-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2017; 7(3): 75-80

doi:10.5923/j.ep.20170703.04

Ecofriendly Synthesis of Silver Nanoparticles Using Oil Seed Cake and Its Application in Biodiesel for Performance Evaluation of 4 Stroke Diesel Engine

Nireeksha K.1, Sanjana S.1, Shreya S. Jathhan1, Sneha Nayak1, Santhosh G.2, C. Vaman Rao1

1Department of Biotechnology Engineering, NMAM Institute of Technology, Udupi District, Nitte, India

2Department of Mechanical Engineering, NMAM Institute of Technology, Udupi District, Nitte, India

Correspondence to: Sneha Nayak, Department of Biotechnology Engineering, NMAM Institute of Technology, Udupi District, Nitte, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Biosynthesis of silver nanoparticles under ambient condition using oil seed cake which is a byproduct from biodiesel industry is investigated. The formation of silver nanoparticles (AgNPs) was analyzed visually and spectrophotometrically. Appearance of brownish color indicated the formation of AgNPs which was confirmed by the appearance of surface Plasmon band at 435 nm by UV-Vis. The synthesized AgNPs were characterized by FT-IR, particle size analyzer, XRD and FESEM. FESEM results revealed the grain size of nanoparticles is in the range of 18-30nm. In the present study, biosynthesized AgNPs were used as an additive for biodiesel and its influence on engine performance was studied. Experiment were carried out on Kirlosker make, 4 stroke, water cooled, single cylinder, direct injection, diesel engine at fixed compression ratio to determine emission characteristics and performance evaluation of diesel &; diesel-biodiesel–AgNPs blends. AgNPs were blended into biodiesel in the mass fraction of 25ppm and 50ppm using ultrasonicator for proper dispersion and for improving the stability of the blends. The results showed significant increase in break thermal efficiency due to addition of silver nanoparticles in biodiesel, where lower dosing level of AgNPs further improved the performance of the engine.Hence usage of nanoparticles blended biodiesel enhances the engine performance efficiency and will facilitate further reduction of carbon footprint in terms of noxious gas emissions. Therefore application of nanotechnology in biofuels will help in reduction of diesel consumption, which in turn will help in boosting the economy by reducing the import of crude oil thereby reducing the burden on government foreign exchange.

Keywords: Biosynthesis, Silver nanoparticles, Performance evaluation, Emission characteristics

Cite this paper: Nireeksha K., Sanjana S., Shreya S. Jathhan, Sneha Nayak, Santhosh G., C. Vaman Rao, Ecofriendly Synthesis of Silver Nanoparticles Using Oil Seed Cake and Its Application in Biodiesel for Performance Evaluation of 4 Stroke Diesel Engine, Energy and Power, Vol. 7 No. 3, 2017, pp. 75-80. doi: 10.5923/j.ep.20170703.04.

Article Outline

1. Introduction

- In present world due to the consequence of spiraling demand and diminishing supply, the fuel prices are hiking up. Hence we need to choose a cost effective fuel to meet our needs. The invention of diesel has proved to be an efficient and cost effective alternative. Diesel fuel has higher energy density when compared to conventional gasoline. However diesel can yield more damaging effects to engine and can cause improper and poor combustions and heavy gaseous emissions. Emissions deposits on internal parts of engine causing malfunctioning in the long run causing engine problems in extreme cold regions. In the recent era there has been major advancements seen in the fuel field to improve engine efficiency and minimize emissions. Biodiesel is a clean burning fuel made from domestic, renewable sources which are grown, produced and distributed locally and can be a good alternative for diesel. It can be used in a pure form (B100) or can be blended with diesel in the form of B20 (20% biodiesel and 80% diesel). It can be used in existing diesel engines, causing less green-house gas emissions since it is biodegradable and non-toxic thereby improving the fuel economy. However in biodiesel due to lower calorific value, more fuel consumption is a major issue which can be addressed by the application of nanotechnology.Nanoparticles can be synthesized using various approaches like physical, chemical and biological. The naturally synthesized nanoparticles are cost effective and environmental friendly compared to chemically synthesized nanoparticles. Recent studies have proved that the addition of nanoparticles can improve the performance and the combustion of biodiesel while producing fewer emissions due to high surface to volume ratio of nanoparticles. High surface to volume ratio gives them more reactive surfaces allowing them to act as more efficient catalyst thus increasing fuel combustion. The presence of nanoparticles also increases fuel- air mixing in the fuel which leads to nearly complete burning. Investigation on exhaust gas characteristics and engine performance of diesel engine using different nanoparticles a catalyst like Cu nanoparticles [1], Alumina nanoparticles [2], Pd nanoparticles [3], TiO2 [4], Al2O3 [5], Fe [6] have been reported which are either chemically synthesized or commercially obtained. Plant mediated synthesis of nanoparticles has been investigated in the recent years which is a green approach. In this paper we report the synthesis of silver nanoparticles using powdered oil seed extract which is a byproduct from biodiesel industry. The synthesized silver nanoparticles where used as additives for biodiesel blend (B20) and further engine performance was studied. The engine used was Kirloskar make, 4 stroke, water cooled, single cylinder, direct injection, diesel engine. Emission characteristic and performance evaluation of diesel, biodiesel, and silver nanoparticles biodiesel blends were observed.

2. Materials and Methods

2.1. Oil Seed Cake Extract Preparation

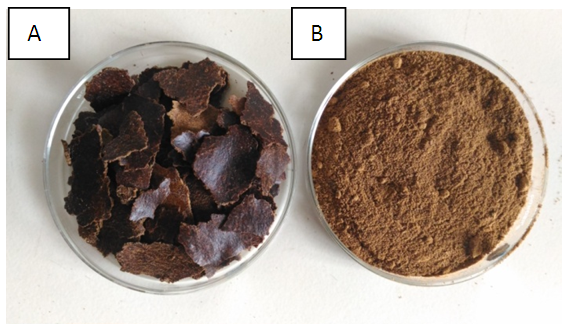

- Oil seed cake (refer Fig 1) was used for the preparation of 10% (w/v) suspension in deionized water by mixing the finely ground powder with water. The suspensions will be kept in the water bath maintained at 80°C for half an hour [7] and filtered and used for nanoparticle synthesis.

| Figure 1. (A) Oil seed cake and (B) Seed cake powder for extract preparation |

2.2. Synthesis of Nanoparticles

- Biosynthesis of silver nanoparticles was undertaken by taking 25 ml of oil seed cake extract prepared in deionized water to which 225 ml of 1mM AgNO3 was added and mixed thoroughly. The resultant mixture was kept in a shaker at 120 rpm at room temperature. Color change in the resulting solution was measured at regular intervals by measuring absorbance at 360 to 700 nm using UV visible spectrophotometer. The reaction mixture was then centrifuged at 10000 rpm for 30 mins and the obtained product was washed thrice with deionized distilled water and finally with ethanol, and stored at - 4°C for further analysis.

2.3. Characterization of AgNps

- UV-visible spectroscopy of AgNPs was accomplished by UV1-Thermo electronic corporation, Merck. Zetasizer nano instrument (Malvern) was used for data acquisition and for estimating the particle size distribution and zeta potential distribution of a colloidal solution of nanoparticles. The functional groups present in the phytoconstituents of Santalum album stem extract and their involvement as capping agents in the biosynthesized nanoparticles was determined by recording the IR on Bruker Alpha. Size and morphology of AgNPs were examined by Field Emission Scanning Electron Microscope (FESEM), CARL ZEISS by sputtering. The sputtered samples were analyzed for their microstructure at 5 KV. FESEM specimen preparation was done by taking small amount of nanoparticles powder dispersed on carbon tape. Thin gold coating over the sample was developed by passing 20 mA current for 10 mins.

2.4. Biodiesel Production

- The transesterification was carried out according to Maa and Hanna method [7] by adding methanol – sodium hydroxide mixture (methoxide) in to the batch reactor containing preheated waste cooking oil. The reaction was continued at 65°C for 90 minutes and then the reaction mixture was transferred to a separating funnel. The separation of biodiesel phase and glycerol phase was achieved in 3 to 4 hours. The biodiesel phase was separated and distilled to remove traces of methanol and then it was washed with warm water at 50°C until the pH of the exhaust water becomes neutral. The biodiesel was then dried by heating it into 110°C for 20 minutes to remove the moisture content.

2.5. Nanoparticle Blending Methodology

- Ultrasonicator with frequency of 40 kHz was used to distribute different mass fractions (25 ppm or 50 ppm) of silver nanoparticles in biodiesel for 30 minutes ( refer Fig 2).

| Figure 2. Blending of biodiesel with silver nanoparticles in ultrasonicator |

2.6. Test Procedure and Experimental Set up

- To study the performance of diesel engine, experiments were carried out using Kirlosker make single cylinder, 4 stroke, water cooled, direct injection using the base diesel, biodiesel and nanoparticles blended biodiesel. Specifications of the engine was used for the experimentations are presented in the table 1. Engine speed was controlled by the engine governor. The engine was supplied with a combustion chamber which was hemispherical with overhead valves controlled through push rods. The cylinder pressure was measured using a pressure transducer made up of piezoelectric material which was attached to the cylinder head surface. The performance parameters like emission of unburnt hydrocarbons, CO, NOx were analyzed during steady state operation of the engine by five gas analyzer and smoke capacity by Hartridge smoke meter.

|

3. Results and Discussions

3.1. Nanoparticle Synthesis

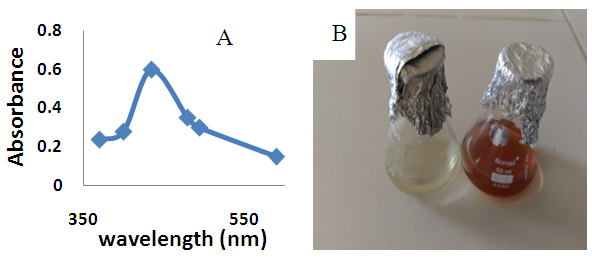

- Change of colour in the solution from light yellow to brown indicated the formation of silver nanoparticles. UV visible spectrophotometer confirmed the production of silver nanoparticles at 435 nm (refer Fig 3).

| Figure 3. (A) Ultraviolet -Visible spectra of biosynthesized AgNps (B) AgNps Synthesis confirmation from flasks |

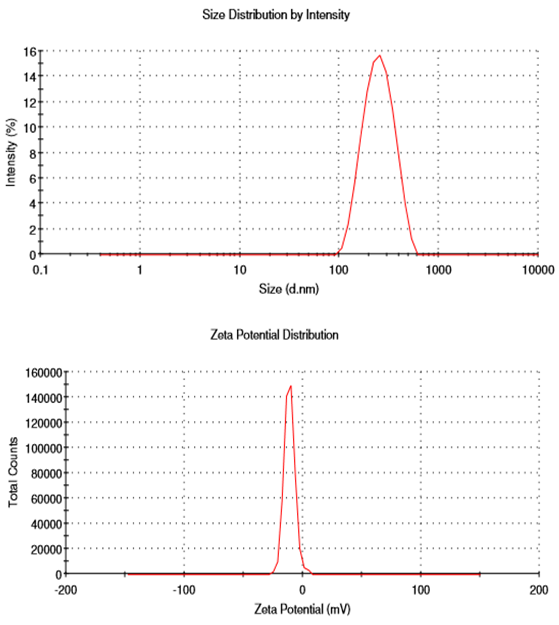

3.2. Size Distribution and Zeta Potential

- Fig. 4 shows particle size with diameter in the range of 260nm and width of 89nm with intensity of 100% with Z-average value of 221.4nm and low polydispersity index (PDI) of 0.149 which indicates monodisperse sample and Zeta potential value – 11.2 of AgNPs. This indicates that, the capping molecules present on the surface of AgNPs are mainly comprised of negatively charged groups and are also responsible for moderate stability of nanoparticles.

| Figure 4. Zetasizer and Zeta potential distribution of biosynthesized AgNPs |

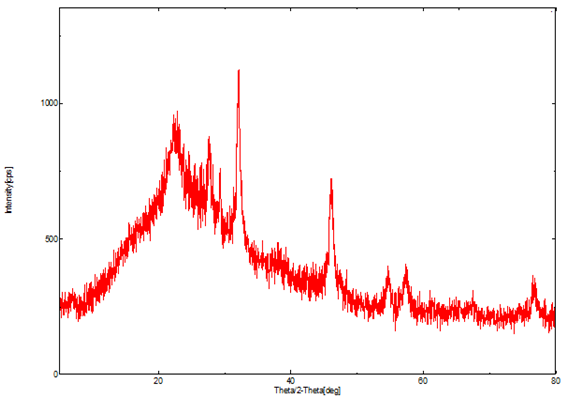

3.3. XRD Studies

- The XRD patterns were recorded for AgNPs as shown in Fig 5. It was found that, the XRD pattern for AgNPs exhibited broader peaks [8]. The pattern of AgNPs showed 3 characteristic diffraction peaks at 31.73, 45.72 and 76.27° in the 2θ range, which can be indexed to the (110), (200) and (311). The peaks revealed that the resultant nanoparticles were in face cantered cube structure. Further, the average crystal sizes of AgNPs were calculated by applying Scherrer equation and were found to be around 20 nm. The observed XRD pattern, thus, evidently confirmed that the silver nanoparticles are formed by the reduction of Ag+ ions by phytochemicals of oil seed cake extracts and the silver nanoparticles are crystalline in nature. Apart from normal peaks, some additional and unidentified peaks were also noticed at the vicinity of the characteristic peaks of silver nanoparticles. These peaks may be due to some bioorganic compounds or proteins of the extract [9, 10].

| Figure 5. XRD pattern of biosynthesized AgNPs |

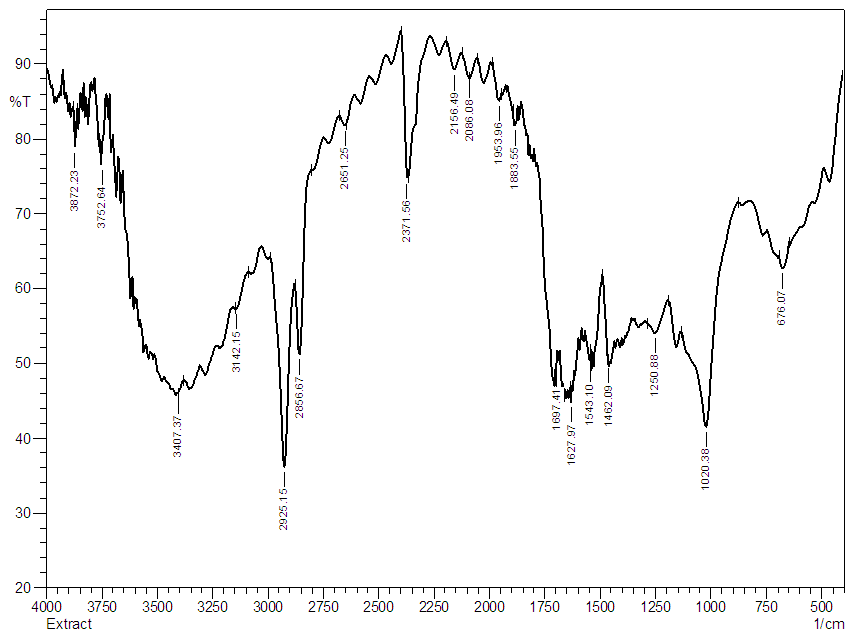

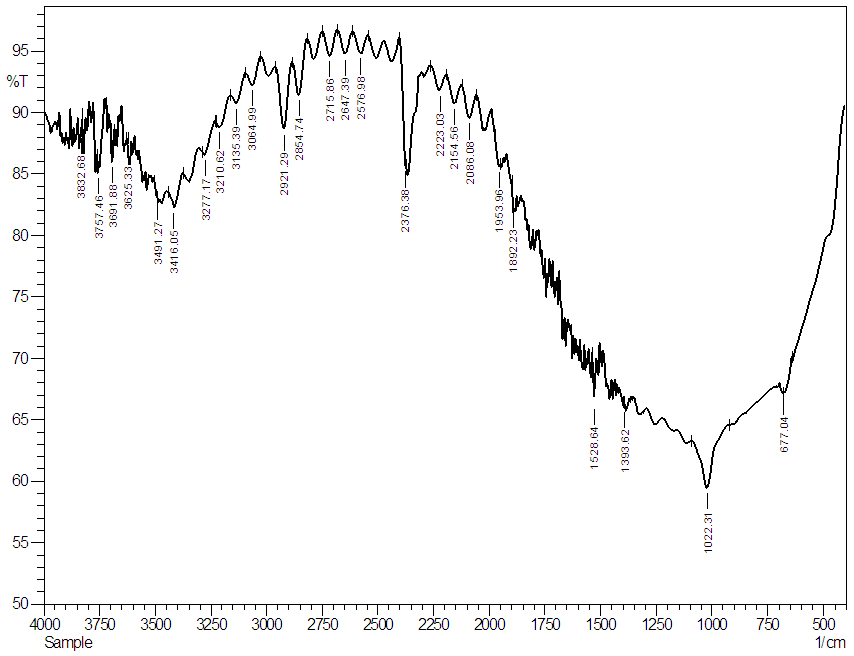

3.4. FTIR Analysis

- The IR absorption spectra seen in the aqueous extract of Oil seed cake extract were also seen in phytocapped nanoparticles synthesized from the extract. AgNps potentially possess rocking vibration of CH3 (676 cm-1), C –OH stretching of secondary alcohols (1020 cm-1) [11], C=H stretching vibration of aldehydic amine group (2925 cm-1) [12]. The most common rocking vibration found between the extract and the AgNps were found to be C=H stretching vibration of aldehydic amine group (2925 cm-1). The Drastic reduction in peak was seen at (2925 cm-1) which corresponds to C=H stretching vibration of aldehyde amide groups. Peaks which were seen at 3407 cm-1 in the extract completely vanished in the AgNps which indicates the involvement of alcoholic, polyphenols and protein groups in the catalytic reduction of AgNO3 to AgNps [12].

| Figure 6. (A) FT-IR of oil seed cake extract |

| Figure 6. (B) FT-IR of Ag nanoparticles produced from oil seed cake extract |

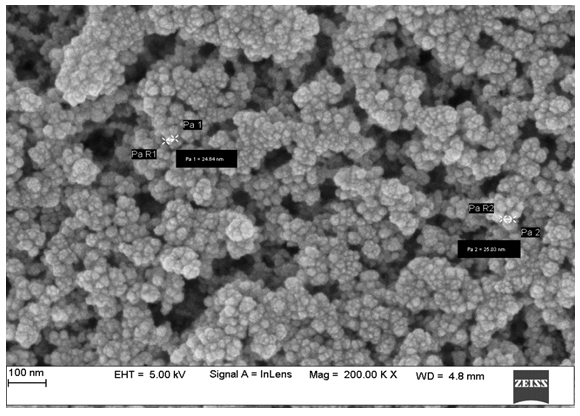

3.5. FESEM Analysis

- Figure 7 reveals that the silver nanoparticles formed were spherical in shape, with size ranging around 100 nm with grain size of 18-25nm. In a study, AgNPs synthesized using Mentha piperita leaf extract had average size of 150nm [13]. Compared to the earlier reports of biosynthesis of AgNPs, AgNPs biosynthesized in the present study from oil seed cake extract were found to be quite comparable.

| Figure 7. Is a field emission scanning electron micrograph of AgNps synthesized using oil seed cake extract |

3.6. Engine Performance Parameters

3.6.1. Variation of Break thermal Efficiency (BTE)

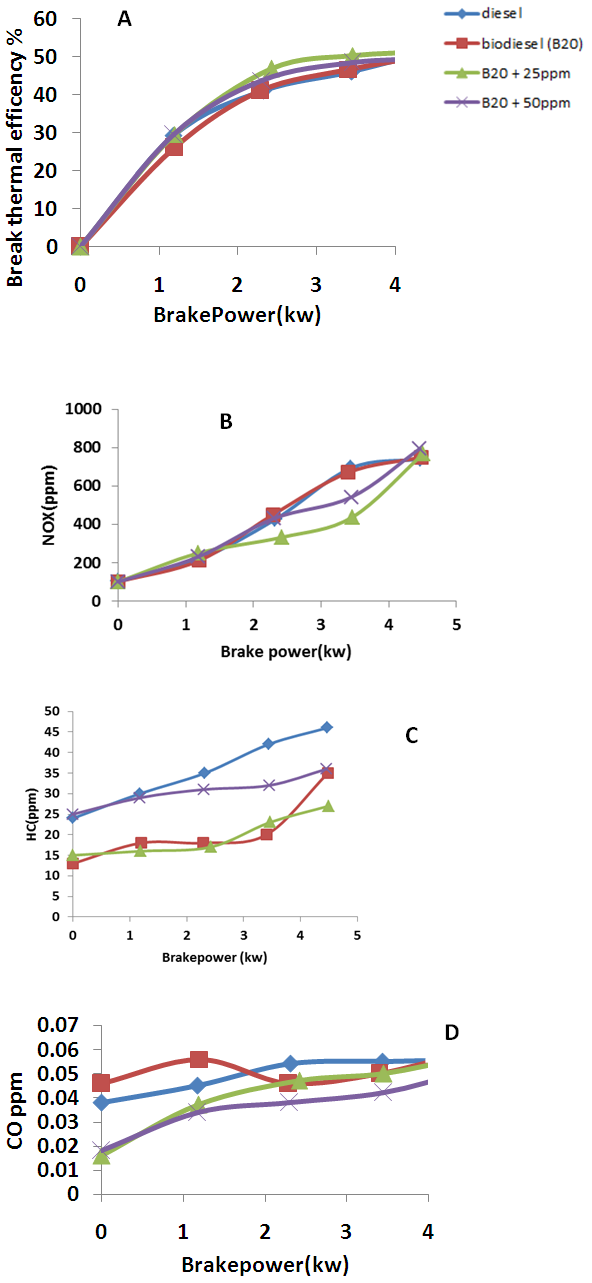

- The variation of break thermal efficiency with the increasing load for the diesel and biodiesel blend (B20) with silver nanoparticles is shown in Fig.8.(A). With increase in load, the break thermal efficiency is increasing. It is observed that break thermal efficiency is higher for diesel compared to 20% biodiesel. But as load increases, the break thermal efficiency of diesel and biodiesel arrive at like values. However improvement of break thermal efficiency is obtained with 25ppm silver nanoparticles than compared with B20 of 50ppm of silver nanoparticles. The maximum break thermal efficiency obtained for 20% biodiesel blend with 25ppm and 50ppm are 51.44% and 49.45%. The increase in break thermal efficiency may be due to addition of silver nanoparticles which act as oxidative catalyst and result in increased combustion. The 25ppm biodiesel blend shows better break thermal efficiency compared to 50ppm of silver nanoparticles blended with biodiesel.

3.6.2. Variation of NOx Emission

- The nitrogen oxide emissions with diesel and biodiesel with the blends of 25ppm and 50 ppm of silver nanoparticles with the load is shown in Fig.8. (B). The NOX emission increases by the addition of silver nanoparticles. It is because of the complete combustion caused by the delay in the ignition that is reduces considerably here. The biodiesel blend with 25ppm silver nanoparticles show NOX emission of 765ppm and biodiesel blend with 50ppm of silver nanoparticles shows 795ppm of NOX emission.

3.6.3. Variation of HC Emission

- The hydro carbon load variation with diesel and biodiesel along with their blends are shown in Fig.8. (C). The addition of silver nanoparticles to the biodiesel blend reduces the hydro carbon emission than compared with diesel. Here silver nanoparticles act as oxidation catalyst which help in the complete and clear combustion. The HC emission for 25ppm and 50ppm biodiesel blend were 27ppm and 36ppm respectively.

3.6.4. Variation of CO Emission

- The variation of carbon monoxide with break power is shown in Fig.8. (D). Initially the carbon monoxide emission decreases with the addition of silver nanoparticles and rapidly increases at full load. The emission for biodiesel with 25 and 50 ppm silver nanoparticles increases rapidly for full load. The emission reduces considerably with addition of silver nanoparticles. The retardation in the emission for 25ppm and 50ppm blends are 0.057 ppm and 0.051 ppm. The highest emission was observed for biodiesel with 0.059 ppm.

4. Conclusions

- By employing ecofriendly, inexpensive biological approach using extract of oil seed cake which is a byproduct from biodiesel plant, silver nanoparticles were synthesized. The organic reducing agents present in the extract reduced the silver ions to their correlative neutral atoms, which then nucleates to become nanoparticles. FESEM of AgNps sample confirmed the particles in nano range. The emission characteristics and performance of 4 Stroke Diesel Engine using green synthesized silver nanoparticles blended biodiesel were analyzed. Reduction in the NOx and HC emission and maximum break thermal efficiency at lower dosing level of 25 ppm for AgNPs synthesized using oil seed cake extract in biodiesel blend (B20) confirms that 25 ppm is the optimum dosing level for better catalytic activity of nanoparticles. Overall it is clear from the results that silver nanoparticles (AgNPs) can be efficiently used for improving the properties of biodiesel. It also enhances the performance of the engine and reduces emissions to certain extent, further investigations are required in trying to reduce CO emission by using modified injection strategies with multiple injection events [14].

ACKNOWLEDGEMENTS

- Authors would like to thank NMAM Institute of technology for technical support in carrying out the work. We would also like to thank Manipal College of Pharmaceutical Sciences, Manipal and Mangalore University for technical support in characterizing the nanoparticles.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML