-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Control Science and Engineering

p-ISSN: 2168-4952 e-ISSN: 2168-4960

2018; 8(1): 13-21

doi:10.5923/j.control.20180801.02

SCADA Systems Architecture Based on OPC and Web Servers and Integration of Applications for Industrial Process Control

Marcel Nicola, Claudiu-Ionel Nicola, Marian Duță, Dumitru Sacerdoțianu

Research, Development Division for Electric Equipment and Energy Efficiency, National Institute for Research, Development and Testing in Electrical Engineering – ICMET, Craiova, Romania

Correspondence to: Claudiu-Ionel Nicola, Research, Development Division for Electric Equipment and Energy Efficiency, National Institute for Research, Development and Testing in Electrical Engineering – ICMET, Craiova, Romania.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

SCADA (Supervisory Control and Data Acquisition) is the most modern tool used for the control and monitoring of technological processes. The main components of SCADA systems are one or more Servers and the Clients (the Viewers). The OPC (OLE-Object linking and embedding for Process Control) aims to define a common interface with a single designing stage and multiple reuses for any other project, SCADA, HMI (Human Machine Interface) or other software packages. An OPC server is an application which functions as an application programming interface (API-Application Programming Interface) or protocol converter. The paper presents an example of OPC server based application software which can be embedded into a SCADA system and which performs the following functions: monitoring a quasi-general industrial process defined by a 2nd order transfer function, identifying the transfer function and managing the client-server communication of the quantities of interest by online viewing and creating a record using TDMS (Technical Data Management Streaming) files, a MySQL database server and allowing the display of data on the Intranet/Internet through Via a Web Server which is embedded in the application.

Keywords: OPC-UA, Database, SCADA, Process control, Transfer function

Cite this paper: Marcel Nicola, Claudiu-Ionel Nicola, Marian Duță, Dumitru Sacerdoțianu, SCADA Systems Architecture Based on OPC and Web Servers and Integration of Applications for Industrial Process Control, International Journal of Control Science and Engineering, Vol. 8 No. 1, 2018, pp. 13-21. doi: 10.5923/j.control.20180801.02.

Article Outline

1. Introduction

- SCADA is the most modern concept and the tool used for the control and monitoring of technological processes, consisting of a computer based system designed for the control and monitoring of technological processes, which includes both software and hardware components. The data are collected and transmitted by the hardware to a PC with installed SCADA software and then they are processed by the PC within an acceptable time period [1-3].Due to the significant progress in this field, the SCADA systems can be used in the most various fields, such as manufacturing of consumer goods, metallurgy, industrial hydraulics and pneumatics, chemistry and power engineering, and the nuclear field.A SCADA system consists of two main hardware components:- One or more servers – various data acquisition systems connect the server(s) to the (process) field elements. Microcontrollers are generally used to achieve data acquisition systems; their task is to acquire data from the process and to monitor and control the operation of the process. Another method of carrying out the data acquisition is by using intelligent sensors which can connect directly to the computer or through some intermediate devices called stations or communication masters which collect data from multiple intelligent sensors. The data acquisition and process control devices in the industry field are represented mostly by programmable automata - PLC’s (Programmable Logic Controller). All the data collected from the process are processed by the server (which also achieves the database, ensures the communication with the PLC’s in the process). - The Client (the Viewer) is connected to the network with the server; it uses the data from it and provides communication with the human operator. A wide range of communication drivers connect the servers to the controllers (hundreds of drivers providing connections with all PLC’s from known companies).A single server can achieve simultaneous communication across multiple protocols, but new communication drivers can also be developed.The servers and viewers are connected to the Ethernet network. A process can also be viewed online now by using the selected web technology.The monitoring and control function is one of the most important functions of the SCADA systems.Graphical pages, also called HMI’s (Human Machine Interfaces) are used for the monitoring and control of technological processes; they imitate the technological process and are displayed on one or more computer monitors. The control operation is also called monitoring. Therefore we can say that the monitoring and control of technological processes is carried out by means of the HMI’s.The main functions of the SCADA system include the following:- The automatic control of the technological process for the optimization of the output parameters and for more efficiency;- The real-time display of the technological process condition;- The graphical display of the process data in order to develop efficient operating strategies;- The efficient control of process quantities logging, equipment condition, and alarm status;- The periodic generation of operating reports;- The possibility for users to intervene directly in the process, depending on their rights of access;- The possibility to achieve remote process control by using SCADA client stations.The OPC Foundation defines a series of specifications which form the OPC (OLE for Process Control) standard or the more recent Openness Productivity Connectivity, developed to facilitate connectivity in industrial automation. The OPC creates a communication line between the OPC servers and OPC clients by using the Microsoft DCOM (Distributed Component Object Model) technology. The main purpose of the OPC is to enable the safe communication in industrial processes, such as in electric power generation and distribution, industrial hydraulics and pneumatics, petrochemical refining, assembly lines for motor vehicles, etc. The state-of-the-art control of industrial processes embedded into SCADA systems uses both up-to-date means of data transmission and management, and the benefits of drive and control software, starting with the estimation of parameters and identification of the linearized transfer function, proceeding with the control design of the controller and finishing with the validation and testing of the entire chain of the industrial process control [3-12].The application described in this article uses the LabVIEW development software which includes all the concepts listed above and the most usual of the control techniques of industrial processes [13-20].The paper is an extension of work of [5] and is structured as follows: section 2 presents the OPC client/server concept, and section 3 presents an application for monitoring a quasi-general industrial process described by a 2nd order transfer function, the identification of the transfer function and management of client-server communication for the quantities of interest by online viewing and creating a record using TDMS files, a MySQL database server and allowing the display of data on the Intranet/Internet through Via a Web Server which is embedded in the application. Section 4 presents conclusions and course of action concerning future research.

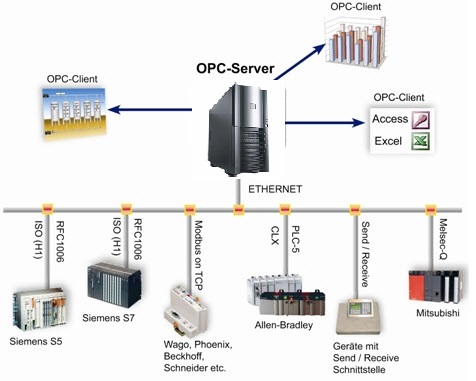

2. OPC Server

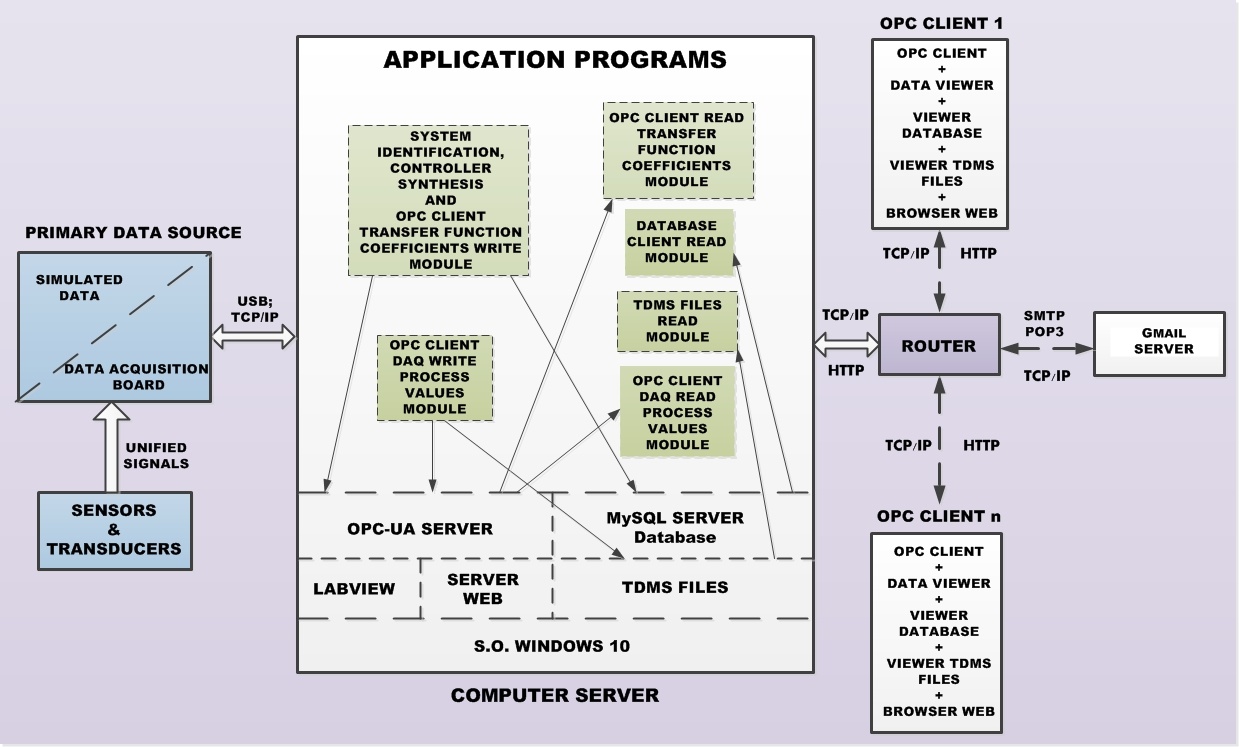

- The industry standard OPC (OLE for Process Control) was developed by a group of important world suppliers of automation software and hardware who collaborated with Microsoft company. The purpose of the standard is to define the methods for data communication between real time automation systems and client applications implemented on computers with Microsoft operating systems, and to allow the automation data to be accessed by client applications in a uniform manner. [7-11].There are many benefits to the widespread conformity to this standard in the industry, such as: - A single set of software components for the products of hardware manufacturers, which will be used by the customers for their applications;- No requirement for rewriting the drivers due to changes or additions of newest hardware versions;- A wider range of options for customers to achieve high quality integrated production systems, in a heterogeneous computer environment.The OPC standard allows the production and economic applications to access field information in real time and in a significant way, facilitating the interoperability between different equipment and the “plug and play” connectivity, but also a greater flexibility, lower costs for the integration, development and assembly of process automation or control systems.An OPC server (see Figure 1) is an application characterized by the same behaviour as an API-Application Programming Interface or protocol converter.

| Figure 1. SCADA system based on OPC server architecture |

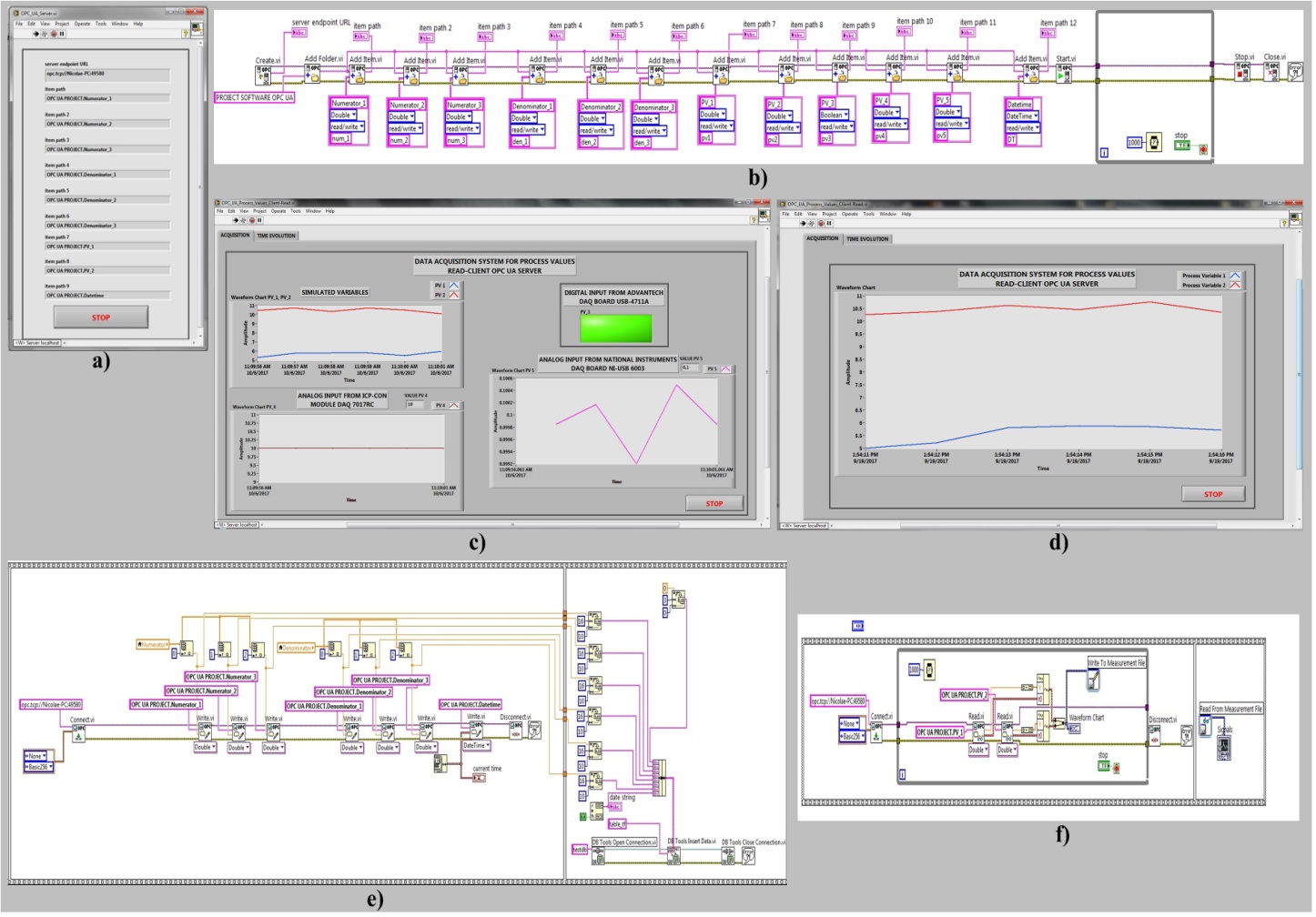

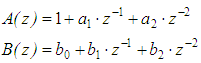

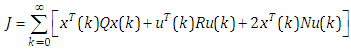

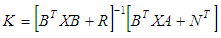

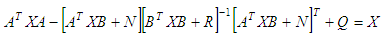

3. Example of OPC-UA Server Based SCADA Application for the Control of an Industrial Process

- The application presented is achieved in the LabVIEW development environment using Mathscript type Matlab scripts, it uses an OPC-UA type server, TDMS type files and a MySQL type database server. The general architecture of the application is shown in Figure 2.

| Figure 2. SCADA application architecture |

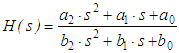

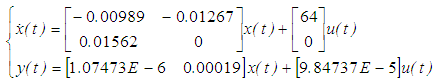

| (1) |

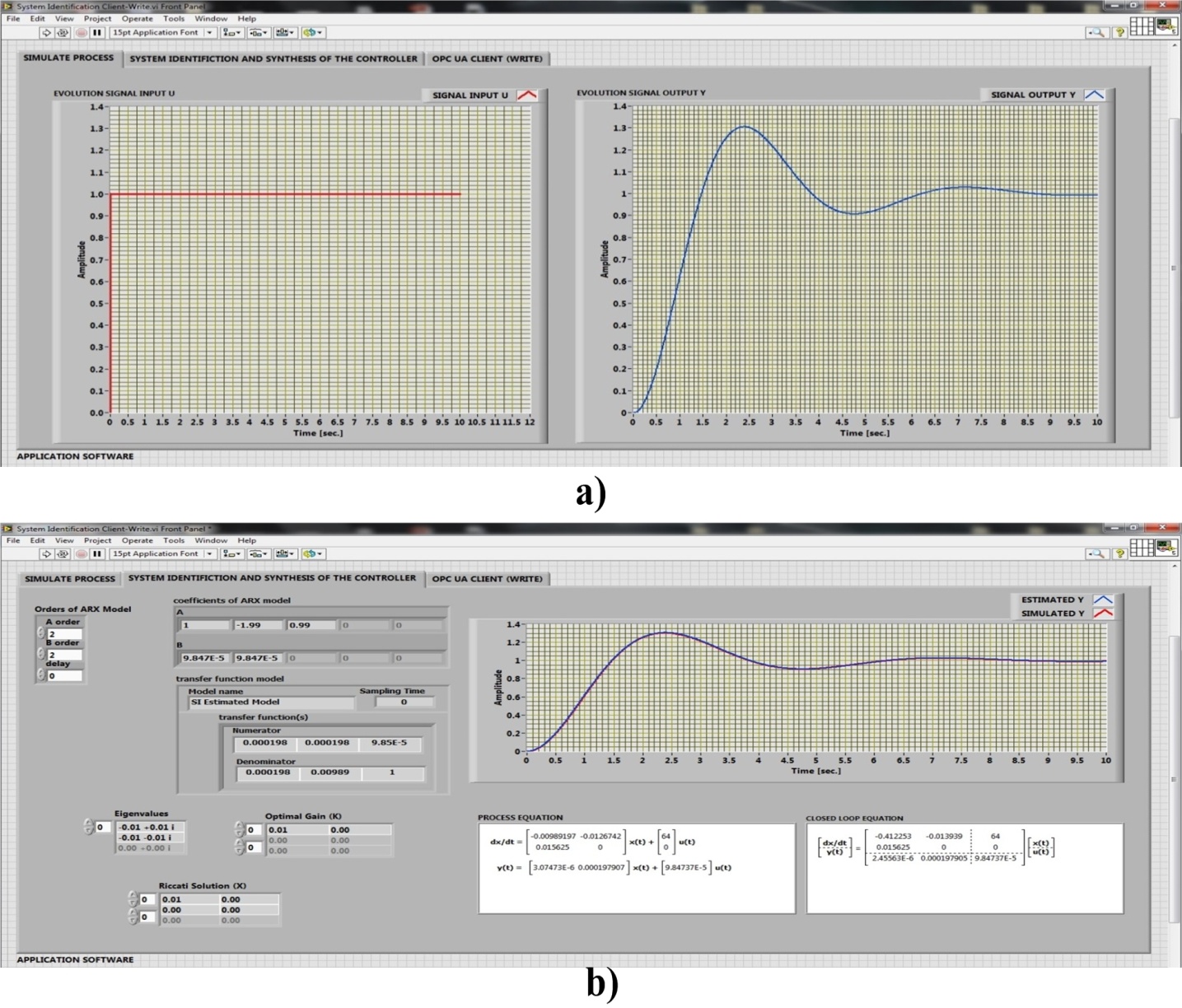

| Figure 3. Software interface: a) The step signal applied and the response of the second order system; b) System identification, LQR controller synthesis, state equations and system validation |

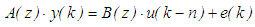

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

| (7) |

| (8) |

4. Conclusions

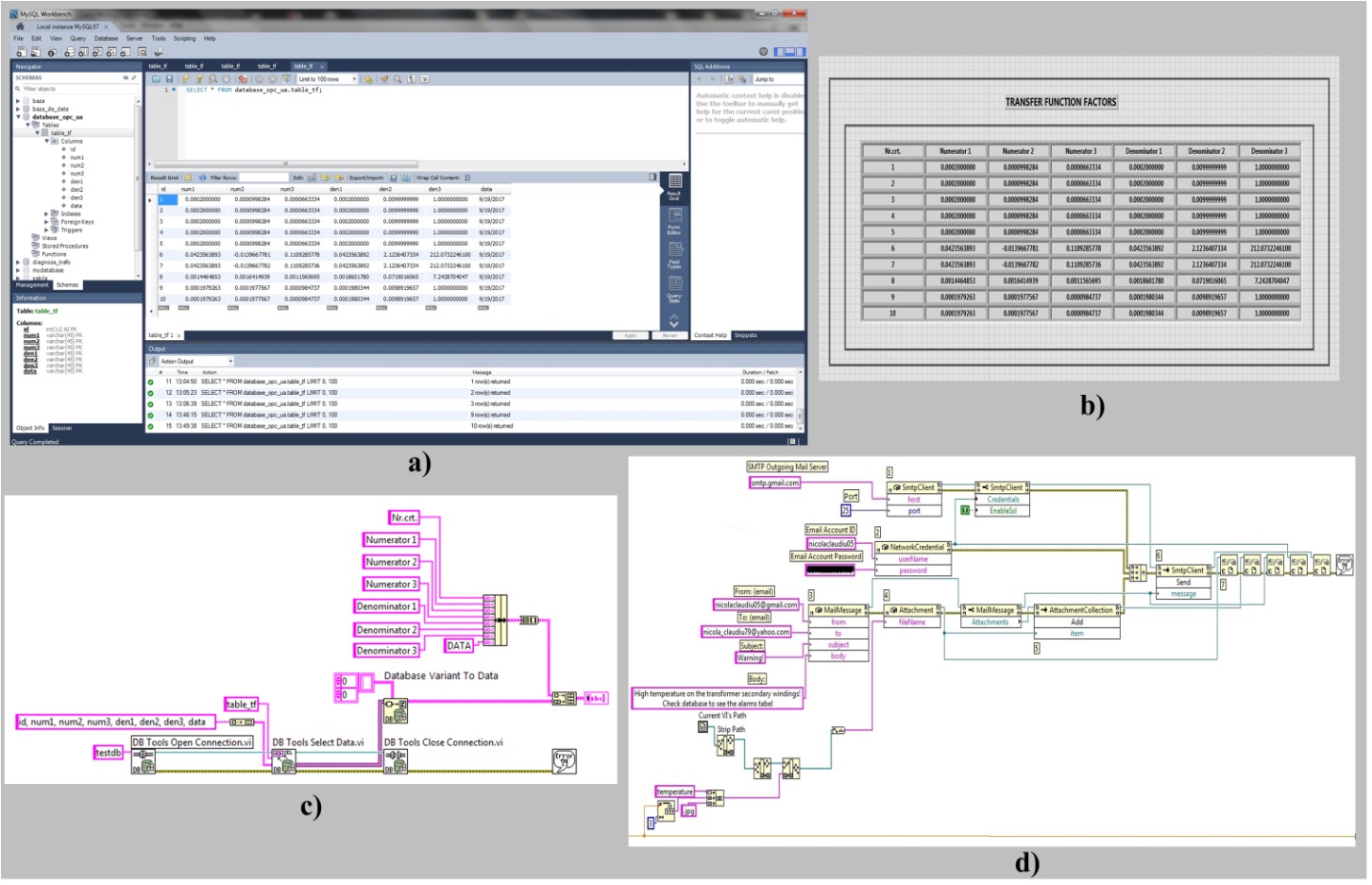

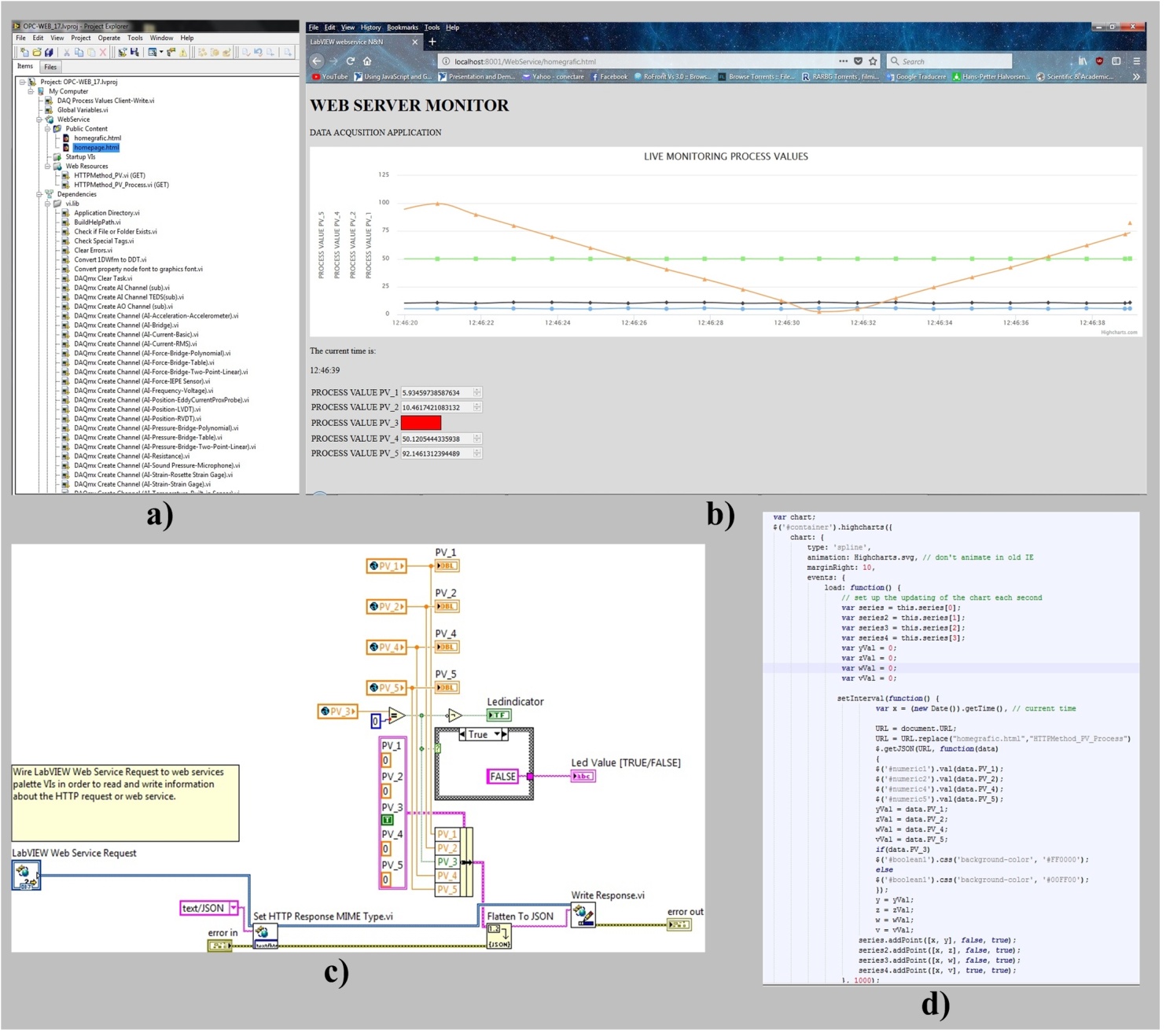

- This article summarizes the SCADA systems and the principles of OPC client-server communication. Hence an application was achieved and presented for monitoring a quasi-general industrial process defined by a 2nd order transfer function, for identifying the transfer function and managing the client-server communication of the quantities of interest by online viewing and creating a record using TDMS files and a MySQL database server.The implemented main software modules achieve the following: writing of the filtered data in the OPC-UA, MySQL, Web servers, showing the instant evolution of the acquired values, achieving automatic reports, storing the evolution in a database, managing the alarms by automatically sending to default email addresses, achieving integration into SCADA and allowing the display of data on the Intranet/Internet through via a Web Server which is embedded in the application. The issue of data communications in industrial environments is not abstract, but arises practically in industrial and monitoring applications, and can become a separate issue, but it can only be studied on condition that minimal software modules are provided for data communication and management from an actual application. We consider that by achieving such an experimental model like the one described above, but especially by means of the experiments conducted on it, the main benefit will consist in the increase of the amount of knowledge on this topic and a significant facilitation in achieving future complex monitoring applications for systems with a relatively large volume of data and for heterogeneous data acquisition systems.

ACKNOWLEDGEMENTS

- The paper was developed with funds from the Ministry of Education and Scientific Research as part of the NUCLEU Program: PN 16 15 02 06.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML