Temitope Adefarati1, Ayodele Sunday Oluwole1, Mufutau Adewolu Sanusi2

1Department of Electrical/Electronic Engineering, Federal University, Oye Ekiti, 370282, Nigeria

2Department of Electrical/Electronic Engineering,Federal ploytechnic Ede Osun State Nigeria

Correspondence to: Temitope Adefarati, Department of Electrical/Electronic Engineering, Federal University, Oye Ekiti, 370282, Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

The production cost of electricity is a very important index in national development. Electricity tariff depends on the fuel cost which carries the highest percentage of the total operation cost in any power plant. In order to keep electricity tariff as low as possible, fuel cost which carries the highest percentage of the total operating cost has to be minimized. Economic operation of the power plants can be achieved through economic load dispatch and unit commitment. Lagrange relaxation is one of the best solutions in solving economic load dispatch problem because it is more efficient and easier than other methods. This approach has been implemented to minimize the fuel cost of generating electricity while taking into account some technical constraints.

Keywords:

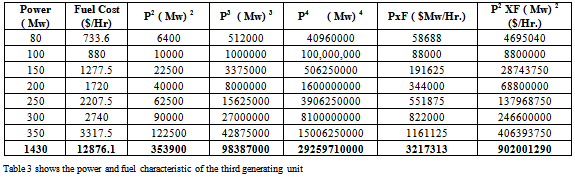

Economic Efficiency, Economic Load Dispatch, Incremental Cost

Cite this paper: Temitope Adefarati, Ayodele Sunday Oluwole, Mufutau Adewolu Sanusi, Computational Solution to Economic Operation of Power Plants, Electrical and Electronic Engineering, Vol. 3 No. 6, 2013, pp. 139-148. doi: 10.5923/j.eee.20130306.01.

1. Introduction

The optimum economic operation of electric powersystem has occupied an important position in the electric power industry. With recent power deregulation all over the world, it has become necessary for power generating utilities to run their power plants with minimum cost while satisfying their customers load demand (Peak and Base load). In order to achieve this, all the generating units in any power plant must be loaded in such a way that optimum economic efficiency can be achieved[2]. The purpose of economic operation of any power plant is to reduce the fuel cost which carries the highest percentage of the operating cost while running the plant[1][2]. The minimum fuel cost can only be achieved by applying economic load dispatch and unit commitment in any interconnected power system. Hence, Economic load dispatch is a powerful and useful tool to assess optimum operation as well as the financial and electrical performance of a power plant.

2. Economic Operation of Power Systems

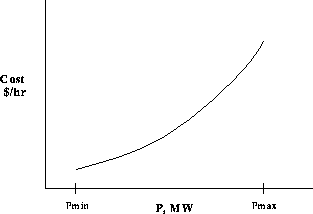

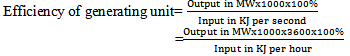

Economical production of electricity is the most important factor in the power system. In any combined power plants, all the generating units should be loaded in such a way that optimum efficiency can be achieved. The purpose of economic operation is to reduce the fuel cost of the operation of the power system. The optimum operation of a power plant can only be achieved by economic load scheduling of different units in the power plants or different power plants in the power system. Economic load scheduling is the determination of the generating output of different units in a power plant in such way to minimize the total fuel cost and at the same time meet the total power demand[2],[7]. The economic load division between different generating units can only be computed if the operating cost expressed in terms of power output If P stands for the power output in megawatts (MW) and C be the fuel cost, then Fig.1 shows a typical input and output characteristic curve of a power plant.

If P stands for the power output in megawatts (MW) and C be the fuel cost, then Fig.1 shows a typical input and output characteristic curve of a power plant. | Figure 1. Typical input/output Characteristic curve for a single unit in a power plant |

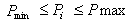

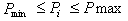

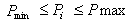

The Pmax is limited by thermal consideration and a given power unit cannot produce more power than it is designed for. The Pmin is limited because of the stability limit of the machine. If the power output of any generating unit for optimum operation of the system is less than a specified value Pmin, the unit is not put on the bus bar because it is not possible to generate that low value of power from that unit[7],[8]. Hence the generating Power Pi cannot be outside the range stated by the inequality, i.e.

2.1. Operational Cost in a Power Plant

The main economic factor in the power system operation is the cost of generating real power. In any power system this cost has two components[1].1. The fixed cost being determined by the capital investment, interest charged on the money borrowed, tax paid, labour charge, salary given to staff and other expenses that continue irrespective of the load on the power[1].2. The variable cost is a function of loading on generating units, losses, daily load requirement and purchase or sale of power[1].The economic operation of an electrical power can be achieved by minimizing the variable factor only while the personnel in charge of the plant operation have little control over the fixed costs[1].

2.2. The Objectives of the Research

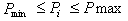

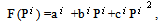

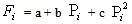

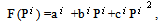

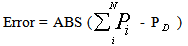

The objectives of the research are as follows: 1. To formulate a mathematical model to minimize the total fuel cost of producing electrical power in a power plant within a stipulated time interval. The cost of each generating unit in a power plant is represented by the quadratic equation of the second order. The objective function of a power plant is the algebraic sum of the quadratic fuel cost of eachgenerating unit in a power plant.[6],[12]. The objective function of each generating unit can be expressed as  Where ai, bi and ci are the cost coefficients of generating unit at bus i[6][12].2. To develop the best approach that will help all the power utility companies to solve the problem of economic load dispatch in an interconnected power system.3. To estimate the output power and fuel consumption of each generating unit in a power plant while meeting the load demands at a minimum fuel cost.4. To design a computer application program to solve the problem of economic dispatch problem in anyinterconnected power system. 5. To deploy all the available resources for power generation such as natural gas, water, diesel, uranium, coal and petrol more efficiently and thus handle peak and base loads more efficiently and reliably with economic load dispatch.

Where ai, bi and ci are the cost coefficients of generating unit at bus i[6][12].2. To develop the best approach that will help all the power utility companies to solve the problem of economic load dispatch in an interconnected power system.3. To estimate the output power and fuel consumption of each generating unit in a power plant while meeting the load demands at a minimum fuel cost.4. To design a computer application program to solve the problem of economic dispatch problem in anyinterconnected power system. 5. To deploy all the available resources for power generation such as natural gas, water, diesel, uranium, coal and petrol more efficiently and thus handle peak and base loads more efficiently and reliably with economic load dispatch.

2.3. Economic Load Dispatch

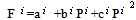

The Economic Load Dispatch is a process of allocating demand loads to different generating units in a power plant at a minimum fuel cost while meeting the technical constraints. It is formulated as an optimization process of minimizing the total fuel cost of all the committed generating units in a power plant while meeting the load demands and technical constraints[3],[7]. | (1) |

The fuel cost function of a generating unit is represented by a quadratic equation of the second order as shown in equation.1 Where  and

and  are constants of

are constants of  generating unit.

generating unit.

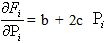

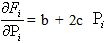

2.4. Incremental Cost

Incremental cost can be determined by taking the derivative of the equation 1.0 | (2) |

| (3) |

| (4) |

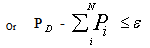

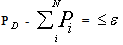

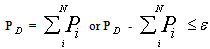

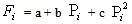

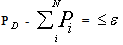

Subject to | (5) |

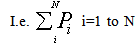

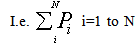

Sum up the entire Pi of the power system | (6) |

| (7) |

| (8) |

Where  . If conditions in equation (5.0) are met, Then Sum up all the Pi(s)

. If conditions in equation (5.0) are met, Then Sum up all the Pi(s)  | (9) |

| (10) |

| (11) |

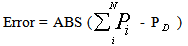

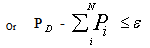

If convergence is not achieved then modifies λ and recompute  , the process is continued until

, the process is continued until  is less than a specified accuracy or

is less than a specified accuracy or If convergence is achieved, then compute the following,1.

If convergence is achieved, then compute the following,1.  2.

2.  for each unit

for each unit

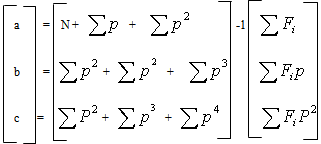

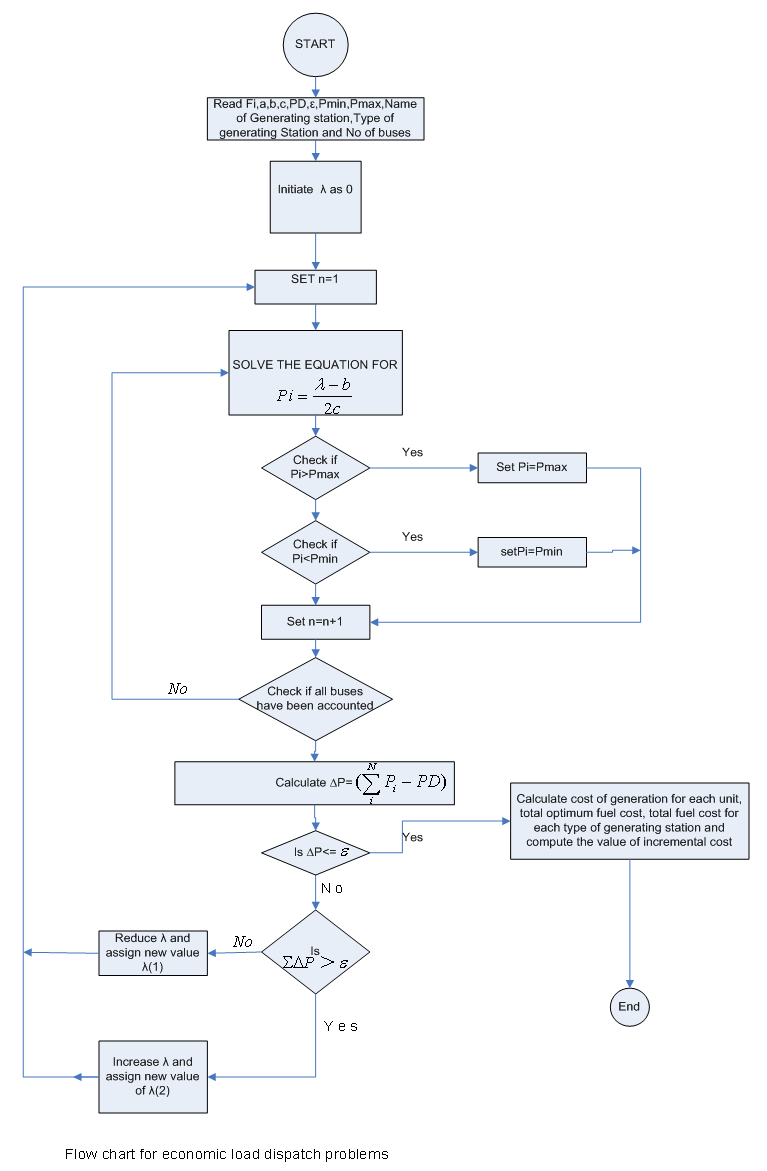

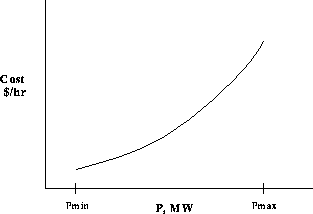

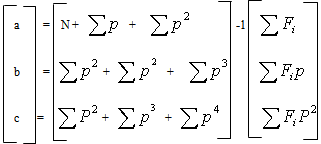

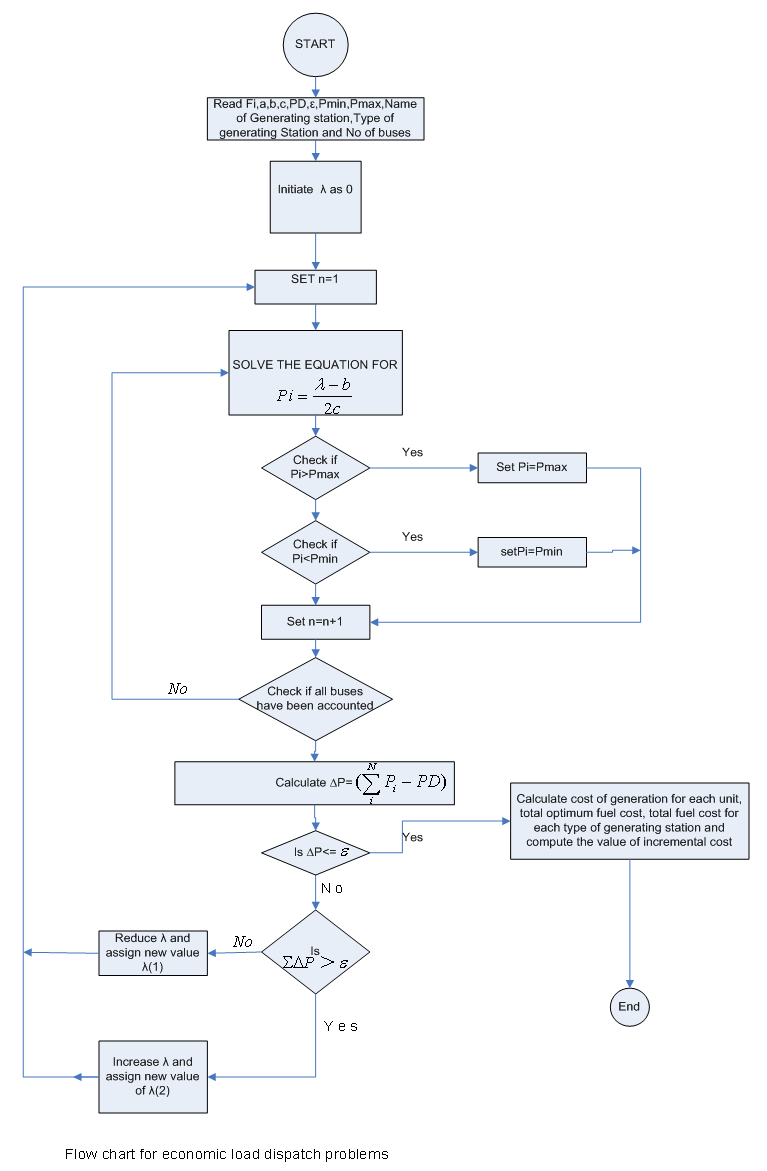

2.5. Computational Algorithms

Step1. Total power demand would be given.Step2. Assign initial estimated value of λ (0).Step3. Let  be equal to

be equal to  .Step4.

.Step4.  For all the units would be given.Step5. Differentiate

For all the units would be given.Step5. Differentiate  with respect to Pi (

with respect to Pi ( = bi + 2ci

= bi + 2ci  =λ)Step6. Rearrange

=λ)Step6. Rearrange  (so that Pi =

(so that Pi = )Step7. Compute the individual Units P1, P2-------Pn Corresponding to λ (0).Step8. Compute

)Step7. Compute the individual Units P1, P2-------Pn Corresponding to λ (0).Step8. Compute  Step9. Check if the relationship ∑Pi (0) =PD is satisfied or

Step9. Check if the relationship ∑Pi (0) =PD is satisfied or  Step10. If the sum is less than total power demand, then assigns a new value λ (1) repeat steps 8 and 9.Step11. If the sum is less than the demand, then assigns a new value λ (2) and repeat steps 8 and 9. Continue the iteration until when it will converge.

Step10. If the sum is less than total power demand, then assigns a new value λ (1) repeat steps 8 and 9.Step11. If the sum is less than the demand, then assigns a new value λ (2) and repeat steps 8 and 9. Continue the iteration until when it will converge. Step12. Calculate fuel cost and

Step12. Calculate fuel cost and  for each generating unit.

for each generating unit.

3. Modelling of Polynomial Equation for Each Generating Unit

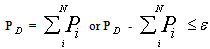

Polynomial model for the generating units can be achieved through the least square method.

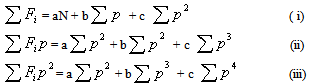

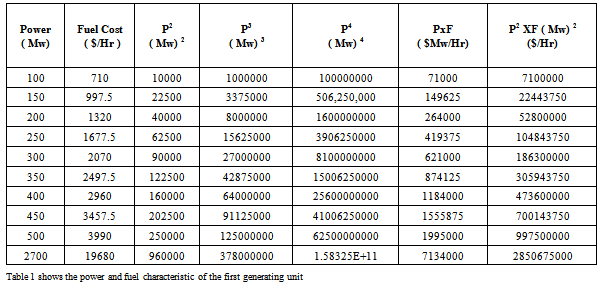

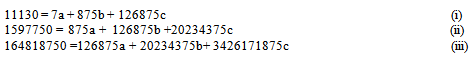

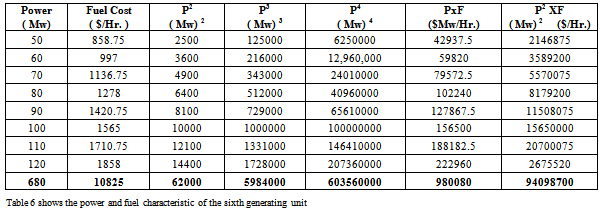

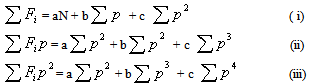

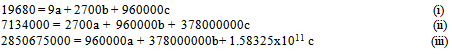

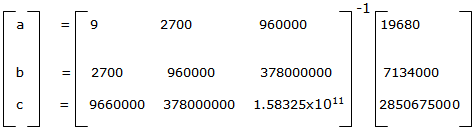

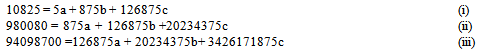

3.1. Least Square Equations

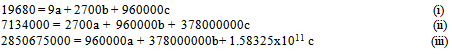

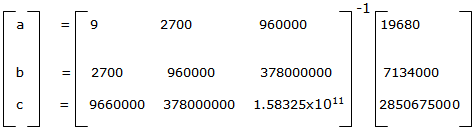

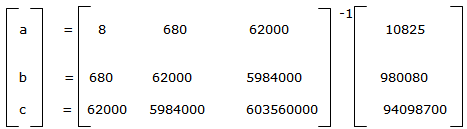

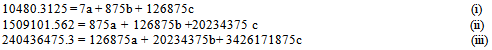

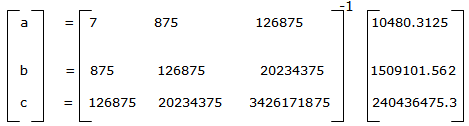

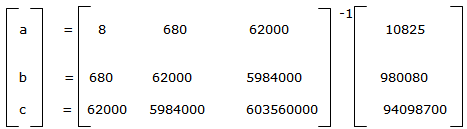

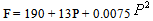

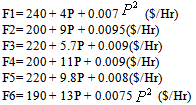

3.2. MAT LAB Simulation

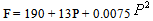

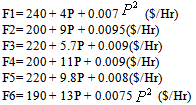

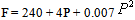

With MAT LAB simulation coefficients a, b and c can be achieved, therefore the polynomial equation for each generating unit is expressed as

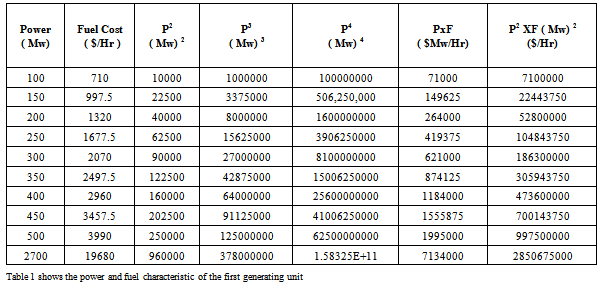

Table 1. The 1st generating unit

|

| |

|

| Figure 2. Flow chart for economic load dispatch |

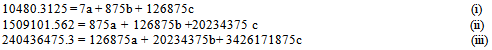

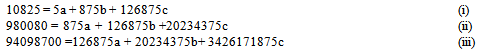

By applying the least square equations

Where a = 240, b = 4 and c= 0.007Therefore, the polynomial equation for the first generating unit can be expressed as

Where a = 240, b = 4 and c= 0.007Therefore, the polynomial equation for the first generating unit can be expressed as

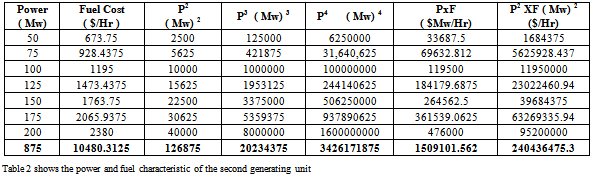

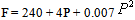

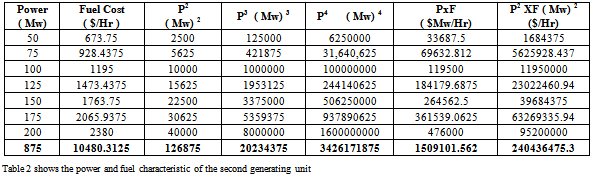

Table 2. The 2nd generating unit

|

| |

|

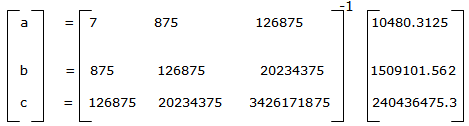

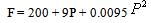

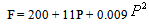

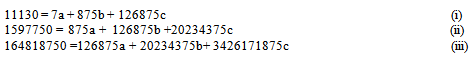

By applying the least square method

Where a = 200, b=9 and c=0.0095 Therefore, the polynomial equation for the second generating unit can be expressed as

Where a = 200, b=9 and c=0.0095 Therefore, the polynomial equation for the second generating unit can be expressed as

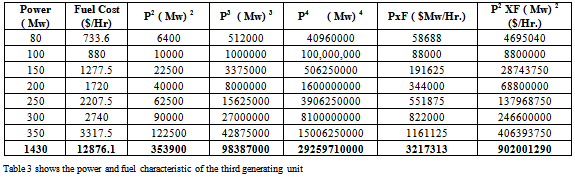

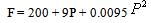

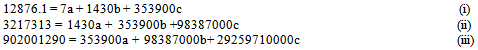

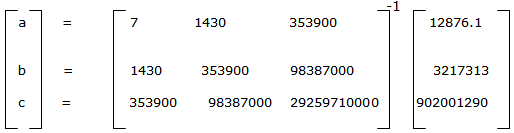

Table 3. The 3rd generating unit

|

| |

|

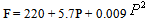

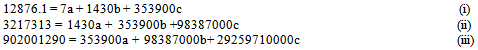

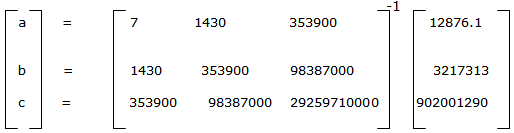

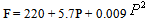

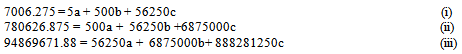

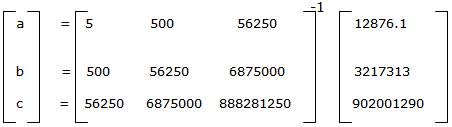

By applying the least square equations

Where a = 220,b = 5.7 and c= 0.009Therefore, the polynomial equation for the 3rd generating unit can be expressed as

Where a = 220,b = 5.7 and c= 0.009Therefore, the polynomial equation for the 3rd generating unit can be expressed as

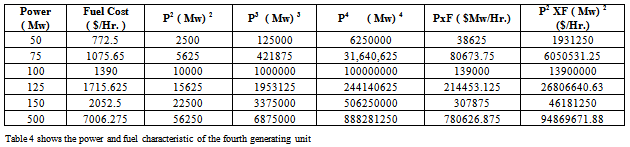

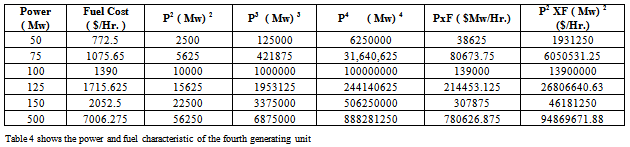

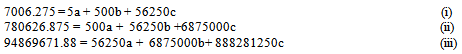

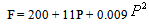

Table 4. The 4th generating unit

|

| |

|

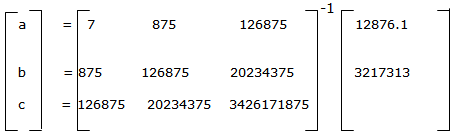

By applying the least square equations

Where a = 200, b = 11 and c= 0.009Therefore, the polynomial equation for the fourth generating unit can be expressed as

Where a = 200, b = 11 and c= 0.009Therefore, the polynomial equation for the fourth generating unit can be expressed as

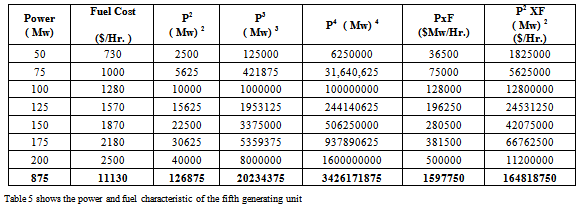

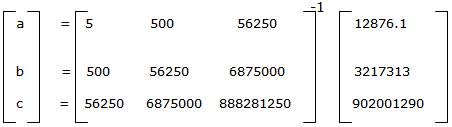

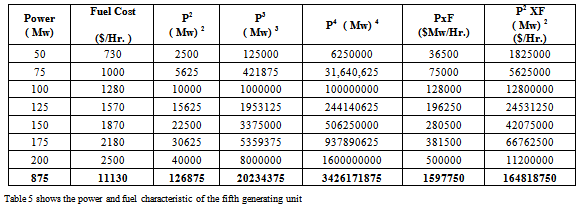

Table 5. The 5th generating unit

|

| |

|

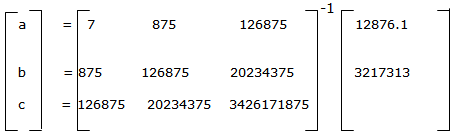

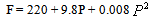

By applying the least square equations

Where a = 220,b = 9.8 and c= 0.008Therefore, the polynomial equation for the fifth generating unit can be expressed as

Where a = 220,b = 9.8 and c= 0.008Therefore, the polynomial equation for the fifth generating unit can be expressed as

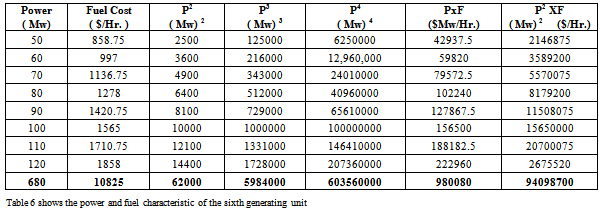

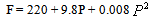

Table 6. The 6th generating unit

|

| |

|

By applying the least square equations

Where a = 190, b = 13 and c= 0.0075Therefore, the polynomial equation for the sixth generating unit can be expressed as

Where a = 190, b = 13 and c= 0.0075Therefore, the polynomial equation for the sixth generating unit can be expressed as

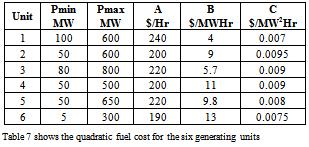

4. Test System

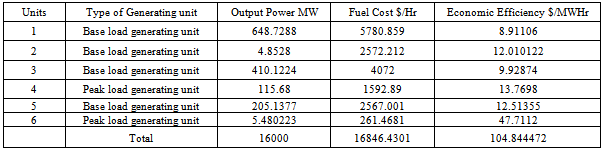

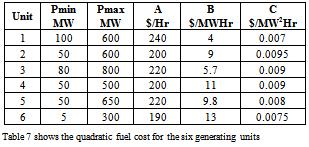

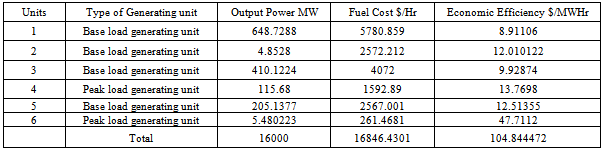

This system has 6 units while the Units Cost data and system load demand are given respectively in Table 7.

Table 7. Test System Data

|

| |

|

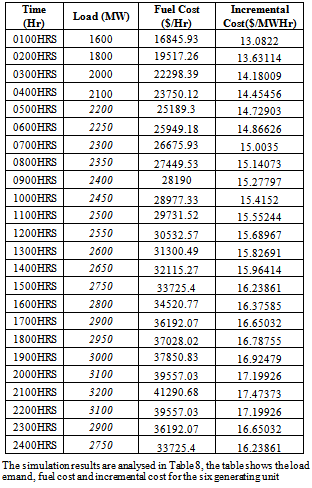

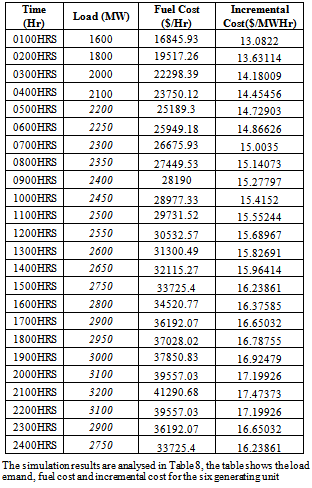

Table 8. The results of the simulation

|

| |

|

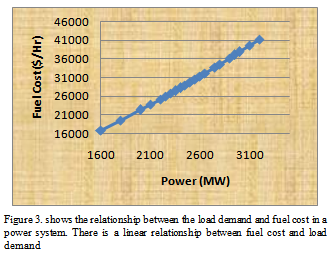

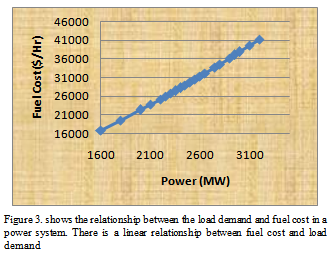

| Figure 3. Power generated vs. Fuel cost |

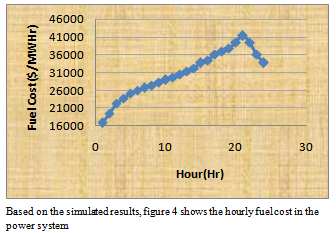

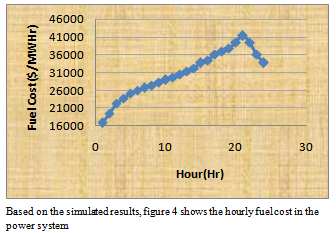

| Figure 4. Fuel Cost per hour |

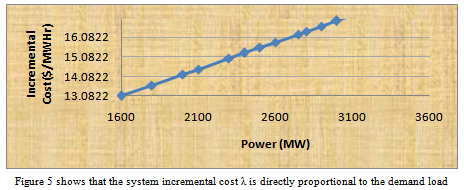

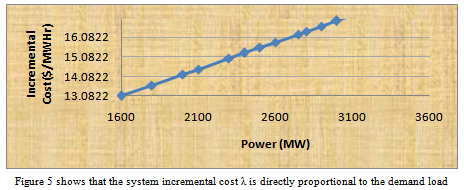

| Figure 5. Power generated vs. Incremental Cost |

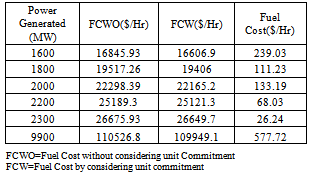

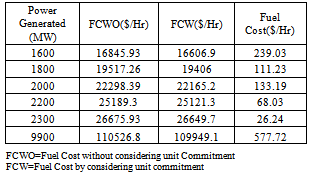

Table 9. The effect of unit commitment in a power plant

|

| |

|

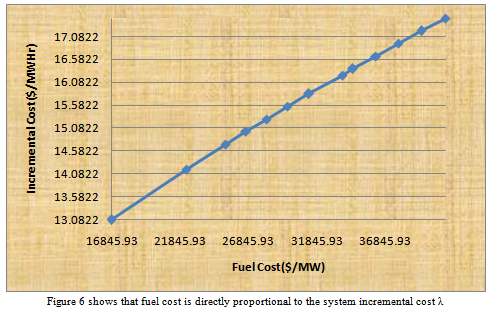

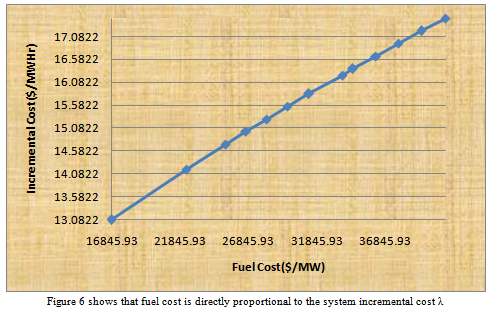

| Figure 6. Fuel cost vs. Incremental Cost |

5. Effect of Unit Commitmen

The first aspect of the Economic Load Dispatch is the unit commitment problem where it is required to select optimally out of the available generating sources to operate, to meet the expected load and provide a specified margin of operating reserve over a specified period of time[10]. From the analysis as shown in Table 9, the base load generating units are 1, 2, 3 and 5 due to their low fuel consumption and optimum economic operation while peak load generating units are 4 and 6.Table 10. Power plant fuel Consumption by considering unit commitment

|

| |

|

6. Results and Discussion

The results for the system incremental cost and operating cost were plotted for the various load levels. From figure 5 and figure 6, it shows that operating cost and incremental cost rise linearly with load values. Therefore, it can be concluded that fuel cost and the system incremental cost λ are directly proportional to the demand load. They follow an approximately linear trend in relation to the load demand. Table 8.0 shows that fuel cost and incremental costs are directly proportional to the demand load in any integrated power system. Table 10 also shows the effect of unit commitment on units 1, 2, 3, 4, 5 and 6. From the table 9, the base load generating units are 1, 2, 3 and 5 due to their efficiency and optimum economic operation while peak load generating units are 4 and 6. In any power plant, the generating unit with the cheapest Fuel Cost, efficiency and the best optimum economic operation will be selected to dispatch first. As shown in Table 3.0, Generating Unit No. 1 is the cheapest while Generating Unit No. 6 is the most expensive in terms of fuel cost and economic efficiency N/MWHr. Hence, Generating Unit No. 1 would be dispatched first and Generating Unit No.6 last. Generating unit 1 is the cheapest and it has the best generating capability of the system.

7. Conclusions

It can be seen that any increase in load demand brings about the same rise in the system fuel cost; a cost that would be passed on to the customers since fuel cost carries the highest percentage of the operating cost of power plants. Hence, it shows that the relationship between fuel prices and Load demands is approximately linear. With the current power deregulation in the world , it is essential to optimise the running cost of power plants by reducing the fuel consumption for meeting a particular load demand. This can only be achieved through the economic load dispatch.

References

| [1] | Abhijit Chakrabarti, Sunita Halder "Power System Analysis Operation and Control", PHI Learning Private Limited, Third Edition, pp548-590, 2010 |

| [2] | Gupta J.B, "A Course on Electrical Power", S.K.Kataria and Sons, Fourteenth Edition, 208-221, 2012. |

| [3] | Manjeet Singh, Mukesh Garg, Vineet Girdher "Comparative study of Economic Load Dispatch using modified Hopfield neural network", International Journal of Computing & Business Research, ISSN (Online): 2229-6166, pp.1,2012. |

| [4] | N. Phanthuna V. Phupha N. Rugthaicharoencheep, and S. Lerdwanittip "Economic Load Dispatch with Daily Load Patterns and Generator Constraints By Particle Swarm Optimization "World Academy of Science, Engineering and Technology 71 2012 pp.1233-1235 |

| [5] | Neetu Agrawal, K.K.Swarnkar, Dr. S.Wadhwani, Dr. A. K. WadhwaniEconomic Load Dispatch Problem of Thermal Generators with Ramp Rate Limit Using Biogeography - Based Optimization International Journal of Engineering and Innovative Technology (IJEIT) Volume 1, Issue 3, March 2012 ISSN: 2277-3754 pp98-102 |

| [6] | Tarek Bouktir, Linda Slimani, M. Belkacemi “A Genetic Algorithm for Solving the Optimal Power Flow Problem” Leonardo Journal of Sciences, ISSN 1583-0233, Issue 4, pp.46, January-June,2004. |

| [7] | Wadhwa C.L, "Electrical Power Systems", New Ageinternational Publishers, sixth Edition, pp627-661, 2010s. |

| [8] | Wood, A, Wollenberg, B "Power Generation Operation and Control", Wiley and Sons, Third Edition, pp154-205, 1984 |

| [9] | Y. Ting-Fang; P. Chun-Hua, “Application of an improved Particle Swarm Optimization to economic load dispatch in power plant,” in Proc IEEE Int. Conf. Advanced Computer Theory and Engineering, 2010. |

| [10] | Wadhwa C. L,"Electrical Power Systems", New Ageinternational Publishers, sixth Edition, pp627-661, 2010s. |

| [11] | Wood, A, Wollenberg, B "Power Generation Operation and Control", Wiley and Sons, Third Edition,pp154-205,1984 |

| [12] | Vijayakumar Krishnasamy “Genetic Algorithm for Solving Optimal Power FlowProblem with UPFC”, International Journal of Software Engineering and Its Applications Vol. 5 No. 1,pp.41 January, 2011. |

If P stands for the power output in megawatts (MW) and C be the fuel cost, then Fig.1 shows a typical input and output characteristic curve of a power plant.

If P stands for the power output in megawatts (MW) and C be the fuel cost, then Fig.1 shows a typical input and output characteristic curve of a power plant.

Where ai, bi and ci are the cost coefficients of generating unit at bus i[6][12].2. To develop the best approach that will help all the power utility companies to solve the problem of economic load dispatch in an interconnected power system.3. To estimate the output power and fuel consumption of each generating unit in a power plant while meeting the load demands at a minimum fuel cost.4. To design a computer application program to solve the problem of economic dispatch problem in anyinterconnected power system. 5. To deploy all the available resources for power generation such as natural gas, water, diesel, uranium, coal and petrol more efficiently and thus handle peak and base loads more efficiently and reliably with economic load dispatch.

Where ai, bi and ci are the cost coefficients of generating unit at bus i[6][12].2. To develop the best approach that will help all the power utility companies to solve the problem of economic load dispatch in an interconnected power system.3. To estimate the output power and fuel consumption of each generating unit in a power plant while meeting the load demands at a minimum fuel cost.4. To design a computer application program to solve the problem of economic dispatch problem in anyinterconnected power system. 5. To deploy all the available resources for power generation such as natural gas, water, diesel, uranium, coal and petrol more efficiently and thus handle peak and base loads more efficiently and reliably with economic load dispatch.

and

and  are constants of

are constants of  generating unit.

generating unit.

. If conditions in equation (5.0) are met, Then Sum up all the Pi(s)

. If conditions in equation (5.0) are met, Then Sum up all the Pi(s)

, the process is continued until

, the process is continued until  is less than a specified accuracy or

is less than a specified accuracy or If convergence is achieved, then compute the following,1.

If convergence is achieved, then compute the following,1.  2.

2.  for each unit

for each unit be equal to

be equal to  .Step4.

.Step4.  For all the units would be given.Step5. Differentiate

For all the units would be given.Step5. Differentiate  with respect to Pi (

with respect to Pi ( = bi + 2ci

= bi + 2ci  =λ)Step6. Rearrange

=λ)Step6. Rearrange  (so that Pi =

(so that Pi = )Step7. Compute the individual Units P1, P2-------Pn Corresponding to λ (0).Step8. Compute

)Step7. Compute the individual Units P1, P2-------Pn Corresponding to λ (0).Step8. Compute  Step9. Check if the relationship ∑Pi (0) =PD is satisfied or

Step9. Check if the relationship ∑Pi (0) =PD is satisfied or  Step10. If the sum is less than total power demand, then assigns a new value λ (1) repeat steps 8 and 9.Step11. If the sum is less than the demand, then assigns a new value λ (2) and repeat steps 8 and 9. Continue the iteration until when it will converge.

Step10. If the sum is less than total power demand, then assigns a new value λ (1) repeat steps 8 and 9.Step11. If the sum is less than the demand, then assigns a new value λ (2) and repeat steps 8 and 9. Continue the iteration until when it will converge. Step12. Calculate fuel cost and

Step12. Calculate fuel cost and  for each generating unit.

for each generating unit.

Where a = 240, b = 4 and c= 0.007Therefore, the polynomial equation for the first generating unit can be expressed as

Where a = 240, b = 4 and c= 0.007Therefore, the polynomial equation for the first generating unit can be expressed as

Where a = 200, b=9 and c=0.0095 Therefore, the polynomial equation for the second generating unit can be expressed as

Where a = 200, b=9 and c=0.0095 Therefore, the polynomial equation for the second generating unit can be expressed as

Where a = 220,b = 5.7 and c= 0.009Therefore, the polynomial equation for the 3rd generating unit can be expressed as

Where a = 220,b = 5.7 and c= 0.009Therefore, the polynomial equation for the 3rd generating unit can be expressed as

Where a = 200, b = 11 and c= 0.009Therefore, the polynomial equation for the fourth generating unit can be expressed as

Where a = 200, b = 11 and c= 0.009Therefore, the polynomial equation for the fourth generating unit can be expressed as

Where a = 220,b = 9.8 and c= 0.008Therefore, the polynomial equation for the fifth generating unit can be expressed as

Where a = 220,b = 9.8 and c= 0.008Therefore, the polynomial equation for the fifth generating unit can be expressed as

Where a = 190, b = 13 and c= 0.0075Therefore, the polynomial equation for the sixth generating unit can be expressed as

Where a = 190, b = 13 and c= 0.0075Therefore, the polynomial equation for the sixth generating unit can be expressed as

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML