Gang Liu

Technology Research Department, Macrofrontier, Elmhurst, New York

Correspondence to: Gang Liu , Technology Research Department, Macrofrontier, Elmhurst, New York.

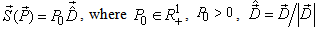

| Email: |  |

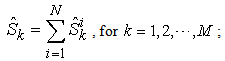

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Supply function and Production Possibility Frontier (PPF) are basic concepts in Economics. We present a model that can give mathematic formula for PPF and the supply as a function of the price vector and capability parameters. With this Supply function, the generic Supply-Demand equilibrium problems can be solved numerically. We apply the supply-demand equilibrium to give optimal solutions for team work management problems or labor assignment problems. Concrete examples are given for managing an engineer team in Boeing Corporation.

Keywords:

Resource Allocation, Labor Assignment, Teamwork Management, Supply Function, Production Possibility Frontier, Supply-Demand equilibrium

Cite this paper: Gang Liu , A Mathematic Model for Supply-Demand Equilibrium and the Optimal Solution for Labor Assignment, American Journal of Economics, Vol. 4 No. 2, 2014, pp. 83-98. doi: 10.5923/j.economics.20140402.01.

1. Introduction

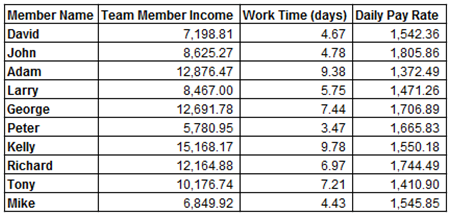

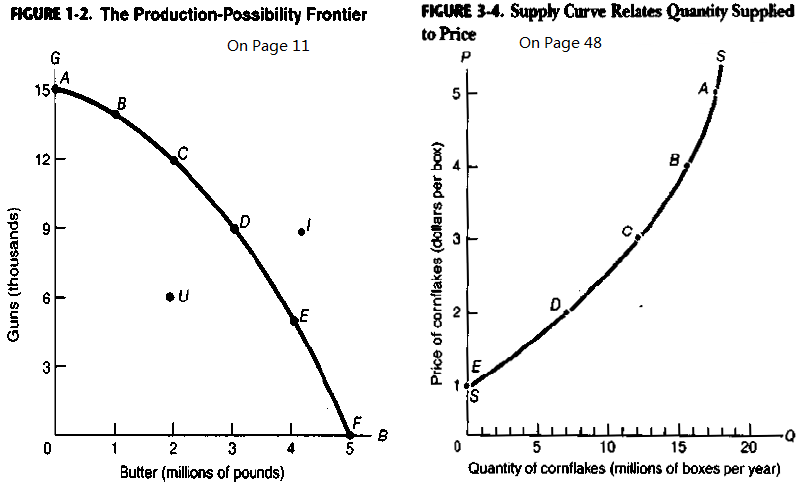

Production Possibility Frontier (PPF) is one of the basic concepts in Economics. PPF can be simply defined as the boundary of frontier of the economy’s production capabilities. Most of Economic books normally have a whole chapter to discuss PPF and its applications [1, 4, 10, 11]. Most of these text books discuss the PPF and supply function for two products and in qualitative format, as shown in Figure 1. It is well-known that the PPF is convex and the supply-price curve is an upward-sloping curve. However, no one has given the PPF nor supply function in mathematic formats. The law of supply and the law of supply-demand equilibrium are basic laws in modern economics. However, without knowing the supply function in mathematic format, these laws can be only discussed quantitatively, and the general supply-demand equilibrium cannot be solved numerically. In early 2002, we have given the PPF and supply function in mathematic format for any number of products [6]. In this paper, we first introduce the model that can formulate the PPF in mathematic format, and then derive the supply as a function of the prices of all products. Some of the basic economic theorems can be derived from the PPF formula, such as the convexity of the PPF curve, the Law of Supply, as well as supply elasticity. We also proposed methods for solving the general supply-demand equilibrium numerically. There are wide applications of the proposed PPF functions. As an example, we apply the PPF function and the Supply-Demand equilibrium equation to give optimal solution for team work management and labor assignment problems. Our analysis and test results show that the proposed model can improve production efficiency by 40% for most of the team work management problems.The rest of the paper is organized as follows. Section 2 introduces some useful notations and definitions. Section 3 formulates the PPF and the supply function for a micro system. Section 4 further formulates the PPF and the supply function for a macro system. Section 5 discusses the lower Production Possibility Frontier. Section 6 discusses the Law of Supply and the Elasticity of Supply. Section 7 introduces two methods for solving the supply-demand equilibrium. Section 8 introduces two special production possibility curves that can be used to show how efficiency of the PPF. Section 9 applies our supply function to a dummy system to show concrete PPF curves and supply curves. Section 10 discusses the best scenario and the worst scenario. Section 11 applies our model to solve the labor assignment problem for a labor oriented team. Section 12 shows a concrete example of labor assignment problem for project oriented team. In Section 13 and 14, we analyze the efficiency improvements by the optimal solution. Section 15 introduces two management methods that can reach the optimal solution for team work management. Conclusions are presented in Section 16. | Figure 1. This is a snapshot from Samuelson’s book “Economics” [11]. Without knowing the mathematic formats of the PPF and supply function, most of the Economics books can only discuss PPF, Supply, and supply-demand equilibrium quantitatively. We proposed a model that can give PPF and Supply as a mathematic function of the price as shown in Equation (17) |

2. Notations and Definitions

In order to describe our model and the PPF curve, let us first introduce some notations and definitions.

2.1. Notations

: An economic system that contains some sub systems. It can be as small as a family, a firm, and can be as large as a country or the whole world.

: An economic system that contains some sub systems. It can be as small as a family, a firm, and can be as large as a country or the whole world.  is also called a macro system compared with its sub systems.

is also called a macro system compared with its sub systems. : An integer represents the total number of the sub systems in

: An integer represents the total number of the sub systems in  .

.  : An integer represents the total number of the products that are produced in

: An integer represents the total number of the products that are produced in  .

.  : The ith unit or sub system in system

: The ith unit or sub system in system  . It could be an individual member, or a group of people, such as a firm or another economic system in

. It could be an individual member, or a group of people, such as a firm or another economic system in  . However, there are no overlaps between different Units. For example, if an individual has been included in one unit, the same individual can’t be included in another unit.

. However, there are no overlaps between different Units. For example, if an individual has been included in one unit, the same individual can’t be included in another unit.  is also called a micro system compared with its parent system.

is also called a micro system compared with its parent system. : The kth product that can be produced in system

: The kth product that can be produced in system  . Actually, the product here means any labor activities that can be done by any unit in

. Actually, the product here means any labor activities that can be done by any unit in  . It can be a real product, a project, a job, a task, and anything that need to be done or produced by any unit in

. It can be a real product, a project, a job, a task, and anything that need to be done or produced by any unit in  .

. : A time span that the above mentioned products are produced in

: A time span that the above mentioned products are produced in  .

. :

:  , which is the set of non-negative M-dimensional real vectors and with the original point

, which is the set of non-negative M-dimensional real vectors and with the original point  excluded.

excluded. : The same as

: The same as  . However, we use it to particularly represent the Production Space with its kth Cartesian coordinate representing the amount of a parameter related to

. However, we use it to particularly represent the Production Space with its kth Cartesian coordinate representing the amount of a parameter related to  product.

product. : The demand amount of

: The demand amount of  product that requested by

product that requested by  .

.  : The maximum amount of

: The maximum amount of  product that can be produced by

product that can be produced by  within time

within time  . Normally

. Normally  can be produced by

can be produced by  when it uses all of its resources to work on product

when it uses all of its resources to work on product  . All the

. All the  make up an

make up an  matrix, which is called the micro capability matrix of system

matrix, which is called the micro capability matrix of system  .

.  : The amount of

: The amount of  product that are actually produced by

product that are actually produced by  . All the

. All the  make up a vector in

make up a vector in  , and is called micro supply vector.

, and is called micro supply vector. : The amount of

: The amount of  product produced by the macro system

product produced by the macro system  . It is also called the macro supply of system

. It is also called the macro supply of system  . All the

. All the  make up a vector in

make up a vector in  , and is called a macro supply vector of system

, and is called a macro supply vector of system  .

. ;

;  : The price of the

: The price of the  product in system

product in system  .

.

2.2. Definitions

Definition: Micro System and Macro System: An economic system is called a macro system if it contains some sub-systems, such as the system  introduced above. An economic system is called a micro system if it is contained in a macro system, such as the sub-system

introduced above. An economic system is called a micro system if it is contained in a macro system, such as the sub-system  described above. Definition: System Parameter: An economic parameter is called a system parameter if it is associated with an economic system. For example, the supply amount, demand amount, and price are all examples of system parameters. Definition: Micro Parameter and Macro Parameter: A system parameter is called a micro parameter if it is associated with a micro system, and is called a macro parameter if it is associated with a macro system. Some parameters may be associated with both micro system and macro system. As long as there is no confusion, we use the same alphabet character to represent a system parameter: if

described above. Definition: System Parameter: An economic parameter is called a system parameter if it is associated with an economic system. For example, the supply amount, demand amount, and price are all examples of system parameters. Definition: Micro Parameter and Macro Parameter: A system parameter is called a micro parameter if it is associated with a micro system, and is called a macro parameter if it is associated with a macro system. Some parameters may be associated with both micro system and macro system. As long as there is no confusion, we use the same alphabet character to represent a system parameter: if  denotes a macro parameter associated with a macro system

denotes a macro parameter associated with a macro system  , then

, then  will be used to denote the same micro parameter associated with micro system

will be used to denote the same micro parameter associated with micro system  .For example,

.For example,  and

and  represent the macro and micro supply amounts of product

represent the macro and micro supply amounts of product  ,

,  and

and  denote the macro PPF of system

denote the macro PPF of system  and the micro PPF of the micro system

and the micro PPF of the micro system  correspondingly. Definition: Vector Parameter and Scalar Parameter: a system parameter may also be associated with each of the production, for example, supply amount normally means the amount of a product that can be provided by an economic system. In a system with

correspondingly. Definition: Vector Parameter and Scalar Parameter: a system parameter may also be associated with each of the production, for example, supply amount normally means the amount of a product that can be provided by an economic system. In a system with  products, a system parameter could be

products, a system parameter could be  -dimensional with each component representing the amount associated with one product. These

-dimensional with each component representing the amount associated with one product. These  -dimensional parameters make up a vector in the production space

-dimensional parameters make up a vector in the production space  , thus is called a Vector Parameter. A vector parameter can be represented by a vector in

, thus is called a Vector Parameter. A vector parameter can be represented by a vector in  . Examples of vector parameters are: Supply, Demand, and Price. A system parameter is called a scalar parameter if it is one dimensional. Examples of scalar parameters are: income, GDP, revenue, etc.Additive Parameter: A system parameter is called additive parameter if the corresponding macro parameter can be derived by aggregating the same parameter over all of its micro systems. Or precisely, system parameter X is additive if

. Examples of vector parameters are: Supply, Demand, and Price. A system parameter is called a scalar parameter if it is one dimensional. Examples of scalar parameters are: income, GDP, revenue, etc.Additive Parameter: A system parameter is called additive parameter if the corresponding macro parameter can be derived by aggregating the same parameter over all of its micro systems. Or precisely, system parameter X is additive if  | (1) |

Where  is a parameter reachable and meaningful to micro system

is a parameter reachable and meaningful to micro system  , while

, while  is the same parameter reachable and meaningful to macro system

is the same parameter reachable and meaningful to macro system  .In our model, we tried to decompose the macro system

.In our model, we tried to decompose the macro system  into some micro systems

into some micro systems  , and divide the products into some products or tasks in such a way that some of the system parameters are additive, particularly, the supply amount, the demand amount, revenue, and income are all additive. However, the price parameter is not an additive parameter. Based on the above notations and definitions, we can say that the supply and demand are vector parameters and are additive, whereas the price is also a vector parameter, but not additive. The income, revenue, GDP, profit and loss are all additive scalar parameters. We are only interested in those parameters in this paper.

, and divide the products into some products or tasks in such a way that some of the system parameters are additive, particularly, the supply amount, the demand amount, revenue, and income are all additive. However, the price parameter is not an additive parameter. Based on the above notations and definitions, we can say that the supply and demand are vector parameters and are additive, whereas the price is also a vector parameter, but not additive. The income, revenue, GDP, profit and loss are all additive scalar parameters. We are only interested in those parameters in this paper.

2.3. Known Parameters and Unknowns

Using the above notations, we can list the input data in table format. Basically, we assume the following data are known input data: , the production capability matrix for each micro system and for each product.

, the production capability matrix for each micro system and for each product. : The macro demand of

: The macro demand of  product that needs to be accomplished by system

product that needs to be accomplished by system  . We assume the following parameters are unknowns and need to be resolved: Price, micro supply, macro supply, micro income, macro revenue.

. We assume the following parameters are unknowns and need to be resolved: Price, micro supply, macro supply, micro income, macro revenue.

3. Micro PPF and Micro Supply Function of a Micro System

For any micro system  , let us assume that it can arrange its resources to make any requested products. However, its production amount for product

, let us assume that it can arrange its resources to make any requested products. However, its production amount for product  should be limited to or bounded by

should be limited to or bounded by  due to its limited resources and capabilities. Any of its feasible production state will be a point or a vector in the production space

due to its limited resources and capabilities. Any of its feasible production state will be a point or a vector in the production space  . All of its feasible production vectors should be a bounded range in the production space

. All of its feasible production vectors should be a bounded range in the production space  . We call this bounded range as its micro Production Possibility Range (PPR) and denoted as

. We call this bounded range as its micro Production Possibility Range (PPR) and denoted as  . The upper boundary of

. The upper boundary of  is called the micro PPF, denoted as

is called the micro PPF, denoted as  . Normally, as long as the micro system

. Normally, as long as the micro system  is small enough compared with macro system

is small enough compared with macro system  , each of the micro PPF can be approximated by the linear plane curve that passing the

, each of the micro PPF can be approximated by the linear plane curve that passing the  axis at

axis at  in production space

in production space  . Given the micro capability matrix, the micro PPF

. Given the micro capability matrix, the micro PPF  can be formulated as:

can be formulated as: | (2) |

can also be expressed in the following format:

can also be expressed in the following format: | (3) |

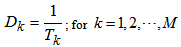

Where  | (4) |

is called the intrinsic price vector of the micro system.Actually,

is called the intrinsic price vector of the micro system.Actually,  is a linear plane curve with vector

is a linear plane curve with vector  as its normal vector. It passes the

as its normal vector. It passes the  axis at the points:

axis at the points: | (5) |

Where  is the unit vector on the

is the unit vector on the  axis.

axis.  and is on the

and is on the  axis of the production space. We call these

axis of the production space. We call these  points as the micro vertex points. Given the price vector as

points as the micro vertex points. Given the price vector as  and the micro supply vector

and the micro supply vector  of the micro system

of the micro system  , the total income or revenue of the micro system

, the total income or revenue of the micro system  can be expressed as:

can be expressed as: | (6) |

As all the supply vectors  is feasible to micro system

is feasible to micro system  , there should have some possible micro supply vectors that can maximize the income or revenue of the micro system

, there should have some possible micro supply vectors that can maximize the income or revenue of the micro system  . Such feasible micro supply vectors can be formulated as:

. Such feasible micro supply vectors can be formulated as: | (7) |

As the objective function  to be maximized is a linear function, according to Lagrange’s theorem, the max-min can only be found on the boundary of the region

to be maximized is a linear function, according to Lagrange’s theorem, the max-min can only be found on the boundary of the region  . Then the above equation is equivalent to:

. Then the above equation is equivalent to: | (8) |

By applying Lagrange’s theorem again, the Max-Min can be found at some of the  vertex points listed in Equation (5). Then, the above equation can be further simplified as:

vertex points listed in Equation (5). Then, the above equation can be further simplified as: | (9) |

Or more explicitly, | (10) |

Where  is an

is an  function defined as:

function defined as: | (11) |

And  is the total number of vertex points that have

is the total number of vertex points that have  maximized for

maximized for  . Number

. Number  can be formulated as:

can be formulated as: | (12) |

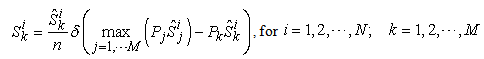

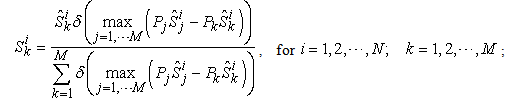

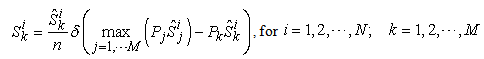

By substituting the above Equation into Equation (10), we have: | (13) |

It can be easily checked that Equation (13) gives the mean vector of all the vertex points that can have  maximized. It gives at least one of the micro supply vectors

maximized. It gives at least one of the micro supply vectors  that can have the micro income

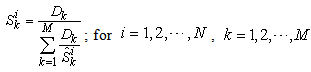

that can have the micro income  maximized. It is an explicit mathematical format for the micro supply as a function of the capability matrix and the price vector. However, it is a discrete function and thus is difficult to deal with. The key step and major contribution of our model is to formulate a continuous and smooth function to approximate the Equation (13). Here are the key steps. Equation (13) is equivalent to the following function:

maximized. It is an explicit mathematical format for the micro supply as a function of the capability matrix and the price vector. However, it is a discrete function and thus is difficult to deal with. The key step and major contribution of our model is to formulate a continuous and smooth function to approximate the Equation (13). Here are the key steps. Equation (13) is equivalent to the following function: | (14) |

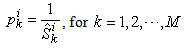

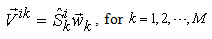

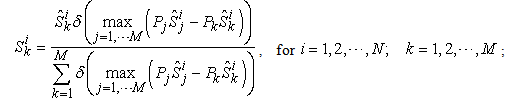

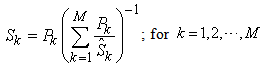

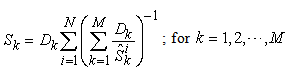

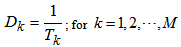

Where  is called the macro capability parameter defined as:

is called the macro capability parameter defined as: | (15) |

It can be easily checked that Equation (14) is exactly the same as Equation (13) once  . In practical applications, we can simply drop the limited function by assigning

. In practical applications, we can simply drop the limited function by assigning  with a large number, thus the Equation (14) can be simply expressed as:

with a large number, thus the Equation (14) can be simply expressed as: | (16) |

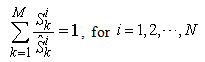

It can be shown that the above micro supply function does depend on the direction of the price vector, but doesn’t depend on the length of the price vector. So, we can normalize the price vector to 1 without any impacts on the supply function. Then, we always have:  for

for  ; Normally, it will be good enough if we assign

; Normally, it will be good enough if we assign  as:

as: Equation (16) will be a good approximation for the micro supply function, and it gives the Micro PPF

Equation (16) will be a good approximation for the micro supply function, and it gives the Micro PPF  once the price vector goes through all possible directions in the production space

once the price vector goes through all possible directions in the production space  .

.  will be good enough for most of the practical applications. We use

will be good enough for most of the practical applications. We use  to get most of the results listed in this paper.

to get most of the results listed in this paper.

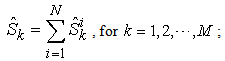

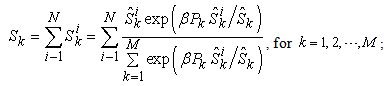

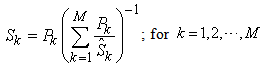

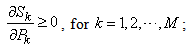

4. Macro PPF and Macro Supply Function of a Macro System

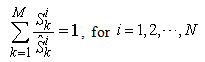

We have formulated the micro PPF  and the micro supply as a function of the price vector and the capability parameters, as shown in Equation (16). As each of the micro system

and the micro supply as a function of the price vector and the capability parameters, as shown in Equation (16). As each of the micro system  has a maximum production frontier and a limited range as its PPR, the macro system should also have a macro PPR in the production space

has a maximum production frontier and a limited range as its PPR, the macro system should also have a macro PPR in the production space  , and must have a macro PPF. As the supply parameter is an additive parameter, we can get the macro supply vector by aggregating all the micro supply vectors, that is:

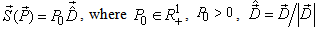

, and must have a macro PPF. As the supply parameter is an additive parameter, we can get the macro supply vector by aggregating all the micro supply vectors, that is: | (17) |

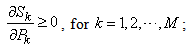

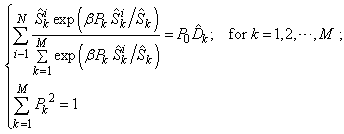

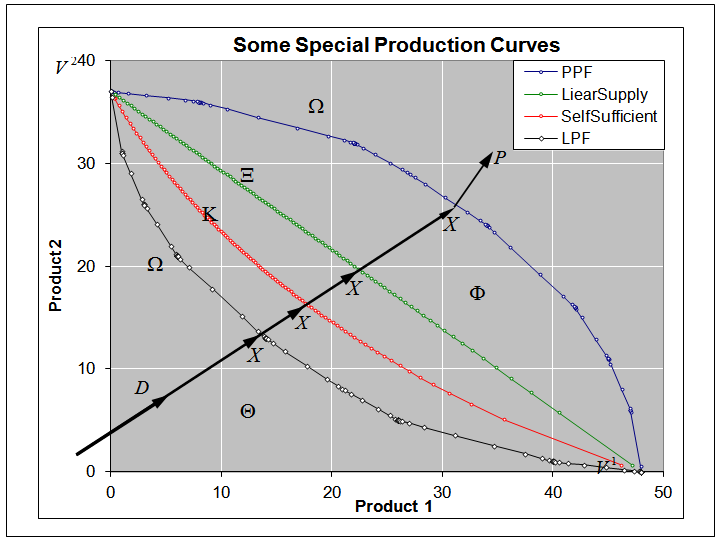

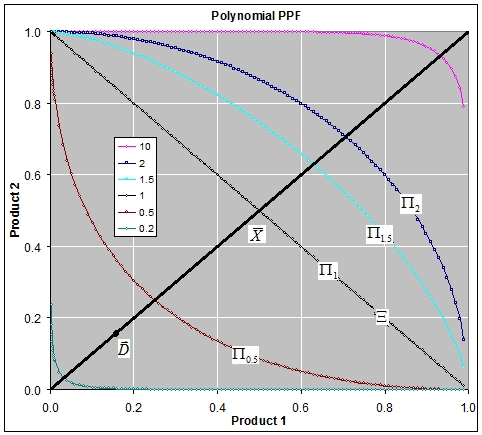

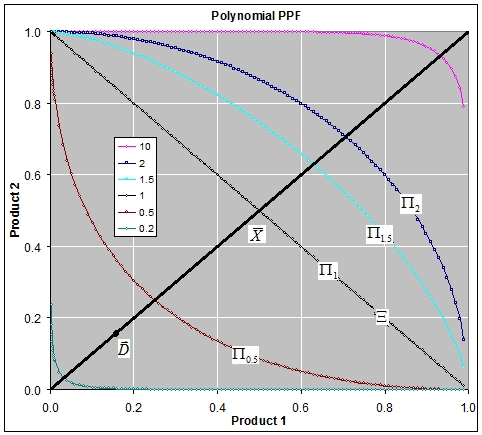

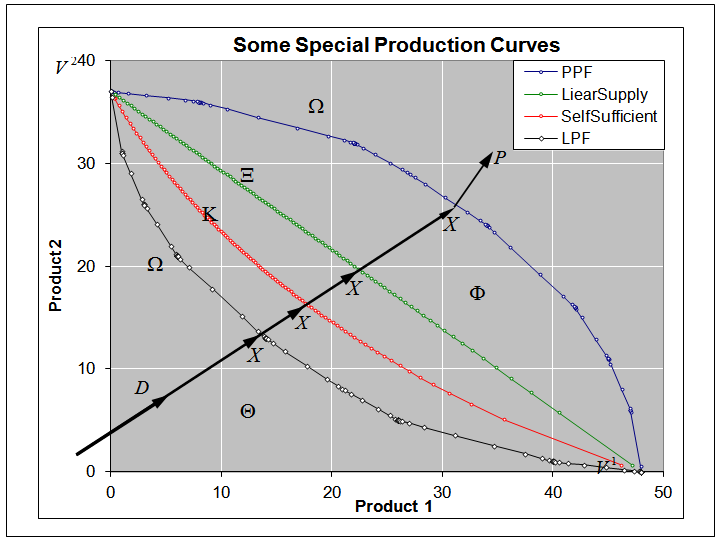

Once the price vector goes through all possible directions, the above Equation will give all the points on the macro PPF  , as shown in Figure 3. So, the above Equation is not only a supply function, but also a function that gives the macro PPF

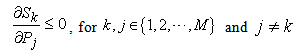

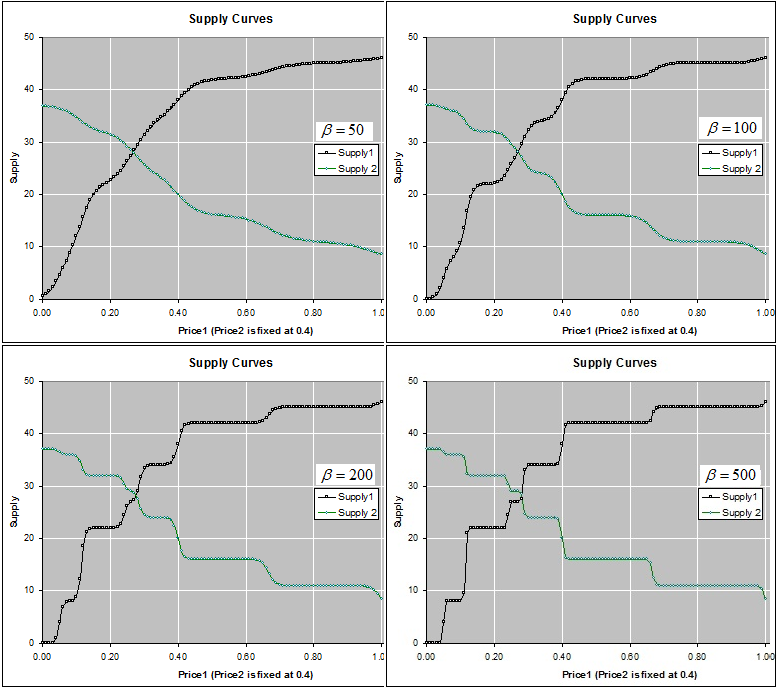

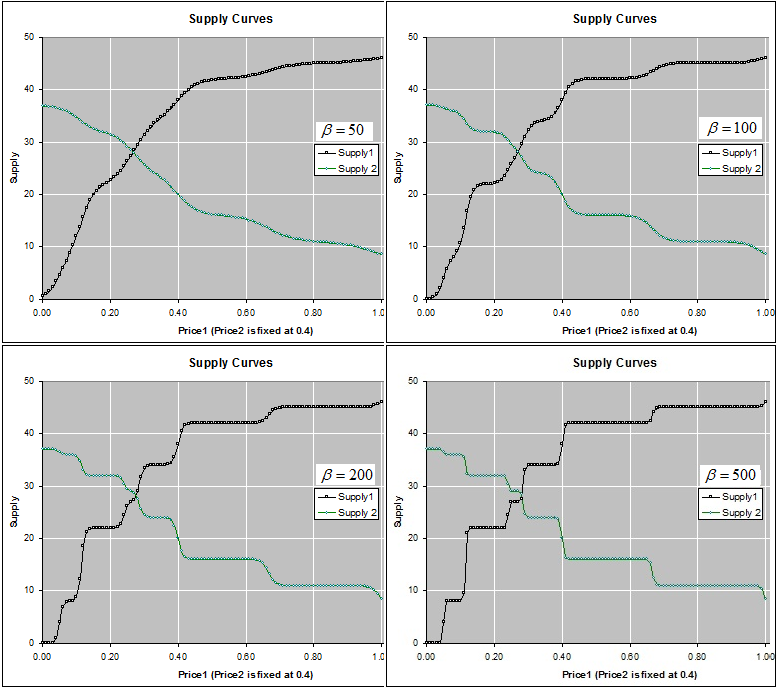

, as shown in Figure 3. So, the above Equation is not only a supply function, but also a function that gives the macro PPF  . Figure 4.shows the Supply-Price curves for various

. Figure 4.shows the Supply-Price curves for various  values. Once

values. Once  is big enough, the Supply-Price curves become step curves. Keeping in mind that each micro system is targeting at maximizing its income, so, when the price

is big enough, the Supply-Price curves become step curves. Keeping in mind that each micro system is targeting at maximizing its income, so, when the price  rises, a micro system

rises, a micro system  may want to switch all of its resources to work on product

may want to switch all of its resources to work on product  , and thus to have the macro supply

, and thus to have the macro supply  be suddenly increased by an amount of

be suddenly increased by an amount of  . At the same time, because

. At the same time, because  switched from working on

switched from working on  to work on some other products, such as

to work on some other products, such as  (

( ), it will have the supply

), it will have the supply  decreased suddenly by an amount of

decreased suddenly by an amount of  . This explains why the Supply-Price curve shows as a step curve, also explained the Law of Supply as discussed in later sections. The supply functions and the PPF given in Equation (17) are the key contributions of this paper. The rest of the paper discusses applications of this supply function, or compare our PPF with some other production possibility frontiers and see how much efficiency can be improved by using our proposed model.

. This explains why the Supply-Price curve shows as a step curve, also explained the Law of Supply as discussed in later sections. The supply functions and the PPF given in Equation (17) are the key contributions of this paper. The rest of the paper discusses applications of this supply function, or compare our PPF with some other production possibility frontiers and see how much efficiency can be improved by using our proposed model.

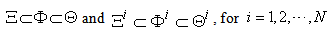

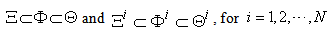

5. Macro Worst Production Possibility Frontier of the Macro System

Similarly, we can formulate the Worst Production Possibility Frontier (WPPF) for the micro as well as the macro system. Let  denote the micro WPPF of micro system

denote the micro WPPF of micro system  , and

, and  denote the macro WPPF of the macro system

denote the macro WPPF of the macro system  .

.  is defined as the lower boundary under the conditions that all of its micro systems have reached their micro PPF

is defined as the lower boundary under the conditions that all of its micro systems have reached their micro PPF  . The WPPF

. The WPPF  is defined as the set of micro supply vectors that are on the

is defined as the set of micro supply vectors that are on the  and results a macro supply vector on the macro WPPF

and results a macro supply vector on the macro WPPF  if aggregated for all micro systems.

if aggregated for all micro systems.  and

and  can be formulated using the same Equations as shown in Equation (16) and (17), as long as we set

can be formulated using the same Equations as shown in Equation (16) and (17), as long as we set  . We will not rewrite these Equations here. Let

. We will not rewrite these Equations here. Let  be the region bounded by

be the region bounded by  and

and  , and

, and  be the region bounded by

be the region bounded by  and

and  .

.  is called the micro Maximum Production Possibility Range (MPPR), and

is called the micro Maximum Production Possibility Range (MPPR), and  is called the macro MPPR. Given a price vector

is called the macro MPPR. Given a price vector  , through Equations (16) and (17),we can get a macro supply vector

, through Equations (16) and (17),we can get a macro supply vector  on

on  , a macro supply vector

, a macro supply vector  on

on  , a micro supply vector

, a micro supply vector  on

on  , and a micro supply vector

, and a micro supply vector  on

on  . It can be shown that the price vector

. It can be shown that the price vector  is the normal vector of those curves at the corresponding points as indicated by these supply vectors [6].

is the normal vector of those curves at the corresponding points as indicated by these supply vectors [6].

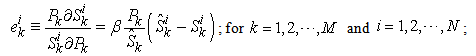

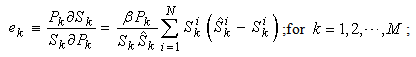

6. The Supply Elasticity and the Law of Supply

The Supply Elasticity is defined as the absolute value of the ratio of the percentage change in quantity supplied to the percentage change in price, which brings about the change in supply. Let  denote the supply elasticity for the

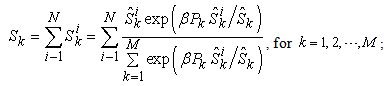

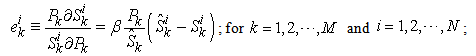

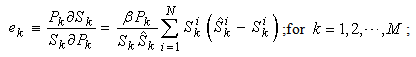

denote the supply elasticity for the  product. By applying partial differentiation to Equation (16) and (17), we can easily have:

product. By applying partial differentiation to Equation (16) and (17), we can easily have:  | (18) |

| (19) |

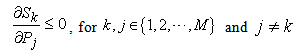

The Law of Supply is one of cornerstones in Economics theory. It states that as the price of a commodity rises, producers supply more. So far, the law of supply has been widely accepted as an empirical law. Using the analytical formats of the supply function, as shown in Equation (16) and (17), we can give a more precise and extended format for the Law of Supply as follows:The Law of Supply: Given an ideal economic system[6] and assuming that all other things remain unchanged (e.g., prices of other products and all production capability parameters remain unchanged), the supply of a commodity rises as the price of that commodity rises, and decreases as the price of any other commodity rises. Or in mathematical formats: | (20) |

| (21) |

Equation (20) is equivalent to say that the elasticity  given in Equation (19) is non-negative. Noting that

given in Equation (19) is non-negative. Noting that  and

and  , thus all items in Equation (19) is non-negative, then the elasticity

, thus all items in Equation (19) is non-negative, then the elasticity  which is a sum of some non-negative numbers is also non-negative. Thus Equation (20) is proven. By applying partial differentiation to Equation (16), we have:

which is a sum of some non-negative numbers is also non-negative. Thus Equation (20) is proven. By applying partial differentiation to Equation (16), we have: ,

,  , for

, for  and

and  Equation (21) follows the above two equations immediately, and thus the Law of Supply is proven.

Equation (21) follows the above two equations immediately, and thus the Law of Supply is proven.

7. Supply-Demand Equilibrium

Supply-Demand Equilibrium is one of the most important theorems in Economics. It states that Equilibrium is defined to be the price-quantity pair where the quantity demanded is equal to the quantity supplied, represented by the intersection of the demand and supply curves. The general format for the Supply-Demand Equilibrium can be expressed as: | (22) |

Where both  and

and  are functions of

are functions of  . Thus, the above general equilibrium equation gives

. Thus, the above general equilibrium equation gives  equations with

equations with  prices as unknowns. Generally, once we know the function format for

prices as unknowns. Generally, once we know the function format for  and

and  , the equilibrium price vector can be solved from Equation(22). We do not try to give a generic format for demand functions in this paper, instead, we just simply assume the demand is given as a vector with fixed direction, thus Equation (22) can be expressed as:

, the equilibrium price vector can be solved from Equation(22). We do not try to give a generic format for demand functions in this paper, instead, we just simply assume the demand is given as a vector with fixed direction, thus Equation (22) can be expressed as: | (23) |

We propose two methods to solve the General Equilibrium Equation (23).

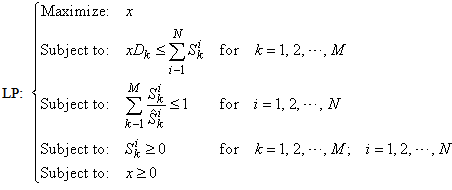

7.1. Solving the General Equilibrium as an Equation Problem

By combining Equation (23) and Equation (17), the General Equilibrium Equation can be formulated as the following equation problem: | (24) |

The above formula gives  equations with

equations with  for

for  as the

as the  variables. Then the price victor

variables. Then the price victor  can be solved by solving the above equation through many mature methods, such as Newton’s method [5, 9], Brent’s method [2, 13]. Thus all the micro supplies

can be solved by solving the above equation through many mature methods, such as Newton’s method [5, 9], Brent’s method [2, 13]. Thus all the micro supplies  can be given through Equation (16), and all the macro supplies can be given through Equation (23) or Equation (17).

can be given through Equation (16), and all the macro supplies can be given through Equation (23) or Equation (17).

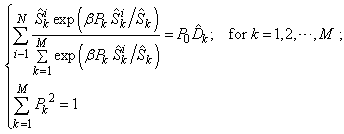

7.2. Solving the General Equilibrium as an Linear Programming Problem

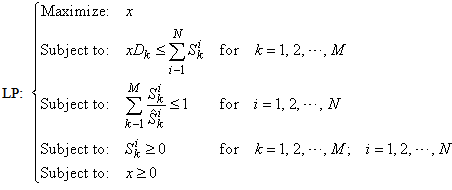

The General Equilibrium Equation (23) can also be formulated as the following optimization problem: | (25) |

This is a linear programming problem with  and

and  as variables. It can be easily solved through the T-forward method [7, 8, 3]. Equation (24) and (25) should give the same solution.

as variables. It can be easily solved through the T-forward method [7, 8, 3]. Equation (24) and (25) should give the same solution.

8. Some Special Production Possibility Curves

In this section, we introduce two special scenarios with special production possibility curves. These curves can be used to compare with the PPF and can show how efficiency of the production states on the PPF.

8.1. Linear Production Possibility Frontier

We have introduced the micro vertex points as shown in Equation (5). A plane curve can be formulated by passing through these vertex points as following: | (26) |

Let us call this plane curve as the micro Linear Production Possibility Frontier (LPPF), and denoted as  . Similarly, we can construct a macro LPPF curve

. Similarly, we can construct a macro LPPF curve  for the macro system

for the macro system  , which can be formulated as:

, which can be formulated as: | (27) |

Using the price vector as a reference vector, the above equation can be expressed as: | (28) |

Note that the above Equation cannot be treated as the supply function, although it is expressed as functions of the price vector. It can be shown that: | (29) |

8.2. Self Sufficient Scenario

Another special scenario is the so called Self Sufficient case, in which every micro system just simply works on itself to provide all products with the amounts to be proportional to the requested demands. Within this scenario, there is no cooperation among micro systems. Let us call the PPF Curve for this scenario as SPPF. Let  and

and  be the micro SPPF and macro SPPF for the Self Sufficient scenario.

be the micro SPPF and macro SPPF for the Self Sufficient scenario.  is the same as the plane curve

is the same as the plane curve  as shown in Equation (26). However, the macro SPPF

as shown in Equation (26). However, the macro SPPF  is different from the Macro LPPF

is different from the Macro LPPF  . By definition, given the requested demand as

. By definition, given the requested demand as  , the micro SPPF

, the micro SPPF  can be expressed as:

can be expressed as: | (30) |

And the macro SPPF  can be formulated as:

can be formulated as:  | (31) |

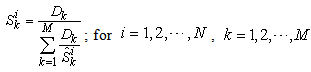

9. A Dummy System with Dummy Data

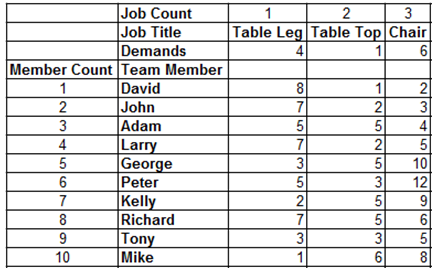

In order to give concrete examples to demonstrate our model and methodology, let us create a dummy system with dummy data. The dummy system  is called the carpenter system, which contains

is called the carpenter system, which contains  units or members, and need to make

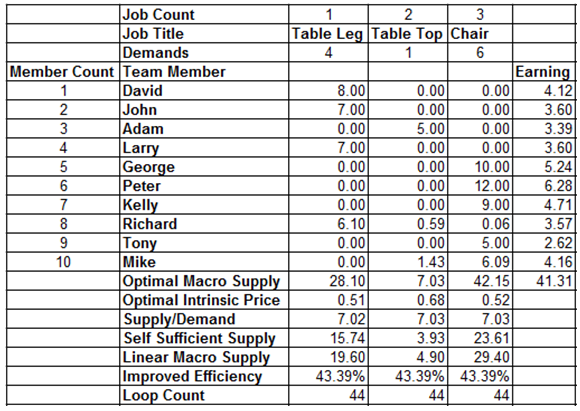

units or members, and need to make  products. The carpenter system needs to produce 4 table legs, 1 table top, and 6 chairs, which make up the 3 components of the demand vector. The micro capability matrix and demand vector are listed in Table 1. The requested amounts or demands are listed in row 3, and the production capabilities are listed in row 5 to 14.

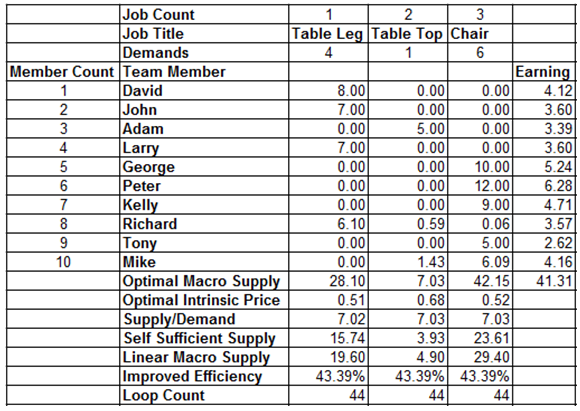

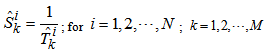

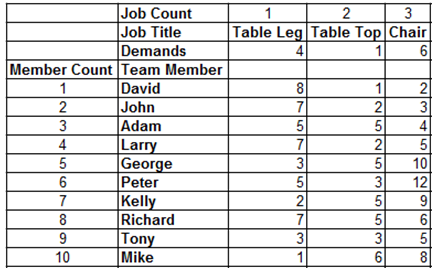

products. The carpenter system needs to produce 4 table legs, 1 table top, and 6 chairs, which make up the 3 components of the demand vector. The micro capability matrix and demand vector are listed in Table 1. The requested amounts or demands are listed in row 3, and the production capabilities are listed in row 5 to 14.Table 1. Input data for the carpenter system with 10 members and 3 products

|

| |

|

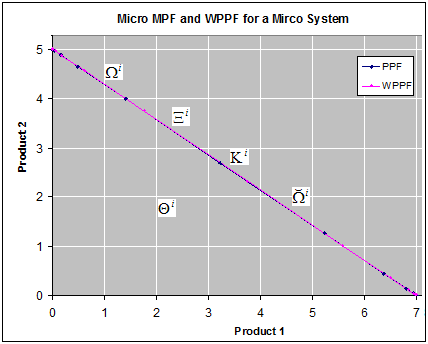

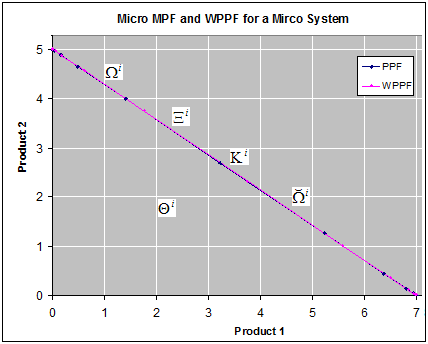

Given the input data as listed in Table 1, by applying Equation (16), (26), and (30), the micro curves  ,

,  ,

,  , and

, and  are derived and are drawn in Figure 2. These four curves are all converged to the same plane curve.

are derived and are drawn in Figure 2. These four curves are all converged to the same plane curve. | Figure 2. The micro PPF , the micro WPPF , the micro WPPF  , the micro LPPF , the micro LPPF  , and the Micro SPPF , and the Micro SPPF  are all shown as the same plane curve in the production space are all shown as the same plane curve in the production space |

According to Equation (16), curves  and

and  could be different from the plane curve for some small

could be different from the plane curve for some small  . However, the difference can be only shown up for 3 or more dimensional case. If we set all other prices to 0 except two of them, then the above four curves always converge to the plane curve.Figure 3. shows the macro PPF

. However, the difference can be only shown up for 3 or more dimensional case. If we set all other prices to 0 except two of them, then the above four curves always converge to the plane curve.Figure 3. shows the macro PPF  , along with some other macro curves, including WPPF

, along with some other macro curves, including WPPF  , LPPF

, LPPF  , and SPPF

, and SPPF  . Figure 4 draws the supply-price curves for various

. Figure 4 draws the supply-price curves for various  value. By comparing with Figure 1, our model gives the PPF and supply functions in more detailed formats and make the general supply-demand equilibrium solvable numerically.

value. By comparing with Figure 1, our model gives the PPF and supply functions in more detailed formats and make the general supply-demand equilibrium solvable numerically. | Figure 3. The macro PPF  is a convex curve, the macro WPPF is a convex curve, the macro WPPF  and the macro SPPF and the macro SPPF  are concave curves, whereas the macro LPPF are concave curves, whereas the macro LPPF  is a linear plane curve in the production space. The maximum PPR is a linear plane curve in the production space. The maximum PPR  is the region bounded by is the region bounded by  and and  . The extension line of the demand vector . The extension line of the demand vector  intersects with these 4 curves at the points intersects with these 4 curves at the points  , ,  , ,  , and , and  respectively. These curves and points are used for improved efficiency analysis respectively. These curves and points are used for improved efficiency analysis |

10. The Best and the Worst Scenarios

Suppose each of the micro system  has reached its micro PPF

has reached its micro PPF , then the aggregated macro state of the macro system must be in the macro MPPR

, then the aggregated macro state of the macro system must be in the macro MPPR . Also, suppose the macro system

. Also, suppose the macro system  is requested to produce the demand vector

is requested to produce the demand vector . The demand vector

. The demand vector  is as shown as the line

is as shown as the line  in Figure 3. Figure 3. also shows the four points

in Figure 3. Figure 3. also shows the four points ,

,  ,

,  , and

, and , which are the intersection points of the line

, which are the intersection points of the line  with the curves

with the curves ,

,  ,

,  , and

, and . For all possible production states in

. For all possible production states in , the Line

, the Line  gives all possible states that are proportional to the requested demand

gives all possible states that are proportional to the requested demand . Any other states in

. Any other states in  may have some products wasted or not needed compared with the requested demand

may have some products wasted or not needed compared with the requested demand . So, for all possible states in

. So, for all possible states in , only the states on line

, only the states on line  can best meet the requested demand

can best meet the requested demand . We are only interested in the states that are on the line

. We are only interested in the states that are on the line . For all states on the line

. For all states on the line , the point

, the point  is the best scenario, because it gives the maximum possible amount for all supplies,

is the best scenario, because it gives the maximum possible amount for all supplies,  is the worst scenario, whereas

is the worst scenario, whereas  and

and  are somewhere in the middle. Point

are somewhere in the middle. Point  can be treated as the average state for all points in the macro MPPR

can be treated as the average state for all points in the macro MPPR . Let us assume that point

. Let us assume that point  is the average state that the macro system reached without using any optimal management method. Now, let

is the average state that the macro system reached without using any optimal management method. Now, let  denote the improved production efficiency by comparing the best scenario

denote the improved production efficiency by comparing the best scenario  with the average scenario

with the average scenario , then

, then  can be formulated as:

can be formulated as: | (32) |

| Figure 4. Supply Curves. When price  rises and all other prices remain unchanged, the supply rises and all other prices remain unchanged, the supply  rises, whereas the supply for other products decreases, for example, Supply rises, whereas the supply for other products decreases, for example, Supply  decreases. When decreases. When  is large, the supply curves is large, the supply curves  and and  become step curves become step curves |

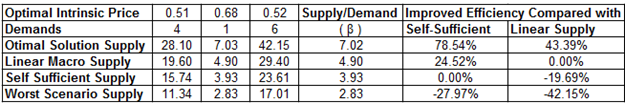

11. Application 1: Labor Assignment for Labor Oriented Team

The mathematic formula for the Macro PPF and the supply function may have lot of applications and can improve the production efficiency significantly. Here we just introduce one of the applications of the macro PPF and the supply function: finding the optimal solution for team work management problems.We have developed a software tool that can find optimal solution for labor assignment problems by solving equation problem listed in Equation (24), or by solving linear programming problem as listed in Equation (25).By applying this software tool to the Carpenter team with the input data as listed in Table 1, we find the optimal solution as shown in Table 2. The solution given in Table 2 tells us at least the following information:Table 2. The optimal solution for the Carpenter team management problem

|

| |

|

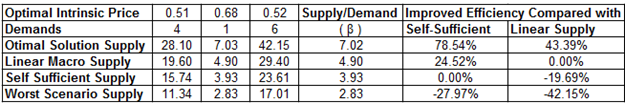

It tells all the information about the production state, including the amount of a production to be made by each team member. Each micro production state is a point on the corresponding micro PPF.Most of the team members should work on only one product. Some of the team members may work on multiple products. For example, team member David should work only on “Table Legs” and make 8 “Table Legs” within requested time T, while Richard should work on all 3 products, and make 6.1 “Table legs”, 0.59 “Table Tops”, and 0.06 “Chairs”. The final macro Supply is 28 “Table legs”, 7 “Table Tops”, and 42 “Chairs”. This macro Supply state is on the macro PPF  and proportional to the requested production demand vector

and proportional to the requested production demand vector  . The last column gives the Earnings or Incomes for each team member.The row with header “Supply/Demand” gives the number

. The last column gives the Earnings or Incomes for each team member.The row with header “Supply/Demand” gives the number defined in Equation (23). It is the ratio between the optimal solution and the requested demand amount.The row with header “Optimal Intrinsic Price” gives the intrinsic prices which can be used to calculate the earnings for each team member. The intrinsic price vector for these 3 products should be (0.51, 0.68, 0.52). Once this intrinsic price vector is known, each team member will reach his maximum income by making the products with the amounts as requested in the optimal solution. In other words, the whole team will realize the optimal solution automatically as long as each sub unit has maximized its income.The row with header “Self Sufficient Supply” lists the supply state

defined in Equation (23). It is the ratio between the optimal solution and the requested demand amount.The row with header “Optimal Intrinsic Price” gives the intrinsic prices which can be used to calculate the earnings for each team member. The intrinsic price vector for these 3 products should be (0.51, 0.68, 0.52). Once this intrinsic price vector is known, each team member will reach his maximum income by making the products with the amounts as requested in the optimal solution. In other words, the whole team will realize the optimal solution automatically as long as each sub unit has maximized its income.The row with header “Self Sufficient Supply” lists the supply state  on the SPPF

on the SPPF  . The row with header “Linear Macro Supply” lists the supply state

. The row with header “Linear Macro Supply” lists the supply state  on the LPPF

on the LPPF  . The row with header “Improved Efficiency” lists the improved efficiency ratio by the optimal solution

. The row with header “Improved Efficiency” lists the improved efficiency ratio by the optimal solution  compared with the Linear Macro Scenario

compared with the Linear Macro Scenario . The row with header “Loop Count” lists the number of loops for our numerical calculation to converge to the results with required precision. The optimal solution not only depends on the capability matrix, but also depends on the direction of the demand vector. Given a team member and his capability matrix, we cannot tell which product is the most specialized product for him. The optimal solution may request him to work on one product. However, once the direction of the demand vector changes, the same team member might be requested to work on some other products to have the whole team to reach the optimal solution.

. The row with header “Loop Count” lists the number of loops for our numerical calculation to converge to the results with required precision. The optimal solution not only depends on the capability matrix, but also depends on the direction of the demand vector. Given a team member and his capability matrix, we cannot tell which product is the most specialized product for him. The optimal solution may request him to work on one product. However, once the direction of the demand vector changes, the same team member might be requested to work on some other products to have the whole team to reach the optimal solution.

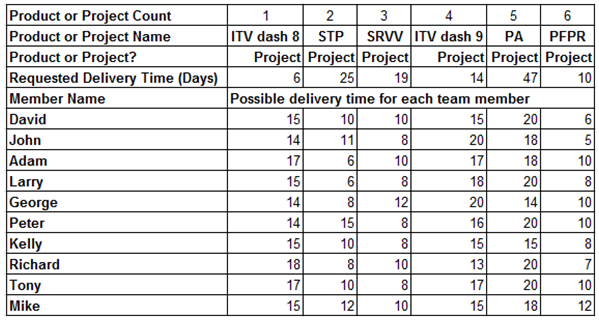

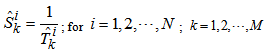

12. Application 2: Labor Assignment for Project Oriented Team

Application 1 gives an example of a team working on products, which is more applicable to a labor oriented team. A product oriented team is basically a team working on products and the demands can be simply formulated as the amounts of the products. A project oriented team is a team working on projects, while each project is required to be delivered in a given deadline. For a project oriented team, the capability parameter  can be explained as the delivery ratio (or amount) of the kth project

can be explained as the delivery ratio (or amount) of the kth project  by team member

by team member  . The demand for each project is 1 within required delivery time. Let

. The demand for each project is 1 within required delivery time. Let  denote the required delivery time for the kth project

denote the required delivery time for the kth project  , and

, and  denote the fastest delivery time of team member

denote the fastest delivery time of team member  to deliver the kth project

to deliver the kth project  under the condition that

under the condition that  works only on project

works only on project  . Then the equivalent demand vector can be expressed as:

. Then the equivalent demand vector can be expressed as: | (33) |

And the equivalent production capability parameters can be expressed as: | (34) |

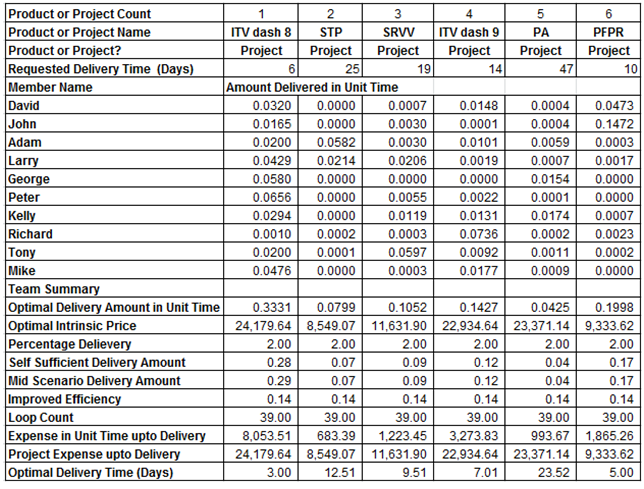

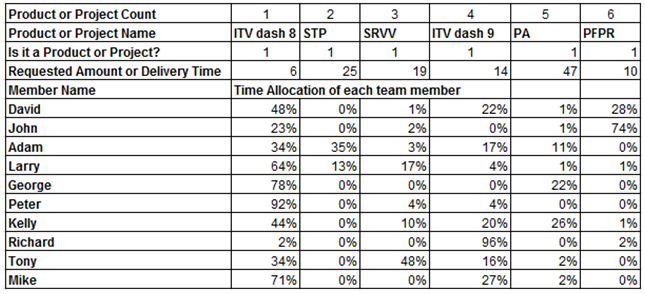

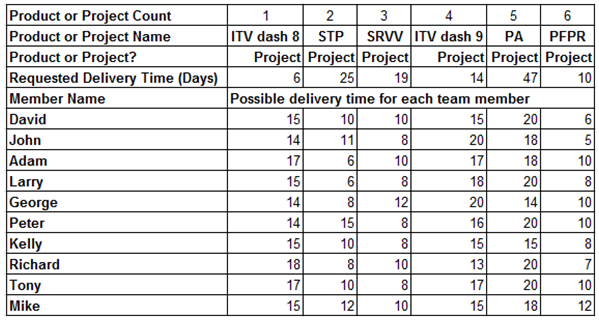

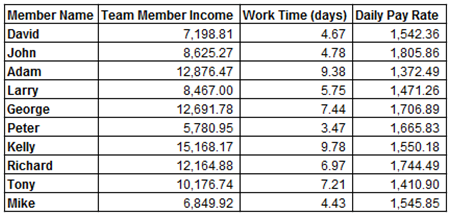

Then, our proposed model for labor assignment is applicable to project oriented teams. We have applied our proposed model to manage an engineer team in Boeing Corporation. Let us call this team as Boeing team. The Boeing team includes 10 Engineers to work on 6 projects that need to be delivered in requested deadlines. The total budget for these projects is 100,000 USD. Table 3 lists the fastest delivery time for each team member to deliver each project. If we inverse each number in this table, it will be the capability parameter matrix. Please note that we have given dummy names for each team member. The Boeing Team was given a strict deadline to finish these projects. The manager had been worried about whether they could deliver these projects and struggled for labor assignment among the team members. By solving Equilibrium Equation (24), or solving the linear programming problem as listed in Equation (25), we can give the optimal labor assignment solution for the Boeing team. Table 4 lists the amount to be delivered in unit time for each team member and each project. Table 5 lists the optimal assignment in terms of time allocation for each team member. Table 6 lists the income, total work days, and the pay-rate for each team member. With our optimal solution for labor assignment, the Boeing Team can deliver all of their 6 projects on time and all the actual delivery time are reduced by half compared with the original requested delivery time. Table 3. The delivery capability matrix and requested delivery time for Boeing team

|

| |

|

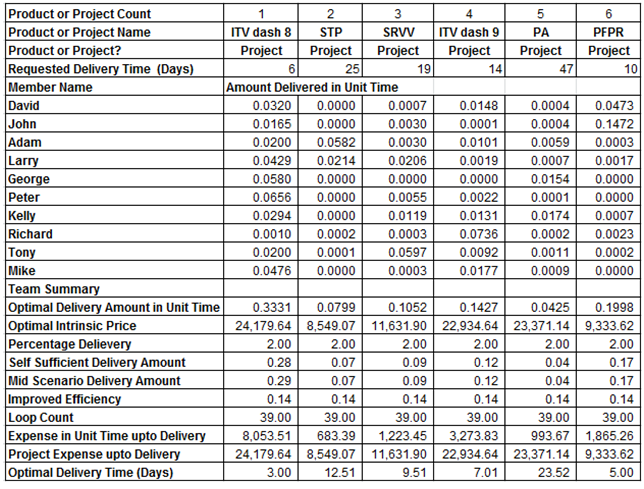

Table 4. The optimal solution for a project oriented team in Boeing Corporation

|

| |

|

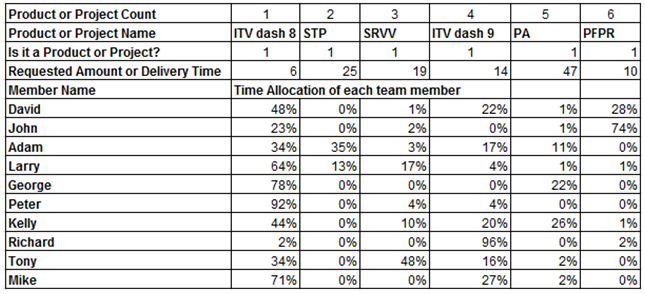

Table 5. Optimal Time allocation for a project oriented team in Boeing Corporation

|

| |

|

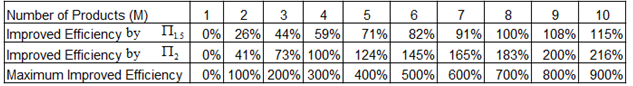

Table 6. Income and pay rate at the Equilibrium state

|

| |

|

13. Production Efficiency Improvement for the Carpenter Team

Note that, even with the worst scenario case, all team members have worked hard to reach their micro PPF states. In other words, although all team members have exhausted all of their resources to work on the requested products, the production output are very different for the macro system. The inefficiency for the worst scenario is completely due to improper management. With proper arrangement, we can have the team to improve production efficiency by 148% compared with the worst scenario.Table 7 lists the macro supplies for the optimal solution, the worst scenario solution, the Linear Macro Supply scenario, as well as the Self-Sufficient scenario. It also lists the improved production efficiency ratios by comparing with the Self-Sufficient scenario as well as the Linear Macro Supply scenario. Table 7. Improved Production Efficiency Ratios for the Carpenter Team

|

| |

|

By comparing with the Self-Sufficient Supply scenario, we can find out how much efficiency improved due to the division of labors and corporations among team members. The Linear Macro Supply scenario can improve the production efficiency by 25%, whereas our optimal solution can improve the production efficiency by 79%. These improved efficiencies come from the division of labor and cooperation among team members. Some managements with good quality are required to realize such kind efficiency improvements. Our proposed method gives the optimal solution for team work management. By comparing with the supply state  , we can find the improved efficiency ratio by the optimal solution. The improved efficiency for the carpenter team is:

, we can find the improved efficiency ratio by the optimal solution. The improved efficiency for the carpenter team is: | (35) |

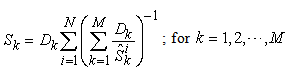

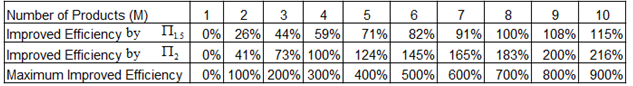

14. Estimate the Improved Production Efficiency for Generic Cases

As discussed in the previous sections, by applying our optimal management method, the Carpenter team can improve its production efficiency by 43%. That is amazing! However, people might argue that the Carpenter team is just a special case. In this section, we estimate the production efficiency improvement ratio that can be brought by the optimal solution for generic cases. Our analysis shows that the optimal solution can really improve production efficiency by 40% for most of the team work management problems.To simplify our analysis, we assume the demand vector as  in this section. Let

in this section. Let  be the intersection point of the demand vector

be the intersection point of the demand vector  (or its extension) with the curve

(or its extension) with the curve  , and

, and  denote the length of the line

denote the length of the line  . Then

. Then  can be easily found as:

can be easily found as: | (36) |

As the macro PPF  is a convex curve, we can use

is a convex curve, we can use  to approximate the PPF

to approximate the PPF  , with

, with  to be a value that can make the

to be a value that can make the  most close to

most close to  . Normally, once we find one point on

. Normally, once we find one point on  , we can calculate the value of

, we can calculate the value of  which can make the

which can make the  most close to the

most close to the  . Further, we assume the average production state is roughly at the point

. Further, we assume the average production state is roughly at the point  on the curve

on the curve  (or denoted as

(or denoted as ). If

). If  is used to approximate

is used to approximate  , the improved efficiency by reaching the macro PPF can be estimated as:

, the improved efficiency by reaching the macro PPF can be estimated as: | (37) |

Actually, the more team members the team has, the more convex the macro PPF tends to be. Based on our test results, we found that  is a good approximation for

is a good approximation for  when

when ; and even

; and even  will be a good approximation for

will be a good approximation for  when

when  and

and . To make it more conservative, we use

. To make it more conservative, we use  to approximate the macro PPF

to approximate the macro PPF . Then the production efficiency ratio that can be improved by the optimal solution can be estimated as:

. Then the production efficiency ratio that can be improved by the optimal solution can be estimated as: | (38) |

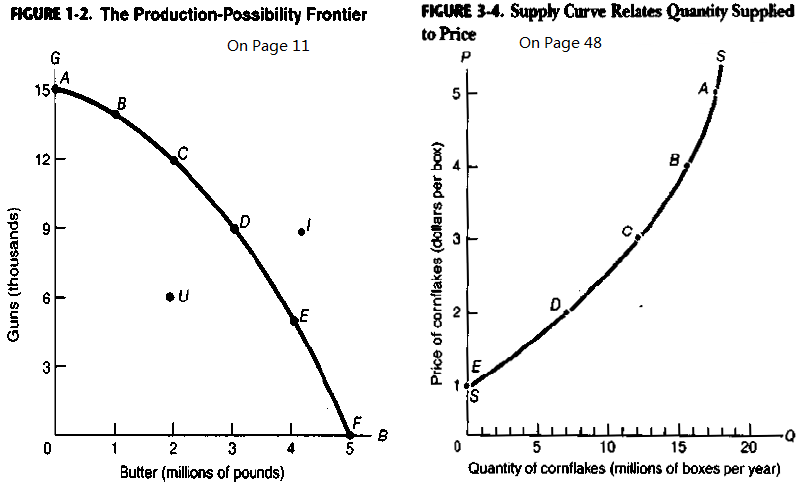

Table 8 lists the possible production efficiency improved by the optimal solution for a team working on  products. Based on our test results and the above analysis, our optimal solution for team work management normally can improve the production efficiency by 40% for most of team work problems!

products. Based on our test results and the above analysis, our optimal solution for team work management normally can improve the production efficiency by 40% for most of team work problems! | Figure 5.  can be used to approximate the PPF can be used to approximate the PPF  and LPPF and LPPF  . Here all the curves are shown in 2-dimensional. You need to imagine it in M-dimensional . Here all the curves are shown in 2-dimensional. You need to imagine it in M-dimensional |

Table 8. Production Efficiency Improved by the Optimal Solution for a Team

|

| |

|

15. Micro and Macro Management

By applying the proposed method and the software tool, we can find the optimal solution for the team work management, or labor assignment problems. Suppose you are the team manager, how are you going to manage your team to reach the optimal management? Here we propose two management methods: Micro Management and Macro Management.

15.1. Micro Management

Our optimal solution for team work management problems, as shown in Table 2 and Table 4, lists all the micro information for each team member, including micro supply amount  , and the micro income amount

, and the micro income amount  . Using these micro information, a team manager can tell each team member

. Using these micro information, a team manager can tell each team member  to work on the

to work on the  with the amount

with the amount  as indicated in the optimal solution. Note that most of the team members may work on only one product. The team manager can also tell each team member

as indicated in the optimal solution. Note that most of the team members may work on only one product. The team manager can also tell each team member  about how much he should be paid, which would be

about how much he should be paid, which would be  . So, with micro management, a team manager manages each of the team members in micro details, including what and how much need to be done, as well as how much should be paid as return. That is why we call this management method as Micro Management.

. So, with micro management, a team manager manages each of the team members in micro details, including what and how much need to be done, as well as how much should be paid as return. That is why we call this management method as Micro Management.

15.2. Macro Management

Our optimal solution for team work management problems, as shown in Table 2 and Table 4, also gives the intrinsic prices  . Given this intrinsic price vector, each team member will reach his maximum income by working on the product with the amount as requested by the optimal solution. Suppose each team member is targeting at maximizing his income, the team manager needs only declare the intrinsic prices, then, every team member will automatically to work on the product with the amount such that the whole team will reach its optimal solution as indicated in the optimal solution. The team manager doesn’t manage the team members in micro details, but manage it in macro level, which simply tells how much will be paid for product or project to be delivered. That is why we call this management method as macro management.

. Given this intrinsic price vector, each team member will reach his maximum income by working on the product with the amount as requested by the optimal solution. Suppose each team member is targeting at maximizing his income, the team manager needs only declare the intrinsic prices, then, every team member will automatically to work on the product with the amount such that the whole team will reach its optimal solution as indicated in the optimal solution. The team manager doesn’t manage the team members in micro details, but manage it in macro level, which simply tells how much will be paid for product or project to be delivered. That is why we call this management method as macro management.

16. Conclusions

The main contributions of this paper include a new model that can formulate the Supply function and the Production Possibility Frontier as a function of the capability parameters and the price vector. The Law of Supply, the supply elasticity can be easily derived from the proposed model. Another contribution is the methods for solving the Supply-Demand equilibrium. Lastly, we present a model and method that can give optimal solution for labor assignment and team work management problems based on the Supply-Demand equilibrium. Our test results and generic analysis show that the proposed management method can improve the team work efficiency significantly. For most cases, it can improve the production efficiency by 40%!

References

| [1] | [Bar10] R. R. Barthwal, Industrial Economics: An Introductory Textbook. P. 31, 2010. |

| [2] | [Bre73] R. P. Brent. Algorithms for Minimization without Derivatives. Chapter 4. Englewood Cliffs, NJ: Prentice-Hall, 1973. ISBN 0-13-022335-2. |

| [3] | [DS97] Robert Dorfman; Paul A. Samuelson; Robert M. Solow. Linear Programming and Economic Analysis. McGraw-Hill College Division, 1997. ISBN: 0486654915. |

| [4] | [Gil07] Andrew Gillespie, Foundations of Economics. Ch. 2. Oxford University Press, 2007. |

| [5] | [Kel03] C. T. Kelley, Solving Nonlinear Equations with Newton's Method, no 1 in Fundamentals of Algorithms, SIAM, 2003. ISBN 0-89871-546-6. |

| [6] | [Liu02] G. Liu, Analytic Economics, P. 39-90, 2002. ISBN 10: 0971893403 / ISBN 13: 9780971893405. |

| [7] | [Liu14] G. Liu, “T-Forward Method: A Closed-Form Solution and Polynomial Time Approach for Convex Nonlinear Programming”. Algorithms Research, Vol.3, No.1: 1-23. 2014. |

| [8] | [Liu14] G. Liu, “T-Forward Method: A Closed-Form Solution and Polynomial Time Approach for Convex Quadratic Programming”. Applied Mathematics, 2014. |

| [9] | [OR00] J. M. Ortega, W. C. Rheinboldt, Iterative Solution of Nonlinear Equations in Several Variables. Classics in Applied Mathematics, SIAM, 2000. ISBN 0-89871-461-3. |

| [10] | [PR09] Robert Pindyck, Daniel Rubinfeld, Microeconomics, The Pearson Series in Economics, 2012. ISBN-10: 013285712X / ISBN-13: 978-0132857123. |

| [11] | [Sam04] Paul A. Samuelson and William D. Nordhaus, Economics. Chapter 1-5.McGraw-Hill; 16th Edition, 1998. ISBN 7-111-06448-8. |

| [12] | [Sam67] Paul A. Samuelson. “Summary on Factor-Price Equalization”. International Economics Review, Vol. 8, No. 3, 8(3): 286-295, 1967. |

| [13] | [Sta13] Steven A. Stage. “Comments on An Improvement to the Brent's Method”, International Journal of Experimental Algorithms 4 (1): 1–16.2013. |

: An economic system that contains some sub systems. It can be as small as a family, a firm, and can be as large as a country or the whole world.

: An economic system that contains some sub systems. It can be as small as a family, a firm, and can be as large as a country or the whole world.  is also called a macro system compared with its sub systems.

is also called a macro system compared with its sub systems. : An integer represents the total number of the sub systems in

: An integer represents the total number of the sub systems in  .

.  : An integer represents the total number of the products that are produced in

: An integer represents the total number of the products that are produced in  .

.  : The ith unit or sub system in system

: The ith unit or sub system in system  . It could be an individual member, or a group of people, such as a firm or another economic system in

. It could be an individual member, or a group of people, such as a firm or another economic system in  . However, there are no overlaps between different Units. For example, if an individual has been included in one unit, the same individual can’t be included in another unit.

. However, there are no overlaps between different Units. For example, if an individual has been included in one unit, the same individual can’t be included in another unit.  is also called a micro system compared with its parent system.

is also called a micro system compared with its parent system. : The kth product that can be produced in system

: The kth product that can be produced in system  . Actually, the product here means any labor activities that can be done by any unit in

. Actually, the product here means any labor activities that can be done by any unit in  . It can be a real product, a project, a job, a task, and anything that need to be done or produced by any unit in

. It can be a real product, a project, a job, a task, and anything that need to be done or produced by any unit in  .

. : A time span that the above mentioned products are produced in

: A time span that the above mentioned products are produced in  .

. :

:  , which is the set of non-negative M-dimensional real vectors and with the original point

, which is the set of non-negative M-dimensional real vectors and with the original point  excluded.

excluded. : The same as

: The same as  . However, we use it to particularly represent the Production Space with its kth Cartesian coordinate representing the amount of a parameter related to

. However, we use it to particularly represent the Production Space with its kth Cartesian coordinate representing the amount of a parameter related to  product.

product. : The demand amount of

: The demand amount of  product that requested by

product that requested by  .

.  : The maximum amount of

: The maximum amount of  product that can be produced by

product that can be produced by  within time

within time  . Normally

. Normally  can be produced by

can be produced by  when it uses all of its resources to work on product

when it uses all of its resources to work on product  . All the

. All the  make up an

make up an  matrix, which is called the micro capability matrix of system

matrix, which is called the micro capability matrix of system  .

.  : The amount of

: The amount of  product that are actually produced by

product that are actually produced by  . All the

. All the  make up a vector in

make up a vector in  , and is called micro supply vector.

, and is called micro supply vector. : The amount of

: The amount of  product produced by the macro system

product produced by the macro system  . It is also called the macro supply of system

. It is also called the macro supply of system  . All the

. All the  make up a vector in

make up a vector in  , and is called a macro supply vector of system

, and is called a macro supply vector of system  .

. ;

;  : The price of the

: The price of the  product in system

product in system  .

. introduced above. An economic system is called a micro system if it is contained in a macro system, such as the sub-system

introduced above. An economic system is called a micro system if it is contained in a macro system, such as the sub-system  described above. Definition: System Parameter: An economic parameter is called a system parameter if it is associated with an economic system. For example, the supply amount, demand amount, and price are all examples of system parameters. Definition: Micro Parameter and Macro Parameter: A system parameter is called a micro parameter if it is associated with a micro system, and is called a macro parameter if it is associated with a macro system. Some parameters may be associated with both micro system and macro system. As long as there is no confusion, we use the same alphabet character to represent a system parameter: if

described above. Definition: System Parameter: An economic parameter is called a system parameter if it is associated with an economic system. For example, the supply amount, demand amount, and price are all examples of system parameters. Definition: Micro Parameter and Macro Parameter: A system parameter is called a micro parameter if it is associated with a micro system, and is called a macro parameter if it is associated with a macro system. Some parameters may be associated with both micro system and macro system. As long as there is no confusion, we use the same alphabet character to represent a system parameter: if  denotes a macro parameter associated with a macro system

denotes a macro parameter associated with a macro system  , then

, then  will be used to denote the same micro parameter associated with micro system

will be used to denote the same micro parameter associated with micro system  .For example,

.For example,  and

and  represent the macro and micro supply amounts of product

represent the macro and micro supply amounts of product  ,

,  and

and  denote the macro PPF of system

denote the macro PPF of system  and the micro PPF of the micro system

and the micro PPF of the micro system  correspondingly. Definition: Vector Parameter and Scalar Parameter: a system parameter may also be associated with each of the production, for example, supply amount normally means the amount of a product that can be provided by an economic system. In a system with

correspondingly. Definition: Vector Parameter and Scalar Parameter: a system parameter may also be associated with each of the production, for example, supply amount normally means the amount of a product that can be provided by an economic system. In a system with  products, a system parameter could be

products, a system parameter could be  -dimensional with each component representing the amount associated with one product. These

-dimensional with each component representing the amount associated with one product. These  -dimensional parameters make up a vector in the production space

-dimensional parameters make up a vector in the production space  , thus is called a Vector Parameter. A vector parameter can be represented by a vector in

, thus is called a Vector Parameter. A vector parameter can be represented by a vector in  . Examples of vector parameters are: Supply, Demand, and Price. A system parameter is called a scalar parameter if it is one dimensional. Examples of scalar parameters are: income, GDP, revenue, etc.Additive Parameter: A system parameter is called additive parameter if the corresponding macro parameter can be derived by aggregating the same parameter over all of its micro systems. Or precisely, system parameter X is additive if

. Examples of vector parameters are: Supply, Demand, and Price. A system parameter is called a scalar parameter if it is one dimensional. Examples of scalar parameters are: income, GDP, revenue, etc.Additive Parameter: A system parameter is called additive parameter if the corresponding macro parameter can be derived by aggregating the same parameter over all of its micro systems. Or precisely, system parameter X is additive if

is a parameter reachable and meaningful to micro system

is a parameter reachable and meaningful to micro system  , while

, while  is the same parameter reachable and meaningful to macro system

is the same parameter reachable and meaningful to macro system  .In our model, we tried to decompose the macro system

.In our model, we tried to decompose the macro system  into some micro systems

into some micro systems  , and divide the products into some products or tasks in such a way that some of the system parameters are additive, particularly, the supply amount, the demand amount, revenue, and income are all additive. However, the price parameter is not an additive parameter. Based on the above notations and definitions, we can say that the supply and demand are vector parameters and are additive, whereas the price is also a vector parameter, but not additive. The income, revenue, GDP, profit and loss are all additive scalar parameters. We are only interested in those parameters in this paper.

, and divide the products into some products or tasks in such a way that some of the system parameters are additive, particularly, the supply amount, the demand amount, revenue, and income are all additive. However, the price parameter is not an additive parameter. Based on the above notations and definitions, we can say that the supply and demand are vector parameters and are additive, whereas the price is also a vector parameter, but not additive. The income, revenue, GDP, profit and loss are all additive scalar parameters. We are only interested in those parameters in this paper.  , the production capability matrix for each micro system and for each product.

, the production capability matrix for each micro system and for each product. : The macro demand of

: The macro demand of  product that needs to be accomplished by system

product that needs to be accomplished by system  . We assume the following parameters are unknowns and need to be resolved: Price, micro supply, macro supply, micro income, macro revenue.

. We assume the following parameters are unknowns and need to be resolved: Price, micro supply, macro supply, micro income, macro revenue.  , let us assume that it can arrange its resources to make any requested products. However, its production amount for product

, let us assume that it can arrange its resources to make any requested products. However, its production amount for product  should be limited to or bounded by

should be limited to or bounded by  due to its limited resources and capabilities. Any of its feasible production state will be a point or a vector in the production space

due to its limited resources and capabilities. Any of its feasible production state will be a point or a vector in the production space  . All of its feasible production vectors should be a bounded range in the production space

. All of its feasible production vectors should be a bounded range in the production space  . We call this bounded range as its micro Production Possibility Range (PPR) and denoted as

. We call this bounded range as its micro Production Possibility Range (PPR) and denoted as  . The upper boundary of

. The upper boundary of  is called the micro PPF, denoted as

is called the micro PPF, denoted as  . Normally, as long as the micro system

. Normally, as long as the micro system  is small enough compared with macro system

is small enough compared with macro system  , each of the micro PPF can be approximated by the linear plane curve that passing the

, each of the micro PPF can be approximated by the linear plane curve that passing the  axis at

axis at  in production space

in production space  . Given the micro capability matrix, the micro PPF

. Given the micro capability matrix, the micro PPF  can be formulated as:

can be formulated as:

can also be expressed in the following format:

can also be expressed in the following format:

is called the intrinsic price vector of the micro system.Actually,

is called the intrinsic price vector of the micro system.Actually,  is a linear plane curve with vector

is a linear plane curve with vector  as its normal vector. It passes the

as its normal vector. It passes the  axis at the points:

axis at the points:

is the unit vector on the

is the unit vector on the  axis.

axis.  and is on the

and is on the  axis of the production space. We call these

axis of the production space. We call these  points as the micro vertex points. Given the price vector as

points as the micro vertex points. Given the price vector as  and the micro supply vector

and the micro supply vector  of the micro system

of the micro system  , the total income or revenue of the micro system

, the total income or revenue of the micro system  can be expressed as:

can be expressed as:

is feasible to micro system

is feasible to micro system  , there should have some possible micro supply vectors that can maximize the income or revenue of the micro system

, there should have some possible micro supply vectors that can maximize the income or revenue of the micro system  . Such feasible micro supply vectors can be formulated as:

. Such feasible micro supply vectors can be formulated as:

to be maximized is a linear function, according to Lagrange’s theorem, the max-min can only be found on the boundary of the region

to be maximized is a linear function, according to Lagrange’s theorem, the max-min can only be found on the boundary of the region  . Then the above equation is equivalent to:

. Then the above equation is equivalent to:

vertex points listed in Equation (5). Then, the above equation can be further simplified as:

vertex points listed in Equation (5). Then, the above equation can be further simplified as:

is an

is an  function defined as:

function defined as:

is the total number of vertex points that have

is the total number of vertex points that have  maximized for

maximized for  . Number

. Number  can be formulated as:

can be formulated as:

maximized. It gives at least one of the micro supply vectors

maximized. It gives at least one of the micro supply vectors  that can have the micro income

that can have the micro income  maximized. It is an explicit mathematical format for the micro supply as a function of the capability matrix and the price vector. However, it is a discrete function and thus is difficult to deal with. The key step and major contribution of our model is to formulate a continuous and smooth function to approximate the Equation (13). Here are the key steps. Equation (13) is equivalent to the following function:

maximized. It is an explicit mathematical format for the micro supply as a function of the capability matrix and the price vector. However, it is a discrete function and thus is difficult to deal with. The key step and major contribution of our model is to formulate a continuous and smooth function to approximate the Equation (13). Here are the key steps. Equation (13) is equivalent to the following function:

is called the macro capability parameter defined as:

is called the macro capability parameter defined as:

. In practical applications, we can simply drop the limited function by assigning

. In practical applications, we can simply drop the limited function by assigning  with a large number, thus the Equation (14) can be simply expressed as:

with a large number, thus the Equation (14) can be simply expressed as:

for

for  ; Normally, it will be good enough if we assign

; Normally, it will be good enough if we assign  as:

as: Equation (16) will be a good approximation for the micro supply function, and it gives the Micro PPF

Equation (16) will be a good approximation for the micro supply function, and it gives the Micro PPF  once the price vector goes through all possible directions in the production space

once the price vector goes through all possible directions in the production space  .

.  will be good enough for most of the practical applications. We use