-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

World Environment

p-ISSN: 2163-1573 e-ISSN: 2163-1581

2011; 1(1): 1-5

doi: 10.5923/j.env.20110101.01

Flyrocks – Detection and Mitigation at Construction Site in Blasting Operation

A. K. Mishra , M.Rout

Department of Mining Engineering, Indian School of Mines, Dhanbad

Correspondence to: A. K. Mishra , Department of Mining Engineering, Indian School of Mines, Dhanbad.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Construction and mining industry spends heavy coins on blasting technology, explosives and their safe detonation, from India’s perspective safe blasting holds even more important stand. In India, around 90% of production comes from surface mines. In any surface mine, blasting is a crucial operation. Explosives in large quantities has been used for fragmentation of rock in surface mines but only a part of the explosive energy has been used in doing the useful work, the rest has been consumed toward unwanted work such as ground vibration, fly rocks, noise and air blast. These blasting practices provide quick, efficient and cheap over-burden removal compared to other processes. However, they are major sources of mine related injuries and accidents. Usually blasting related injuries are related to fly rocks, lack of blast area security, premature blast and misfire. Out of these, fly rocks and lack of security accounts for 68% of total injuries incurred by blasting practices. The blasting is required for fragmentation and displacement of the broken rock. Fragmented rock is not expected to travel beyond the limit of blast area or the desired throw. However, sometimes they do. These rocks travelling beyond blast area or the throw due to force of explosion is known as fly rock. As fly rock is a critical issue in mining and construction industry, hence it becomes more so important to learn the causes for generation of flyrock and the mitigation measures. This paper deals with causes of fly rock, hazards associated with flyrock and precautions to be taken to control them with the help of a case study at a construction site. The Flyrock accident can be averted by sticking to basic principles of primary as well as secondary blasting. The shock tube initiation system may be preferred over detonating cord. Further, supervision of blast hole charging should get high order preference and care.

Keywords: Flyrock, Blasting Hazard, Surface Blasting, Construction Blasting

Cite this paper: A. K. Mishra , M.Rout , "Flyrocks – Detection and Mitigation at Construction Site in Blasting Operation", World Environment, Vol. 1 No. 1, 2011, pp. 1-5. doi: 10.5923/j.env.20110101.01.

Article Outline

1. Introduction

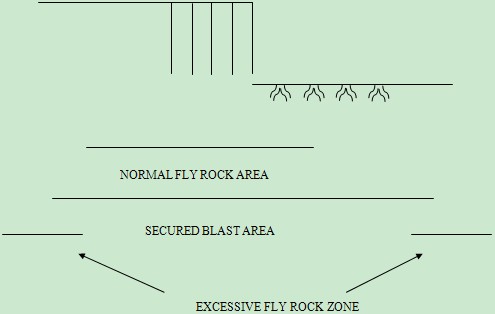

- In any surface mines, blasting operation plays a vital role. Commensurate with the increasing production from surface mines; the explosive demand is also on the rise. The explosives demand by the mining sector has risen from 153 thousand tonnes in 1989-90 to 450 thousand tonnes in 2010, which consumes around 80% of total explosives produced in the country. On the surface mine benches, when any blasting activities are carried out, rock gets fragmented in such a way that the fragmented material is moved forward to make easier mucking of the fragmented mass with reduced cost (Little, 2007). During such blasting process, unexpectedly some stone can get torn and travel to very large distances in addition to this desirable displacement of rock fragments, which is termed as ‘fly rock’. This unanticipated fly rock is hazardous to men and machineries which are employed in the mine and also to the surrounding environment, therefore, the blasting engineer should take appropriate measures to control them on the field, (Lundborg, et al 1975).This paper discusses the causes and control of fly rock in detailed manner. In general, there are two kind of movements associated with bench blasting in open cast mines. Initially, there is forward movement of entire rock mass in the horizontal direction which depends on specific charge and secondly on fly rock (Bhandari, 1984), Mishra and Gupta, (2002) and (Bajpayee et. al., 2004). Fly rock is a rock or stone that is propelled beyond the blast area by the force of explosion. Generally our blasts are expected to generate some amount of fly rock but it is the distance of travel which makes huge difference on its impact on surrounding environment.BLAST SITEA study of blasting accidents has revealed that more than 40% of fatal and 20% of serious accidents resulting from blasting occur due to fly rock, Mishra, (2003).Each mining operation has a normal fly rock range that can be evaluated, based on blasting experience, available mathematics and software, the blasting area radius is established as some distance greater than the normal. There are certain mitigation measures discussed to control this abnormal distance travel of flyrock.Most of flyrocks fall in the region that forms a semi-circle in front of the face, Ludwiczak, (1985). These flyrock impacts cause craters or blownouts on the surface of bench. The direction of fly is difficult to predict and depends on local conditions and blasting parameters.

| Figure 1. The excessive fly rock zone in surface blasting |

2. Calculation for Normal Fly Rock Zone

- 1. Calculation of throw distance and initial velocity of rock fragments can be done with the help of few empirical formulae derived for granite blast, Raina, et al (2007).However, these formulae hold good for granite only. Hence a more general form is still to be derived.Also, there is a probability that some flyrock will be thrown a longer distance.2. Gurney developed a model to describe the expansion of a metal cylinder driven by the detonation of explosive. The model closely predicts the initial vel. of the fragment produced by break-up of cylinderHowever, determining the initial velocity of fragment throw and maximum range of fly rock was of no use in solving our problems which are:a) Demarcating risk zone.b) Defining blast area.c) Calculation of risk analytical method (probabilistic approach).

3. Calculation of Risk

- With the advent of high speed digital video camera we can find the ejection angle of fly rock with initial velocity of fly rock ejection. The computer code can find the probable distance of travel and the point of strike at ground. This enables to find the cause and distance travelled by fly rock which can be used to find the risk associated with the blasting at studied mine site.

3.1. Causes of Flyrock

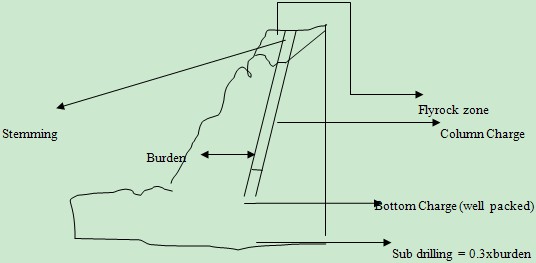

- Fly rock in open pit mine blasting usually means that it is unexpected projection of rock mass from blasting beyond blast area. Blast area is an area in which shock wave, flying material or gases from an explosive may cause injury to person. There are numerous factors which determine the blast area:Geology or material to be blasted Blast patternBurden, depth, diameter and angle of hole.Blasting experience of mining personnel.Delay system, powder factor and pounds per delay.Type and amount of explosive material.Type and amount of stemming.Generally fly rocks are caused due to mis-match of explosive energy with the geo-mechanical strength of the rock mass surrounding the explosive charge.Factors responsible for such mis-match are discussed below:A. Burden: An insufficient burden is a primary cause of flyrock (Figure 2) from a high wall face. High wall faces are irregular and therefore do not provide uniform burden form each point of the loaded borehole. Wherever, there will be weak points in the high wall, high pressure gases will try to vent out from such points and pose threat. Blasters need to visually examine and profile high wall face and search for zones of weakness, back break, concavity, unusual jointing and overhang.Problems related to burden causing flyrock:1. Too short a distance to the bench slope wastes energy.2. Too great a burden distance causes improper fracturing of rock, creating oversize boulders and potential of Flyrock for next round.3. Due to irregularity of bench slope, energy of blast pos4. es hazard at the weakest point of bench.Any deviation while drilling reduces or increases burden.

| Figure 2. Typical blasting hole in surface mining |

4. Flyrock Accident Occurred at a Construction Site

4.1. Background

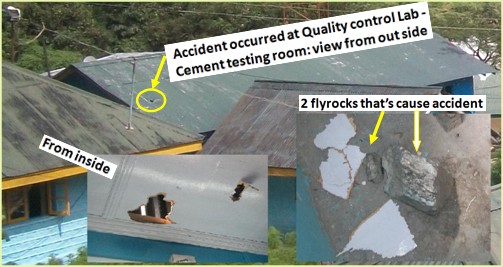

- On September 22nd 2010, at 17hr 10minute an incident occurred at working place of Quality Control lab-Cement testing room near the dam site. The boulder formed at the blasting site of power intake of concrete face rock fill dam (CFRD) which was at a distance of 200m towards north from the face of dam. The size of the boulder was biotite-gniess rock type with dimensions of 3m, 1.5m and 1.6m in respect of length, breadth and height (Figure 3). For the secondary blasting, the boulder was drilled with two holes of 45mm diameter with a spacing of 0.6m and depth of 1.5m. The explosive cartridge of 40mm (390gm/cart.) and 300mm length were used with a detonating cord of 10g/m. After the charging of 1560gm explosive per single hole 0.3m was left for stemming. When the blasting occurred a huge sound was heard and two flyrocks ejected from the boulder which covered a distance of 550m from the blasting site to the Quality control laboratory (Figure 5). Two persons were working in that testing laboratory where the two flyrocks punctured in the iron sheet roof as well as the underneath card board. Fortunately the two fly rocks fell 3m apart from the working personnel in that quality control laboratory. The location and effect of flyrock are shown in underneath pictures.

4.2. Causes of Flyrock Generation

- On investigation of the charging practice and other details, it was observed thatThe initiation system was detonating cord, which was used. It is a destructive type of initiative system which might have disturbed the stemming material and would have caused sudden release of detonation gases through the collar of the hole.The burden from one of the free face (edge) was too less which might have caused the excessive flyrock generation.Explosive charge was more than optimum in one of the hole.The blasting crew was not trained and did not have enough knowledge about the consequence of secondary blast.

| Figure 3. The boulder which was blasted |

| Figure 4. Photograph showing the place after boulder blasting |

4.3. How Could Have We Averted It?

- Probably it was sheer luck which saved two of the persons who were working in the laboratory. If this would have fallen on them, consequences could have been severe.After the investigation it revealed that if following measures would have been taken then the accident might have be-en averted.1. Shock tube initiation system would have been used instead of detonating cord.2. The blasting in charger should have taken personal care to supervise the charging operation.Training of blasting crew would have been done and an internal certification procedure would have averted the situation.

| Figure 5. Distance covered by the flyrock |

| Figure 6. Effect of flyrock to the structures |

5. Conclusions

- Flyrock can occur due to various reasons as discussed in the paper. Mainly fatal accidents have occurred due to fly rock in mines and at construction sites. Even a small mistake can be disastrous for the operating firm engaged in excavation job. The basic fundamentals of primary as well as secondary blasting should always bestick to avoid any unwanted incidence. Safety first should not only be communicated and discussed but should also be followed religiously at work place. Shock tube initiating system should be preferred over detonating cord. Supervision of charging should be done carefully and the blast design should be followed meticulously. Training and refreshment training should be organized on periodic basis to avert any accident at work site.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML