-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

World Environment

p-ISSN: 2163-1573 e-ISSN: 2163-1581

2014; 4(3): 151-160

doi:10.5923/j.env.20140403.06

On the Most Efficient Hot-water Supply Method Used in Japanese Houses

Masakazu Yamashita, Kenji Yoshida

Department of Environmental Systems Science, Doshisha University, 1-3 Miyakodani, Tatara, Kyo-tanabe, Kyoto 610-0394, Japan

Correspondence to: Masakazu Yamashita, Department of Environmental Systems Science, Doshisha University, 1-3 Miyakodani, Tatara, Kyo-tanabe, Kyoto 610-0394, Japan.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

The present study focuses on the system of hot-water supply, which consumes the largest amount of energy in the house, and includes a discussion on the most efficient hot-water supply method that takes into account economic efficiency and the environment. Electricity or gas is used to supply hot water. The electricity-based method is economically inefficient, and the gas-based method is more environmentally friendly. The use of a latent heat collection-type water heater is the most efficient hot-water supply method using gas, and it is also economically efficient. The results suggest that it is the optimal hot-water supply method for Japanese houses.

Keywords: Hot-water supply, Efficiency, Energy, Water heater

Cite this paper: Masakazu Yamashita, Kenji Yoshida, On the Most Efficient Hot-water Supply Method Used in Japanese Houses, World Environment, Vol. 4 No. 3, 2014, pp. 151-160. doi: 10.5923/j.env.20140403.06.

Article Outline

1. Introduction

- When we develop measures to protect the environment, we are almost always required to take into account economic problems. The environment had long been positioned outside of the market economy. However, currently, the environment is not only being incorporated into the market economy; its territory is also expanding in various markets [1]. We can no longer recognize and understand both environmental and economic trends at the same time unless we have accurate knowledge of environmental and economic structures and functions. The relationship between the environment and the economy should also be discussed at the household level. For example, it is necessary for us to consider carefully what should be purchased to protect the environment in a real sense: an environmentally friendly product or an ordinary product of a similar type and a different price. In addition to environmental measures at the national level, efforts to address environmental problems by households and individuals, and particularly measures to improve the home environment, are essential.The close relationship between the environment and the economy in households is represented by electricity and gas generated using energy resources. The hot-water supply requires the largest amount of energy in the house, and its energy consumption accounts for a considerable percentage of the total. Hot-water supply is related not only to the issue of energy consumption, but also to global warming, because greenhouse gas is emitted during the production of energy. In this context, in the present study, the system of hot-water supply is examined and the optimal hot-water supply method that is economically efficient and environmentally friendly is discussed.

2. Analysis of Present Conditions

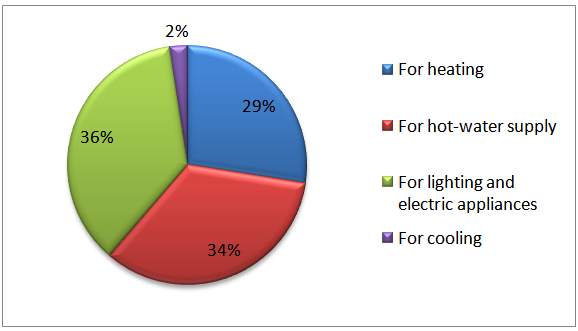

- The daily activities of Japanese people closely associated with energy consumption include the use of lights and other electrical appliances, hot water, and heating (Figure 1) [2]. As each of these three accounts for approximately 30% of the total, a significant percentage of the energy used in a house is required for the hot-water supply.

| Figure 1. Purpose-specific energy consumption in households |

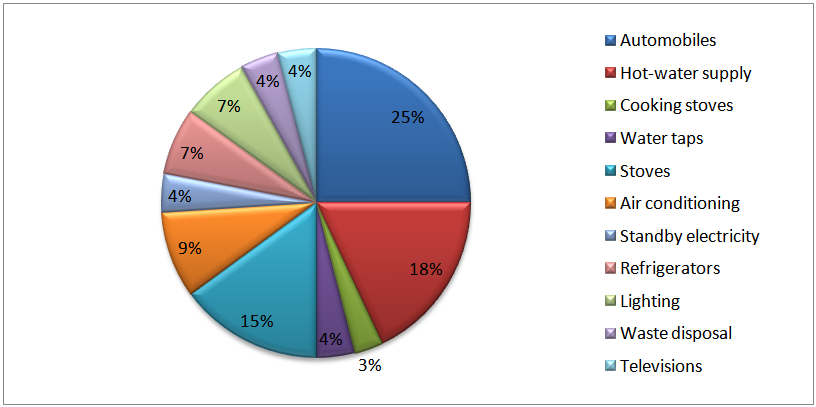

| Figure 2. Comparison of CO2 emitted from households |

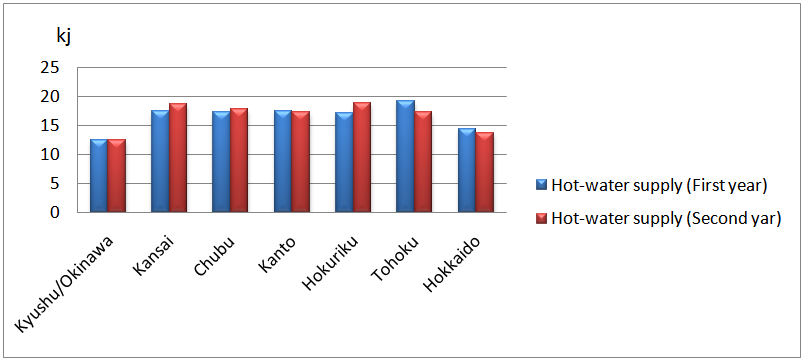

| Figure 3. Energy consumed for hot-water supply in different areas |

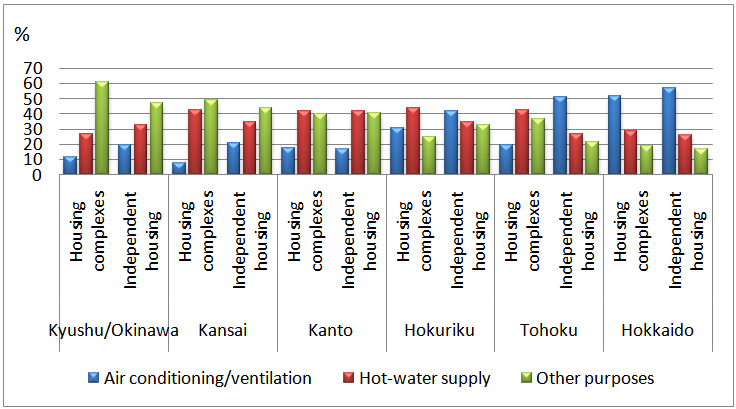

| Figure 4. Percentages of purpose-specific energy consumption |

3. An Examination of Methods for Hot-water Supply

- Usually, electricity or gas is used for the hot-water supply in households. Electricity-based hot-water supply methods include heating wire-type and natural refrigerant heat-pump-type electric water heaters, and gas-based ones include conventional gas-based, latent heat collection-type, and gas engine-type water heaters. These are discussed based on the following conditions for calculation [6]:- 1 cal≒4.2 J (calorific value to increase the temperature of 1 g of water by 1°C) - 1 kWh≒3.6 MJ≒860 kcal.

3.1. Hot-water Supply Method Using Electricity

3.1.1. Hot-water Supply Equipment Using Heating Wire

- In this method for supplying hot water, an electrical heater in the tank heats the water. The following example was examined based on data published by a distributor of hot-water supply equipment using heating wire [7]. According to the published data, the monthly costs of supplying a certain amount of hot water for utility-gas-based hot-water supply equipment and an electric water heater were 7,293 and 4,610 yen, respectively. Although the data suggest that hot water is supplied at lower costs by electric water heaters, this is due to the midnight power distribution control service: a discount service for users to save money (approximately 30% of the electricity charge during the daytime) by boiling water at night, during which time electricity rates are lower [8]. However, people who want to be eligible for this service are required to use only electricity to operate their household equipment (including cooking and hot-water supply equipment) and no gas at all. For example, Kansai Electric Power Co., Inc, allows users to choose from two types of contract for nighttime electricity services:A. Under the time period-based contract, electricity used during the daytime and nighttime is measured with a single electric power meter. Since the current is applied to water heaters throughout the day, users can warm or boil water whenever it becomes cold. The electricity fee during the daytime is 10% higher.B. The other type of contract is a nighttime electricity service dedicated to water heaters. An additional power circuit is connected to the water heater through a dedicated power meter with a timer to apply the current only at night. Since electricity is distributed to the water heater only during the nighttime, users may not be able to warm or boil water once it becomes cold.The difference in the cost of supplying hot water during the nighttime between heating wire- and utility gas-based hot-water supply equipment was only approximately 2,500 yen. The cost of supplying hot water during the daytime by the same heating wire-based hot-water supply equipment was calculated to be 15,367 yen, using the following formulas:1:3/10 = x:4,610 x = 15,367.This means that there is no point in using heating wire-based hot-water supply equipment unless a nighttime discount is available.In the comparison of the two types of hot-water supply equipment, the capacity of the tank is important. In the case of [A], the users of equipment with a small tank have to pay attention to the remaining amount of hot water because boiling water during the daytime is expensive. The electricity fee during the daytime is approximately 23 yen/kWh [9]. The present study assumed a 10% increase, and the fee was calculated to be approximately 25 yen/kWh. Therefore, if the cost difference between Methods A and B is approximately 2,500 yen, and when an amount of heat of 100 kWh or higher is required to boil water, it is more inexpensive to use utility gas. What amount of water can be heated using 100 kWh? The calorific value required to heat 370 L of water (standard tank capacity) from 15 to 85°C was calculated using the following formula [10]:370 × (85 - 15) = 25,900 kcal.A tank full of water can be heated approximately 3.3 times according to the following formula:100 kWh≒360 MJ≒86,000 kcal.Since the mean daily use of hot water is 600 L [11], the daily consumption of hot water may often exceed the capacity of the tank. Heating only the shortfall is economically inefficient, and the cost may be higher than that required for supplying hot water using utility gas. The service described in [B] does not allow users to boil water once the tank becomes empty, and this is very inconvenient. However, if the hot water in the tank is not used up, the cost in the case of [B] will be lower than the cost of supplying hot water using utility gas, from an economic viewpoint.The following is a calculation of greenhouse gas or CO2 emissions to assess the effects of hot-water supply equipment on the environment. Since utility gas-based hot-water supply equipment consumes 50 m3 of gas and the amount of CO2 emissions per 1 m3 is 2.29 kg [12], the total amount of CO2 emissions is calculated using the following formula:50 × 2.29 = 114.5 kg.Since an electric water heater consumes 540 kWh of electricity and the amount of CO2 emissions per 1 kWh is 0.358 kg [13], the total amount of CO2 emissions is calculated using the following formula:540 × 0.358 kg = 193.3 kg.The amount of CO2 emitted from an electric water heater was 1.7 times as large as that emitted from gas-based equipment, which suggests that the introduction of an electric water heater increases the environmental load. The economic efficiency of heating wire-type hot-water equipment is lower and its environmental load is greater than those of a utility gas-based one. Therefore, the use of heating wire-type hot-water equipment is not the optimal method for hot-water supply.

3.1.2. Natural Refrigerant Heat-pump-type Electric Water Heaters

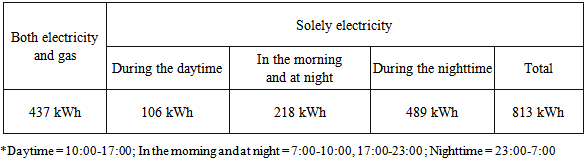

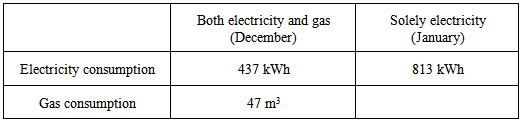

- This paragraph describes the heat-pump system used for natural refrigerant electric hot-water supply equipment. The heat-pump system compresses and expands a refrigerant, a substance that carries heat, to change its temperature, using exhaust heat from the atmosphere, underground water, households, and factories as a heat source. The system incorporates heat from the atmosphere to warm CO2, a refrigerant, and conveys it to a compressor. The CO2 is then compressed (at this point, its temperature rises to approximately 100 to 120°C) and transferred to a heat exchanger to convey its heat to water. Following this, the CO2 is sent to an extension valve and expanded so that it can incorporate heat again. Finally, the CO2 is cooled, transferred to another heat exchanger for air, and circulated. Electricity is primarily used by the compressor. The natural refrigerant heat-pump system consumes a small amount of electricity to generate a significant amount of thermal energy. This system installed in a house can supply hot water without using gas, and it has been promoted as part of the electricity-for- all-household-equipment system. Refrigerant heat-pump systems for households, which utilize the atmosphere as a heat source, increase its temperature by compressing it for heating and hot-water supply. The system has adopted CO2, as a natural refrigerant, instead of chlorofluorocarbons, which severely affect the ozone layer, although the latter are the most effective refrigerant. The ozone depletion potential of natural refrigerant hot-water supply equipment is zero, and its global warming potential is approximately 1/1,700 of equipment using chlorofluorocarbons as a refrigerant. As its most noticeable feature, the system does not include a combustion unit. According to the advertisement of a natural refrigerant hot-water supply system, when the input of electricity is 1, the amount of heat acquired from the atmosphere is 2, and the amount of energy generated for hot-water supply is 3 [14].The usability of natural refrigerant heat-pump-type electric hot-water supply equipment was examined using actual data. Table 1 represents the monthly power consumption by a household in Tokyo, consisting of a couple and two children (elementary students or younger), that has shifted from a combination of gas and electricity to the sole use of electricity to operate their household equipment. They are considered to be a typical Japanese family. As hot-water supply equipment is primarily used in winter, data on the electricity consumption in winter were examined.

|

|

3.1.3. Heating Equipment

- Since the users of natural refrigerant heat-pump-type electric water heaters are not allowed to subscribe to utility gas, IH cooking heaters are used as heating equipment. The monthly economic efficiencies of an IH cooking heater and utility gas stove as well as the levels of their influences on the environment were compared. IH (induction heating), which is based on the principle of electromagnetic induction, generates Joule heat and applies it to the bottom of the pan placed on the heater to cook food. The cost of supplying hot water under this condition was calculated based on the monthly uses of electricity and gas in a typical household.The monthly usage fee of an IH cooling heater was calculated with the monthly electricity consumption set at 55 kWh. As the electricity fee was 23 yen/kWh [13], the following result was obtained:55 × 23 = 1,265 yen/month.When the gas consumption was 8 m3 and the fee of utility gas was 153 yen/m3 [12], the monthly usage fee of the utility gas cooking heater was as follows:8 × 153 = 1,224 yen/month.The difference between these is minimal, which means that there is no significant difference in the economic efficiency of heating equipment using gas and electricity.The environmental effects are also discussed. The heat efficiencies of IH and utility gas cooking heaters are 90 and 50%, respectively [21]. However, the energy efficiency of electricity generation is low: approximately 65% of electricity is lost from the time when it is generated to its transmission to each house [19]. Therefore, the thermal efficiency of electricity is reduced to approximately 32% by the time it is used for electric heating equipment (0.35 × 0.9 = 0.315). The temperature is also important in terms of cooking. A form of energy is only required to provide heat of approximately 300°C to serve as a heat source. As electricity is a flexible type of energy, substances can be heated to up to several thousand degrees using the energy obtained by electric discharge. Therefore, the use of electricity, energy of high quality, for boiling water and cooking is very wasteful because water and food only need to be heated to relatively low temperatures. Although the study results suggest little difference in the economic efficiency of the two methods, utility gas cooking heaters should be adopted, taking into account their environmental and other factors.

3.2. Hot-water Supply Using Utility Gas

3.2.1. Conventional Gas-based Water Heaters

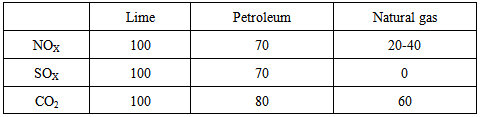

- Conventional water heaters use gas to supply hot water. The burners are heated to approximately 1,500°C to boil water. Air of approximately 200°C is exhausted. The heat efficiency is approximately 80% [22].The energy efficiency of electricity generation in power plants is low, as described in the preceding paragraphs. This study thus also examined the energy efficiency of utility gas. Utility gas is primarily imported into Japan from abroad. Its energy efficiency will hardly be reduced during its supply to each house, and instead depends on the heat efficiency of the equipment used by each household. This suggests that the economic efficiency of utility gas is high. Table 3 shows a comparison of the environmental load generated during the combustion of coal, petroleum, and natural gas, in order to examine their environmental effects.

|

3.2.2. Latent Heat Collection-type Water Heaters

- This method is considered to be a revision of a conventional heat pump-type water heater with increased energy efficiency. The burner is heated to approximately 1,500°C, as in conventional water heaters. Latent heat collection-type water heaters first distribute water to a secondary heat exchanger, which preliminarily heats the water using heat discharged from the primary heat exchanger (approximately 200°C). The water is further heated by the primary heat exchanger to provide hot water. The heater uses only a small amount of gas to provide hot water because it utilizes exhaust heat effectively. The heat efficiency is approximately 90% [25]. As the equipment is an instantaneous water heater without a storage tank, it minimizes the loss of energy. There is a device for drain neutralization, or a secondary heat exchanger, in the device. The vapor removed of heat is turned into acid drainage (condensed water), which is processed by the neutralizing equipment and discharged. As conventional gas-based water heaters were revised into latent heat collection-type ones to increase their thermal efficiency, the energy-saving effect of the latter is significantly higher, which is also supported in an interim report issued by the Subcommittee for Goal-achievement Scenarios, Global Environment Committee, Central Environment Council, established by the Ministry of the Environment [26].

3.2.3. Gas Engine-type Water Heaters

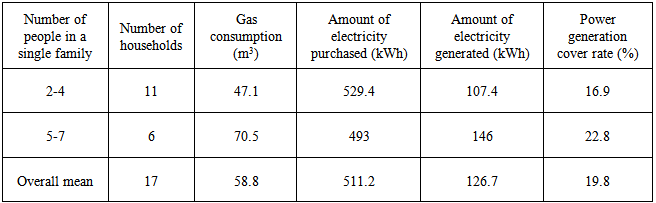

- In general, gas engine-type water heaters are included in the gas co-generation system. Co-generation is a new energy supply system designed to increase the total energy efficiency. It acquires power, heat, and cold energies using exhaust heat discharged from internal- and external-combustion engines. A gas engine-type water heater for households generates electricity, using utility gas as fuel, and boils water by utilizing exhaust heat. Most gas engine-type water heaters are equipped with conventional 4-stroke engines to operate the generator. Although gas engine-type water heaters targeted for households have been available since around the spring of 2003, they are still not popular. Experiments were conducted to establish the energy-saving effect of the gas co-generation system. However, they did not involve large numbers of households as the subjects of study, and failed to evaluate the market as a whole. Furthermore, surplus electricity cannot be sold to electric power companies. Only the users of gas engine-type water heaters are eligible for a gas-fee discount, which is considered to be a measure to compete with electric power companies. Table 4 shows monthly mean data regarding gas engine-type water heaters.

|

3.2.4. Comparison of Hot-water Supply Equipment Using Utility Gas

- It has not been long since the first hot-water supply equipment with a gas-based engine was released, so gas utility companies do not have a sufficient volume of data on its use in actual households.<Requirements to qualify as a typical household>- Single-family housing- Four family members- Floor area of 150 m2- The trial calculation is based on the annual amount of load generated by hot-water supply, not monthly data. (The amount of hot water used is the largest in winter, at which time the load generated by hot-water supply increases.)The following are the annual uses of gas when each of the above-mentioned types of hot-water supply equipment was used, based on a trial calculation by Tokyo Gas Co., Ltd. [29]:- Conventional gas-based hot-water supply equipment: 988 m3- Latent heat collection-type hot-water supply equipment: 873 m3- Gas engine-type hot-water supply equipment: 1,326 m3.The annual use of gas was the smallest when latent heat collection-type hot-water supply equipment was used. Although a sufficient volume of data on the actual use of gas engine-type hot-water supply equipment by households is not available, its annual use was approximately 1.5 times as large as the volume of gas consumed by gas engine-type hot-water supply equipment. If the amount of gas is calculated based on a sufficient volume of data on the actual use of equipment, the figure may be larger.The gas fee was 153 yen/m3, as stated in the preceding paragraphs [17]. Since the gas fee is discounted by ca. 5% if latent heat collection-type equipment has been introduced [30], regardless of the gas consumption, the fee was calculated to be 145 yen/m3. When the gas fee was discounted by introducing gas engine-type hot-water supply equipment (the total use of 50 m3 or more), the fee was 79 yen/m3 [31]. The annual costs of operating each type of equipment were as follows.- Conventional gas-based water heaters988 m3 × 153 yen/m3 = 151,164 yen/year- Latent heat collection-type water heaters873 m3 × 145 yen/m3 = 126,585 yen/year- Gas engine-type water heaters1,326 m3 × 79 yen/m3 = 104,754 yen/yearOn the basis of these data, the time required to compensate for their introduction costs was discussed. The costs of introducing each type of gas-based water heater were as follows: The introduction costs for conventional gas water heaters, latent heat collection-type, and gas engine-type hot-water supply equipment were approximately 320,000, 380,000, and 870,000 yen, respectively [32].<Comparison of conventional and gas engine-type water heaters>The cost of heating water using a gas engine-type water heater is lower:151,164 - 104,754 = 46,410 yen.The cost of adopting a gas engine-type water heater was approximately 550,000 yen higher than the cost of introducing a conventional gas-based one. When the time (number of years) is represented by x, the following formulas can be developed:46,410 x>550,000 x>11.9.If gas engine-type water heaters are used for twelve years or longer, the cost will be lower than that of conventional gas water heaters.<Comparison of latent heat collection-type and gas engine-type water heaters>The cost of heating water using a gas engine-type water heater is lower:126,585 - 104,754 = 21,831 yen.The cost of adopting a gas engine-type water heater was approximately 490,000 yen higher than the cost of introducing a latent heat collection-type one. When the time (number of years) is represented by y, the following formulas can be developed:21,831y>490,000 y>22.4.If gas engine-type water heaters are used for 22.5 years or longer, the cost will be lower than that of conventional gas water heaters.<Comparison of conventional and latent heat collection-type water heaters>The cost of heating water using a latent heat collection-type water heater is lower:151,164 - 126,595 = 24,579 yen.The cost of adopting a latent heat collection-type water heater was approximately 600,000 yen higher than the cost of introducing a conventional water heater. When the time (number of years) is represented by z, the following formulas can be developed:24,579z>60,000 z>2.4.If latent heat collection-type water heaters are used for 2.5 years or longer, the cost will be lower than that of conventional gas water heaters.As gas engine-type water heaters for households were introduced only recently, accurate data on the length of time for which they can be used have not yet been determined. However, the period stated in brochures and advertisements is ten years [33]. When the period is set to ten years, the economic efficiencies of conventional gas and latent heat collection-type water heaters are higher, as described in the preceding paragraphs. Furthermore, the economic efficiency of a latent heat collection-type water heater is higher than that of a conventional gas water heater when it is used for 2.5 years or longer. Therefore, if the length of time a gas water heater can be used is ten years, the cost of supplying hot water can be compensated for by using a latent heat collection-type water heater.

4. Conclusions

- Hot-water supply methods using electricity and gas are available. Since the electricity-based method is economically inefficient, the gas-based one is recommended from an environmental perspective. The study results suggest that latent heat collection-type hot-water supply equipment is most suitable for Japanese households because it is the most efficient of all gas-based hot-water supply methods and its economic efficiency is high.At present, both gas- and electricity-based hot-water supply methods primarily focus on economic efficiency, and more environmentally friendly and efficient methods should be developed. Price competition between gas and electric utilities is severe. As the number of users of nighttime discount services increases, the demand for electricity increases. Most of the electricity used at night is supplied by nuclear power generation and the rest is supplied by thermal power generation. Therefore, the demand for nuclear power generation is very likely to increase. Although natural gas is environmentally friendly, its use in large quantities has adverse effects on the environment. It is essential to review our lifestyles to reduce the total consumption of energy as much as possible.Furthermore, the above-mentioned equipment is almost always promoted with catchwords such as "environmentally friendly", which can convince consumers. However, consumers should do more than pursue economic efficiency. They are required to consider a long-term perspective and determine what is actually environmentally friendly.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML