-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2013; 3(4): 51-60

doi:10.5923/j.ep.20130304.03

The Technology Roadmap for Biorefinery Lignin in the U.S.

Márcia França Ribeiro Fernandes dos Santos1, Suzana Borschiver1, Maria Antonieta Peixoto Gimenes Couto2

1Escola de Química da Universidade Federal do Rio de Janeiro (UFRJ). Cidade Universitária – Centro de Tecnologia, Bloco E – 2º andar – DPO – Área de Gestão e Inovação Tecnológica – Rio de Janeiro/RJ – CEP: 21949-900

2Escola de Química da Universidade Federal do Rio de Janeiro (UFRJ). Cidade Universitária – Centro de Tecnologia, Bloco E – 2º andar – DEB – Área de Processos Bioquímicos – Rio de Janeiro/RJ – CEP: 21949-900

Correspondence to: Márcia França Ribeiro Fernandes, Escola de Química da Universidade Federal do Rio de Janeiro (UFRJ). Cidade Universitária – Centro de Tecnologia, Bloco E – 2º andar – DPO – Área de Gestão e Inovação Tecnológica – Rio de Janeiro/RJ – CEP: 21949-900.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

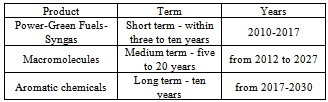

This article aims to describe, present and analyze the technology roadmap for biorefinery lignin in the United States (U.S.). It was created an own methodology inspired by the process of technology roadmapping developed by Garcia & Bray (1997) and the information that supported the construction of the roadmap were extracted from the document entitled Top Value-Added Chemicals from Biomass - Volume II - Results of Screening for potential Candidates from Biorrefinery Lignin prepared by the U.S. Department of Energy (USDOE). The roadmap´s analysis was conducted over time noting that the three product categories - Power- Green Fuels - Syngas, Macromolecules and Aromatic Chemicals are respectively the short, medium and long term.

Keywords: Lignin, Biorefinery, United States, Technology Roadmapping Method, Roadmap

Cite this paper: Márcia França Ribeiro Fernandes, Suzana Borschiver, Maria Antonieta Peixoto Gimenes, The Technology Roadmap for Biorefinery Lignin in the U.S., Energy and Power, Vol. 3 No. 4, 2013, pp. 51-60. doi: 10.5923/j.ep.20130304.03.

Article Outline

1. Introduction

- Nowadays, the world attention turns to alternative energy sources due to economical, geopolitical and environmental issues. The global industry, in particular chemistry, has intensified efforts in Research, Development & Innovation (R, D & I) in the search for products that can be obtained from renewable sources in order to reduce the dependence and the vulnerability of oil through a dynamic of its processes and its product lines[1].The biomass, potential renewable sources, encompass all renewable organic matter including plant, whether grown on land or in water, manure and animal products, byproducts of food processing and forestry and waste[2, 3, 4] There are several ways to obtain biomass for energy, either through plantations of energy crops, or the use of waste agricultural, agroindustrial and agroforestry. The use of biomass has to be encouraged as an opportunity to mitigate the problems associated with the use of oil as main source of energy. Biomasses are processed in so-called biorefineries, structures analogous to petroleum refineries that use renewable raw materials and produce multiple fuels and products from oil; in industrial biorefineries identify promising routes in order to create an economy based on renewable products. According Jong et al[5] biorefinery is a facility that integrates biomass conversion processes and equipment to co-produce fuels, power, and chemicals from different biomass sources. There are several types of biomass, in special the lignocellulosic feedstock composed of three main fractions: hemicellulose, cellulose and lignin. Cellulose and hemicellulose are rich in carbohydrates and they are presented in a lot of applications, in particular obtaining the second-generation ethanol from cellulose. With regard to lignin, Gosselink et al[6] affirm that there is still a very small market for large quantities of industrial lignins produced in the world, particularly in the U.S. and in the industries of pulp from agricultural residues.Santos[7] estimates that the potential amount of lignin produced by the United States from the pulp and agricultural waste industry is about 22 and 264 million tonnes respectively - base year 2009.Lignin is the second most abundant source of natural raw material, the largest source of phenolic polymers aromatic in nature and also present adhesive properties[8]. These characteristics motivated its study in this article. Furthermore, lignin can become a valuable renewable feedstock for the chemical industry. Lignin has many applications in industry as, for example, in producing aromatic products, adhesives, and phenolic resins as substitutes.In order to organize the study on the availability of new technologies associated with the use of lignin on a commercial level in the U.S. it was necessary to use a methodology, based on marketing tools that can arrange the information obtained in the publication Top Value-Added Chemicals from biomass - Volume II - Results of Screening for Potential Candidates from Biorrefinery Lignin[9] to transform them into knowledge and then into business intelligence. The Technology Roadmapping Method (TRM) was chosen for this article because it is a tool which enables to integrate and communicate the strategic of development market, product and technology with business goals over time. Also, it helps to identify, evaluate and select technology alternatives, therefore, a complex process that requires simultaneous consideration of markets, products, technologies and their interactions[10, 11]. The paper proposes and describes in detail a new methodology for the development of technology roadmap for biorefinery lignin in the U.S. connecting product, market and technology over time. With this study, it was intended to identify the progress of R, D & I in the short, medium and long term needed to make the biorefinery more economically attractive through better use of lignin.

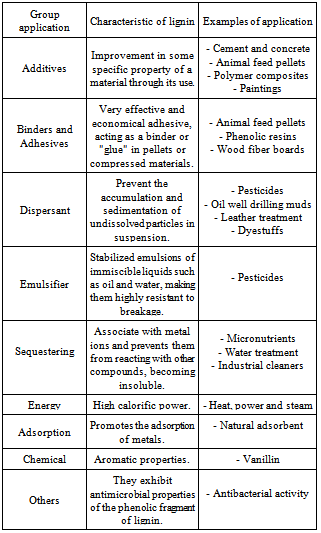

2. Lignins

- Lignin is the second most abundant source of natural raw material, after the cellulose, and the major source of phenolic aromatic polymers in nature[8]. It is an amorphous and branched compound, present in woody plants, whose function is to provide stiffness, strength and flexibility to the cell wall, assist in the transport of water, serve as a barrier to enzymatic degradation of cell wall and protect against insect and pathogenic microorganisms attack. Contrary to cellulose, lignin has a molecular structure complex and variable depending on the plant species, location, plant age, season, etc.[12]. The lignin may be classified as: (i) native lignin, ie that which is present in the biomass, and (ii) technical lignin, also called industrial lignin which is isolated from biomass by a variety of processes[9]. Lignin is still classified as a low-value waste cellulosic pulping, being used mainly as fuel in the paper and pulp industry. Only about 2% of lignins derived from this industry are marketed[6]. The main difficulties for full commercialization are linked to their characteristics of low purity. It should be noted also that almost all marketed lignin today is obtained from lignosulfonates. Table 1[7] summarizes the differents industrial applications of lignins in the literature with emphasis characteristics applied in different industrial sectors.Despite presenting several applications, some already in use and other potential, researches concerns new industrial applications in products with higher added value has been developed so that the difficulties associated with their commercial use are overcome.

|

3. Global Market for Applications of Lignin

3.1. Production of Concrete and Cement

- American companies such as W.R.Grace and Master Builders use extensively lignin products in this application. Lignosulfonates for concrete applications can be as high as $ 4.00-5.00/gal as aqueous solution. A very rough calculation (8 lb/gal, assume 50% aqueous solution) gives a sales price for lignosulfonates of $ 1.00-1.25/lb[9].Furthermore, Eastman Chemical distributes a high market value material named Vinsol, which has a high concentration of lignin and lignin-like material. As a concrete additive, Vinsol is $ 3.50-4.00/gal (sales price), again in a concetrated aqueous form from the manufacturer. More broadly, the lignin and Vinsol might be interchangeable in some applications, given the similarity of their chemical structure.

3.2. Adhesives

- The market for epoxy resin is economically active, with specific reference to phenol-epoxy resins in which the lignin may appear as a crosslinking agent. In 1999, the estimated value for the production of epoxy resin in the United States, Western Europe and Japan was US$ 2 billion. The growth of consumption of epoxy resin in the U.S. and Western Europe had an average of 3.5-4% per year from 1999 to 2004. The three main producers of epoxy resins are Hexion (formerly Shell Epoxy Resins), Dow and Huntsman. These producers represent approximately 75% of the world capacity. Since the market is expanding and continues to do so in the medium and long term, there will be distinct opportunities especially for lignin as its inherent properties, also reflected in the final product[13].

3.3. Polyolefins

- The polyolefins’ global market is huge representing approximately 60% of all thermoplastic resins produced and sold worldwide. For example, low density polyethylene remains a major global business with a value of $ 19 billion for the year 2001. The global demand for all types of polyethylene was about 63.4 million tons in 2006. Polypropylene resins had a consumption of 38 million tons in 2005, representing a value of about $ 42 billion[13]. Surveys predict that developing countries will migrate from an agrarian to an industrial economy, creating growth opportunities for polypropylene to replace paper, metal, glass, wood and natural fibers. In this context, it is very likely that, given the distinctive properties associated with lignin, some inroads are made in this market, especially the mixed approach of the polymer leading to products with unique features directly attributed to the lignin

3.4. Phenolic Resins

- According to Stewart[13], the introduction of lignin on the phenol compounds market is viavel. The world production of phenol is almost exclusively based on the co-production of acetone-based cumene and produced approximately 8.25 million tons in 2004, of which 30.6% were for use as phenolic resins. Also according to the author, the total world production of phenol was valued at about US$ 107 billion and forecasts for the future indicate that the current price of 1,380 euros / tonne increase according to the annual demand forecast. Furthermore, the increased pressure surrounding the efficient management of waste and its use in other applications likely leads to the conclusion that the use of new applications of the lignin will be stimulated by the market.

3.5. Aromatics - benzene-toluene-xylene (BTX)

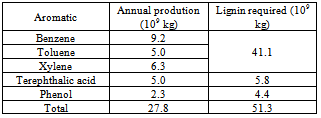

- Lignin is the only renewable source of one class of high volume aromatic chemicals that can be obtained, for example, by fast pyrolysis of biomass. Table 2[14] shows the estimate of the replacement for the U.S. of aromatic derivatives.It can be seen that the direct and efficient conversion of lignin in discrete molecules or classes of aromatic molecules high volume and low molecular weight target is attractive from the point of view of the market. As oil supplies diminish and prices rise, this objective is very desirable, and perhaps the most challenging technological barrier involving lignin[9].

|

4. Lignocelulosic Biomass Biorefineries

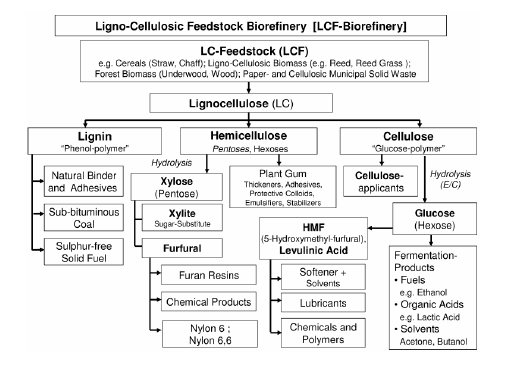

- The lignocellulosic biomass is processed in biorefineries. Pereira Jr.[4] affirms that biorefinery is a relatively new term, referring to the use of renewable materials (biomasses) and their residues, in a most integral and diversified way for the production of fuels, chemicals and energy, with minimal generation of wastes and emissions.The biorefinery, to integrate the processes of biomass conversion to produce different products, allows a range of greater efficiencies in the short and long term, both from the standpoint of thermodynamics as the point of view economic and environmental[5, 15, 16].The biorefinery concept is applicable if it is possible to use renewable raw materials, abundant, cheap and specific, such as lignocellulosic biomass, unlike the various fossil fuels, are not affected by fluctuations in the market. To consolidate this new technology platform it is necessary to support the government so that biorefineries are able to compete economically with oil refineries[17].In the literature, it can find different categories of biorefineries. Annevelink & Ree[18] classify seven types of biorefineries: Conventional biorefinery (CBR), Green biorefinery (GBR), Whole Crop biorefinery (WCBR), Ligno Cellulosic Feedstock biorefinery (LCFBR), Two Platform Concept biorefinery (TPCBR), Thermo Chemical biorefinery (TCBR) and Marine biorefinery (MBR).The emphasis in this study are those that use lignocellulosic biomass, in its whole or fractional, Ligno Cellulosic Feedstock biorefinery (LCFBR), Two Platform Concept biorefinery (TPCBR), Thermo Chemical biorefinery (TCBR).The Ligno Cellulosic biorefineries (LCFBR) based on the fractionation of biomass rich in these materials for the production of intermediate streams of cellulose, hemicellulose and lignin, which can be subsequently processed to obtain a final product portfolio, as shown in Figure 1[ 19]. It consists of the use of three basic chemical fractions: hemicellulose, cellulose and lignin.

| Figure 1. Lignocellulosic feddstock biorefinery |

| Figure 2. Two Plataform Concept Biorefinery |

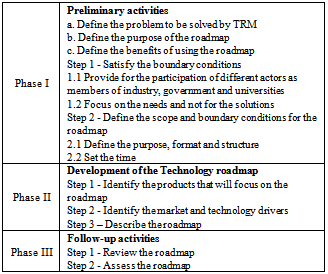

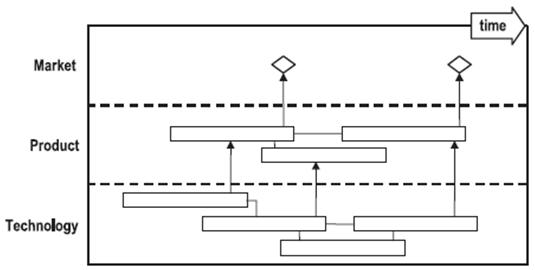

5. Technology Roadmapping Method

- The technology roadmapping method (TRM) is part of technological forecasting tools that have emerged in the last years to explore the dynamics of emerging technologies in the industrial sectors in a long-term horizon and, especially, develop, implement and execute strategic roadmaps to align the company's strategy to the technological capacities[21, 22]. The technology roadmaps have been developed for several different types of public and specificities, being characterized by predicting what is possible or likely to happen, and also by planning a joint action. Thus, roadmaps help to focus the planning processes of a corporation in the future and provide consistent information about the portfolio to support decision-making[21, 22, 23, 24]. This method seeks to assist in structuring the planning process of an institution, industry or company, allowing the visualization of gaps in strategic planning, through alignment between future goals and activities present in the organization. This enables the identification and prioritization of sustainable competitive advantages and the correct allocation of human and technological resources of the organization. Roadmaps may have various shapes, but the most common approach is that generic one which is a time-based graphical representation comprising a number of layers that cover the key parameters as market, product and technology over time for a portion of business as shown in Figure 3[21]. An important feature of the roadmaps is its concise presentation that enables a structured discussion and constructive processes of technological forecasting.

| Figure 3. Schematic technology roadmap showing how technology can be aligned to the development of products and services, business strategies and market opportunities |

| Figure 4. The three phases in the technology roadmapping process according to Garcia & Bray (1997) |

6. Methodology

- It was created an own methodology, inspired by the process of technology roadmapping developed by Garcia & Bray[25], allowing to use the information and create a roadmap for industrial level and guided by information technology in the format of multiple layers as shown in Figure 3. Table 3 shows the phases and stages of the technology roadmapping process adopted for the preparation of this roadmap.

|

6.1. Source of information – USDOE’s document

- The document was prepared by U.S. Department of Energy (USDOE)[9] in order to evaluate the role of lignin as a source of renewable raw material and in order to subsidize the American researches on the use of lignin in both power generation and for the production of fuels and chemicals, according to the lignocellulosic biorefinery concept.This document aims to point out products that are currently more favorable and may have greater impact on the replacement of oil as raw material and economic viability of biorefineries. The main focus is the identification of R, D & I progress in the short, medium and long term, necessary to make the biorefinery more economically attractive through better use of lignin.Initially, the list of potential uses of lignin was compiled and assembled from several sources. The opportunities for product types were divided into three categories described as followed[9]:(I) Power-Green Fuels- Syngas: use of lignin as a pure carbon source, by aggressive media to break down its polymeric structure. The green fuels are described as those that resemble the fuels used today, but are derived from biomass rather than petroleum;(Ii) Macromolecules: the opposite extreme and seeks to take advantage of the macromolecular structure imparted by nature in high-molecular weight applications, and(Iii) Aromatic chemicals: between the two extremes, corresponds to technologies that could cause the breaking up lignin´s macromolecular structure but maintain the aromatic nature of building block molecules.After classified, the opportunities for products in each category were analyzed. The study included evaluation in the state of current technology, and how products fit into the current infrastructure and future biorefinery and markets chemicals or fuels.In this evaluation, the opportunities were also classified as short, medium and long term. This concept represents the odds for the use of lignin in the biorefinery and have been defined[9]:(i) Short-term: is defined as current uses and those that seems possible within three to ten years. Some technology development will be required, but much can be borrowed from currently available processes, for example, pyrolysis and syngas;(ii) Medium-term: the technology used perhaps five to 20 years, requiring a significant technological development and some fundamental knowledge, such as the use of lignin in applications of high molecular weight, and(iii) Long term: technologies employed from ten years and that require significant new fundamental knowledge and significant new technology development, such as the direct catalytic conversion of lignin to fuels like gasoline or aromatic chemicals.

6.2. Application of the Methodology

- The methodology was applied according to the stages and phases shown in Table 3.

6.2.1. Phase I: Preliminary Activity

- a. Define the problem to be solved by TRMThe problem to be solved consists in guiding investments in R, D & I, through good public policy to ensure a safe and clean energy future for the U.S., according to the research needs of the U.S. DOE.b. Define the purpose of the roadmapThe roadmap biorefinery lignin prepared seeks to identify the progress of R & D in the short, medium and long term, necessary to make the biorefinery more attractive economically, through better use of lignin.c. Define the benefits of using the roadmapResearch and understanding of the structure, types, sources and methods of production of lignin, as well as their current and future potential applications with the TRM using the tool, helps to identify specific opportunities that meet the overall objectives of the U.S. DOE, with views energy independence and replacing oil.Step 1 - Satisfy the boundary conditions1.1 Provide for the participation of different actors as members of industry, government and universitiesThe TRM requires the participation of various groups, considering the different perspectives of the industrial object of study in order to concentrate efforts on R, D & I.The document has met this condition since there was participation of different players led by USDOE (government involvement) in partnership with Pacific Northwest National Laboratory (research laboratory), University of Tennessee (university) and the Laboratory of National Renewable Energy (research lab).1.2 Focus on the needs and not for the solutionsThe study sought to identify as lignin can be used to support the economic health of the biorefinery.Step 2 - Define the scope and boundary conditions for the roadmapThe roadmap prepared was driven by the product, ie, the uses of lignin in the production/formulation of different products and relates to a roadmap industrial level since its focus is in the applications of lignin in the context of US biorefinery.2.1 Define the purpose, format and structureThe roadmap produced has the purpose of product planning (applications/uses of lignin) and the generic structure described by Phaal et al[21] (see Figure 3) in which the layering includes the three key parameters: market, product and technology.The market layer is related to changes in economic, social and environmental. The product layer is a link between the market trends and technologies. The technology layer is related to processes required for the production of different products identified.2.2 Set the time As previously mentioned, the study divided the horizon in the short, medium and long term, as shown in Table 4. The time was calculated assuming that the study of U.S. DOE was published in 2007.

|

6.2.2. Phase II: Development roadmap

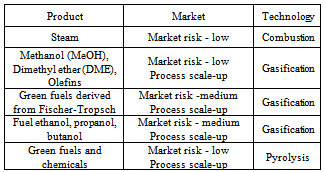

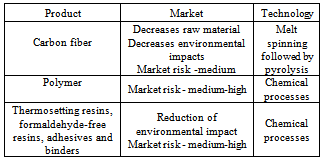

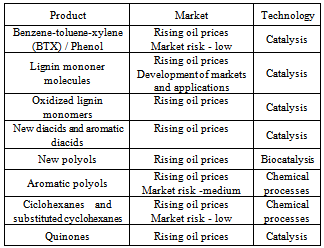

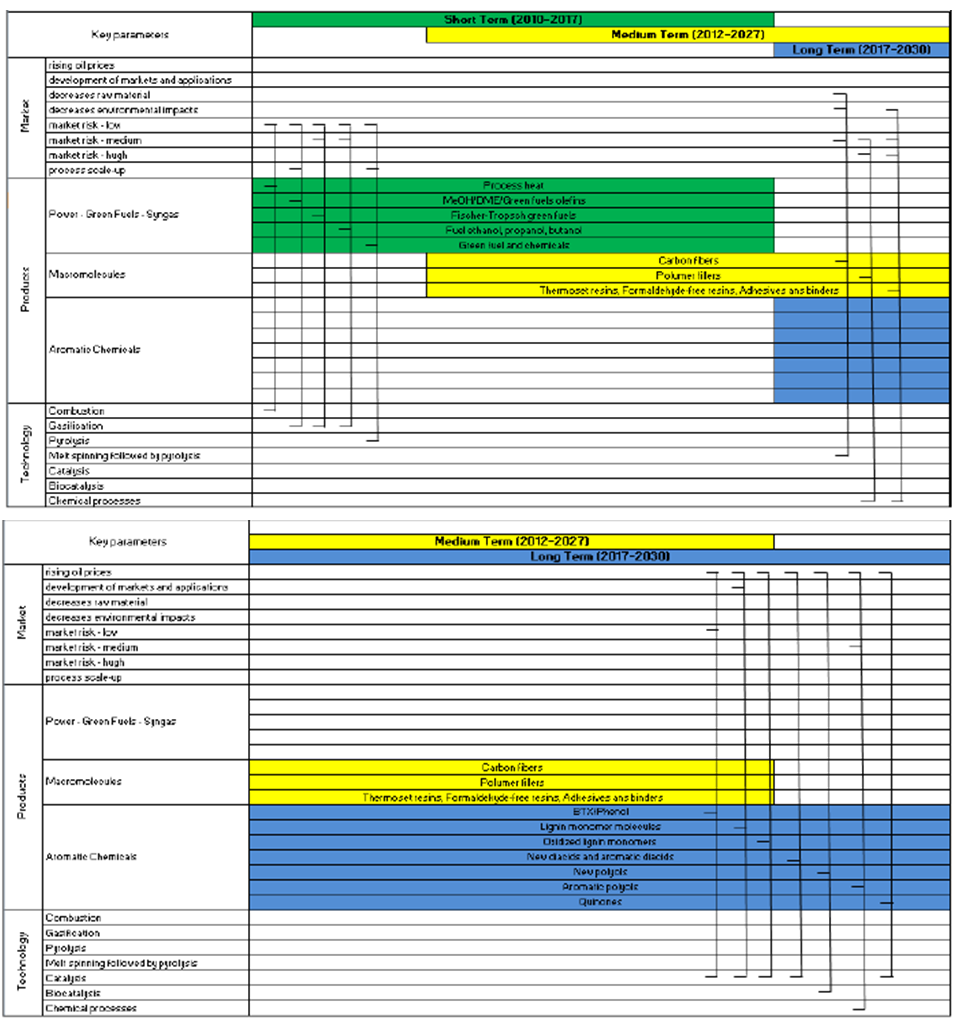

- Step 1 - Identify the products that will focus on the roadmapAs previously mentioned, in the study were categorized three types of products that will be the focus of the roadmap: (i) Power – Green Fuels - Syngas, (ii) Macromolecules, and (iii) Aromatic Chemicals.Step 2 - Identifying the market and technology driversEach of the key parameters of the roadmap (market, product and technology) contain drivers (drivers elements), also known as critical applications that depend on the technological area, which will determine the technological alternatives to be selected according to the potential market.In this paper, presentation and analysis of the drivers were broken elements throughout the document, especially in topics dealing with the three product categories selected. This analysis considered the opportunities to use the products selected based on criteria: economic, state of current technology, the products of the biorefinery infrastructure and market fuels and chemicals.Tables 5, 6 and 7 were listed the elements drivers (product, technology and market) for the short, medium and long term.

|

|

|

6.2.3. Phase III: Activity of continuity

- Step 1 - Review the roadmapThe roadmap generated passed through a general review in order to detect if there was no inconsistency for the document which served as a source of information.Step 2 - Assess the roadmapAlthough the main objective is to produce the roadmap, the technology roadmapping process is significant value. The quality and credibility of the roadmap depends on your describe process, particularly in terms of ensuring that the entry of information reflects the best available knowledge;

7. Roadmap Biorefinery Lignin in the U.S.

- Figure 5 shows the roadmap biorefinery lignin in the United States described according to the methodology presented in Table 3 and based on information in the document U.S. DOE.The analysis of the roadmap of the U.S. was conducted over time, since each of the three product categories (Power – Green fuels - Syngas; Macromolecules and aromatic chemicals) were placed respectively in the short, medium and long term.

7.1. Short Term

- In short term, it is possible to observe that the USDOE points in their studies that lignin will consolidate its position as an energy source to produce steam by direct combustion, as a raw material for production of various fuels such as methanol, ethanol and other using thermochemical processes, such as pyrolysis and gasification.Also, it was observed the integration of the thermochemical and biochemical routes. An example of this integration can be seen in the Forest Products Industry Technology Roadmap[26] which adopts the advanced biorefinery concept of forest products involving the development of technologies to support two new parallel processes pulp production: Hemicellulose Extraction & Conversion in chemicals such as ethanol and acetic acid and Biomass & Black Liquor Gasification for production of power and fuel.

| Figure 5. Roadmap Biorefinery Lignin in the U.S. |

7.2. Medium Term

- On the other hand, medium-term applications have been more as the use of lignin or lignin products of added / mixed with other products such as polymers and thermoset resins, in order to improve the physicochemical properties, such as thermal and oxidative stability.In this case, there is need for purification and so further studies are required for the use of lignin does not cause defects such as voids and contaminants that can cause breakage of the material. As an example of the use of lignin, the roadmap shows its use in the production of carbon fibers as a filler in the production of polymers and resins, adhesives and binders.Lignin is a source potential and low cost carbon appropriate to replace the synthetic polymers such as polyacrylonitrile fibers in the production of carbon fibers. The use of lignin in the process of manufacture of carbon fibers encourages the use of renewable raw materials, thereby decreasing the sensitivity to fuel costs and reducing environmental impact[27].The lignin may be sufficient to move the steel used in domestic passenger vehicles in the USA, making the steel panels are replaced with plastic light yet strong, reinforced with carbon fibers, thereby reducing significantly the weight of vehicles and promoting improvement in fuel consumption.The second use of the lignin was found in the roadmap as a filler for polymers, the lignin is a modified polymer which is used as an additive which promotes improvements in physical properties and performance of the polymers. The research focuses on the control of molecular weight, the introduction of reactive functionality and polyelectrolyte among others[9].The technical challenges surrounding polymer modifiers (fillings) include understanding how to make these modifications in an economic and effective with lignins from different sources. The modified lignin must be validated in accordance with their applications, which may include high strength plastics engineering polymers resistant to heat and adhesive free of formaldehyde.The global polyolefins, in particular U.S., moving large values, which makes it possible to create opportunities for growth in the use of lignin to improve the properties of polymers, allowing the replacement of other materials more polluting and depletable sources such as paper, metal and glass.Finally, lignin, due to their phenolic character may be used to substitute for the phenol in phenol formaldehyde resins. The interest in replacing phenol lies in the fact that nowadays it is obtained from a non-renewable petroleum, while the lignin can be obtained from renewable raw material[28].Studies by Stewart[13] show that the introduction of lignin phenolic compounds on the market is viable and that the predictions of the future indicate that the current price of phenol will increase according to the annual demand forecast.

7.3. Long Term

- The roadmap shows that biorefineries products obtained from lignin will focus on the production of aromatic chemicals with higher added value, such as BTX, phenols, polyols, among other quinones. The key technology for the production of those products is catalysis, in particular biological catalysts more tolerant of temperatures and highly selective catalysts, to improve process efficiency.Furthermore, the R & D is required in catalytic substrates designated for the production of products, fuel and specific energy, so that less processing is necessary having thus further reducing costs.Regarding the need for raw material, Table 2 shows the estimates for the US replacement of aromatic derivatives, requiring a required amount of lignin 41.1 109 kg. This quantity availables in the U.S., whereas the availability of this material is about 286 million tons of lignin (22 million coming from the pulp and 264 million of agricultural waste).

8. Conclusions

- The roadmap for biorefinery lignin to the U.S. was prepared in accordance with an own methodology presented and based on the information contained in the document entitled "Top Value-Added Chemicals from Biomass - Volume II - Results of Screening for Potential Candidates Lignin from Biorrefinery "prepared by the U.S. DOE. It is observed that in the short term the focus is on power generation and fuels that can be obtained by direct use of lignin or biomass that contains a fraction of lignin in order to obtain self-sufficiency in biorefineries. The thermochemical routes are in evidence, especially the processes of gasification and pyrolysis.In the medium term, the macromolecular nature products require a purification step and further studies, so that the lignin or biomass containing lignin does not cause defects such as voids and contamination when mixed with polymers and resins to improve their physical and chemical properties.In the long term, the key process is the catalyst that is more like biological catalysts tolerant to high temperatures and highly selective in order to improve process efficiency and reduce costs. The targets are the aromatic products that have a high value on the world market.

ACKNOWLEDGEMENTS

- Financial support of the Agência Nacional do Petróleo, Gás Natural e Biocombustíveis and CTPetro/Financiadora de Estudos e Projetos.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML