-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2014; 4(3): 54-57

doi:10.5923/j.ep.20140403.02

Combustion Properties of Some Tropical Wood Species and Their Pyrolytic Products Characterization

Adegoke O. A.1, Fuwape J. A.2, Fabiyi J. S.2

1Department of Wood and Paper Technology, Federal College of Forestry, Ibadan, Nigeria

2Department of Forestry and Wood Technology, Federal University of Technology, Akure, Nigeria

Correspondence to: Adegoke O. A., Department of Wood and Paper Technology, Federal College of Forestry, Ibadan, Nigeria.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

This paper evaluates the combustion properties of fuelwood and pyrolytic products from three selected sawmill wood residues - Gmelina arborea, Terminalia superba and Triplochiton scleroxylon. Pyrolysis experiments were performed at 450, 500 and 550 °C. The percentage oil, pH, viscosities were considered. The highest yield of oil yield was at 550°C (45.70%) for Triplochiton scleroxylon out of the three sawmill wood residues. The analysis of variance conducted on pyrolytic oil produced at 450, 500 and 550 °C for the G. arborea, and T. scleroxylon showednosignificant difference but there were significant differences in the pH and viscosity of the pyrolytic liquid produced from selected wood species at the same conversion temperatures. The result showed the proximate analysis of the selected wood residues with the ash content (2.75, 2.61, and 3.57 %); fixed carbon (10.52, 12.07 and 10.23 %); volatile (87.55, 85.48 and 86.46 %) and heating value of 32792.75, 32691.56 and 32794.15 KJ/kg for Gmelina arborea, Terminalia superba and Triplochiton scleroxylon respectively. Proximate analysis results showed that the selected wood residues have good potential for domestic cooking and the characterized pyrolytic oil produced for biofuel production, most importantly for bioenergy sustainable system.

Keywords: Combustion,Pyrolysis, Pyrolytic oil, Wood residues, Bioenergy

Cite this paper: Adegoke O. A., Fuwape J. A., Fabiyi J. S., Combustion Properties of Some Tropical Wood Species and Their Pyrolytic Products Characterization, Energy and Power, Vol. 4 No. 3, 2014, pp. 54-57. doi: 10.5923/j.ep.20140403.02.

Article Outline

1. Introduction

- Wood which is the dominant biomass used in energy generation is a lignocellulosic biomass that is a clean biomass. The products from wood comprises of slab, twigs, leaves off-cut, branches, planks, boards, sawdust, among others. Wood has been extensively studied because of its use as a construction material [1, 2] and as fuel source [3]. Combustion properties of wood are also important because of safety issues since it is one of the more commonly available flammable materials. Based on its widely usage, wood has been the major source of renewable energy for developing countries The renewable energy source can play a major role for sustainable development. The urgent need in most developing countries like Nigeria is the migration to sustainable energy system and one of the energy sources is wood waste or sawmill residues which are regarded as waste in many sawmills industries. The availability of fossil fuels is limited, considering the fact that the demand for energy from fossil fuel is growing at high rate due to industrial development and is a major contributing factor to energy crisis. The energy crisis and fuel tension made biomass (forest residues) fast pyrolysis liquefaction a more important area of research and development [4-6]. In particular, the most advanced biomass pyrolysis processes, oriented to the production of an organic liquid fuel (referred to as bio-oil, bio-fuel-oil or bio-crude-oil, pyrolytic oil), appear to be very interesting for several possible energy application that can be envisaged for this fuel. The combustion property of selected tropical wood species was considered investigated and its pyrolytic oil characterization. This study became important in view of the recent interest in the use of wood biomass, sawdust in particular as waste. However, the study seeks to find a path way of utilizing sawdust during the conversion of the wood in sawmill as domestic wood fuel and bio-oil production thus, minimizing waste and reducing global warming through drastic burning [10].

2. Materials and Methods

2.1. Samples Preparation

- Gmelina (Gmelina arborea), Afara (Terminalia superba) and Obeche (Triplochiton scleroxylon) wood residues (sawdust) collected from a local sawmill located at Akure, Ondo State, Nigeria were used as feedstock for the production of pyrolysis oil. The sawdust was air-dried to eliminate excess free water and prevent degradation by fungi. The samples were later oven dried at a temperature of 103 ± 2 °C for until constant weight was achieved. Nine replicates of 100 g specimens were weighed per wood species for pyrolysis experiment.

2.2. Pyrolysis Experiment

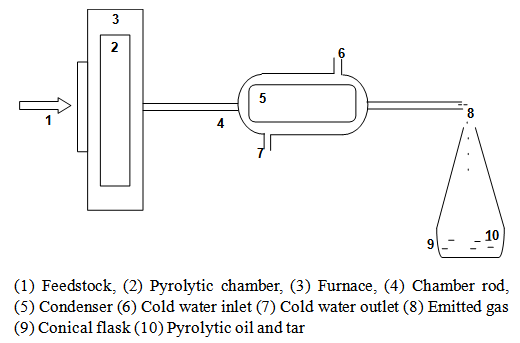

- Each wood species was put inside the pyrolytic chamber and then subjected to a predetermined temperature. Three different temperature regimes were considered which include 450, 500 and 550 °C while three replicates per wood species at each temperature were considered. The gases that evolved were distilled in the condenser to form pyrolytic oil which was retained in a conical flask. The oil retained was condensed at 4 °C using a reflux system.

| Figure 1. Schematic diagram of pyrolyser experimental set-up |

2.3. Pyrolytic Oil Products Characterization

2.3.1. Physical Properties Pyrolytic Oil

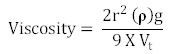

- The viscosity of the condensate was determined using Ostwald Viscometer at 20 °C. The oil was released to flow through the capillary tube and the time for the upper bulb to be measured. The mathematical formula used to calculate the viscosity was expressed as written in equation 1. The pH of the pyrolytic oil was determined with the use of a pH meter with a calibrated electrode using buffer solutions of pH 2 and 7. The density was determined by taking the weight of the oil using an electronic weighing balance and measuring the volume using a graduated cylinder. The formula for calculating the percentage oil yield and char are expressed in equations 1 and 2, respectively [7, 8]. The oil density and char yield were calculated using the formula expressed in equations 3 and 4, respectively.

| (1) |

| (2) |

| (3) |

| (4) |

2.3.2. Proximate Analysis of the Feedstocks

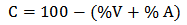

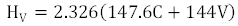

- The proximate analysis determined includes percentage volatile matter (PVM), fixed carbon (FC), ash content (AC) and heating value (HV). The PVM and AC were determined in accordance with the ASTM E872-82 [9] and ASTM E1755-01 [10] respectively. For the PVM, 1 g of the wood residue was placed in a crucible of known weight and oven dried to a constant weight after which it was heated in the furnace at temperature of 600°C for 10 minutes. The PVM was then expressed as the percentage of loss in weight to the oven dried weight of the original sample. The percentage of AC followed the same procedure with volatile matter except that the sample was heated in furnace for 3 h. The ash content obtained after cooling in a desiccator was expressed as percentage of the original sample. The percentage of FC was calculated as expressed in equation 5 [11]. The heating value was computed from the percentage fixed carbon and percentage volatile matter using Gouthal formula (equation 6).

| (5) |

| (6) |

2.4. Data Analysis

- The physical properties (percentage oil yield, char, volume, density, pH, and viscosity) of pyrolytic oil and proximate analysis of the wood residues (sawdust) obtained for the three different wood species were determined. Analysis of variance (ANOVA) was carried out on physical properties and proximate analysis while Duncan multiple range test (DMTR) was used to evaluate the effect temperature and sawdust types on physical properties of the oil and proximate analysis.

3. Results and Discussion

3.1. Physical Properties Analysis

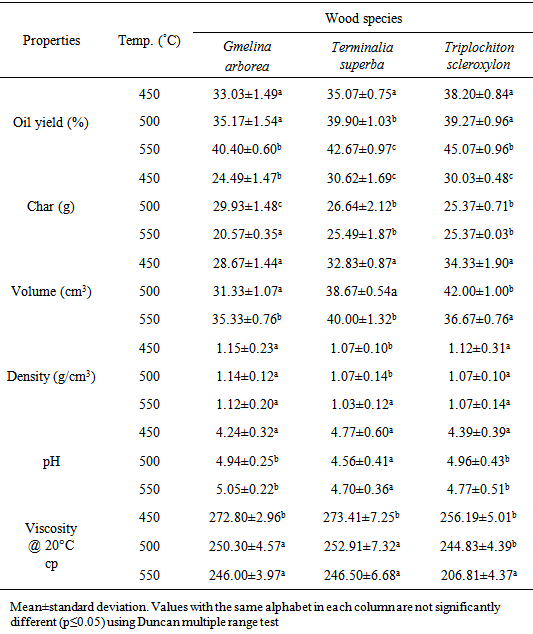

- The physical characteristics considered for pyrolytic oil of the various wood species include percentage oil yield, volume, density, pH, viscosity at three pyrolytic temperatures of 450, 500 and 550°C (Table 1).

|

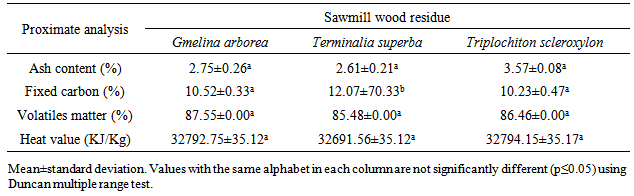

3.2. Proximate Analysis

- The proximate analysis of the three selected wood species’ residues is presented in Table 2. Percentage ash content, fixed carbon and volatile matter ranged from 2.61 to 2.75%, 10.23 to 12.07% and 85.48 to 87.55% for G. arborea, T. superba and T. scleroxylon, respectively. It was observed that there was no significant different in the percentage ash content, volatile matter among the selected wood species but differed significantly for percentage fixed carbon (p<0.05).

|

4. Conclusions

- This study investigated the combustion property and pyrolysis experiment of sawdust of Gmelina arborea Terminalia superba and Triplochiton scleroxylon at three different temperatures (450, 500 and 550°C). The highest oil yield was at 550°C (45.70%) for T. scleroxylon. The result obtained from this present study put forward that the pyrolytic oil from the pyrolysis of the sawdust is suitable as a feedstock for the production of alternative fuels. The proximate analysis of the selected wood species showed that they have good potential for domestic cooking.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML