-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Control Science and Engineering

p-ISSN: 2168-4952 e-ISSN: 2168-4960

2017; 7(2): 25-31

doi:10.5923/j.control.20170702.01

Integration Intelligent Estimators to Disturbance Observer to Enhance Robustness of Active Magnetic Bearing Controller

Mohammad Gohari

Faculty of Mechanical Engineering, Arak University of Technology, Iran

Correspondence to: Mohammad Gohari, Faculty of Mechanical Engineering, Arak University of Technology, Iran.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

One of the essential components of rotary systems is bearing which is supporting load of rotor. Active magnetic bearings can remove contact point between rotor and supports by magnetic force. Controlling magnetic force is key point of this system to keep mechanical balancing of rotor. Due to high revolution speed of rotors, disturbances produce instability. The Disturbance Observer Algorithm (DO) is an approach to reduce effects of disturbances. The DO Controller was combined to generic PID Controller to improve performance of AMB. In DO, estimation mass is vital to enhance stability and accuracy of that. So, artificial neural network and iterative learning were hybridized to DO as intelligent techniques in estimation mass. Simulation assessment reveals iterative learning showed superior results in terms of accuracy and stability of AMB responses to the disturbances.

Keywords: Active Magnetic Bearing, Disturbance Observer, Iterative Learning Algorithm, Neural Network, System Dynamics

Cite this paper: Mohammad Gohari, Integration Intelligent Estimators to Disturbance Observer to Enhance Robustness of Active Magnetic Bearing Controller, International Journal of Control Science and Engineering, Vol. 7 No. 2, 2017, pp. 25-31. doi: 10.5923/j.control.20170702.01.

Article Outline

1. Introduction

- Bearing plays important role in rotary machineries such as pumps, turbines, engines, and compressors etc. one of the bearing family which was introduced recently is Active Magnetic Bearing (AMB). This type of bearing can prepare proper conditions to remove any physical contact between rotor and bearing via magnetic field. So, rotor weight and external loads are supported without contact, and rotational speed can reach to very higher values. To prevent of failure, the air gap between rotor shaft and stator (electromagnetic coils) must be kept constant via controller system. AMBs are nonlinear and unstable naturally, and most of controller designs are based on linear dynamic models [1]. The PD controller for an AMB evaluated and compared to fuzzy controller [2]. They were success to reduce instability of AMB. Using PID controller in low frequency range showed that AMB has low damping property [3]. In other hand, based on a research finding, the PID controller is not suitable for AMB [4]. Moreover, LQR was exploited in AMB, and results demonstrated better performance compared to PID [5, 6]. Generally, PID controllers are not suitable for high speed disturbances. One of the control schemes which were used to face on this problem is Disturbance Observer (DO). Current paper is aimed to develop Disturbance Observer Algorithm with using Iterative Learning (IL) and Neural Network (NN) to cancel disturbances effect.

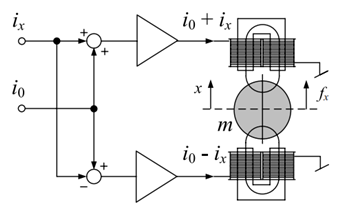

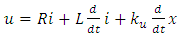

2. Dynamic Model of AMB

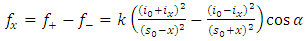

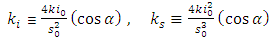

- As stated previous, the major duty of control system is stabilizing rotor motion around balancing point. Thus, controller must supply return force for rotor to balancing point like as spring force. Besides, force control must present damping to decrease vibration around balancing point.The magnets forces are related to electrical current according to bellow equation:

| (1) |

| (2) |

| Figure 1. Mode of differences in AMB actuator [1] |

| (3) |

| (4) |

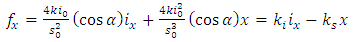

| (5) |

| (6) |

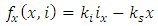

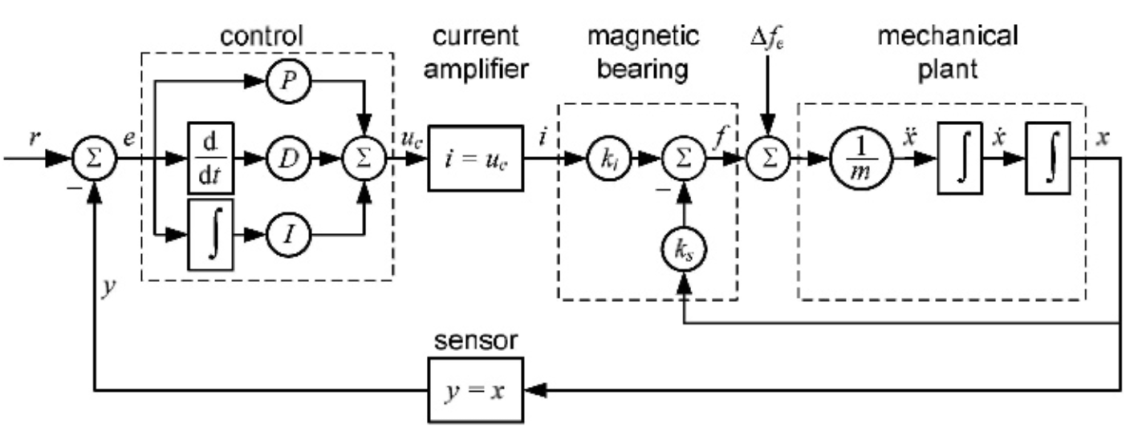

3. Design Position Control

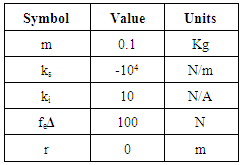

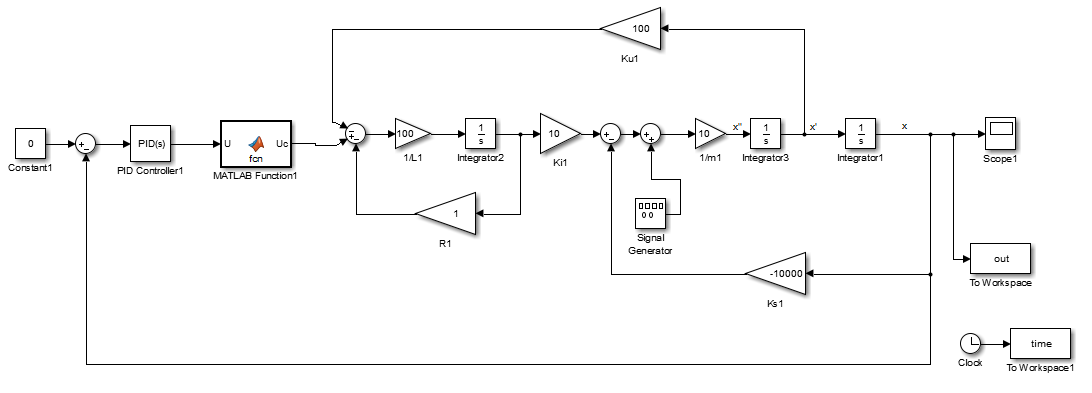

- Firstly, a generic controller from PID family was designed to control position of rotor in balancing point. Fig.2 and 3 present block diagram of AMB controller and simulated that in MATLAB/Simulink, respectively. Also, AMB parameters are listed in Table 1. The PID parameters were reached by crude method.

| Figure 2. Block diagram of AMB controller [1] |

| Figure 3. The schematic PID designed for AMB |

|

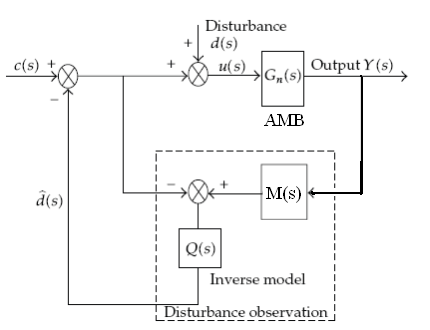

4. Integration Disturbance Observer to AMB Position Controller

- The main concept of the DO scheme is exemplified in Fig.4. The output of system can be mentioned in terms of the reference control input, the external disturbance, and the measurement noise. In fact, the DO prepares compensation force calculated from disturbance, and it is returned to actuator to face to disturbances. This outer loop increases stability of the system by force control.

| Figure 4. Block diagram of DO |

| (7) |

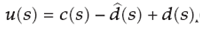

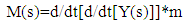

is disturbance estimation. The position signal, Y(s), is converting to estimated force signal by following equation:

is disturbance estimation. The position signal, Y(s), is converting to estimated force signal by following equation: | (8) |

, can be acquired. The key part of DO is estimation of mass, and accuracy of controller can be increased by that [9]. Various techniques can be utilized to this purpose such Fuzzy Logic [11], On-line NN [10], IL [12-14], Off-line ANN [15-18]. In this paper, the results of integration NN and IL in predicting estimated mass to AMB controller are compared together.

, can be acquired. The key part of DO is estimation of mass, and accuracy of controller can be increased by that [9]. Various techniques can be utilized to this purpose such Fuzzy Logic [11], On-line NN [10], IL [12-14], Off-line ANN [15-18]. In this paper, the results of integration NN and IL in predicting estimated mass to AMB controller are compared together. 4.1. Iterative Learning Algorithm in DO Controller of AMB

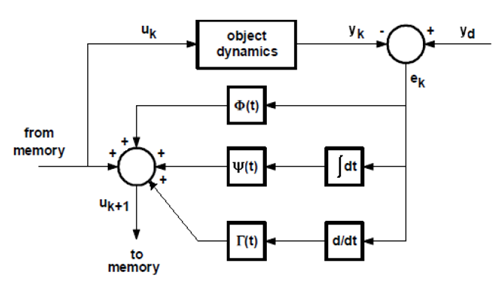

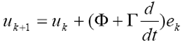

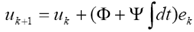

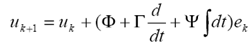

- The iterative learning algorithm (ILA) is an intelligent technique during the performance of a dynamical system be improved and improved as time increased based on reducing the error. Uchiyama first time represented the basic concept of the ILA [19]. Fig.5 reveals a block diagram of the proportional-Integral-Derivative type (PID-type) of ILA.

| Figure 5. Block diagram of the PID-type of ILA |

| (9) |

| (10) |

| (11) |

,

,  and

and  are proportional, derivative and integral learning parameters, respectively. The coefficients of ILA “

are proportional, derivative and integral learning parameters, respectively. The coefficients of ILA “ ,

,  , and

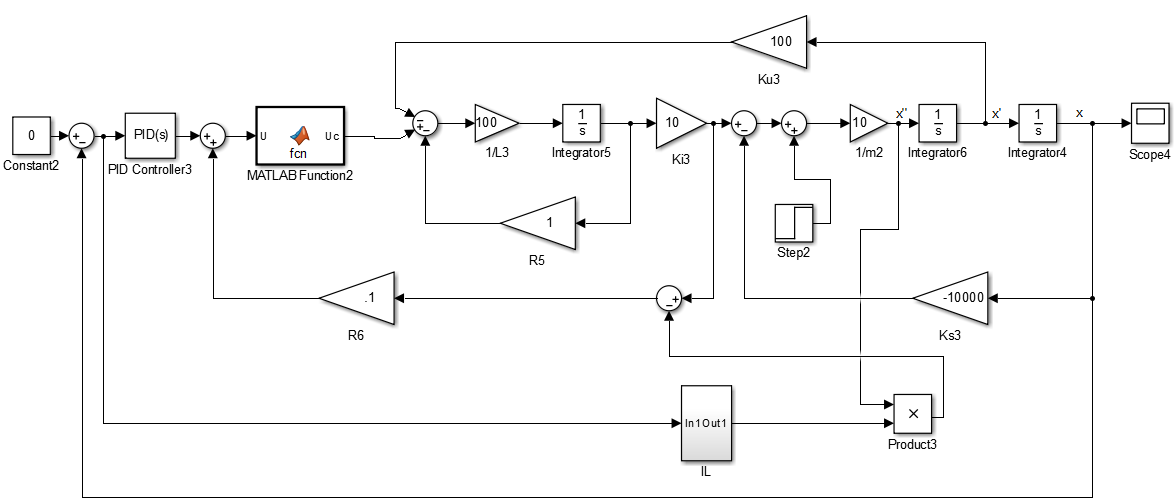

, and  ” were tuned as 0.0001 by Heuristic method. The simulated DO-IL is exemplified in Fig. 6, and results of that is discussed and compared to DO-NN and PID in next section.

” were tuned as 0.0001 by Heuristic method. The simulated DO-IL is exemplified in Fig. 6, and results of that is discussed and compared to DO-NN and PID in next section.  | Figure 6. Applied DO-IL in AMB |

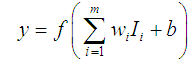

4.2. Neural Network Algorithm in DO Controller of AMB

- A typical NN multilayer feed forward structure involves of neurons as input, hidden and output layers. They are interrelated through weights refreshed as the training process. Threshold or activation functions are applied at the output. The mainly ordinary equation that stated the input/output relationship of a neuron is expressed as following:

| (12) |

| Figure 7. AMB PID controller integrated to NN-DO |

5. Results and Discussion

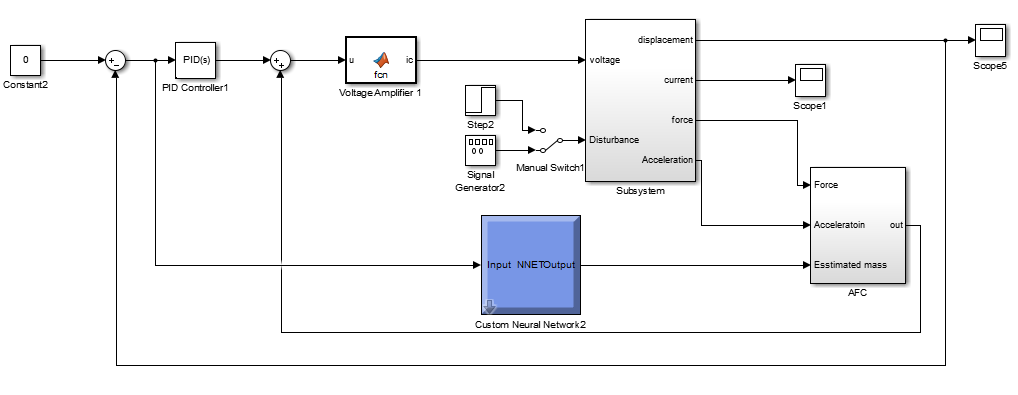

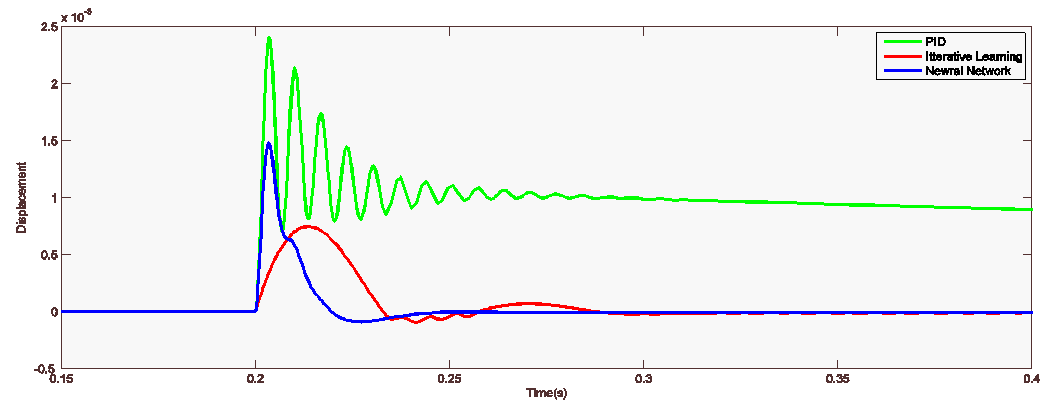

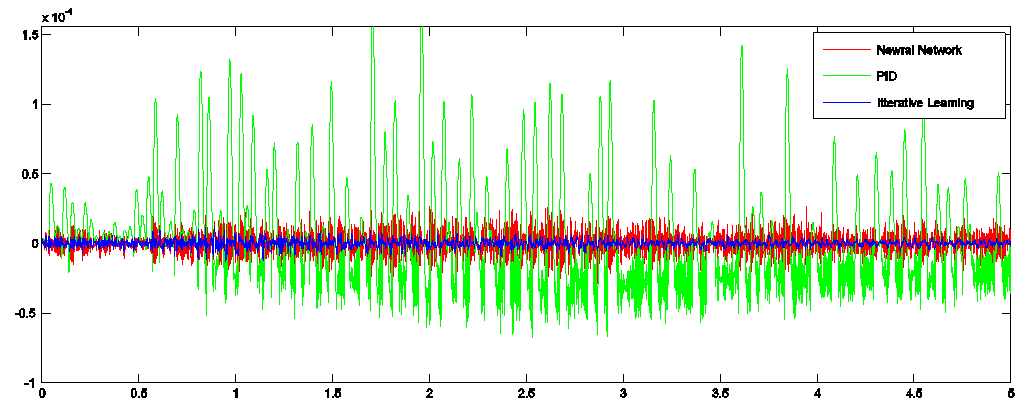

- Fig.8 illustrates responses of AMB to the step input via PID Controller, IL-DO, and NN-DO. As can be seen, the overshoot by conventional PID is higher than NN-DO and IL-DO. Moreover, the overshoot of IL-DO is half of NN-DO, and both of them reach to set point faster than PID. In Fig.9, previous result is zoomed to better comparison. The stability of output by IL-DO was increased. Therefore, the robustness of AMB was increased and variation was decreased dramatically by DO Controllers.

| Figure 8. Time responses of AMB with different controllers |

| Figure 9. Magnification of Fig.7 for more comparisons |

| Figure 10. AMB responses to the White Noise Random disturbance with three controllers |

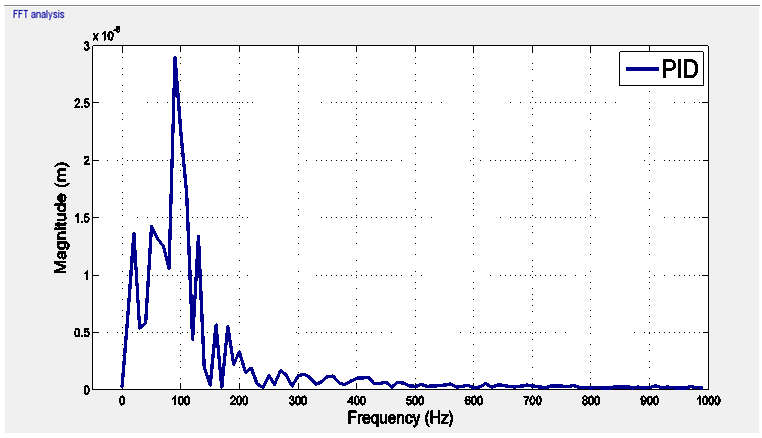

| Figure 11. PID responses to the White Noise Random disturbance in frequency domain |

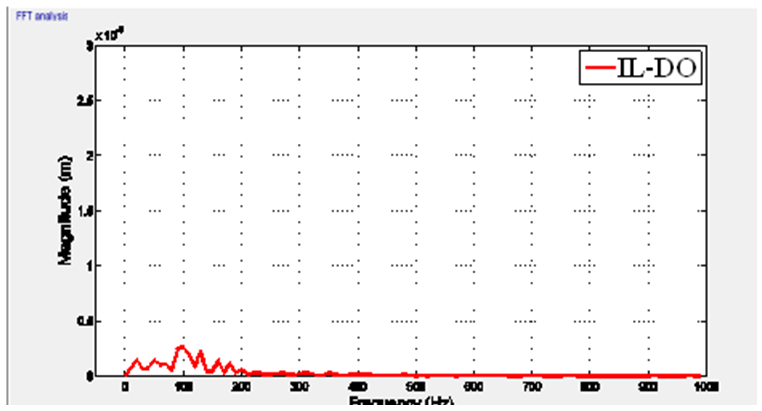

| Figure 12. IL-DO responses to the White Noise Random disturbance in frequency domain |

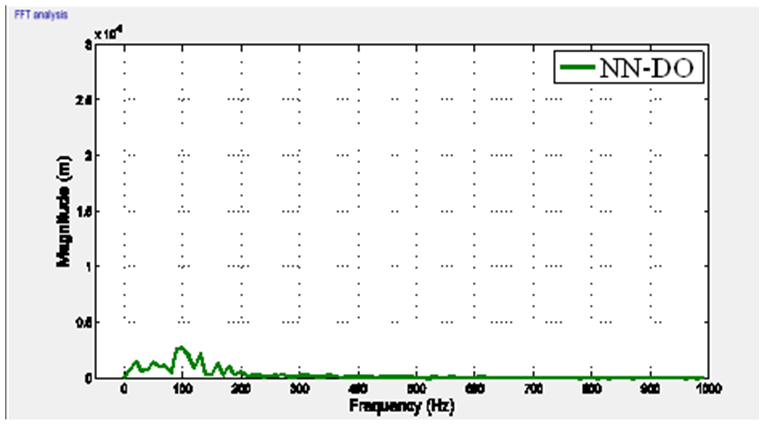

| Figure 13. NN-DO responses to the White Noise Random disturbance in frequency domain |

6. Conclusions

- A novel controller called the disturbance observer (DO) was integrated to the active magnetic bearing. The DO Controller can eliminate effect of disturbances by simple inner control loop. This DO controller was combined to artificial neural network and iterative learning algorithm named NN-DO and IL-DO, respectively. The designed controllers were simulated for the suppression of disturbances inserted to AMB balance point. The results of simulations illustrate that the performance of DO is better than traditional PID Controller. In addition, combining NN and IL to DO generates different responses of AMB with higher stability. IL-DO shows superior efficiency in suppression of overshoot compared to NN-DO. However, complementary study should be conducted to investigate the effects of other forms of disturbances, uncertainties and parametric changes in practical condition.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML