-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

World Environment

p-ISSN: 2163-1573 e-ISSN: 2163-1581

2024; 14(1): 20-30

doi:10.5923/j.env.20241401.02

Received: Oct. 16, 2023; Accepted: Nov. 20, 2023; Published: May 13, 2024

Characterization of Biochar Produced from Sawdust for Environmental Management

Kumar Latchman1, Dawn Fox1, Patrick Ketwaru1, Dharamdeo Singh2, Diana Seecharan3

1University of Guyana, Chemistry, Turkeyen Campus, Greater Georgetown, Guyana

2University of Guyana, Agriculture, Turkeyen Campus, Greater Georgetown, Guyana

3University of Guyana, Biology, Turkeyen Campus, Greater Georgetown, Guyana

Correspondence to: Kumar Latchman, University of Guyana, Chemistry, Turkeyen Campus, Greater Georgetown, Guyana.

| Email: |  |

Copyright © 2024 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Biochar is a natural carbon-rich material produced via the thermochemical decomposition of biomass under inert atmosphere, a process known as pyrolysis. Sawdust is considered a forest waste and has long been researched and considered a feedstock for biochar production. The main objective of this research is to investigate how different types of sawdust composition (Peltogyne spp and Ocotea oblonga) and pyrolysis temperature affect selected properties of biochar. The two types of sawdust were collected from a sawmill in Guyana and were pyrolyzed using a thermogravimetric analyzer at 300°C and 700°C to produce four prototypes of biochar. The two types of sawdust and the four prototypes of biochars were characterized using International Biochar Initiative (IBI) standard. The results indicated the following: (1) there are statistically significant differences between the characterized properties of the types of sawdust, (2) pyrolysis temperature affects biochar yield, and (3) there are statistically significant differences between the physicochemical properties of four prototypes of biochars, specifically volatile matter, fixed carbon, ash, selected total and exchangeable elements, pH and conductivity.

Keywords: Biochar, Pyrolysis temperature, Sawdust

Cite this paper: Kumar Latchman, Dawn Fox, Patrick Ketwaru, Dharamdeo Singh, Diana Seecharan, Characterization of Biochar Produced from Sawdust for Environmental Management, World Environment, Vol. 14 No. 1, 2024, pp. 20-30. doi: 10.5923/j.env.20241401.02.

Article Outline

1. General Introduction and Overview

- Biochar is a natural carbon-rich material produced via the thermochemical decomposition of biomass under an inert atmosphere, a process known as pyrolysis (Verheijen et al., 2010). This process is very similar to that of the production of other charred materials such as charcoal. However, it is the application of biochar that distinguishes it from other charred materials. The term “biochar” is a relatively recent name given to charred materials intended for soil application (O'Laughlin & McElligott, 2009). The term was first proposed in 2005, however, as a material, biochar application to soil is an ancient practice dating back to thousands of years (Adeyemi & Idowu, 2017). The incorporation of biochar into soil has been reported to improve soil physical and chemical properties (Wang et al., 2015), including soil organic carbon, aeration, cation exchange capacity, water holding capacity, pH regulation and microbial ecology (Ronsse et al., 2013). The highly porous structure of biochar is potentially responsible for improved retention of water in the soil as well as nutrients and agrochemicals for plants and crops. As a result, more nutrients stay in the soil instead of being leached into groundwater which can lead to environmental pollution. Therefore, biochar has remarkable potential in food security, especially where there is a shortage of water or chemical fertilizers, and areas with poor soils.Biochar has considerable carbon sequestration value. The international biochar organization proposed that biochar is expected to sequester 2.2 gigatons of carbon by 2050. When biochar is incorporated into soil its carbon fraction is known to be very stable with a half-life of approximately 1000 years (Ronsse et al., 2013). The stability of biochar carbon is of critical importance in the context of environmental management for two main reasons: the stability of the carbon will determine how long the biochar will stay in the soil and help with the mitigation of climate change, and stability will influence how long biochar will aid in providing secondary benefits to soil such as improving its physical and chemical properties (Budai et al., 2013).Perhaps the most easily and readily understood application of biochar is its role in agriculture and forestry waste management. Biochar can be produced from many different biomass materials including crop residues, manures, forest residues, and urban organic waste (Duku et al., 2011). Thus, residues which pose serious waste disposal issues such as contaminating ground and surface waters can be converted to biochar. Moreover, a significant amount of forest and crop residues in most traditional agroforestry systems is allowed to burn or decay, releasing carbon dioxide and other greenhouse gases into the atmosphere. Hence, converting organic waste into biochar can help in the mitigation of climate change (Lehmann & Joseph, 2015). Biochar production is a technology that has tremendous potential as an emerging solution in environmental management, climate change mitigation, biomass waste disposal and protection of soil environment (Tag et al., 2016). However, the feedstock composition is highly determined by the botanical species, plant part, soil types, climate conditions, and the time of harvest (Suliman et al., 2016). Further, both feedstock composition and pyrolysis temperature highly influence biochar yield and properties such as ash content, hydrogen/carbon ratio, oxygen/carbon ratio, carbon/nitrogen ratio, pH, surface area, and cation and anion exchange capacity (Mukome et al., 2013). These properties function as proxy and indicator of biochar potential in environmental management via carbon sequestration, mitigation of greenhouse gas emission, soil improvement, and crop productivity (Leng et al., 2019). Currently, there is no comprehensive assessment of sawdust biomass in Guyana as a feedstock for biochar production. The composition is expected to be unique and will influence biochar properties very differently. Therefore, investigating the effects of sawdust composition and pyrolysis temperature on resulting biochar properties is an area of research that is needed in order to adopt this technology. This knowledge can be utilized in designing and optimizing biochar with properties for the intended application. The main objective of this research was to investigate how the composition of low density Ocotea oblonga (locally known as Silverballi) and high density Peltogyne spp (locally known as Purple Heart) species biomasses and pyrolysis temperature affect selected properties of biochar. The specific objectives were to: 1. characterize the physicochemical properties of the two types of sawdust feedstock (low density and high density), 2. produce biochar and determine precent yield from the two types of sawdust feedstocks at two different pyrolysis temperatures, and 3. characterize the physicochemical properties of the resulting biochars produced from the two types of sawdust feedstocks under the two different pyrolysis temperatures.

2. Materials and Method

- Sample collection Low density (Silverballi) and high density (Purple Heart) sawdust samples were collected at the time of production from a sawmill on the East Bank of Demerara, Georgetown, Guyana. The Guyana Forestry Commission reported the density of these two types of wood as 840 kg/m3 and 420 kg/m3 for the Purple Heart and Silverballi respectively. In this research, the Purple Heart was referred to as high density (HD), while the Silverballi as low density (LD).Feedstock PreparationPrior to the experiments, the samples were washed several times with deionized water and dried in an air oven at 80°C for 24 hours. Using a food processor, the sample size was reduced and sieved through an 80 mesh to obtain a uniform particle. The samples were placed in zip-lock bags and stored in a dry environment.Biochar Production Pyrolysis experiment was carried out in a thermogravimetric analyser (LECO 701 TGA) under a nitrogen stream (at 5 L min -1, ambient temperature and pressure). A pre-drying programme was carried out at 105°C to establish constant weight, and then pyrolysis was carried out at different temperatures (300 and 700°C) for each species of feedstock. The pyrolysis heating rate employed was 4°C min -1 and a resident time of 1 hour. After pyrolysis, samples were left in the TGA to cool to room temperature under a nitrogen stream of 3 L min-1. The biochars obtained were labelled LD 300, HD 300, LD 700 and HD 700.Biochar Sample PreparationThe biochar samples were reduced in size using a mortar and pestle, and sieved to obtain a uniform particle size of 80 mesh. Further, they were placed in zip-lock bags and stored in a desiccator.

3. Procedure

- The toxicological characterization (As, Cd, Cr, Co, Pb, Ni, Se, Zn, B & Na) and (Hg) of the two types of feedstocks and the four prototypes of biochar were determined by the method TMECC (2001) and US EPA (2007) (Initiative, 2015). The proximate analysis was done using the thermogravimetric analyser (LECO 701) and the temperatures outlined by the American Society of Testing and Materials (ASTM) D1762-84 method. Total Nitrogen of biochar was conducted by Kjeldahl Digestion for nitrogen followed by measurement at 420 nm with accordance with the manufacturer manual (Agilent Carry UV-VIS spectrophotometer). Total Sulphur was conducted by using 1 g of ground, oven dried (60°C) sample and digested in 10 ml hydrochloric acid to approximately 5 mL in volume, and then 1 mL of hydrogen peroxide was added. The digest was quantitatively transferred to a 100 mL volumetric flask, filtering through Whatman # 40 filter paper, and left to stand for an hour. 10 mL aliquot of solution was transferred into a 50 mL volumetric flask. The following were added: 2 mL of distilled deionized water, 1 mL of 0.5% Gum acacia, 1mL of 6 M hydrochloric acid and 0.5 g of barium chloride. The flask was swirled and made up to mark with distilled deionized water, capped, mixed thoroughly and left to stand for 10 minutes. Measurement was made at 420 nm with accordance with the manufacturers Manual (Agilent Carry UV-VIS spectrophotometer). Conductivity and pH of biochar was determined by using 5.0 g of air-dried biochar sample (ground < 2mm) that was weighted into a shake bottle and 50 mL of deionized water was added. The bottle was then shaken for 90 minutes at 25°C on a mechanical shaker. Further, it was allowed to stand for an additional 30 minutes. Measurement was made using pH and conductivity meter. Extractable metals (Ca, Mg, and Fe) in biochar were determined using 1g of air-dried biochar weighed into a bottle and 20 mL of 1 M hydrochloric acid was pipetted into the bottle. The bottle was shaken on a reciprocal shaker 2 hours at 25°C and was further allowed to stand for 16 hours. The suspension was then filtered through a Whatman no. 42 paper into a 25 mL volumetric flask. The flask was filled to mark with 1 M hydrochloric acid. The samples were then analysed using the flame atomic absorption spectrophotometer (Agilent 240 AA series).

3.1. Experimental Design

- The Completely Randomized Design (CRD) experimental design was utilized in this research. This experimental design was used because there was no need for blocking since the experimental units are homogenous. There were four (4) treatments and each treatment was replicated three (3) times. The four (4) treatments used were Treatment 1: LD BC300, Treatment 2: LD BC 700, Treatment 3: HD BC 300, and Treatment 4: HD BC 700.

3.2. Data Analysis

- The two feedstock and four prototypes of biochar toxicology data were compared with International Biochar Initiative (IBI) standards. STATISTIX 10 software was used to generate simple ANOVA table at a 95% confidence interval to check for significant difference between the properties of the two types of feedstocks, the yields of the four prototypes of biochars and their properties. A completely randomized design (CRD) ANOVA with replication table was generated using Microsoft Excel to specifically check if there is interaction between temperature and feedstock in determining any define properties in biochar. Further, this design allowed for the approximation of which factor (type of feedstock or pyrolysis temperature) had a greater influence on a given biochar property. Further, Microsoft Excel was used to generate graphs, tables and charts.

4. Results and Discussion

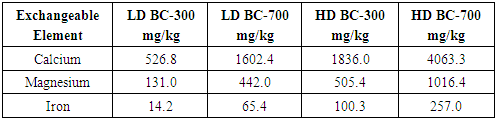

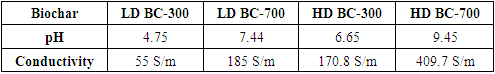

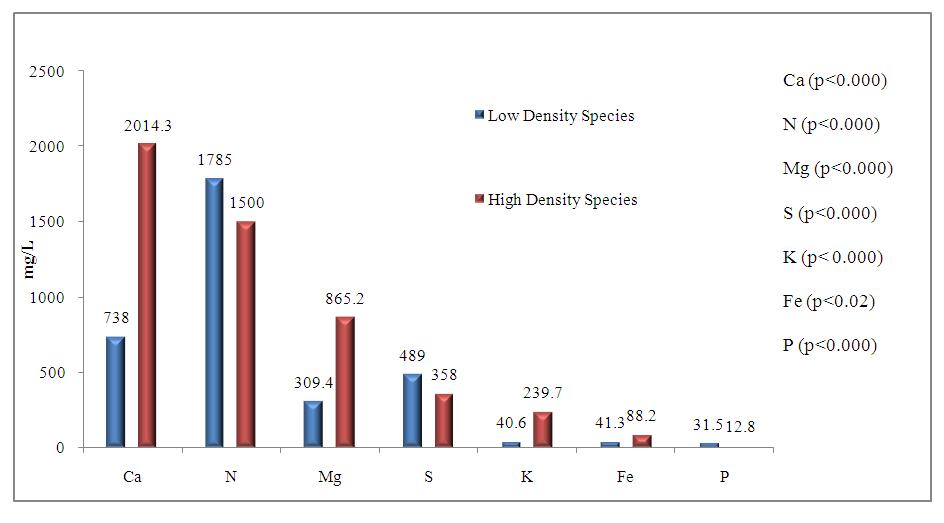

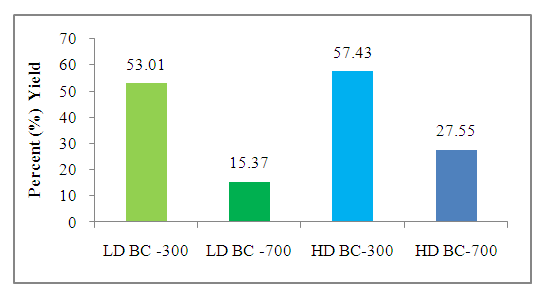

- Toxicological Assessment The two types of biomasses (low density species and high density species) and the four prototypes of biochar (LD BC- 300, LD BC-700, HD BC-300 and HD BC-700) were characterized according to requirements of Test Category B Toxicant Assessment: (As, Cd, Cr, Co, Pb, Ni, Se, Zn, B, Na and Hg) of the IBI Standard (Initiative, 2015). The standard declared that feedstock used for biochar production must not contain unacceptable levels of toxins. Quilliam et al. (2013) reported biochar derived from feedstock contaminated from copper-preservative treated wood and presence of preservative treated timber in the feedstock increased available soil copper. In this study, there was an apparent increase in Cu, Na and B in the resulting biochar relative to the concentration in the respective feedstock. This concentration of elements during pyrolysis was further noted when Zn was not detected in the feedstocks but were quantified in four prototypes of biochar. The process of pyrolysis is known to concentrate inorganic elements present in the feedstock in the resulting biochar (Ok et al., 2015). The other elements were not detected in either feedstocks or the prototypes of biochar. Therefore, it can be concluded that the two types of biomass and the four prototypes of biochar meet toxicological criteria to be qualified as safe feedstocks for biochar production and safe for soil amendment respectively.Proximate Analysis FeedstockThe proximate analysis includes the determination of moisture, volatile matter, ash and fixed carbon content. Knowledge of proximate analysis gives an insight of the thermal reactivity of the biomass and, therefore, can be useful in understanding how thermochemical conversion processes like pyrolysis will affect the biomass and properties of the resulting biochar, e.g., yield and composition (Acquah et al., 2017). Analysis of Variance (ANOVA) indicated that there is a statistically significant difference (p < 0.05) between the parameters of the proximate analysis for the two types of biomass species. The moisture contents were 13.97% and 12.03% for the low density species (LDS) and high-density species (HDS) respectively. Therefore, it may be necessary to dry this biomass before it is used for biochar production since the recommended moisture content of feedstock for pyrolysis is less than 10% (Ahmad et al., 2019; Sudagar et al., 2020). The moisture content of biomass is one of the parameter that significantly defines the energy input necessary to achieved pyrolysis temperature (Tomczyk et al., 2020). Generally, lower moisture content biomass is preferred to high moisture biomass because less heat and time will be required to achieve pyrolysis and therefore, the process is more cost effective. The low-density species had higher volatile matter (83.64%) content relative to the high-density species (78.05%). A study indicated that less thermally stable polysaccharides are responsible for the yield of volatiles (Acquah et al., 2017). Therefore, this variation can be as a result of difference in cellulose and hemicellulose content of biomass. In fact, the proportion of cellulose and hemicellulose is known to vary within the same type of biomass. For example, wood contains approximately 40–45% cellulose and hemicelluloses 15-30% (Waliszewska et al., 2019). The volatile matter content of biomass correlates with the production of bio-oil, one of the co-products of pyrolysis. Therefore, it is expected that feedstock with higher volatile matter content will promote the formation of higher quantity of bio-oil relative to the other co-products such as biochar and syngas (Di Stasi et al., 2021). In fact, the yield obtained from this study supports that the low-density species yielded lower biochar content relative to the high density species because of its higher volatile matter content (see Figure 3).This study found significantly higher fixed carbon content for high density species (20.89%) relative to low density species (16.12%). This variation in fixed carbon content in wood waste from sawmills is in agreement with findings from similar studies, such as Ogunsola et al. (2018) and Hayee (2012). Acquah et al. (2017) suggested that more recalcitrant lignin composition of biomass is responsible for this higher yield of fixed carbon. Thus, the difference in fixed carbon content in the two types of wood biomass in this study may be as a result of differences in their lignin content relative to hemicellulose and cellulose. Lignin is a type of hydrocarbon polymers (amorphous and hydrophobic) with a high molecular weight and functional groups that are aromatic in nature (Abu & Dahman, 2017). While, hemicellulose and cellulose are simple monomer with low molecular weight (Tomczyk et al., 2020). As a result, each of these chemical polymers has a different temperature range at which they decompose. Hemicelluloses are degraded at 200°C–260°C, while cellulose at 240°C–350°C and lignin at 280°C–500°C (O'Laughlin & McElligott, 2009). Another study done on producing biochar from woody feedstock showed thermochemical lignocellulose degradation begins at approximately 130°C, which is the temperature where lignin starts softening. Hemicellulose degrades at 150–350°C, cellulose at 275–350°C, and lignin at 250–500°C. Thus, hemicellulose and cellulose degrade at relatively lower pyrolysis temperatures compare to lignin (Gezahegn et al., 2019). Wang et al. (2015) stated that higher lignin biomass is known to enhance carbonization and facilitate higher biochar production rate. Therefore, during the thermochemical degradation of biomass the feedstock composition is expected to determine the quantity of pyrolysis co-products of biochar, bio-oil and syn-gas. Biomass with higher lignin content will enhance carbonization and favor the production of biochar (Shengsen Wang et al., 2015; Yadav & Jagadevan, 2019), while, hemicellulose and cellulose promotes the formation of bio-oil and syn-gas (Yadav & Jagadevan, 2019). As a result, the high-density species is expected to yield higher biochar since biomass with higher fixed carbon promotes the formation of solid products during pyrolysis. In fact, this study supports that higher fixed carbon biomass promotes the formation of greater biochar yield (see Figure 3). Thus, prior knowledge of the fixed carbon content of feedstock can be useful in predicting the yield of biochar.The ash content is the residue remaining after the biomass is completely oxidized. The main components of this residue are oxides of various metals (Di Stasi et al., 2021). In this study, the high-density species reported significantly higher ash content (1.06% dry wt) relative to low density species (0.25% dry wt). This variation in ash content is also observed in other independent studies. Gérard et al. (2019) surveyed 599 hardwood species and reported a minimum and maximum ash content of 0.02% and 5.00% wet weight. Further, Hayee (2012) reported higher ash content in hardwood species (0.8% dry weight) relative to softwood (0.3% dry weight). This variation in ash content in biomass depends on the organic and inorganic matter, which is influenced by a number of factors such as the species, sampling point and harvesting time (Zajac et al., 2018). Biomass ash content retained in biochar can enhance soil properties to a greater extent than fertilizer (Saletnik et al., 2018). Therefore, high ash content species may be the feedstock to produced biochar with higher ash content with more inorganic metals that can supply soil that is deficient in metals.Total Selected elements of Feedstock Biomass The elements N, S, K, Fe, Ca and Mg are among the list of plant macro and micro nutrients and it was on this basis they were selected as the elements for this characterization. The elemental composition of the two types of woody biomass in this study found that low density species has higher N, and S content, while the high-density species has higher content of K, Fe, Ca and Mg (see Figure 1). The higher concentration of the inorganic elements K, Fe, Ca and Mg in high density species can be attributed to the higher ash content reported in this feedstock. On the other hand, greater N and S content in low-density species maybe as a result of more proteins and amino acids in this material (Ippolito et al., 2020; O'Laughlin & McElligott, 2009). The differences in elemental composition were statistically significant for the two types of feedstocks (p < 0.05) in this study. This variation in elemental composition of woody biomass was reported in other studies (Hayee, 2012; Zajac et al., 2018), which can be influenced by a number of factors such as the species, sampling point and harvesting time (Zajac et al., 2018). Therefore, knowledge of elemental composition of biomass can provide information that can give a reasonable prediction about the elemental composition of biochar because it has been correlated with feedstock total nutrient content (Ippolito et al., 2020).

| Figure 1. Total Elements composition of the two species biomass |

|

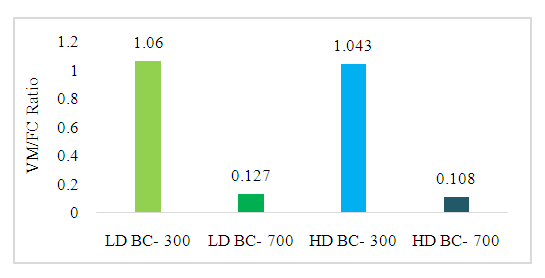

| Figure 2. Volatile Matter/ Fixed Carbon Ratio of the four Prototypes of Biochar |

|

|

|

| Figure 3. % Yield of the Four Prototypes of Biochar |

5. Conclusions

- There were statistically significant differences between the physicochemical properties of the two types of sawdust feedstock in this study. Both pyrolysis temperature and feedstock origin affect the yield of biochar. Further, it was inferred that lower temperature and higher density were predictors of higher yield. There were statistically significant differences between the physicochemical properties of biochars produced from the two types of sawdust feedstock under the two different pyrolysis temperatures specifically volatile matter, fixed carbon, ash, selected total and exchangeable elements, pH and conductivity.These findings hold significant implications for the optimization of biochar production processes. By understanding the influence of pyrolysis temperature and feedstock density on yield, biochar producers can make informed decisions to enhance biochar production efficiency. Moreover, the observed variations in biochar properties across different feedstocks and pyrolysis conditions open avenues for tailoring biochars to specific applications in agriculture, environmental remediation, or carbon sequestration.Although this study provides valuable insights, future research could look deeper into the effects of additional factors, such as heating rate and residence time on biochar yield and properties. Exploring the optimization of biochar production under varying conditions and assessing its performance in practical applications would contribute to a more comprehensive understanding of this versatile material.This study significantly advances our understanding of biochar production by exploring the roles of pyrolysis temperature and feedstock density in biochar yield and properties. The identified predictors of yield provide valuable guidance to the agro-industry, while the observed variations in biochar characteristics underscore its versatility for tailored applications. By bridging these knowledge gaps, this research contributes to the ongoing development of sustainable biochar-based solutions.

ACKNOWLEDGEMENTS

- Above all, the Almighty God receives the highest appreciation and acknowledgment for sparing life and for providing the energy, time and wisdom to complete this research. Thank you to the numerous persons who assisted in this research. Special thanks the Government Analysis Food and Drug Department (GA-FDD) and the Guyana Sugar Corporation (GUYSUCO) Central Laboratory for giving the opportunity to utilize their laboratory to complete this research in the midst of a global pandemic. Greatest appreciation to the Department of Chemistry, University of Guyana for use of the laboratory and all its equipment and reagents.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML