-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Economics

p-ISSN: 2166-4951 e-ISSN: 2166-496X

2014; 4(3): 144-149

doi:10.5923/j.economics.20140403.02

Sericulture Industry in Bangladesh: Problems and Prospects

Md. Abdur Rashid 1, Omar Faroque 2, Anwarul Kamal Chowdhury 3

1Senior Lecturer, Department of Business Administration, Northern University Bangladesh, Dhaka, Bangladesh

2Lecturer, Department of Management, Bangabandhu Sheikh Mujibur Rahman Science & Technology University, Gopalganj, Bangladesh

3Assistant Professor, Department of Business Administration, Northern University Bangladesh, Dhaka, Bangladesh

Correspondence to: Omar Faroque , Lecturer, Department of Management, Bangabandhu Sheikh Mujibur Rahman Science & Technology University, Gopalganj, Bangladesh.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

The silk industry is key role player among the all industry in Bangladesh. Once Bangladesh was known as a heaven of silk around the world but now days because of few reasons it is not on its glorious track. The aim of this study is to identify the problems and opportunities of the sericulture industry in Bangladesh. Sericulture industry is facing many problems like high cost of production, limited production of local of yarn and depending on the imported yarn to produce silk fabrics etc. It is also may result in positive economic gain from growth of export, employment generation, increasing earning capacity for rural and urban people. But at the present context it is about to stop forever. Substantial amount of working capital, skilled human resource, modern technology, proper training, and government and non -government initiatives and other infrastructural support are required for its survival. So urgent action and necessary steps is so required for its existence.

Keywords: Sericulture, Economic development, Problems, Prospects, Bangladesh

Cite this paper: Md. Abdur Rashid , Omar Faroque , Anwarul Kamal Chowdhury , Sericulture Industry in Bangladesh: Problems and Prospects, American Journal of Economics, Vol. 4 No. 3, 2014, pp. 144-149. doi: 10.5923/j.economics.20140403.02.

Article Outline

1. Introduction

- Sericulture is identified as a prospective earning sector in Bangladesh. It is capable of creating employment as well as alleviating poverty for major portion of the population in the country especially in rural areas. Bangladesh has huge prospect for developing this sector with proper aids and necessary supports of Government and non-Government organizations. But because of various socio-economic reasons it is not considered as an established sector and the survivability of it becoming questionable. Certainly now this industry is highly struggling to survive. There are some factors like access to finance, infrastructure, inconsistencies government policy and bureaucracy, environmental factors, multiple taxes and levies, access to modern technology, unfair competition, marketing problems and non-availability of raw materials locally etc. are making this industry pitiable. So there is need of conducting a study on sericulture industry to measure the effectiveness of it and to understand the level of progress in concerned areas.In a report titled ‘Fifth Years of Bangladesh Silk Foundation’ published by Bangladesh Silk Foundation (BSF) focused on the modern technology and technical assistance from government and NGO to reform this technology [1]. It also pointed out the significance of building relationship with stakeholders and development partners. In a report of Malekha khan ‘Silk Fabrics and Product Design Advisor’ demonstrated that Bangladesh Silk Foundation (BSF) should develop its own design development unit [2]. New introduced design should be commercially measured. Various promotional fair and activities should take place. In a bulletin of Bangladesh Sericulture Research and Training Institute by M. A. Rashid and M. A. Bari ‘Study on Seasonal performance in Silk Worm Seed Cocoon Rearing’ illustrated that performance of sericulture production is varied on seasonal deviation. Better quality and quantity cocoon should be maintained by optimum environment management [3]. Information and Statistics report by Bangladesh Sericulture Board focused on the employment generation for women in rural and urban areas who are staying below poverty line and expansion of sericulture industry widely [4]. A discussion and recommendation conference ‘Bangladesh Sericulture Industry: Problems and Solution of Factories’ participated by the owner of different firms focused on the major problems of firms such as technology, raw materials, uncertain market, insufficient capital, Improper coordination among firms etc [5]. In another discussion and recommendations conference ‘Development of Bangladesh Sericulture Industry’ held by the participation of NGOs brought many problems and suggestions regarding sericulture development like frequent change of BSB chairman, capturing the international market, cultivation and expansion of silk, training of worker, high cost of imported silk yarn, expansion different project of silk etc [6]. In a bulletin of Bangladesh Sericulture Board (BSB) by Dr. M. A. Rashid ‘Cultivation of Mulberry and Rearing the Silk Worms’ showed the proper way of nurturing the mulberry garden and silk worms as well as the healthy and diseases free production of cocoon [7]. The significance of financial aspects and other advanced factors of sericulture are discussed also. In a report of Bangladesh Small and Cottage Industry Corporation (BSCIC) by M. A. Wadud ‘Current Scenario Analysis of Sericulture’ focused on the creation of new competitive market for sericulture at home and abroad by enhancing the productivity and standardizing the quality of it [8]. Few production problems and recommendations are pointed out about sericulture. In a manual of Ministry of Textiles and Jute, People’s Republic of Bangladesh ‘Jubilee of Three Years; 2009-2011’ demonstrated the success of sericulture in terms of new dimension of superior cocoon production, employment generation and investment in research and development field [9] and another important report of Bangladesh Sericulture Board by M. A. Rahman ‘Orientation and Training Course’ focused on the benefits and methods of cocoon production and the need of proper training in this regard [10]. Therefore, the purpose of the study is to show the overall scenario of sericulture as well as the problems and prospects of survivability in greater Rajshahi district of Bangladesh.

2. Methodology

- The paper is based on primary and secondary data. This study is descriptive in nature. Primary data gathered with the help of a designed unstructured questionnaire. Variables such as problem of production, marketing, financing, skill of workers, number of employees and workers, technology used etc. were taken into consideration. Based on questionnaire, data on the variables for 5 silk industries were collected in Rajshahi district during March- June, 2012 by purposive sampling technique. These steps included personal interviews with the owners and top level officers and workers to gather information regarding the variables related sericulture industry. The numbers of respondents were 100 at different levels of the organization including 5 owners, 30 employees and 65 workers.

3. Current Status of Sericulture Industry in Bangladesh

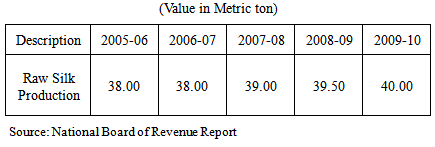

- Silk is a small sector in Bangladesh. Although it plays a momentous role in employment generation particularly for the rural people, it can not do anything miraculous over night. The allocation of it is also less in comparison with other industrial sector. At the period of beginning silk started its journey with 18 private and 21 public owned organizations. Now the number of public bodies involved at the national level is about ten, whereas the number of private bodies (national and international) stands at about fifteen. In addition to these, more than 400 different types of organizations or agencies at the village level are pursuing sericulture schemes. Moreover, there are more than 40 seri-producers’ cooperatives scattered all over the silk producing regions. Presently this industry is going to expire with its least image of survivability because of various economic and non economic reasons. Such as high cost of production, overall infrastructure, employment migration, farm and cultivation management, Government’s initiative, high competition, inappropriate policy etc. Rajshahi is known as home land of silk but at the present only two silk firms (Sopura and Usha silk) are continuing its modest type of production. Two public silk firms (Rajshahi and Thakurgaon) are closed by the ordinance of Jute and Textile Ministry on November 30, 2002. Currently few private silk firms are producing very limited amount of silk goods which are struggling with high cost of production and huge foreign competition. Now large portion of silk firm is turned into the garage of auto rickshaw and the workers involved in this sector are unemployed or migrated to other pitiable profession. Current production scenario of silk noted that more than 60 per cent of the total cocoon is still produced in 29 villages spread over 2 unions in the Bholahat upazila- a traditional silk producing area of the country located in the north-eastern part under the (greater) district of Rajshahi. In some of the new areas such as Bogra where satisfactory initial expansion took place, production shrunk back to near zero level in the later years. In terms of productivity the performance has also been unsatisfactory. The total annual demand of raw silk is 300 metric tons but the local production is 40 metric tons. The rest of the demand is filled up by the imported raw silk from China. The production of raw silk is shown at Table 1 and Figure 1 during the period 2005 to 2010.

|

| Figure 1. Raw Silk Production: 2005-2010 |

|

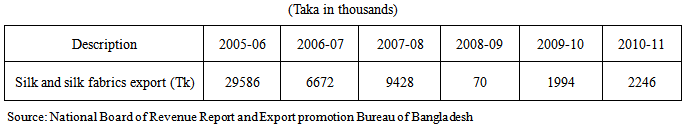

| Figure 2. Raw Silk Import: 2005-2010 |

4. Scenario of Sericulture from Export and Employment Generation

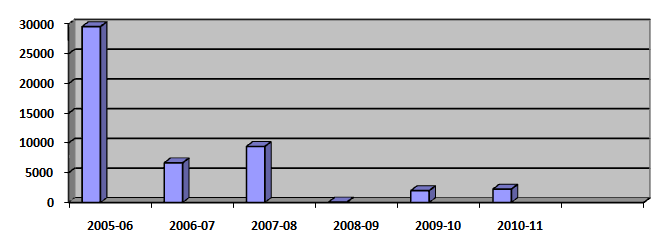

- Silk is a small sector. Being an important and potential means of generating employment opportunities, sericulture and silk industry can play a crucial role in export trade, earn much foreign currency and contribute to economic development for the nation. There is great demand for silk products all over the world and demand is increasing every day. The silk products of Bangladesh are known to the world and have already earned good reputation. So, there is an ample scope for Bangladesh to enter into the world silk market. There is no export of silk products from the public sector. The private sector however, exports a very small quantity of silk fabrics to few countries like India, Hongkong, Malaysia, Norway, UAE, Denmark, Spain, and Taiwan in the world. Export achievements of private sector in different fiscal years are given at Table 3 and Figure 3 during 2005 to 2011.Bangladesh is one of the poor country in the world suffers from chronic employment. The present rate of unemployment is alarming. Reduction of poverty and socioeconomic development is possible through the creation of productive employment opportunity. As pointed out earlier Bangladesh is small country with smaller arable land which is gradually decreasing due to urbanization. Further absorption of unemployed people in agriculture is not possible. On the other hand capital shyness and lack of entrepreneurship are the main factors and crucial constraints on the way to industrialization. As a consequences creation of off-farm employment by setting up small and cottage industries has become imperative. Under these circumstances sericulture may come forward as a relief to the situation.

|

| Figure 3. Export Earnings by Private Sector: 2005-2011 |

|

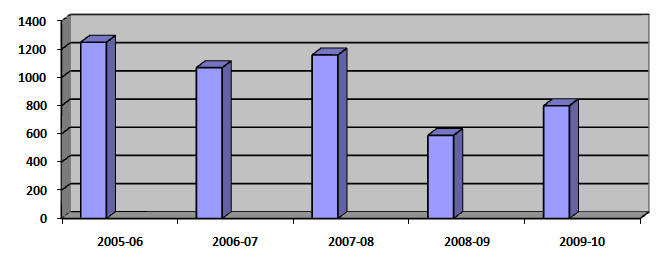

| Figure 4. Employment level in Private Sector: 2005-2010 |

5. Results and Discussion

- This study presents the overall scenario of sericulture industry in Bangladesh. Currently the total silk production is not enough and the firms are not producing the silk products satisfactorily except a few. All of the silk producing firms are facing the different challenges to stay alive. These firms are about to stop forever due to many direct and indirect problems especially high cost of production, limited amount of local yarn production, heavy dependency on imported yarn to produce silk fabrics etc. According to the sources concerned, the running industries are incurring loss of around Taka 4 to 5 thousand everyday while at least 60 factories have been shut down and many others are on the dying condition. According to the owner of firms the price of China silk was Taka 2500 per kilogram in last few years but the current price has been stood to Taka 5600 to Taka 6000 or more. Even owners said the price of locally produced yarn was Taka 1300 per kg while the china-yarn was Taka 2500. Presently the local production has been reduced to zero level and the price of imported yarn is the sky-high. So this situation will lead to shut down of this industry and the professional cocoon farmers will stop their yarn production after being deprived of getting reasonable price of it. The industry owners specifically identified some major problems like high cost of raw materials, high bank interest rate and charge of letter of credit, frequent increase of electricity bill, import duty, VAT, high promotional cost, competitive wages and salaries of employees, different rent, etc. As a result the price of finished silk goods are becoming comparatively high than the price of foreign countries. It is also creating challenge for native firms to compete in foreign market. Owners pointed out that now the silk factories are highly suffering from the shortage of financial support especially the limited working capital, incentives, subsidies and other kind of aids from Government and Non-government organization. The owners of industries argued that the policy making problem of different Government is highly responsible for creating such feeble condition of silk industry. The employees of the different firms strongly showed the numerous marketing problems like limited promotional activities, improper distribution system, huge competitive pricing, instable market, improper coordination among factories, limited scope of research and development, inadequate training of sales staff, limited scope of knowing the contemporary information of national and international market situation etc.According to workers of the industries some major production related problems are found as preservation of cocoon, shortage of fuel, supply of raw cocoon and fuel, dye and chemicals, low skilled workers, old technology, equipment maintenance etc. There are many uncovered problems are identified by the owners of the firms like inadequate initiative of Government to promote the silk sectors, migration of workers to other job, limited cultivable land, inadequate modern technology, climate change, limited knowledge of factory owners, conflict among employers and employees, unavailability of training and guidance facility, high absenteeism of workers, dissatisfaction with payment etc. These problems are blocking the way of flourishing the silk industry in Bangladesh. In this regard despite of having problems of sericulture it bears a huge prospect both at home and abroad. Bangladesh Sericulture Board (BSB) is trying to expand program of sericulture in order to increase silk yarn production in the country. According to the table and graph of production, current demand for raw silk in the country is about 300 tons, whereas the local production is only 38-40 tones and it increased little bit gradually. At this situation there is a serious need to create the interest among the farmers to produce raw silk as well as silk yarn so that the cost of production is reduced. It will help sericulture to survive strongly. So if the government and other regulatory bodies take the necessary actions and formulate effective policies of course it must be continued to exist and will be able to regain its historic glory. On the other hand from the table and graph of import it is found that in 2005-06 the total import of raw silk were 197.777 tones and in 2009-10 were 197.501 tones. It shows that after the year 2005-06 the dependency on imported goods is increased and in 2009-10 it is reduced which explicate that there is ample scope of producing local goods and it should be sustained if the silk producers are facilitated and treated fairly for their production.The locally produced silk products are used only in the local market. Most of the silk product manufacturers do not produce any export items widely. If the silk producers are able to produce export items and create the foreign market it will be certainly possible to retain its own existence. So the prospect and survivability of sericulture industry is still intense. If we see a graphical presentation of export earnings from silk and silk fabrics it will be clear to us about the survivability of it. Here in 2005-06 the total earnings was Taka 29,586,000 and in 2010-11 was Taka 2,246,000 which was less than previous. Despite of gradual decline of export the prospect of earnings and creating a strong position in foreign market is ample if the export policy of government is favourable and the production cost is reduced. On the other hand if the exporters are able to overcome the difficulties of producing the differentiated product or meeting the demand of buyers in respect of quantity, design, colour and other aspect of production then it will be possible to stay alive. The demand of silk product is increasing day by day both at home and abroad and this opportunity may be capitalized if this industry can use its experienced people, proper administration and production system, global image, well infrastructure, facilities of research and training institute and other concerned forces.Finally employment level of different fiscal years of this industry presents the explicit scenario. There is a significant relationship between export and employment level. As the export increases and the employment opportunity also grows up and vice versa. Here in 2005-06 the total export earning was Taka 29586000 and the same time the number of employee was 1250 and in 2009-10 the total export earning was 1994000 and the number of employee was 800. So it is apparently seen that if we the export of silk product is increased then certainly this sector will be enriched and expanded immensely.

6. Conclusions

- In Bangladesh sericulture has a historic status. Silk is an attractive and deluxe product around the world. This is the high time to take the realistic steps to return its preceding pride and image. Research and development activities should be conducted enormously and proper coordination should be made among the concerned groups for its further development. It will be helpful also if any support or aid is taken from our neighbour countries in this regard. Bangladesh Sericulture Board (BSB) and Bangladesh Silk Foundation (BSF) should take the immediate programs and initiatives to develop the sericulture and proper monitoring system should be established in concerned areas. Government and other concerned organization should take the effective actions for the greater interest of sericulture.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML