-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2014; 4(3): 49-53

doi:10.5923/j.ep.20140403.01

Solar Tracking System Installed with photovoltaic (PV) Panels to Connection Grid Tie Low Voltage (Sunflower)

H. J. Loschi1, R. Ferrarezi1, N. M. Rocha2, A. A. Silva2, Y. Iano1

1Department of Communication (Decom), The Faculty of Electrical and Computer Engineering (Feec), The State University of Campinas

2The University of São Paulo (Unip)

Correspondence to: H. J. Loschi, Department of Communication (Decom), The Faculty of Electrical and Computer Engineering (Feec), The State University of Campinas.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

The electricity is an essential factor in everyday society, and this consumption is increasing exponentially. Beyond this fact, there is also concern about the impacts suffered by the environment, caused by the current system of generation electric power system. Systems for solar, renewable and clean energy is one of the most used and implemented around the globe. This article presents a proposal for a solar tracking system installed with photovoltaic (PV) panels to connection Grid Tie low voltage, named Sunflower. The main content of this research focuses on the operating principles of Sunflower, as well as the development of a prototype Sunflower in reduced scale. The principal experiment focuses on tests between the Sunflower prototype and photovoltaic (PV) panels, to compare the efficiency of solar tracking. The deductions, based on the research tests, confirm that the Sunflower prototype is more efficient than photovoltaic (PV) panel. Furthermore, the cost of energy production is close to the price of electricity, for residential customers in Brazil.

Keywords: Photovoltaic (PV), Tracking, Residences

Cite this paper: H. J. Loschi, R. Ferrarezi, N. M. Rocha, A. A. Silva, Y. Iano, Solar Tracking System Installed with photovoltaic (PV) Panels to Connection Grid Tie Low Voltage (Sunflower), Energy and Power, Vol. 4 No. 3, 2014, pp. 49-53. doi: 10.5923/j.ep.20140403.01.

Article Outline

1. Introduction

- NOWADAYS, renewable energy sources provide approximately 8% of world energy (increasing to 22% if we include all uses of biomass) in many parts of the world this percentage is increasing significantly. Wind energy is the energy source whose use is increasing faster in the world. Then comes to photovoltaic (PV), with 24% growth per year in the world. Some recent studies indicate that renewable sources should increase its share to 30% to 40% of the total in 2050, assuming global efforts in public policies for environmental issues, especially those related to climate change [6], [9].The Grid-Tie concept, attributed to solar energy, tries to enable the implementation of photovoltaic (PV) systems to connect of the electricity transmission grid, promoting economic growth, improving the living conditions of the population and as an important factor in generating employment [9]. Photovoltaic (PV) systems are composed of modules, inverters, protective devices, system of fasteners and cable. In addition to the usual components of a photovoltaic (PV) system, the Sunflower because of its logical tracking also has linear actuator, auxiliary relays, Programmable Logic Controller (PLC), power supply, single-pole circuit breakers, among other features.The dimensioning of a photovoltaic (PV) system for residences is done in order to produce part or all of the electricity consumed, and can exchange the surplus of energy in credits of kW. In the case of residence export energy, its electricity generation ends up benefiting other consumers, who use the energy injected into the utility distribution network [1], [9].Typically, it can be conceptualize as follows: • When the residence consumes more than the photovoltaic (PV) system is generating, the part of the consumption is lacking is supplied by the power gird [9]. • When the photovoltaic (PV) system generates more than is being consumed by the residence, the excess energy is automatically injected into the grid. The meter records this energy and the client shall be in kW credits to utility [9]. The use of photovoltaic (PV) systems in all Brazilian households could reduce energy deficit and sustain the Brazilian industrial growth in the coming years, as households could generate power during the day, precisely at a time when residential consumption is lower and the industries demand more energy [6], [9].The next sections of this article will be organized as follows: Section 2 will address the potential of insolation in Brazil. Section 3 the development and the operation principle of Sunflower. Section 3.1 will present the development of a prototype small-scale and their results. Section 4 will present a projection of the results of the prototype and their strategies for achieving the Sunflower. Finally, in section 5 will be the final considerations.

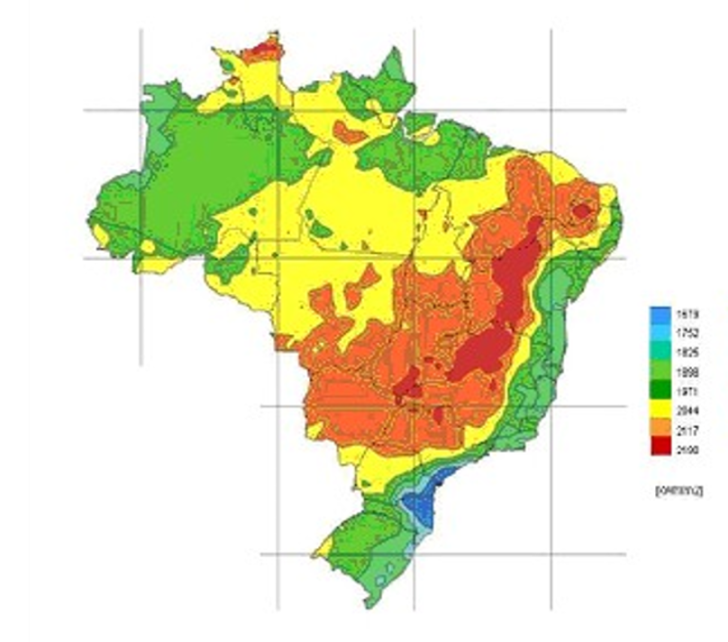

2. Potential of Insolation in Brazil

- The solar irradiation maps for Brazil and South America were developed by the National Institute for Space Research (INPE) under the project "Solar Wind Energy Resource Assessment (SWERA)" who did the survey about the solar energy resources in Brazil. The project's key objective is to facilitate the inclusion of renewable energy in the energy matrix of a group of selected countries. The coordination of activities in Brazil and Latin America was with the Center for Weather Forecasting and Climate Studies (CPTEC).In 2010, the National Institute for Space Research (INPE) published in Brazil, as result of the project Solar Wind Energy Resource Assessment (SWERA), the Brazilian Atlas of Solar Energy.The figure 1 shows the global solar radiation (annual average) of Brazil. Observed daily average concentration of radiation from 4.8 to 6.0 kWh/m²/day (scale, right side), while in Germany, figure 2, and the maximum value is 3.4 kWh/m²/day (scale, right side). I.e. the location with lower insolation in Brazil is better than most sunshine in Germany, which is the country with the largest installed capacity in photovoltaic energy [5], [6], [9].

| Figure 1. Solar Radiation Brazil |

| Figure 2. Solar Radiation Germany |

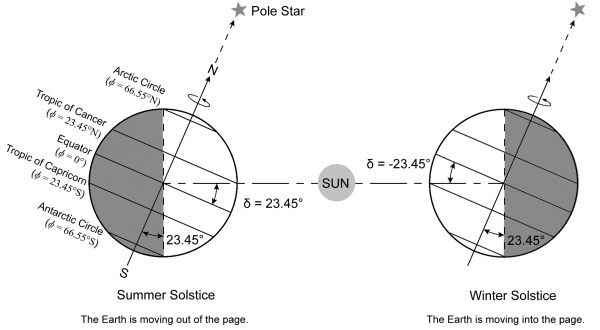

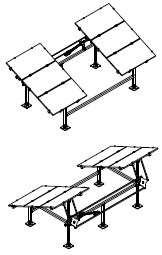

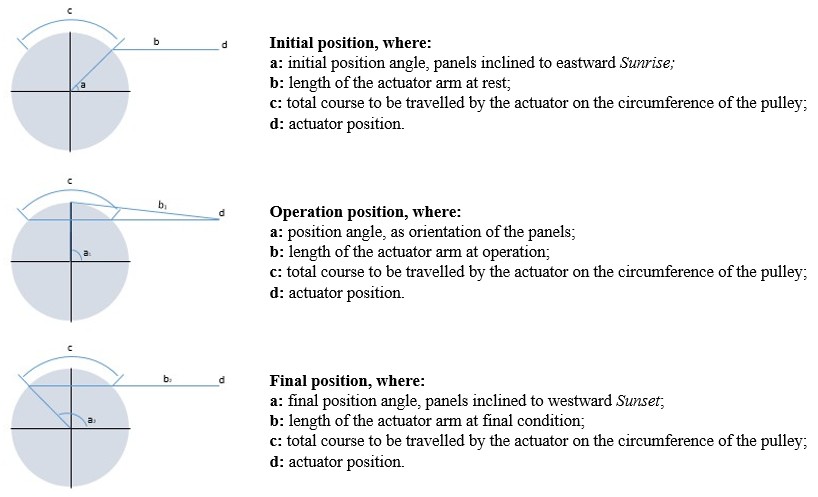

3. Development and Operation Principle

- To develop the Sunflower was necessary to consider the inclination of the axis of rotation of the earth relative to the elliptical orbit around the Sun, forming an angle of 23.45°, approximately, that determines the seasons depending on the position of the planet in its translational trajectory [2]. The Sunflower through its operating principle ensures full tracking of the azimuthal angle during the daily period of higher solar radiation and through a system of mechanical actuation, corrects over the course of the seasons (Winter Solstice will Midsummer) solar declination, according illustrated in Figure 3.

| Figure 3. Solar Declination Illustrated |

| Figure 4. Metal Frame Sunflower |

| Figure 5. Representation of Cinematic Actuation Pulleys |

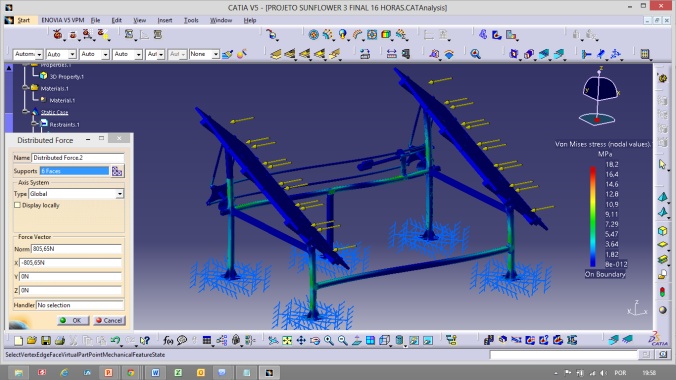

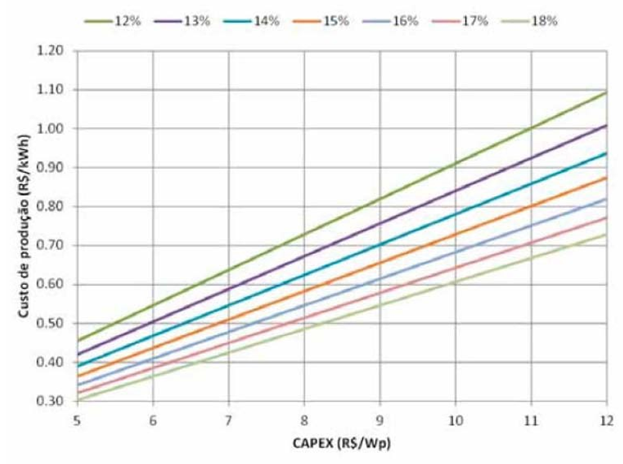

| Figure 6. Analysis of Strain on Structure |

| Figure 7. Analysis of Strain on Structure |

3.1. Development of Prototype

- For the prototype, the operating principle follows the concept of Sunflower project however on a reduced scale (panel’s 5W each). Not made use of inverters to obtain the load values, was used fan, compatible with the power of the panels were used to simulate the load operation, the tests were performed daily during the month of August 2013 (winter), October 2013 (spring), January 2014 (summer) and March 2014 (Fall), thereby obtaining results in all seasons.To performance tests between Sunflower prototype and photovoltaic (PV) panels (5W), according Figure 8 e 9, to provide an analysis about efficiency of solar tracking.

| Figure 8. Installation of Sunflower Prototype |

| Figure 9. Installation of photovoltaic (PV) Panels |

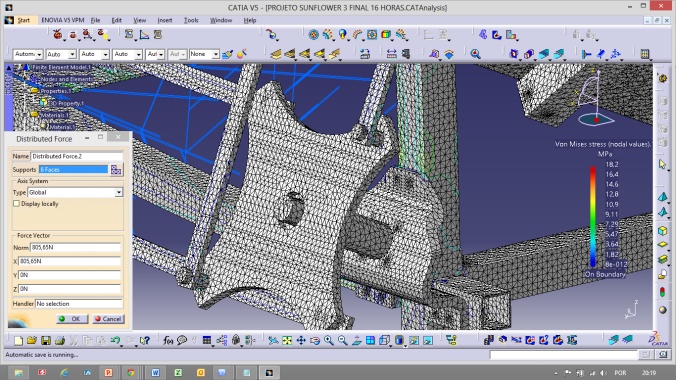

| Figure 10. Comparison Results of the photovoltaic (PV) Panels and Sunflower Prototype |

4. Results

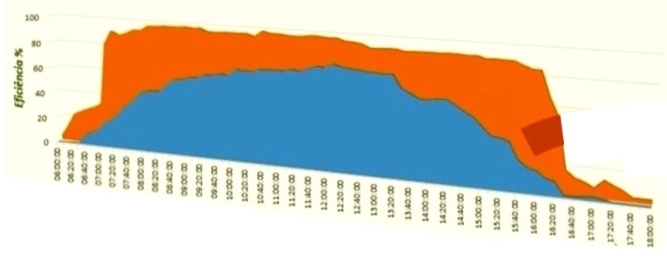

- Through comparison analysis of the results obtained, it is possible to observe the difference in efficiency that according to the tracking system prototype Sunflower keeps completely perpendicular to the apparent motion of the sun panels. After conducting several tests, we observed a difference of 31% with a variation of + / - 0.8%, higher than the prototype Sunflower compared to photovoltaic (PV) panels.This result already considers the following factors used in the sizing of photovoltaic (PV) systems for residences:• Loss in power inverter DC to AC; • Any shading on installation;• Possible accumulation of dust or dirt on the modules, reducing the absorption capacity of the irradiation; • Losses (Ohmic) in the wires, both in AC and DC side of the facility; • Power consumption of the system.The Figure 11, presents the cost of electricity production (R$ / kWh) for investment costs (X axis) and curves with capacity factors (FC) ranging between 12% and 18% bands, as caption at the top of the graph [4], [9].

| Figure 11. Production cost (R$/kWh) vs. CAPEX (R$/Wp) vs. Capacity Factor |

5. Conclusions

- The Sunflower project in defining of their concept sought to follow business models standard for photovoltaic (PV) energy of ANEEL (National Electric Energy Agency), development of electronic components in search of the best cost benefit, reliability and technical excellence in quality and the development of a product as an entrepreneur factor to generate employment, always focusing on residences. Especially considering the data of production costs, the Sunflower project is able to perform the installation in most Brazilian states [4], [9].

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML