-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

World Environment

p-ISSN: 2163-1573 e-ISSN: 2163-1581

2014; 4(4): 180-184

doi:10.5923/j.env.20140404.04

Assessment of Olive Oil Mills Efficiency and Olive Oil Quality in the West Bank for the Years 2012/2013

Orwa Jaber Houshia1, Mohammed Abueid2, Ruba Abu Amshah2, Ramiz Obaid3, Deena Arafat2, Mohamad Riyad Qadri2, Marina Qadry2, Maazoz Jaber2, Omayya Hammad2

1Arab American University, Department of Chemsitry, Palestine

2National Agricultural Research Center, Jenin, Palestine

3Ministry of Agriculture, Ramallah, Palestine

Correspondence to: Orwa Jaber Houshia, Arab American University, Department of Chemsitry, Palestine.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

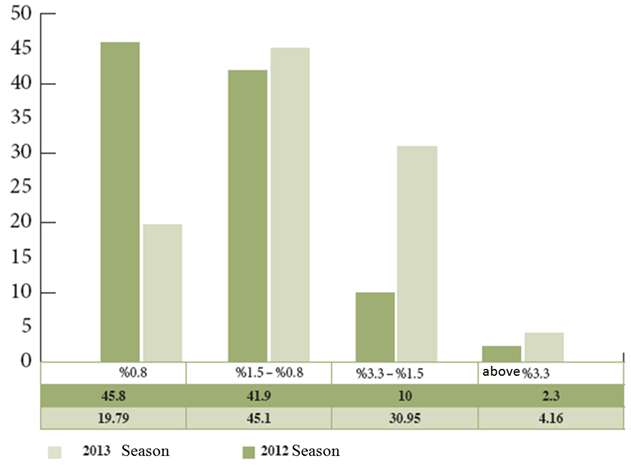

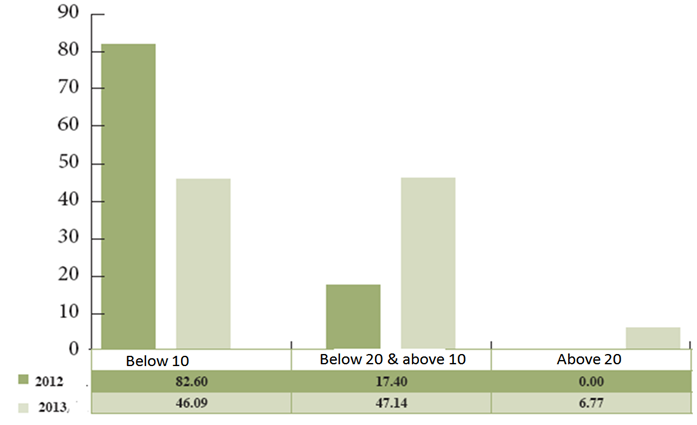

The purpose of the study was to evaluate the Olive Mills Efficiency and study Olive Oil Quality in the West Bank for the Years 2012/2013. Investigation of efficiency not only on olive growing farms but also olive oil manufacturing firms may provide valuable insights into potential improvement of productivity. Another aim was to create a Database which we proceed to develop strategies and systems for the management and organization of operation of the mills. Oil testing was carried out to study quality of oil for those seasons. The Peroxide value (PV) is relates to storage of the oil and measures chemical products that are produced through reaction with oxygen to ultimately cause rancidity. The IOC standard is < 20 mEq O2 /kg of oil for the peroxide value. The IOC acidity test standard for free fatty acids in extra virgin olive oil is a maximum of 0.8, in agreement with most of our results that ranged from 0.8- 3.3% for the acidity, and 6.77 to 46.09 for the peroxide value.

Keywords: Olive mills effeciency, Peroxide value, Olive oil acidty, Palestine

Cite this paper: Orwa Jaber Houshia, Mohammed Abueid, Ruba Abu Amshah, Ramiz Obaid, Deena Arafat, Mohamad Riyad Qadri, Marina Qadry, Maazoz Jaber, Omayya Hammad, Assessment of Olive Oil Mills Efficiency and Olive Oil Quality in the West Bank for the Years 2012/2013, World Environment, Vol. 4 No. 4, 2014, pp. 180-184. doi: 10.5923/j.env.20140404.04.

Article Outline

1. Introduction

- Olive oil is well established in the food industry. Demand continues to grow worldwide not only because of its distinct flavor, but also because of an increased awareness of its health benefits. There are some scientific evidence and health claims that consumption of olive oil reduces coronary heart diseases [1]. Olive oil is an integral part of the Palestinian economy and it plays an essential part of the Mediterranean diet. About 95% of the olives picked in the Palestinian territories is converted to olive oil, most of which is exported internationally [6-8].Because olive oil sector constitutes an important part of the Palestinian agricultural economy and is a good source of revenue for many Palestinians, it is vital to the socio-economical life of Palestinians. This sector contributes about 13% of the value of annual agricultural production. Due to this importance, and to preserve the economic value and quality standards of olive oil, the Ministry of Agriculture MoA is aiming at reducing the amount of lost oil during milling and extraction. Thus, a comprehensive study was put in place to evaluate the olive oil mills in terms it its efficacy. The olive tree cover approximately 45% of the area of agricultural land in Palestine and is considered the most widespread tree where the olive tree area takes about 80% of the cultivated land area that is planted with fruit bearing trees. According to the latest statistics released by the Ministry of Agriculture, cultivated land area of olive tree covers 900 acres (donums). The estimated number of trees in this area is about ten million trees spread out all over Palestine. The variety of most of the area planted with olives trees in Palestine can classified as either Nebali or Souri cultivar. The Nabali (baladi) occupies about 80% of the area. [2] Palestine production of olive oil is about thirty five thousand tons (35) in a good years. This production decreases to about seven thousand tons in the years of poor harvest. The average annual production of oil during the last thirty years has been estimated at 16 thousand tons. Investigation of efficiency not only on olive growing farms but also olive oil manufacturing firms may provide valuable insights into potential improvement of productivity. And to create a Database which we proceed to develop strategies and systems for the management and organization of operation of the mills. Further, to regulate each inputs and outputs of Production from the field through the mills and ending consumers, regardless whether it is for domestic or international markets. It is noteworthy that Palestinian olive oil is considered a world-class high quality oil and can be marketed at competitive international prices.Olive oil mills in the Palestinian territories has witnessed a distinct technological quantum leap and modernization during the past few years, in the pursuit of producing olive oil with ultra fine high quality specifications. The olive mills play a big role in influencing the quality and quantity. The number of modern high tech mills in Palestine has reached 299 mill, mostly of the automated modern type.Chemical tests were conducted in the laboratory of Council of the Palestine National Agricultural Research Center in order to determine the proportion of oil residue that was lost in the pomace as well as to assess the quality of the oil by analyzing each of the acidity and peroxide value. The IOC set some standards and testing procedures for extra virgin olive oil quality. The free fatty acids is the simplest test and indicative of good harvesting and handling processes. Peroxide value (PV) is an important test which growers should also carry out on every batch of their oil. This test relates to storage of the oil and measures chemical products that are produced through reaction with oxygen to ultimately cause rancidity. It is noteworthy to mention that the origin, cultivar, extraction technology, condition of ripening of the fruit, climatic conditions, and rainfall all influence biosynthesis within the fruit which can influence the composition and quality of the oil [3-5].The data within this paper will serve as a solid ground for future research and analysis in identify inappropriate practices and replace these practices with sustainable better use and improve handling of olives in Palestine. The sampling sites were from Yatta, Dura, Hebron, Salfeet, Qalqilia, Jerusalem, Tubas, Jenin, Bethlehem, Nablus and Ramallah, which represent a comprehensive depiction of Palestine olive mills.

2. Materials and Methods

2.1. Sample Collection

- Sample collection Included of all the provinces of the West Bank, which was taken by the different Directorates of Agriculture starting from 06-October-2013 until 10- December-2013. Sample collection was done by specially trained Agricultural Engineers and Extension. All technical, theoretical and practical aspects on sample collection matters were included in form for each representative sample. The laboratory distributed empty containers for samples with thermometers to take the temperature of the dough during the process of the olive grinding. Samples were dried and tested using an instrument called “Fat Extractor” to examine the proportion of oil in the olive peat (pomace). Chemical tests were conducted to evaluate the quality of oil acidity and peroxide value.

2.2. Instrument

- ANKOM XT15 Extractor, 120v: The ANKOMXT15 Extractor provides an Official Procedure for efficient and economical solvent extractions. Fat ranges from 0% to 100% have been determined using this procedure.• Official Crude Fat Procedure – AOCS Am 5-04• Totally Automatic Operation• Up to 150 Extractions per Day• Microprocessor Controlled with LCD Readout• Solvent Recovery at a rate of ~97%• Solvent Usage per Sample ~ 0.5 ml

2.3. Peroxide Value

- Quantity of those substances in the sample, expressed in terms of active oxygen, which oxidize potassium iodide under the conditions specified in this International Standard, divided by the mass of the test portion. Add 50 ml of acetic acid/isooctane solution to 10g of oil in conical flask and replace the stopper. Swirl the flask until the sample has dissolved. Using a suitable volumetric pipette, add 0.5 ml of saturated potassium iodide solution and replace the stopper. Allow the solution to react for 1 min, thoroughly shaking it at least three times during this period, then immediately add 30 ml of distilled water.Titrate the solution with sodium thiosulfate solution, adding it gradually and with constant, vigorous agitation, until the yellow iodine color has almost disappeared. Add about 0.5 ml of starch solution and continue the titration with constant agitation, especially near the endpoint, to liberate all of the iodine from the solvent layer, adding the sodium thiosulfate solution drop by drop until the blue color just disappears.

2.4. Acidity Value

- Weigh into a flask a sufficient mass of the test sample, according to the color and expected acid value. NOTE: The mass of the test portion and the concentration of the titrate should be such that the titrate does not exceed 10 ml.Heat to boiling 50 ml of the ethanol containing 0.5 ml of the phenolphthalein indicator in a second flask. Whilst the temperature of the ethanol is still over 70℃, neutralize it carefully with a solution of 0.1 mol/1 sodium or potassium hydroxide.The endpoint of the titration is reached when the addition of a single drop of alkali produces a slight but definite color change persisting for at least 15 seconds. Add the neutralized ethanol to the test portion in the first flask and mix thoroughly. Bring the contents to the boil and titrate with the sodium or potassium hydroxide solution, (depending on the expected acidity of the sample), agitating the flask contents vigorously during the titration.

3. Results and Discussion

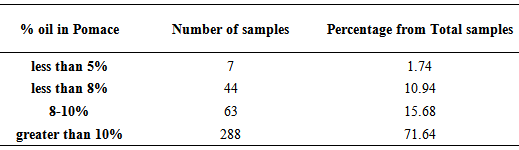

- The mechanical extraction of olive oil entails crushing the olives into a paste. The majority of the oil is released from the mesocarp of the fruit itself. The remainder is lost to the pomace. After crushing the olives into a paste, the olive paste must be mixed by stirring and then pressed, centrifuged, or percolated. Pomace (peat) and vegetable water are by-products of the olive mills. Pomace is sold to industrial factories where the residual oil is extracted using hexane or other solvents.The main specifications of dried olive pomace consists on proportion of oil in the mills that use centrifugal technology ranges between 1.8% 6%, and 38 - 60% while the percent of oil in modern mills that uses pressure –technology ranges from 4.5 to 9% and the relative humidity and 35 -, 20%.Table 1 indicates that 71.64 % of samples taken from the westbank olive mills pomace (peat) contains more than 10% of lost oil residue that is discarded with the pomace. Fllowed by 15.68 % of the samples which ranged between 8-10% of oil residue in pomace. Followed by less than 8% of oil lost in pomace was represented by 10.94% of samples. And finally less than 5% of lost oil was represented by 1.74 % of the samples.

|

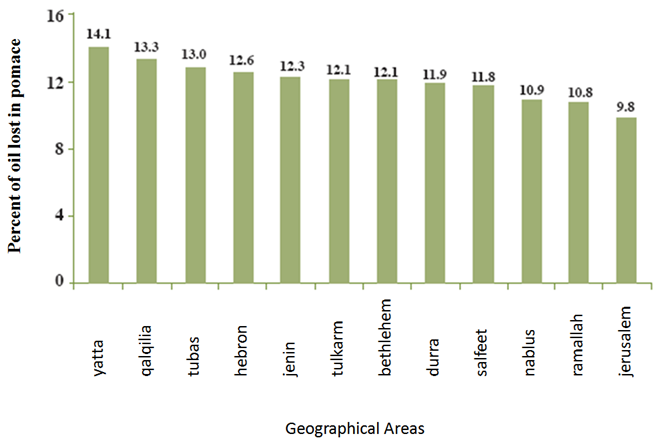

| Figure 1. Distribution of olive oil residue in pomace from westbank governorates for the 2013 season |

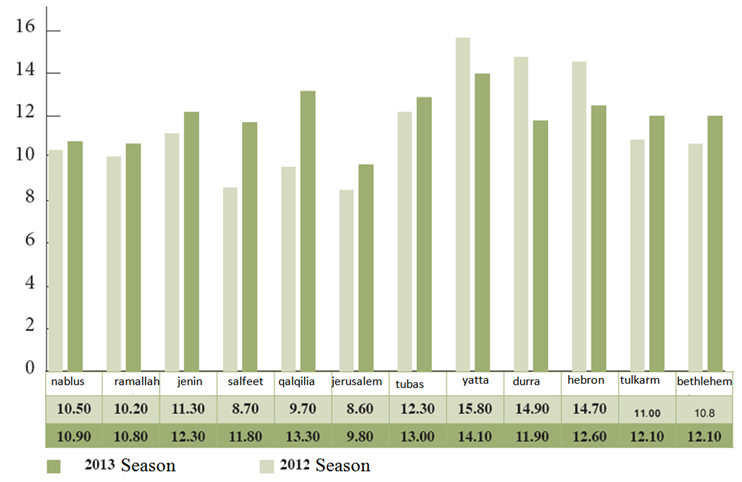

| Figure 2. Comparing the percent of lost oil in pomace from 2013 an d 2012 seasons |

| Figure 3. Percent of the acidity from the 2013 and 2012 seasons |

| Figure 4. The peroxide values for the two seasons |

4. Conclusions

- It is apparent from the data provided that there two elements that can be concluded within this project. The first one is that the inappropriate management of the mills results in olive oil being lost in the pomace, which results in a financial loss for the farmers and the country. This problem maybe circumvented by training the technicians operating these machines. The second conclusion, is that the mishandling of the olive fruits can result in the deterioration of the quality of olive oil which is also a financial loss for both the farmers and consumers. Education and capacity building and workshops in handling olive fruits may help improve the quality of olive oil. Take better measure to control the olive tree disease and encourage research in the field of olives and olive oil.

ACKNOWLEDGEMENTS

- The authors would like to thank his Excellency Eng. Waleed Assaf, the Minister of Agriculture in Palestine. Also many thanks to all those who collected samples, and those who contributed to the analysis during this project.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML