-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2015; 5(1): 17-23

doi:10.5923/j.ep.20150501.03

The Production of Biodiesel from Animal Tallow to be Used for Electric Generators: A Case Study

Jafar A. Ali, Ribwar K. Abdulrahman, Mohammed H. Zangana

Faculty of Engineering, Koya University, Koya, KOY45, Kurdistan Region, Iraq

Correspondence to: Jafar A. Ali, Faculty of Engineering, Koya University, Koya, KOY45, Kurdistan Region, Iraq.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Huge amounts of animal fats are disposed every day at the slaughter houses across the world. Waste animal fats may be considered as a promising and cheap raw material for biodiesel Production. This study is described a scientific and engineering method that can use these undesirable products and convert them to valuable fuel such as, biodiesel, having Koya city in Kurdistan Region as a case study. Biodiesel is one of the most important types of sustainable fuels that need more investigation and discussion. The utilizing of biodiesel instead of petro diesel could reduce carbon dioxide emission to the environment. As a result, reduce greenhouses gases and global warming phenomenon in the earth plant. The current study is to utilize waste animal fat for biodiesel production using different catalysts for instance KOH, the production process is validated. As a result, the disposed animal fats could be utilized to produce useful product rather environmental pollution. The city of Koya can produce 30000L of B100 every month, which can be blended to B20 then use for IC engines. The blended biodiesel can be supplied to the private electric generators in the city, 3410L of B20 for each generator, a similar power and output current will be obtained with less emission.

Keywords: Animal fats, Biodiesel, Petro diesel, Electric generator, Power

Cite this paper: Jafar A. Ali, Ribwar K. Abdulrahman, Mohammed H. Zangana, The Production of Biodiesel from Animal Tallow to be Used for Electric Generators: A Case Study, Energy and Power, Vol. 5 No. 1, 2015, pp. 17-23. doi: 10.5923/j.ep.20150501.03.

Article Outline

1. Introduction

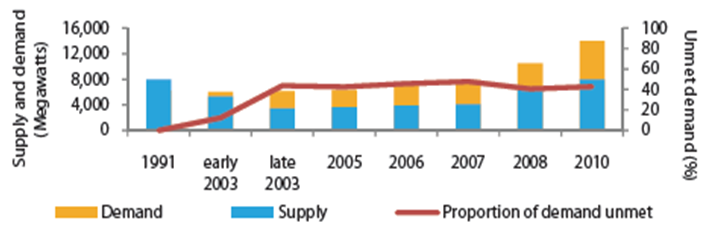

- Iraq’s electricity infrastructure was severely damaged during the Gulf War, suffered from lack of investment and lack of available equipment under sanctions, and suffered again following the US-led invasion in 2003. While the supply of electricity is increasing, it is unable to keep pace with rising demand. According to the Ministry of Electricity, Iraq is only generating 8,000 of the 13-15,000 megawatts of power currently required to meet Iraqi needs today, figure 1 [1]. Figure does not include Kurdistan Regional Government, a semi-independent Region to the North of Iraq. According to UNDP, the electricity supply has since deteriorated in some areas, particularly Baghdad, but in Kurdistan region has seen some improvement. The increase in the power production capacity of the region has been on a constant increase recently. The region was only producing 482 MW in 2007, which was raised to 484 MW in 2008, 809 MW in 2009, 1047 MW in 2010, 1435 MW in 2011 and finally to 2700 MW in 2012, showing its highest jump of around 100% in one year. This means that the total demand in 2004 was 829 MW and this has reached 3279 MW in 2012, almost 4 times higher in less than a decade [2].

| Figure 1. Iraq’s electricity: supply and demand [1] |

| Figure 2. Private electric generator at Koya city |

2. Environmental Impacts

- Animal fats, vegetable oils and petroleum oil are sharing common physical properties. These types of oils and fats could produce similar environmental effects when it is spilled into the environment. In fact, animal fats such as, caw and sheep fats can affect the environment and cause several diseases. It might spill to the underground water and rivers and cause harmful effects. The disposal fat may throttle plants with oil and cause oxygen depletion. It can also form toxic materials and form toxic products [9]. Moreover, it could destroy future and existing food supplies and produces rancid odors. It can plug and pollute the water treatment plants and cause several microorganism bacteria in the treated water. It may also catch fire when ignition sources are present and cause extreme fires such as bushfires. It can form products that linger in the environment for many years. Indeed, many researches and experience with actual spills have shown that spills of animal fats kill or injure wildlife and produce other undesirable effects. Wildlife that becomes coated with animal fats or vegetable oils could die. Aquatic life may suffocate because of the depletion of oxygen caused by spilled animal fats and vegetable oils in water [4]. Moreover, spills of animal fats and vegetable oils have the same devastating effects on the environment as petroleum oils.As for Koya city the situation is worst as the slaughter house dispose these fats in unhealthy method. The disposed fats are spilled to the river and the valley near the house. This will contaminate the surface, underground water and the whole environment. The spill fats are affecting the air and lead to several problems and diseases. It has observed that huge amounts 2000kg of animal fats; caw, goat and sheep are disposed every day, Figures 3 and 4.

| Figure 3. Shows disposed animal fats in Koya city slaughter house |

| Figure 4. Shows the local river which is closed to the slaughter house |

3. Materials and Methods

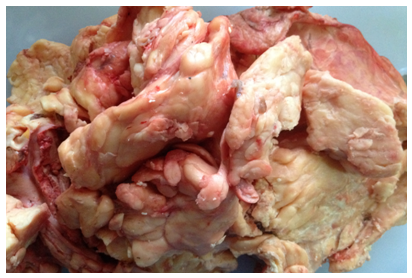

- The animal fats obtained from a slaughter house at Koya city in Kurdistan region. The fat washed, cleaned with de-ionized water and was free of flesh and other materials. The solid fat was melted at around (60 -70)°C. The fat then filtered and stored in special bottles. A sample of the collected animal fat is shown in Figure 5.

| Figure 5. Sample of the collected fat |

| Figure 6. Shows the heating and melting process |

4. Experimental Design

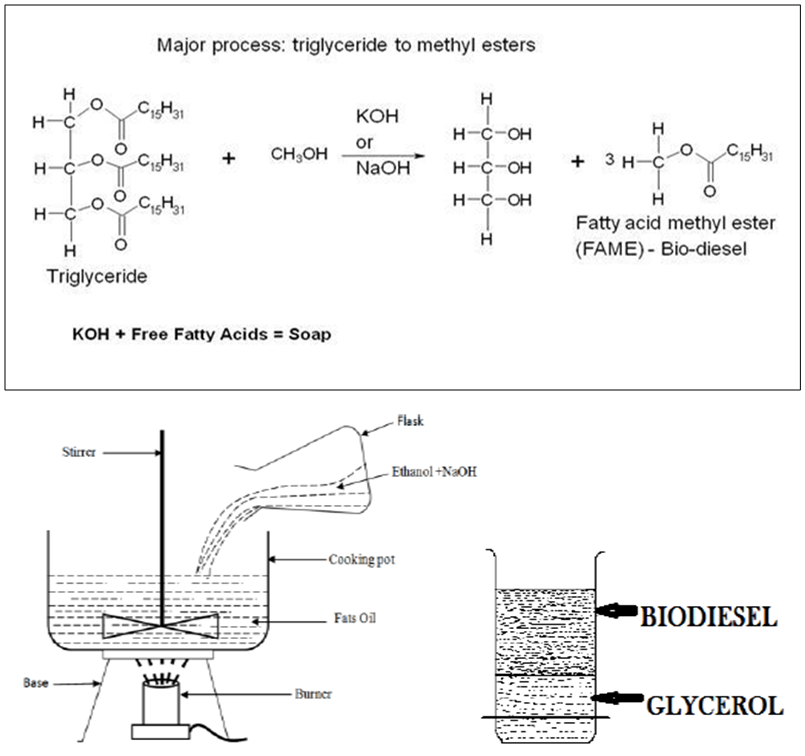

4.1. Transesterfication Process

- The esterification reaction is needed between acid and free fatty acid (FFA) to produce ester (biodiesel) and water. The FFA reduced in the fat to less than 2 mg KOH/g of fat, which to be suitable to produce biodiesel in transesterification reaction [10]. The system could be achieved at atmospheric pressure and the experiments were carried out at a constant temperature. The agitation is required at constant 300rpm. This method could be achieved at different percentages of methanol/fat wt. ratio from 20/100 to 40/100, and used 1% of sulfuric acid as a catalyst at a constant time of about 30 minutes, and at different temperatures (40 to 70°C). The reactor can be loaded with about 50g of sheep fat, preheated to the desired temperature and the agitation started. The reaction started when ethyl alcohol need to be added to the fat in the reactor. After 10 minutes from the reaction, one percent of sulfuric acid was added and the reaction continued to 30 minutes. Then, the mixture should be transferred to the separating funnel to separate treated fat from alcohol. The top layer was alcohol acid, and part from FFA in the fat and the bottom layer was a treated fat. The separating time was about 30 minutes and it was instant to start the transesterification method [10]. This production method could be considered trusted method. The production process sketch is presented in Figure 7. The petro diesel oil (B0) was obtained from specialist oil suppliers as commercially available diesel is B5. The biodiesel from fat was blended at B5 (5% of biodiesel to 95% of standard diesel by volume), B10, B15 and B20 and evaluated for engine performance and exhaust gas emissions compared to standard diesel [11].

| Figure 7. Shows biodiesel production process at the laboratory |

4.2. Generator Engine Test Setup

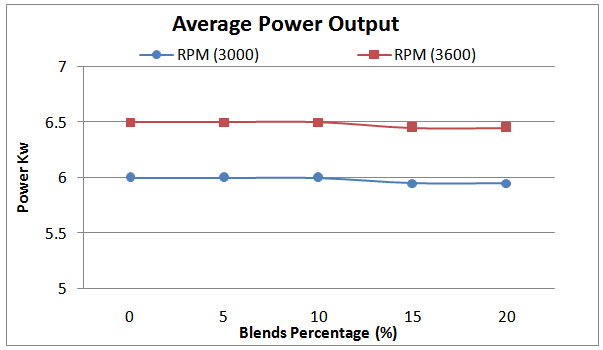

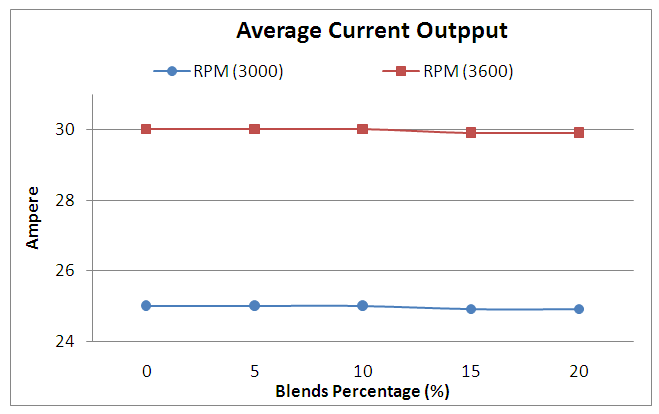

- The performance of the biodiesel produced by the transesterification process was evaluated on a basic diesel engine generator. The engine was a four-stroke, direct injection diesel engine, single cylinder. The general specification was, engine capacity = 456cc, max power = 6.5 kW @ 3600 rpm, 6 kW@ 3000 rpm. The test procedure was to run the engine at 70 and 100% engine load over a range of predetermined speeds 3000 & 3500 rpm. At each of these settings the efficiency and output electric were measured for each of the diesels, the standard diesel forming the benchmark.

5. Results and Discussion

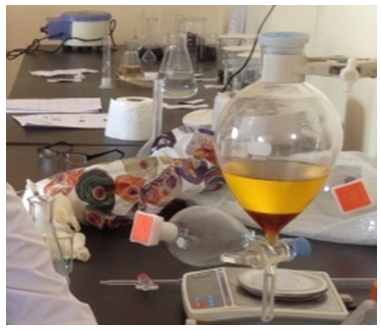

- Oils and fats are basically triacylglycerols (TAG) composed of three long-chain fatty acids. These triacylglycerols have higher viscosity and cannot be used as fuel in common diesel engines. In order to reduce viscosity the triacylglycerols are converted into esters by transesterification reaction. By this means, three smaller molecules of ester and one molecule of glycerin are obtained from one molecule of fat or oil. Glycerin is removed as by-product and esters are known as biodiesel. Biodiesel fuels are attracting attention worldwide as a blending component or a direct replacement for diesel fuel in vehicle engines. Biodiesel consists of a mixture of fatty acid [10]. Alkyl esters, derived from a renewable lipid feedstock, such as vegetable oil or animal fat. In the case when methanol or ethanol is used as reactants. It will be a mixture of fatty acid methyl esters (FAME) or fatty acid ethyl esters (FAEE), respectively. However, methanol is commonly and widely used in biodiesel production due to its low cost and availability [11].Biodiesel has been obtained from transesterification reaction. Figure 8 shows the biodiesel sample in upper layers of the separator funnel.

| Figure 8. Shows the produced biodiesel sample |

5.1. Engine Performance and Electric Output

- The variation of engine efficiency and output current with a fixed load is presented in Figures 9 and 10. The produced biodiesel from the animal fat is diesel blended with fossil diesel. Although the engine efficiency was nearly same, but B20 showed higher reduction in the value of current output when compared with petro diesel at all loads of engine operation.Animal fat has relatively low energy content, but the blended biodiesel fuel produced from it has a value close to that of fossil diesel; this means that efficiency and output is lower but only by a small percentage. Figures 9 and 10 show the curves for power and electric current respectively. By simple proportions the energy content of the blend can be calculated, energy content of blend = (%diesel x 42.5 + %bio-diesel x 37.5), [12]. At 20% biodiesel the calculated power is 41.5 MJ/kg, a decrease of 0.007% compared to petroleum diesel for the engine efficiency whilst a decrease was about 0.004% for the output current.

| Figure 9. Average power output for different biodiesel blends |

| Figure 10. Electric current output for different biodiesel blends |

5.2. Engine Exhaust Gas Emissions

- As the load on the engine increase there is a little rise in smoke emissions from the engine exhaust. Exhaust gas recirculation aggravates the formation of smoke. The increased amount of ethanol in diesel resulted in less smoke in the exhaust, and the addition of ester slightly reduced these emissions [5]. The results of biodiesel blend fuels over the petroleum diesel should show decrease in the emissions of CO, HC, with a slight increase in NOx, and overall similar values for CO2. Following this trend it is estimated that at higher concentrations of biodiesel blends (> B20) the CO2, HC and CO emitted would actually be lower than for fossil fuel, [12].

5.3. Daily Diesel Production

- As it’s mentioned above the disposal fat in the city of Koya is reached 2000kg every day. From the laboratory experiments and during the biodiesel production from animal fat it’s found that 1kg of fat will produce 750ml of biodiesel. A total of 1500l of biodiesel will produce everyday at the city, 30000l per month (20 working days, two days a week the slaughter house is off). Therefore each private generator at the city of Koya can obtain 680l of B100 every month. This can be blended to obtain 3410L of B20.

6. Conclusions

- In this study it is concluded that the disposed animal fat can be invested and used as raw materials for biodiesel production. The production process of biodiesel from animal fats is validated. 750mL of biodiesel can be obtained from 1kg of animal fat. The blended biodiesel B5, B10, B15 and B20 were tested on IC engine of electric generator, the power and output current were nearly similar to B0. The risk of the environmental pollution by the gas emission from the local generators is reduced.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML