vateria Indica and Honge Oil Methyl Esters on a CI Engine, Energy and Power, Vol. 7 No. 3, 2017, pp. 88-92. doi: 10.5923/j.ep.20170703.06.

1. Introduction

A fuel is any substance that can be made to react with other substances so that it releases chemical or nuclear energy as heat or to be used for work. The heat energy released by reactions of fuels is converted into mechanical energy via a heat engine. Vegetable oils present a very promising alternative to diesel since they are renewable, biodegradable and have similar properties. Reduction of engine emissions is a major research aspect in engine development with the increasing concern on environmental protection and the stringent exhaust gas regulation. Vegetable oils are a mixture of organic compounds ranging from simple straight chain to complex structure of proteins and fat-soluble vitamins [1]. Skyrocketing of petroleum fuel costs in present day has led to growing interest in alternative fuels like vegetable oils, alcoholic fuels, CNG, LPG, producer gas, biogas in order to provide a suitable substitute to diesel for a compression ignition (CI) engine. Utilization of producer gas in CI engine on dual fuel mode provides an effective approach towards conservation of diesel fuel [2]. Unlike rest of the world, India’s demand for diesel fuels is roughly six times that of gasoline hence seeking an alternative to diesel is a natural choice. Alternative fuels should be easily available at low cost, be environment friendly and fulfill energy security needs without sacrificing engine’s operational performance. Now-a-days biofuels are getting a renewed attention because of global stress on reduction of greenhouse gases and clean development mechanism. The fuels of bio-origin may be alcohol, vegetable oils, biomass and biogas. Some of these fuels can be used directly while others need to be formulated to bring the relevant properties close to conventional fuels [3]. The use of vegetable oil as a biodiesel can be either edible or non-edible. The non-edible vegetable oils are not suitable for human food due to the presence of some toxic components in the oils [4]. The selection of non-edible vegetable oils as feedstock for biodiesel production requires reviewing of the existing work. The production of biodiesel from non-edible oil feedstock can overcome the problems of food versus fuel, environmental and economic issues related to edible vegetable oils [5].

2. Methodology

The seeds of Vateria Indica and Honge were collected and dried. Honge oil extraction was directly done in mill and Vateria Indica oil extraction was done using Soxhlet apparatus. The oils were transesterified and the physical properties of biodiesel have been evaluated for 100% biodiesel as well as B10 blends.

3. Experimental Setup

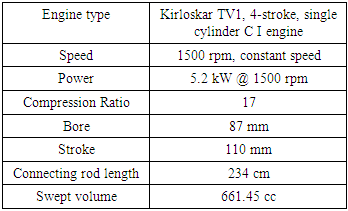

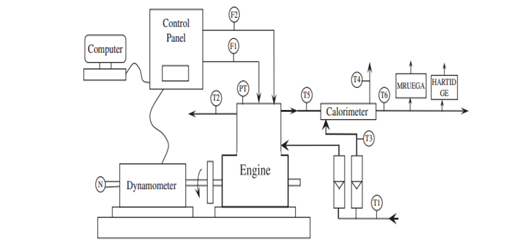

The Experiments were conducted on a four-stroke single cylinder direct injection CI engine as shown in Figure 1. The engine specifications, combustion and performance parameters are shown in Tables 1, 2 and 3 respectively. T1, T3 – inlet water temperature; T2 – outlet engine jacket water temperature; T4 – outlet calorimeter water temperature; T5 – exhaust gas temperature before calorimeter; T6 – exhaust gas temperature after calorimeter; F1 – fuel flow DP (differential pressure) unit; F2 – air intake DP unit; PT – pressure transducer; N – RPM decoder; MRU – exhaust gas analyzer (5 gas); HARTRIDGE smoke meter. | Figure 1. Schematic diagram of the experimental setup |

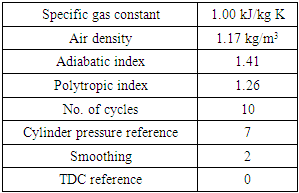

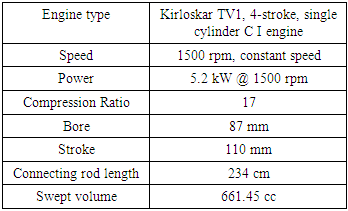

Table 1. Specifications of Engine

|

| |

|

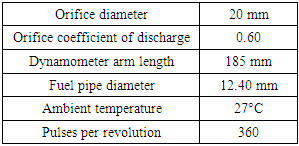

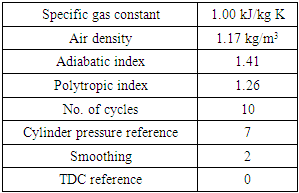

Table 2. Combustion Parameters

|

| |

|

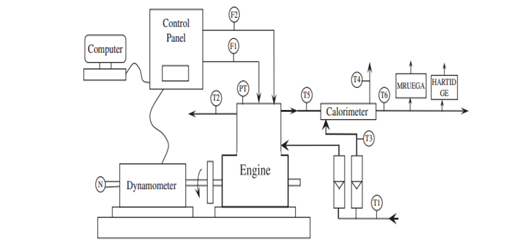

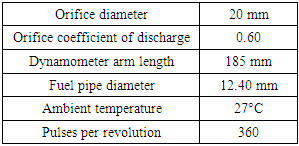

Table 3. Performance Parameters

|

| |

|

4. Results and Discussion

4.1. Combustion Analysis

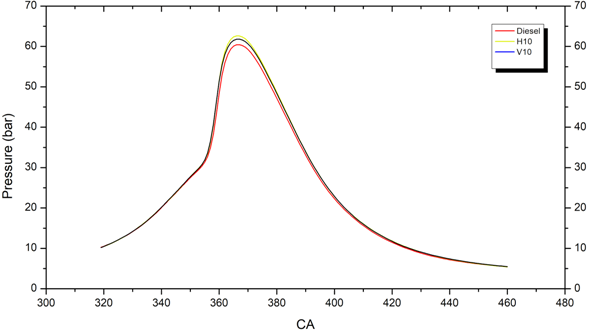

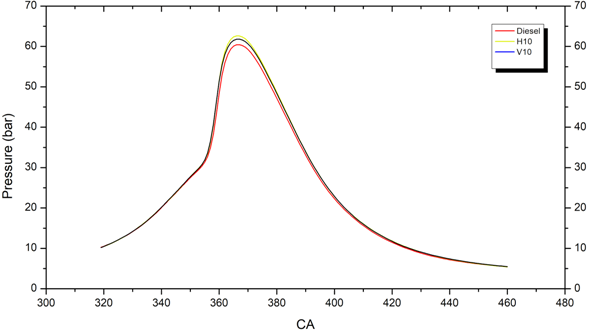

The Figure 2 shows the variation of pressure inside the cylinder with crank angle. It was observed that B10 blend of Honge oil methyl ester (HOME) has the highest peak pressure during combustion whereas diesel has the least peak pressure. The peak pressures were found to be 60.4, 61.8 and 62.6 Bars for diesel, VIOME B10 and HOME B10 respectively. | Figure 2. Graph of Pressure vs Crank Angle |

4.2. Performance Results

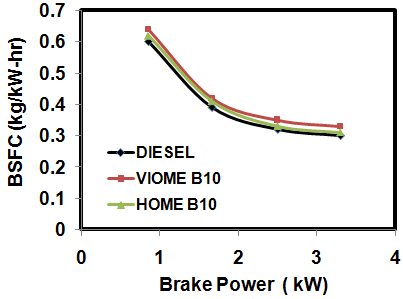

4.2.1. Brake Specific Fuel Consumption (BSFC)

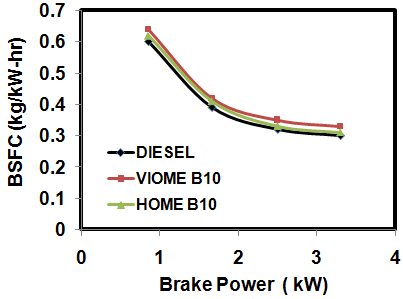

The Figure 3 shows the variation of Brake Specific Fuel Consumption with Brake Power (BP). The Brake Specific Fuel Consumption for all the fuels decreases with an increase in load, because of better combustion at higher loads. The B10 blends showed a similar trend with slightly higher Brake Specific Fuel Consumption as compared to that of diesel. This could be due to the presence of oxygen in biodiesel. At the full load condition, the Brake Specific Fuel Consumption was found to be 0.3, 0.31 and 0.33kg/kWh for diesel, HOME B10 and VIOME B10 blends respectively. | Figure 3. Graph of Brake Specific Fuel Consumption vs Brake Power |

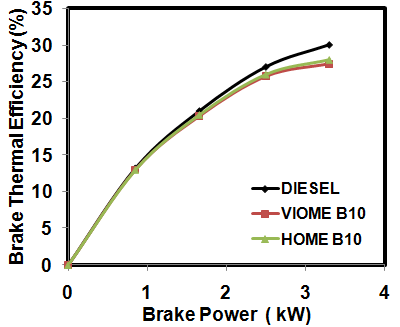

4.2.2. Brake Thermal Efficiency

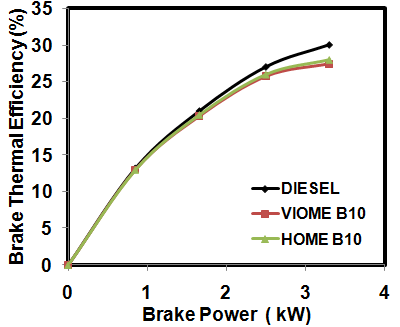

The Figure 4 shows the variation of brake thermal efficiency with brake power. The brake thermal efficiency of VIOME B10 and HOME B10 blends is slightly less than that of neat diesel. At the full load condition, the brake thermal efficiency was found to be 30%, 28% and 27.4% for diesel, HOME B10 and VIOME B10 blends respectively.  | Figure 4. Graph of Brake Thermal Efficiency vs Brake Power |

4.3. Emission Characteristics

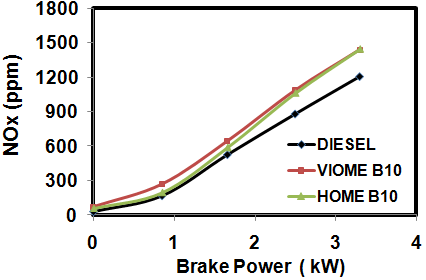

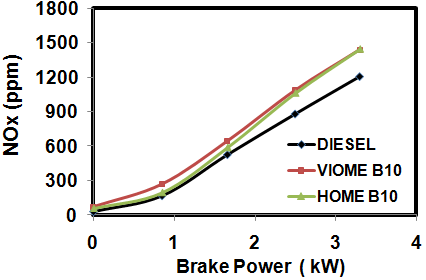

4.3.1. Oxides of Nitrogen (NOx)

The Figure 5 shows the NOx emissions. It was found that biodiesel produces more NOx than neat diesel. At the full load condition, the NOx emissions were found to be 1207 ppm, 1445 ppm and 1437 ppm for diesel, HOME B10 and VIOME B10 respectively. | Figure 5. Graph of Oxides of Nitrogen vs Brake Power |

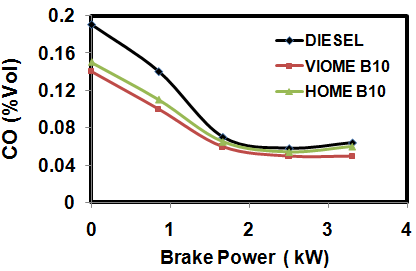

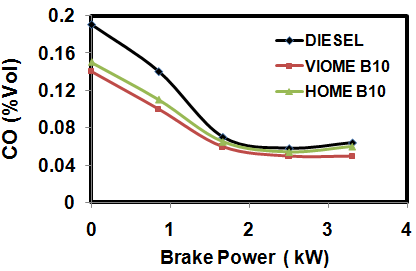

4.3.2. Carbon Monoxide (CO)

The Figure 6 shows the CO emissions. It has been observed that the CO emissions are less for biodiesel as compared to neat diesel. At the full load condition, the CO emissions were found to be 0.064%, 0.06% and 0.05% for diesel, HOME B10 and VIOME B10 blends respectively. | Figure 6. Graph of Carbon Monoxide vs Brake Power |

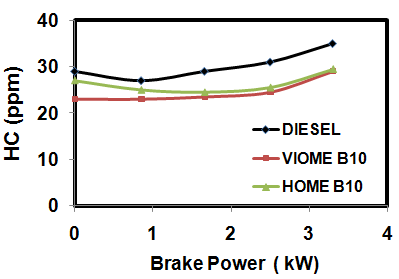

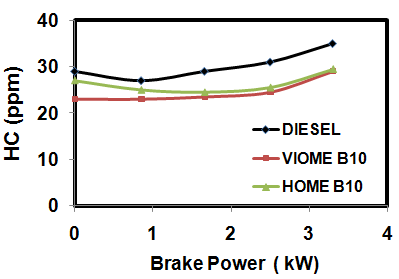

4.3.3. Hydrocarbons (HC)

The Figure 7 shows the HC emissions. It was found that HC emissions were highest for diesel at full load, followed by HOME B10 and VIOME B10. The HC emissions were found to be 35, 29.4 and 29 ppm for diesel, HOME B10 and VIOME B10 respectively.  | Figure 7. Graph of Hydrocarbons vs Brake Power |

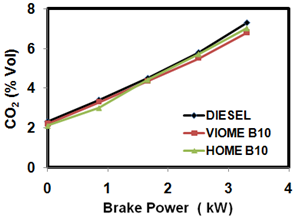

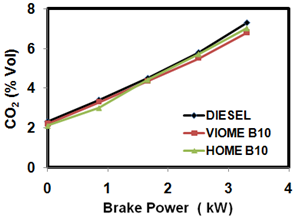

4.3.4. Carbon Dioxide (CO2)

The Figure 8 shows the CO2 emissions. At all loads the CO2 emissions were found to be higher in diesel than in biodiesel blends. At the full load condition, the CO2 emissions were found to be 7.3% for diesel, 7% for HOME B10 and 6.8% for VIOME B10 respectively. | Figure 8. Graph of Carbon dioxide vs Brake Power |

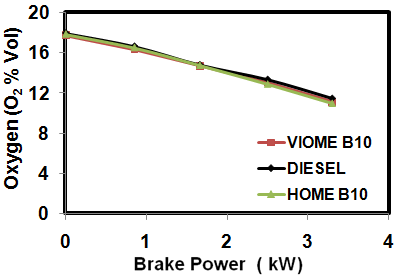

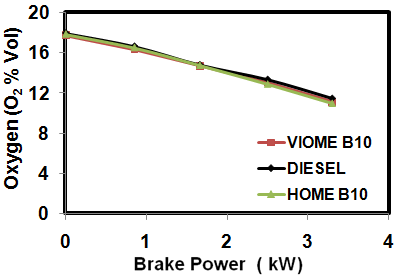

4.3.5. Oxygen (O2)

The Figure 9 shows the variation of O2 in exhaust gases. The O2 content in exhaust gases was found to be high in the case of diesel than that of biodiesels. At the full load condition, the O2 content in the exhaust gases was found to be 11.5%, 11.1% and 10.9% for diesel, VIOME B10 and HOME B10 respectively.  | Figure 9. Graph of Oxygen vs Brake Power |

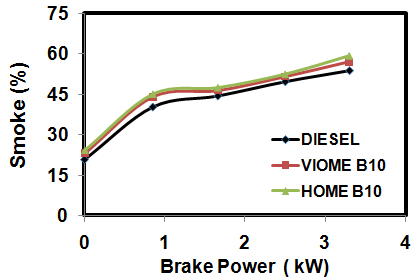

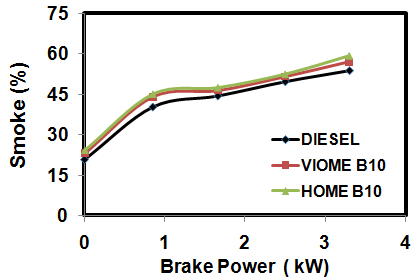

4.3.6. Smoke

The Figure 10 shows the change in smoke opacity with Brake Power. Biodiesels emitted more smoke as compared to that of diesel when operated on a 4-stroke engine. At the full load condition, the smoke opacities were found to be 54%, 57% and 59% for diesel, VIOME B10 and HOME B10 respectively. | Figure 10. Graph of Smoke vs Brake Power |

5. Conclusions

The following conclusions may be drawn from the present study. 1. Among the biodiesel (B10) blends, Honge Oil Methyl Ester has a slightly higher thermal efficiency than that of Vateria Indica Oil Methyl Ester. 2. At the full load condition, the brake thermal efficiency of Honge and Vateria Indica Oil Methyl Esters was less than that of neat Diesel by 7% and 9% respectively.3. The CO, CO2 and HC emissions were found to be low whereas NOx emission was found to be high for Vateria Indica and Honge Oil Methyl Esters as compared to that of neat diesel.4. The resultant smoke was slightly more opaque in the case of biodiesel blends by an average of 8% as compared to that of neat diesel.

ACKNOWLEDGEMENTS

The authors are grateful to the Management, St. Joseph Engineering College, Mangaluru for providing the facilities for conducting the performance and emission testing.

References

| [1] | N.R. Banapurmath, P.G. Tewari, R.S. Hosmath, Performance and emission characteristics of a DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters, Renewable Energy, 2008, 1982–1988. |

| [2] | N.R. Banapurmath, P.G. Tewari, V.S. Yaliwal, Satish K, Y.H Basavarajappa, Combustion characteristics of a 4-stroke CI engine operated on Honge, Neem and Rice Bran oils when directly injected and dual fuelled with producer gas induction, Renewable Energy, 2009, 1877–1884. |

| [3] | B.K. Barnwal and M.P. Sharma, Prospects of biodiesel production from vegetable oils in India, Renewable and Sustainable Energy Reviews, 9 (2005) 363–378. |

| [4] | Ahmad AL, Yasin NHM, Derek CJC, Lim JK, Microalgae as a sustainable energy source for biodiesel production, Renewable and Sustainable Energy Reviews, 15 (1) 2011, 584–593. |

| [5] | Balat M and Balat H, Progress in biodiesel processing, Applied Energy, 87 (6) 2010, 1815–1835. |

| [6] | Mohammed Faizan Shaikh and Sudhakar Umale, Noise and Vibration analysis of Diesel Engine Using Diesel and Jatropha Biodiesel, International Journal of Engineering Trends and Technology (IJETT), 5 (2014) 228–231. |

| [7] | Bobade S.N. and Khyade V.B, Preparation of Methyl Ester (Biodiesel) from Karanja (Pongamia Pinnata) Oil, Research Journal of Chemical Sciences, 2012, 43–50. |

| [8] | Agarwal D and Kumar Agarwal A, Performance and emission characteristics of a Jatropha oil (preheated and blends) in a direct injection compression ignition engine, Int J Appl Therm Eng, 27, 2007, 2314–2323. |

| [9] | Masjuki H and Salit, Biofuel as diesel fuel alternative: an overview, J. Energy Heat Mass Transfer, 15, 1993, 125–133. |

| [10] | Piyaporn K, Narumon J, Kanit K., Survey of seed oils for use as diesel fuels, J. Am. Oil Chem. Soc. , 71 (4) 1996, 471–477. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML