M.Z. Hussin , A. Yaacob1 , R.A. Rahman1 , Z.M. Zain1 , S. Shaari2 , A.M. Omar1

Faculty of Electrical Engineering, Universiti Teknologi MARA, 40450 Shah Alam, Selangor Darul Ehsan, Malaysia

Correspondence to: M.Z. Hussin , Faculty of Electrical Engineering, Universiti Teknologi MARA, 40450 Shah Alam, Selangor Darul Ehsan, Malaysia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

This paper presents the current status of the grid-connected photovoltaic (GCPV) system installed in Malaysia. There are 113 sites with total PV capacity power, of 1008.73 kWp GCPV systems are monitored by the Photovoltaic Sys- tem Monitoring Centre (PVSMC). This paper focus on the PV system performances under Malaysian Building Integrated Photovoltaic (MBIPV) project which relates the performance of the system failures due to technical and environmental factors. Both factors will contribute to the reduction of the PV system performances in terms of final yield. It would later lead to energy inefficiency as the energy harvested from PV array will be wasted which later cause the time taken for en- ergy payback period of the system to be lengthen. Proper and sufficient practical knowledge in designing a GCPV system is needed in order to achieve maximum energy production. A database with minimum period of 4 years was selected as the benchmark for problem identification at PVs site in hot and humid climate. All issues affecting the system performances and BOS component of the GCPV system for optimization purpose.

Keywords:

Photovoltaic (PV), Grid-Connected (GC), Malaysian climate, Building Integrated Photovoltaic (BIPV)

1. Introduction

Renewable energy in Malaysia was first stated in the 8th Malaysia Plan (2001-2005) by the introduction of Small Renewable Energy Programme (SREP), and in the Third Outline Perspective Plan 2001-2010. Under this SREP, small power generation plants which utilizes of all types of Renewable Energy, including biomass, biogas, municipal waste, solar, mini-hydropower and wind, are allowed to sell electricity to the Utility through the Distribution Grid sys- tem. Once again, renewable energy (RE) is explicitly ad- dressed in the 9th Malaysia Plan (2006-2010), with the aim to develop an appropriate, proactive and integrated plans and policies to exploit the solar PV market in Malaysia. Under the 9th Malaysia Plan, the Government of Malaysia (GoM) had launched the MBIPV project started from July 2005 and planned to finish around December 2010[1]. The MBIPV project will specifically focus on the market de- velopment for BIPV technology, and building the national capacities on three major areas: (a) policy and education(b) technical skill and market implementation; (c) technology development support. Subsequently from 9th Malaysia Plan, the GoM targets in the 10th Malaysian Plan (2011-2015), with introduction to the National RE Policy & Action Plan and giving the MBIPV project as a significant input toward RE development in the country.The Malaysian Building Integrated Photovoltaic (MBIPV) Project is administered by the Ministry of Energy, Green Technology and Water Malaysia (KeTTHa) with supported from United Nations Development Programme (UNDP) and Global Environment Facility (GEF). The objective is to promote all GCPV application through the Malaysian Building Integrated Photovoltaic (MBIPV) project. The MBIPV project implemented under four main strategies: (i) awareness and capacity building; (ii) market development; (iii) policy development; (iv) industry and technology de- velopment.Photovoltaic System Monitoring Centre (PVSMC) is a body that monitors the performance of PV and BIPV instal- lations under MBIPV project. The MBIPV project team agreed and awarded a contract to the Universiti Teknologi MARA (UiTM) on 29th November 2006 to classify PVSMC as a PV monitoring centre[2]. This is done as an effort to fulfil one of the objective components of the Malaysian Building Integrated Photovoltaic (MBIPV) project.All grid-connected PV system installations which re- ceived Malaysian government’s grant are monitored by PVSMC whereby the performances of a PV system can be accessed via web portal[3]. This web portal is used as a database for all monitored PVs site installation all over Ma laysia. The current development and reliability issues of the Grid-Connected PV (GCPV) systems in the Malaysia con- text are presented below.

2. Status of GCPV System Application in Malaysia

2.1. Malaysia Climate

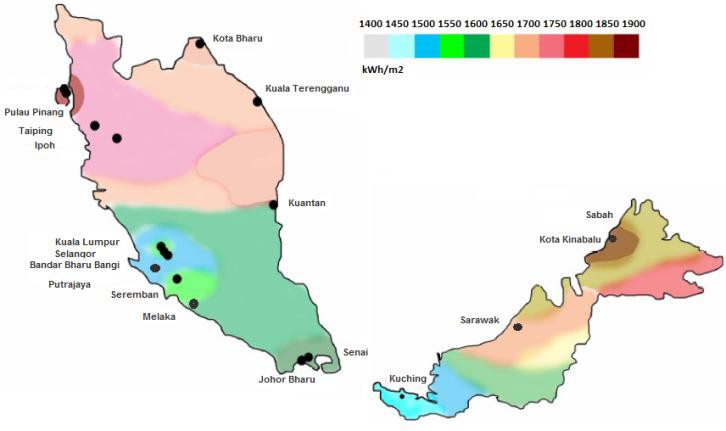

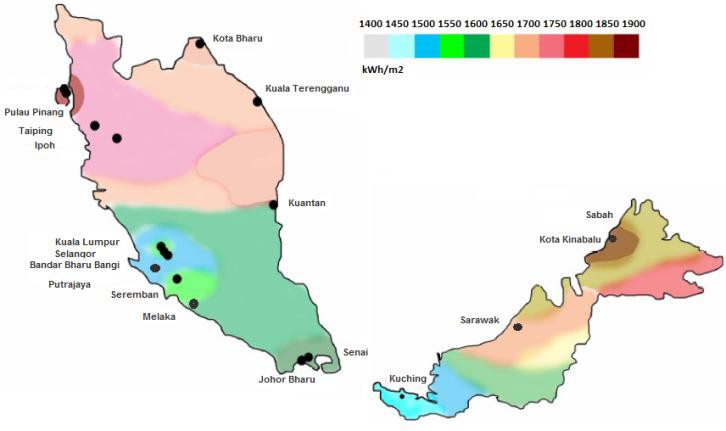

Malaysia lies entirely on the equatorial region with an average daily global solar irradiation of approximately 4.5 kWh/m2. On average, Malaysia receives around 6 hours of sunlight per day. The average temperature per day ranges from 33°C during the day to 23°C during the night[4]. The orientation of the BIPV installation is not so important as in European countries. A tilt angle in between 2° to 7° and true South direction for PV array will give an ideal orientation of the system[5]. However, PV installation with an inclination angle of about 5° until 15° is more favourable as it allows the PV array surface to be cleaned by the rain[6], as Malaysia located near to the equator line with heavy rainfalls varies from 2000mm to 2500mm per year[4]. Based on Malaysia solar irradiation’s latitude under tropical hot and humid climate, the annual average solar irradiation was estimated to be approximately 1,643 kWh/m2/yr[7],[8]. Figure 1 and 2 shows the distribution of the solar irradiation around Ma- laysia. | Figure 1. Annual average daily global solar irradiation for Malaysian Map[2] |

| Figure 2. Yearly average global solar irradiation around Malaysia’s state[7] |

2.2. PV site installation monitored by PVSMC

The total PV capacity of GCPV systems under MBIPV project installed and commissioned in Malaysia around 1,516 kWp until 31st December 2010,which includes 468 kWp baseline of GCPV systems installed before the MBIPV project commenced of which some have been dismantled[1]. A total of 113 sites were monitored by PVSMC from July 2005 until the end of December 2010 with total PV capacity of 1008.73 kWp, but it still continuous monitoring since today. Selangor has the highest recorded with 51 sites of PV installation compared than the other states as depicted in Figure 3. | Figure 3. Selected locations in Malaysia monitored by PVSMC[1] |

2.3. Market Share of PV cell technologies under MBIPV project

From Figure 4 below presents the total number of PV site installed using different types of PV cell technologies in the Malaysian field. The total of PV system installed in Malaysia is 113 sites and more than half of them were used came from monocrystalline module technology type. This PV module technology dominates about 53% of the market share under MBIPV project. Meanwhile, the polycrystalline module was installed at 42 sites. These crystalline technologies mostly installed at the residential house. For the thin-film modules, a-Si, CdTe and CIS were 8% and the other portion of 1% was used technologies from Heterojunction with Intrinsic Thin-layer (HiT) and Tandem (a-Si/µc-Si) modules based on the data were monitored by PVSMC, UiTM. | Figure 4. Market share percentage of PV cell technologies installed in Malaysia until the end of December 2010[3] |

2.4. PV installation capacity around Malaysia

In Figure 5 presents the total of 113 sites with various state around Malaysia which the overall PV capacity had installed was approximately 1008.73 kWp under MBIPV project recorded by the end of December 2010. Selangor recorded the highest total power of PV capacity about 406.49 kWp. In contrast, the lowest PV capacity power was Negeri Sembilan with 10.08 kWp. | Figure 5. Total power of PV capacity in different states under MBIPV project installed[3] |

Under MBIPV project, PV application was divided into four different types of building, which is commercial, school, residential house and industrial building types. The majority PV application of GCPV system came from a public resi- dential was 62 sites with total PV capacity of 406.49 kWp was recorded. The minority of PV application at Robert Bosch (M) Sdn Bhd’s site in Penang state from industrial type. | Figure 6. Total number of PV site installation based on building type[1] |

In Figure 7 illustrates the cumulative growth in PV ca- pacity since 1998 within the two primary status for PV de- velopment in Malaysia context. About 462.78 kWp of total PV capacity were installed from 1998 until 2004 including baseline of GCPV installation. After MBIPV project was launched in July 2005, an increase of more than 60% over the previous year, which brought the total PV capacity installed up to 1600 kWp by the end of December 2010. By far, the greatest proportion was installed in Selangor and Kuala Lumpur state. To date, the largest PV installation with 362 kWp is the Enterprise Four Building at Technology Park Malaysia, whereas the second largest PV installation is a number of BIPV systems at the Malaysian Green Technol- ogy Corporation (MGTC) with total PV capacity of 92.00 kWp, commissioned in June 2007[1]. | Figure 7. Total cumulative number of PV site installation until the end of December 2010 |

3. Issues of GCPV system in MBIPV project

3.1. Environmental problem under MBIPV project

After 4 years monitoring process done by PVSMC, sev- eral problems were identified such as environmental prob- lems, e.g. shading effect, lightning strikes because of im- proper grounding and the technical problem which influ- ences the PV system performance. The data was extracted from[3]. | Figure 8. Monash University, Sunway Campus, Malaysia[3] |

Shading is an unavoidable presence on the PV array in many PV systems. It is always advisable to eliminate shading to the best of the installer’s ability and keep away from ex- cessively shaded on the PV array surfaces. Other than that, shading problem that occurs even in one PV module will give a strong influence to the overall PV performances which contributes to the power output wastages. A shadow by clouds across on the PV array surface can almost stop energy production at that time. It mostly influences the PV modules come from crystalline type whereas the minimum affects to the thin-film technologies type. Typically, it is the advan- tages of thin-film modules, however it should still be un- shaded. Generally, the shadow on PV array’s surface is usually caused by trees, houses or building in the neighbourhood that may fall at part of area or only for a relatively short time. So, it is very important especially in hot and tropical climate to determine the direction on the sun movement to ensure the various object such as trees, houses or building will not shade the PV array’s surface. One site was took as a case study that affected by shading problem as shown in Figure 8 and the site description was depicted in Table 1 below.| Table 1. Case 1: Monash University’s system description |

| | Subject | Specification | | Site | Monash University | | Location | Sunway Campus Malaysia | | Type of PV system | Grid-connected | | Mounting type | Retrofitted | | Nominal power | 7.36 kWp | | PV module typeType of PV technology | Kaneka GPA 064 (64W)Amorphous Silicon (a-Si) | | Inverter brand | Solarmax 4200C & Solarmax 2000C | | No. of PV modules | 115 units | | Commissioning Date | June 2007 |

|

|

Figure 9 shows the final yield values had decreased sig- nificantly from November 2007 until April 2009 (red) after two years the system was commissioned. The system was operated in a low condition in terms of final yield perform- ance over the monitored period. In addition, it can be seen that the reduction pattern on the final yield performance at Monash University was caused by building shading. | Figure 9. Monthly profiles of final yield generated by 7.36 kWp GCPV system in Monash University, Sunway Campus Malaysia[3] |

For Kuala Lumpur, the sun will be directly overhead on March, 29th and September, 14th (Equinox). For the period from March 29th to September 14th, the Sun will be facing due to the northern direction. So, the huge potential caused by shading effect will be occurred in northern and southern direction[5]. The installer requires to be familiar with the sunpath diagram to estimate the percentage of shading will be occurring and be able to use the Solar Pathfinder equip- ment to identify possibilities shading at the site before any installation to prevent this shading problem. The appropriate sunpath diagrams selected should be matched with latitude at the specific location. Typically, the latitude in between 4° to 8° N is widely used in Malaysia. Other than that, the PV installer needs to determine the solar resources at a particular site, e.g. how much of the solar available at the site, an in- clination angle of the PV array is tilted , and the suitability on the PV array oriented either in South, North, East or West in order to obtain the highest energy harvested and lastly, identify the possibilities of any shading will occur after PV array had installed. Figure 10 below illustrates the compo- nents of Solar PathfinderTM equipment such as tripod, sun- path diagram, dome with lens, compass, etc. | Figure 10. The Solar PathfinderTM equipment set[9] |

Over monitored period, several sites were recorded by shading problem. There are 10 sites were influenced with the shading effect in the outdoor field around Malaysia as de- scribed in Table 2 below. In each case for 10 sites above, a reduction in the final yield was occurred. A yellow indicator will be displayed in the graph, means the average on per- formance of PV system not achieve more than 80% of actual over the expected final yield, whereas the red indicator ex- plains the lower performance less than 50% of the expected final yield as illustrated in Figure 9. The environmental factor caused by shading effect was identified as one of the problems frequently occurred in the GCPV systems installed in Malaysia during MBIPV project.Other than that, GCPV system also facing the low energy problem at the certain sites and most were occurring in Se- langor’s state. About 6 sites facing in lower energy were reported over monitored period and only 1 site was detected in the low energy caused by Surge Protection Device (SPD) damage on DC side as tabulated in Table 3.

3.2. Technical problem under MBIPV project

Short-term behaviour study on the problem was conducted under MBIPV project. During the investigation, 12 sites were identified facing technical problems such as inverter shutdown, datalogger/sensor failure and PV meter which not accessible was the most frequent effect had occurred on the GCPV systems in Malaysia’s environment[10].| Table 2. Number of sites that possibility of shading effect on the PV array surface |

| | State | Site | Array nominalpower (kWp) | PV cell technology | | Kuala Lumpur | Private Bungalow House, Jalan Maarof, Bangsar. | 3.20 | Kyocera KC200GHT-2 (polycrystalline) | | Private Bungalow House (2), Kota Damansara. | 3.06 | Sharp NUS0E3E (monocrystalline) | | Private Bungalow House, Bangsar. | 4.80 | Mitsubishi PVMF120TE4N (polycrystalline) | | Private Bungalow House, Bukit Damansara. | 4.32 | Sharp NUSOE3E (monocrystaline) | | Melaka | Private Bungalow House, Bukit Beruang. | 4.80 | Kyocera KC200GHT-2 (polycrytalline) | | Selangor | BORID Energy, seksyen U1, Glenmarie, Shah Alam | 3.92 | BS 40 (thin film) | | Private Bungalow House, Bangi, | 3.06 | Sharp NUSOE3E (monocrystalline) | | Private Bungalow House, Salak Tinggi, Sepang | 4.40 | Kyocera KC200GH-2P (polycrystalline | | Private Bungalow House Subang Jaya, Subang Jaya | 3.15 | Solarworld 175 (monocrystalline) | | Monash University, Sunway | 7.36 | Kaneka GPA 064 (amorphous Silicon) |

|

|

| Table 3. Number of site that low energy issue detected in MBIPV project |

| | State | Site | Array NominalPower (kWp) | PV cell technology | Problem | | KualaLumpur | Private Bungalow House, Taman Desa | 4.2 | Solarworld 175 (monocrystalline) | Lower energy on; February 2009 | | Selangor | Private Bungalow House, Bandar Kinrara. | 4.8 | Mitsubishi PVMF120TE4N (polycrystalline) | Low energy on February 2009and defective on Surge Protection Device at the DC side. | | Show Unit Bungalow HouseZ1B (COLUMBA), Setia Eco Park | 5.28 | Solarworld 165 (monocrystalline) | Extreme low energy on; January 2010 and May 2010 | | Show Unit Bungalow HouseZ1A(AQUILA), Setia Eco Park. | 5.775 | Solarworld 175(monocrystalline) | Extreme low energy on;June 2008. | | Show Unit Bungalow HouseZ1E (LEO),Setia Eco Park. | 5.28 | Solarworld 165(monocrystalline ) | Extreme low energy on;October 2009 | | Monash University, Sunway | 7.36 | Kaneka GPA 064 (amorphous silicon) | Extreme low energy;September and October 2008, Feb 2009 |

|

|

| Table 4. Inverter issue of grid-connected MBIPV project in Malaysia |

| | State | Site | NominalPower (kWp) | PV Module/Inverter | Problem | | Putrajaya | Show Unit Bungalow HouseLot 2422. | 5.40 | Sharp NUS0E3E (monocrystalline)/Fronius IG 60 | Inverter shutdown;September - December 2010 | | KualaLumpur | Private Bungalow House, Taman Duta. | 9.75 | Sharp ND130TJ (monocrystal- line) /SMA SMC 10000TL | Inverter shutdown; May 2009. | | Private Bungalow House, Taman Desa. | 4.20 | Solarworld 175(monocrystalline) /Fronius IG 40 | Inverter shutdown;March 2009 and June - Sept 2010. | | Selangor | Government Office – MGTC Pack B, Bandar Baru Bangi | 6.08 | Kaneka GPA 064 (amorphous silicon) / Fronius IG 60 | Inverter shutdown;March - April 2010, August – Nov 2010. Replacement new inverter on;10th December 2010. | | Government Office – MGTC Pack D, Bandar Baru Bangi. | 27 | Sharp NUSOE3E (monocrystal- line) / Fronius IG300 | Inverter shutdown;June 2009 and November - December 2010 |

|

|

From Table 4 below, 5 sites having problems due to the inverter malfunction. It can be seen that the PV cell tech- nology using monocrystalline was more dominant than the other PV modules as a most frequent result of inverter fail- ures. The selection and suitability in terms of inverter issues such as the operating window voltage of the inverter and de-rating factor, may contribute to the inverter failure during initial sizing and design phases. Besides that, the installer should also consider other issues on how fit the PV modules and inverters endure various environmental effects such as operating ambient condition. In order to enhance the lifespan of inverter, particular attention needed to ensure that in- verter’s components cannot overheat where the inverter may be installed in surrounding at maximum operating tempera- ture. Additionally, the inverter must be kept free from dust, moisture and destructive gases especially if in the outdoor installation.Apart from that, the appropriate of PV array power needs to be matched with respect to the inverter nominal power to avoid the inverter clamping the power produced by PV array. If the PV array output is larger than the inverter’s nominal power, the inverter will reduce the output from PV array to the inverter’s nominal power output. If the inverter oversize than PV array output, the inverter will operate at a low effi- ciency rate during low irradiance occurred. From Table 4, it can be seen the inverter defect in Selangor’s state at Gov- ernment Office – MGTC Pack B due to the combinations of the PV array and inverter sizing. The new replacement of the inverter had made on 10th December 2010. | Figure 11. The percentage of environmental issues under MBIPV project over monitored period |

From the view of MPP-voltage inverter, if the operating DC voltage falls outside the MPP-voltage limit, also known as operating window voltage boundary, the inverter might act to turn off if the operating DC voltage is lower than the minimum window voltage of MPP-voltage limit, otherwise if the operating DC voltage exceeds than maximum window voltage, it will damage the inverter. To ensure the operating DC voltage within the operating window voltage, the ar- rangement of the number PV module per strings need to be calculated. The compact design and sizing procedures in GCPV system needs to be studied and become the most important in order to maximize energy harvest and prevent other failures in the system. | Figure 12. The percentage portion of technical issues under MBIPV |

Another critical in design issues is the air ventilation or air circulation between air gap on the back of the PV modules, it should be considered to provide a sufficient ventilation thus module temperature on the backside of PV module does not rise and reduce the output power. For example, leave 4 inches of air gap in between the roof and module frame to allow cooling air to circulate and also, to allow any con- densation or moisture to dissipate[11]. Typically, the crys- talline technology is the most affected on the temperature level. So, this situation needs to be counted for the installer as the technical problem during designing a system before PV installation had implemented.| Table 5. The reliability issue of PV installation problems in MBIPV project until the end of December 2010 |

| | Effect | Factor / Fault | No. of PV site | | Environmental | Shading effect | 10 | | Low energy | 6 | | Technical | PV meter | 5 | | Inverter shutdown | 5 | | Inverter defect | 1 | | Datalogger/Sensor | 1 | | Surge Protection Device | 1 | | System failure | 6 | | Site Renovation | 1 |

|

|

There are 9 problems shows the influence on the GCPV system performances under MBIPV project over the moni- tored period around Malaysia as summarized in Table 5 below. About 62% of the environmental problem due to the shading issue whereas another portion was recorded on the lower energy crisis was 38% with 6 cases were reported. In contrast, there are 7 problems were involved in technical issues such as inverter shutdown was approximately 25%, as well as PV meter not accessible was 25%, and other fail- ures (inverter defect, datalogger/sensor, SPD and site reno- vation). The majority problem was occurred in the system failures about 30% of the portion in technical issues during the PV performances monitoring done by PVSMC.

4. Conclusions

The problems and challenges in handling of the GCPV system in Malaysia are recognized. After 4 years experience in monitoring system PV performances, more than 56% of the interruptions on the GCPV systems installation in Ma- laysia’s condition was caused by the technical problem, whereas the environmental recorded around 44% of the portion over the monitored period. The system PV per- formance also affected by different combinations of the PV array and inverter in terms of sizing and as well the envi- ronmental problem such as the inverter performance and reliability issues were identified after 4 years monitored period. All issues are identified through the monitoring process was done by PVSMC. For the meantime, the in- staller should also consider the other issues such as PV array matches with respect to inverter power, the suitability in- verter of the operating ambient condition, MPP-voltage inverter’s selection, air ventilation or circulation, etc. Before any PV installation, the installer needs to conduct the site inspection or site survey to know the geographical site, dis- tribution level of solar irradiance and operating temperature, and identify the possibility of any shading will be occurred at that site. Generally, the installer needs to make a right deci- sion when dealing with BOS components of GCPV system and seek advice from an experienced system designer in solving the design issues if beyond the installer’s acquaint- ance and capabilities. A proper training and competency for the installer, first-class in handling of safety and high-quality on the maintenance of GCPV system will contribute the better performance of the GCPV system operation in terms of durability and reliability.

ACKNOWLEDGEMENTS

The researchers would like to thank the Photovoltaic System Monitoring Centre (PVSMC) for providing the data for the research. Also thank to Faculty of Electrical Engi- neering, UiTM Shah Alam, Malaysia for the support and commitment for this work.

Subcripts

SREP Small Renewable Energy ProgrammePVSMC Photovoltaic System Monitoring CentreMMD Malaysia Meteorological DepartmentMPP Maximum Power PointBOS Balance-of-SystemGEF Global Environment FacilityMBIPV Malaysia Building Integrated PhotovoltaicUNDP United Nations Development Programme

References

| [1] | (2010) Malaysia Building Integrated PV (MBIPV) Project portal,[Online]. Available: http://www.mbipv.net.my |

| [2] | M. Nazri, Malaysia PV Industry- Prospects & Challenges. MBIPV Project Malaysia Energy Centre (PTM), Report SEMI Round Table Discussion, 2008. |

| [3] | (2010) Photovoltaic System Monitoring Centre(PVSMC),[Online]. Available: http://pvmc.uitm.edu.my |

| [4] | (2011) Malaysia Meteorological Department (MMD) portal,[Online]. Available: http://www.met.gov.my |

| [5] | S. Shaari, A.M Omar, A.H. Haris & S.I. Sulaiman. Solar Photovoltaic Power: Designing Grid-Connected Systems, 1st ed., Ministry of Energy, Green Technology and Water, Ma- laysia / MBIPV. Putrajaya, Malaysia, 2010. |

| [6] | Sharp Electronics Corporation, Installation And User Manual For Sharp Photovoltaic Modules.[Online]. Available: http:// http://www.sharp-world.com/solar (Issue 03/2010) |

| [7] | A.H. Haris, “A Unique Policy Development Outside Europe: The Example of Malaysia,” MBIPV Project Malaysia Energy Centre (PTM), 2nd International Conferences on Solar Pho- tovoltaic Investments, Frankfurt am Main, Germany, 2008. |

| [8] | M.Z. Hussin, M.H.A. Hamid, Z.M. Zain, R.A. Rahman.“An Evaluation Data of Solar Irradiation and Dry Bulb Tempera- ture at Subang, under Malaysian Climate,” In proceedings of 2010 IEEE Control and System Graduate Research Collo- quium (ICSGRC), pp. 55-60, 2010. |

| [9] | Solar Pathfinder. Available: http://www.solarpathfinder.com |

| [10] | M.Z. Hussin, A. Yaacob, Z.M. Zain, S. Shaari, A.M. Omar. “Status of a Grid-connected MBIPV Project in Malaysia”, In proceedings of 2011 3rd International Symposium & Exhibi- tion in Sustainable Energy & Environment (ISESEE), Melaka, Malaysia, pp. 4-11, 2011. |

| [11] | Sanyo Electric Co. Ltd, General Installation manual of Sanyo.[Online]. Available: http://www.us.sanyo.com (issue 06/2007) |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML