-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Computer Science and Engineering

p-ISSN: 2163-1484 e-ISSN: 2163-1492

2025; 15(5): 114-123

doi:10.5923/j.computer.20251505.02

Received: May 30, 2025; Accepted: Jun. 26, 2025; Published: Jul. 4, 2025

Advanced Catch Weight Management in SAP EWM for Food & Beverage and Meat Processing Industries

Harendra Singh Gangwar

Manager Global IT Transportation, TopGolf Callaway Brands, Fort Worth, USA (TopGolf Callaway Brands)

Correspondence to: Harendra Singh Gangwar, Manager Global IT Transportation, TopGolf Callaway Brands, Fort Worth, USA (TopGolf Callaway Brands).

| Email: |  |

Copyright © 2025 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Catch weight management (CWM) is a critical capability for industries dealing with variable-weight products, especially in food & beverage and meat processing. This paper provides an in-depth, academic-style examination of advanced catch weight management in SAP S/4HANA Extended Warehouse Management (EWM). We explore the concept of catch weight (managing inventory in two independent units of measure), review industry use cases in food and meat sectors, and detail the technical implementation and configuration in SAP EWM. We draw on SAP documentation, industry best practices, and real-world examples to discuss how catch weight is activated and used in S/4HANA (on-premise and cloud), including integration with handling units, tolerances, and parallel valuation. Business benefits such as increased pricing accuracy, inventory transparency, and compliance are highlighted, alongside operational challenges like process changes and system integration considerations. The paper also outlines an implementation strategy, configuration guidelines, and innovations (such as tolerance checks and accelerated weighing) that SAP’s advanced catch weight functionality enables. Through case examples and a review of literature, we demonstrate how advanced catch weight management improves supply chain efficiency for variable-weight goods. Finally, we conclude with the key findings and a reference list for further reading.

Keywords: SAP - Systems, Applications, and Products in Data Processing, EWM – Extended Warehouse Management, UoM-unit of measure, CWM - Catch Weight Management, EWM - Extended Warehouse Management, SCM - Supply Chain Management, CIF - Core Interface, HU - Handling Unit, ASN - Advance Shipping Notifications, QA - Quality, RF-Radio Frequency, PP - Production Planning, QM - Quality Management, CO - Controlling, MRP - Material Requirement Planning, ATP - Available-to-promise, EDI - Electronic Data Interchange, MM - Materials Management, SD - Sales & Distribution, LIV - Logistics Invoice Verification, PI - Process Integration, GR - Goods Receipt, PM - Plant Maintenance, CO-PA - Costing Profitability Analysis, IoT - Internet of Things, ML - Machine Learning

Cite this paper: Harendra Singh Gangwar, Advanced Catch Weight Management in SAP EWM for Food & Beverage and Meat Processing Industries, Computer Science and Engineering, Vol. 15 No. 5, 2025, pp. 114-123. doi: 10.5923/j.computer.20251505.02.

Article Outline

1. Introduction

- In industries where products do not have uniform weight – for example, cuts of meat, wheels of cheese, produce, or bulk liquids – managing inventory and pricing by exact weight is essential. Catch weight management refers to the practice of handling products in two units of measure simultaneously: a base unit (often a count like pieces or cases) and a parallel unit (often a weight like kilograms or pounds). Each item has an “approximate” standard weight but an actual weight that can vary. For instance, a box of four chicken breasts might weigh 22 ounces for one customer and 26 ounces for another; selling both boxes at a fixed price per box would be unfair and inaccurate. Instead, catch weight management allows each box (or piece) to be tracked and billed by its true weight. This capability is especially important in the food & beverage and meat processing industries, where products like meats, seafood, cheese blocks, fruits, and vegetables are sold by weight but handled in discrete units (packages, cases, etc.).SAP’s solution to this need is SAP Catch Weight Management (CWM), an industry-specific functionality originally introduced as an extension in SAP ERP and now integrated into SAP S/4HANA. CWM enables businesses to keep inventory records in two independent units of measure for the same material, with equal status. In practice, this means a product can be stocked and moved in one unit (e.g. pieces) while simultaneously being tracked for valuation and sales in another unit (e.g. kilograms). The food processing industry benefits greatly from this, as it requires exact weight-based valuation for compliance and profitability. This paper focuses on advanced catch weight management in SAP Extended Warehouse Management (EWM) within S/4HANA, highlighting how it addresses the needs of variable-weight goods. EWM is SAP’s advanced warehouse management system, and when combined with catch weight functionality, it ensures that warehouse processes (goods receipt, storage, picking, packing, and shipping) accommodate dual units of measure. We will discuss how catch weight is configured and used in EWM, with attention to the technical settings (such as parallel units, catch weight profiles, tolerance groups, and valuation methods) and process integration points. Real-world examples from food and meat sectors illustrate the usage: for example, a meat processor weighing each carton of beef at goods receipt to record exact weights for inventory and billing, or a cheese distributor tracking each wheel’s weight as it ages and loses moisture.

2. Literature Review

- Early enterprise systems managed variable-weight items manually, often using average weights or standard conversions. This led to inventory errors and revenue loss. For instance, assuming each lettuce case weighs 10 kg ignores real fluctuations, causing misstatements and disputes. Literature emphasizes the need for precise tracking, as traditional systems struggle with such variability. Manual corrections are labor-intensive and error-prone, prompting specialized solutions.Two main approaches are discussed: batch-specific unit of measure (UoM) and Catch Weight Management (CWM). Batch-specific UoM allows unique conversion factors per batch—useful when variability exists between lots. For example, batch A might average 20 lb/case, while batch B averages 22 lb. This is managed in batch master data but doesn’t capture item-level differences, which is critical in industries like meat processing.CWM, introduced in SAP ERP 6.0, tracks both base and weight units for each transaction. Unlike batch-specific UoM, CWM requires actual weight entry per item or handling unit. The system proposes a default weight, but users must confirm or adjust it. This ensures accuracy but limits automation—automated movements without user input (e.g., backflushing) are blocked. Literature highlights the need to balance automation with accurate weight capture.Case studies show CWM improves billing accuracy, inventory valuation, pricing flexibility, and compliance—especially in food and meat sectors. Many countries require products to be sold by actual weight, making CWM essential for legal and trust reasons.Tolerance handling is also key. Since actual weight rarely matches nominal exactly, SAP allows tolerance ranges. For example, a 200g cheese with 10% tolerance must weigh between 180g and 220g. Outliers are flagged, adding control to dual-unit tracking.In summary, advanced CWM extends inventory systems with parallel quantity tracking, transaction-time weight capture, and tolerance validation—crucial for industries with variable-weight products. The next sections explore SAP EWM’s application of these principles.

3. Case Examples (Food & Meat Industry Use Cases)

3.1. Meat Processing Plant – Variable Weight Cuts

- Consider a beef processing plant, each steak varies in weight, even when packed by count—like 10 steaks per box. Without catch weight management, inventory may record “1 box = 10 steaks” without knowing the actual weight, creating issues since sales are based on kilograms. Using SAP EWM with catch weight, the plant can log both piece count and actual weight—e.g., 10 steaks totaling 5.47 kg. At goods receipt, each box is weighed, and that weight is recorded in the system. If the weight is outside a set range (e.g., 4.90 kg), the system flags it for review. Later, when shipping, both the number of steaks and their exact weight are included, ensuring accurate billing.This case shows how catch weight management integrates with shop-floor devices (scales) and enhances billing accuracy. It also highlights process changes: workers must weigh each box and input the data, which is a new step enabled by EWM’s catch weight functionality.

3.2. Cheese Manufacturer – Aging and Weight Loss

- A cheese company ages large parmesan wheels, which lose weight over time. Since they sell by weight, SAP Catch Weight Management tracks each wheel in pieces and kilograms. Initially, an estimated weight (e.g., 8.0 kg) is recorded, but actual weight is updated later, often before shipment, using EWM’s efficient weighing tools. If a wheel drops below a set tolerance (e.g., 7.2 kg), the system flags it for review. This ensures accurate labeling and valuation. The system’s ability to update actual weights maintains financial accuracy and compliance, showcasing CWM’s strength in managing variable-weight products.

3.3. Processed Food Distributor – Mixed Unit Sales

- A food distributor handles variable-weight canned goods, like ham sold in 12-packs. Though sold by case, pricing depends on total meat weight. Using SAP S/4HANA and EWM, each case is treated as a catch weight item, tracking both pieces and pounds. At receiving, clerks scan labels and enter or auto-capture weight via integrated scales. EWM logs each handling unit (e.g., 12 pieces, 10.4 lbs), and totals can be easily calculated for stock planning. Outbound deliveries include both units so pickers verify quantity and weight. SAP ensures seamless tracking from supplier to shipment, reducing manual work and improving transparency.

3.4. Seafood Supplier – Pricing by Catch Weight with Quality Grading

- A food distributor handles variable-weight canned goods, like ham sold in 12-packs. Though sold by case, pricing depends on total meat weight. Using SAP S/4HANA and EWM, each case is treated as a catch weight item, tracking both pieces and pounds. At receiving, clerks scan labels and enter or auto-capture weight via integrated scales. EWM logs each handling unit (e.g., 12 pieces, 10.4 lbs), and totals can be easily calculated for stock planning. Outbound deliveries include both units so pickers verify quantity and weight. SAP ensures seamless tracking from supplier to shipment, reducing manual work and improving transparency.

4. Implementation Strategy

- Implementing advanced catch weight management in SAP EWM requires a careful strategy that addresses both system setup and business process adaptation. Below we outline a recommended implementation strategy, assuming an organization is running SAP S/4HANA (either on-premise or private cloud edition) and planning to use embedded EWM with catch weight functionality:

4.1. Feasibility and Scope Assessment

- First, confirm that your SAP S/4HANA environment supports Catch Weight Management (CWM). In on-premise or private cloud versions, CWM is standard for relevant industries but must be activated. Ensure you're on S/4HANA 1709 or later, as earlier versions lack full support. For S/4HANA Cloud (public edition), check the latest scope—CWM is limited and mainly available in the Consumer Products package. If public cloud features are insufficient, consider switching to private cloud or on-prem for full functionality.Clearly define the scope: which materials will use catch weight and in which processes (e.g., goods receipt, production, shipping). Typically, only products with significant weight variation need dual-unit tracking—decide if raw or semi-finished goods also require it, or just finished products.

4.2. Business Function Activation and Master Data Preparation

- In SAP S/4HANA, Catch Weight Management (CWM) is mostly built-in once the relevant industry solution (like Consumer Products) is activated. Unlike ECC, where it required a business function switch, S/4HANA enables CWM through industry settings. Once active, the material master includes new fields for catch weight setup.A key step is defining a parallel unit of measure (e.g., LB or KG) alongside the base unit (e.g., CASE). You must mark this as a catch weight unit and set a planned conversion (e.g., 1 CASE ≈ 40 LB for chicken boxes). In the logistics or WM Execution view, you flag the material as catch weight relevant and assign a Catch Weight Profile and Tolerance Group. These control where weight is captured (e.g., at goods receipt) and define acceptable variance (e.g., 5% for fresh meat, 1% for packaged goods).Batch management should also be enabled if traceability is needed—common in food and meat industries. While batch-specific UoM can be used as an alternative, most S/4HANA projects choose either batch-specific UoM or CWM per material, not both.

4.3. SAP EWM Configuration and Integration

- In embedded EWM within SAP S/4HANA, catch weight data is read directly from central master data—no CIF interface is needed. This simplifies setup compared to decentralized EWM, which requires extra integration steps like replicating customizing (e.g., tolerance groups) and running reports (e.g., /SCWM/VALUATION_SET) to sync valuation data. Best practice is to use embedded EWM when possible, as it fully supports Catch Weight Management (CWM) and avoids redundant data sync. If decentralized EWM is required (e.g., for multiple ERP clients), confirm CWM support—SAP supports it from EWM 9.5+ with some configuration.In EWM configuration, focus on Handling Units (HUs). Decide whether catch weight will be captured per HU (e.g., per pallet) or per piece. Most warehouses weigh at the HU level. While HUs already store gross weight, CWM tracks the catch weight quantity at the HU item level (e.g., total weight of 10 pieces in a carton). Configure the inbound process to prompt for weight entry when HUs are created. This can be done via packaging or work center settings. SAP also offers an Accelerated Weighing function to quickly record tare and net weights for multiple HUs, improving efficiency during receiving.

4.4. Process Design and Device Integration

- To implement Catch Weight Management effectively, system setup must match real-world processes. Start by mapping where weight should be captured:• Goods Receipt: Decide when to weigh incoming goods—at delivery creation (if weights are provided), packing stations, or during quality checks. Many warehouses use inline or dedicated scales. SAP EWM supports weighing via Work Centers, and scales can be integrated using telnet, PC connections, or SAP Plant Connectivity. Initially, weights may be entered manually, with automation added later.• Internal Movements: Weight usually isn’t captured during internal transfers (like bin-to-bin), since weight doesn’t change. However, for items like cheese or ham that lose weight over time, periodic re-weighing may be needed. This can be handled through cycle counting or physical inventory in EWM, which supports dual-unit counting.• Picking and Shipping: Decide if weights should be rechecked before shipping, especially for items stored long-term or sold by weight. EWM allows editing catch weight on outbound deliveries. Outbound HUs can be routed over a scale, and if the weight differs beyond tolerance, the system can trigger inventory updates or alerts.

4.5. Training and Change Management

- Implementing Catch Weight Management (CWM) is a major change that affects warehouse, sales, and procurement teams. Training is essential so users understand how and why to enter weights. For example, receiving clerks must enter both carton count and total weight—this isn’t optional unless defaulted. Inventory and finance teams also need to interpret dual-quantity stock reports (e.g., “100 CS / 2045 LB”).Master data teams must learn to maintain catch weight materials, including setting correct unit relationships and tolerance profiles. SOPs should be updated to reflect these new steps. Change management should highlight benefits like fewer invoice corrections, better compliance, fewer customer complaints, and more accurate profit tracking.

4.6. Phased Rollout and Testing

- It’s best to roll out Catch Weight Management (CWM) in phases—starting with a small group of materials or one processing line to test the full process. In the QA system, test:• Configuration: Ensure the system blocks entries outside tolerance by testing with incorrect weights.• Integration: Run through the full flow—PO creation, goods receipt with weight in EWM, ERP document validation, delivery, goods issue, and billing by weight.• Performance: Check if weight entry slows operations. For example, can 100 catch weight HUs be processed per hour? If not, consider adding scales or staff.• Edge Cases: Handle partial picks carefully—usually, catch weight items aren’t split unless reweighed.Gather feedback during rollout. In one case, a bottleneck at a single scale led to adding more scales and redistributing work. Stay flexible—adjust tolerances or processes based on real-world results.

4.7. Parallel Units in Financial and Reporting Systems

- A key strategic point is how parallel units (like weight) affect financials and reporting. If weight is used as the valuation unit (common in CWM), inventory is valued by weight (e.g., $2 per kg instead of per piece). Finance must update standard costs, sales pricing conditions, and custom reports to reflect this. Involve the controlling team to ensure the inventory and cost of goods sold are correctly posted during transactions.It’s also helpful to run a period-end test—perform a physical inventory for catch weight materials and check how SAP handles weight differences and adjustment postings. The project plan should include time for these cross-functional validations.By following this approach, CWM becomes a fully integrated part of operations—not just a technical feature. Each step builds on the last, from activation and data setup to process changes, training, and validation—resulting in a system that handles dual units smoothly across procurement, inventory, and sales.

5. Configuration Guidelines

- Configuring catch weight management in SAP EWM involves settings both in core S/4HANA (for materials and valuation) and in the EWM module (for process control). This section provides detailed guidelines for key configuration steps, assuming an S/4HANA 2021 (or newer) environment with embedded EWM:

5.1. Activate Catch Weight Management

- Use transaction SFW5 (Switch Framework) to find and activate switches related to Catch Weight (e.g., IS-CWM). For S/4HANA on-premise, activation brings in the CWM fields to the material master and related tables. (In S/4HANA Cloud, private edition, this may be done by SAP or via SSCUI if available, in public cloud.

5.2. Material Master Setup

- The material master is central to catch weight config: - Units of Measure: Define the base unit (BUoM) and at least one alternative unit that will serve as the parallel (catch weight) unit. Example: Base UoM = “CA” (case), Alternative UoM = “KG” (kilogram). In the Units of Measure tab, maintain the conversion (e.g., 1 CA = 20 KG as an estimate). Check the “parallel unit” indicator for the KG unit. The system will then mark KG as the Logistics Unit of Measure for catch weight.

5.3. Catch Weight Indicators

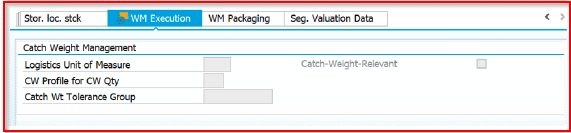

- Navigate to the Warehouse Management or Logistics view (in S/4HANA this might be under the “WM Execution” sub-view for EWM). Here, you will see a section for Catch Weight Management.

| Figure 1. SAP S/4HANA Material Master (WM Execution View) with Catch Weight fields |

5.4. Define Catch Weight Profile

- In SPRO (SAP Implementation Guide) for EWM (embedded EWM is under SCM Extended Warehouse Management > Extended Warehouse Management), locate the configuration for Catch Weight Profile for CW Quantity. This profile determines at what point in processes the catch weight quantity must be entered or can be adjusted. Options might include: - At Goods Receipt (inbound delivery). - At Goods Issue (outbound delivery). - At production order confirmation (if integrated with PP). - At internal movements or not at all.Each profile will have flags for various processes. For example, Profile “01” might mean “Capture CW at GR and GI, allow changes until GI posting”. Assign a meaningful code and description (e.g., “A1 – CW at GR, GI, no auto-post”). According to SAP content, the catch weight profile can be assigned per material in the material master.

5.5. Define Catch Weight Tolerance Groups

- In SPRO, find Catch Weight Tolerance Group settings (likely under Materials Management or Logistics – might even be under Global settings or Material Master settings since tolerance could be an ERP-level config).Here, create tolerance group codes (alphanumeric, e.g., “MEAT”, “PRODUCE”) and set percentage or absolute tolerances. Typical fields are: - Lower tolerance limit (%) for warning. - Upper tolerance limit (%) for warning. - Lower/upper limits for error (if separate from warning). For example, Tolerance Group “MEAT” could have ±5% as warning limits and ±10% as error limits, meaning if a piece is more than 5% off the nominal weight, the system warns, and if more than 10% off, it blocks posting. Assign each catch weight material a tolerance group in the material master. (If left blank, maybe no tolerance check is applied or a default is used – better to explicitly assign for clarity.)

5.6. EWM-Specific Config: Handling Units and Delivery Customizing

- In EWM, ensure that the delivery item types and warehouse process types can handle catch weight. Standard SAP has extended the delivery item data to include fields for catch weight quantity. Check the delivery item type configuration for inbound and outbound deliveries in EWM to see if any indicators need turning on (in standard S/4, it might work out of the box if CWM active). Specifically, confirm that EWM delivery can display both quantity units. Testing in a sandbox: create an inbound delivery with a catch weight material, distribute to EWM, and open it in /SCWM/PRDI (display inbound delivery) to verify you see base quantity and catch weight quantity fields.For Handling Units, configure packaging specifications or handling unit types as needed. While not specific to catch weight, having consistent HU types (with known tare weights) helps. One advanced feature: Tare Weight Check. SAP EWM has a function to verify tare weights of containers (Accelerated Weighing Entry: Tare Weight Check). If you are using returnable containers or pallets with known weight, you can ensure those are accounted for so that net weight of goods is correctly derived. Configuration for this might be under EWM > Monitoring or Utility settings.

5.7. RF (Radio Frequency) Screen Adjustments

- If the warehouse uses RF handheld devices for tasks, the standard RF transactions might need to be adjusted to prompt for catch weight. For example, during putaway or packing confirmation on RF, after scanning an HU, you want a prompt “Enter weight”. SAP’s RF framework transactions (/SCWM/RFUI) can be customized by screen layout or by user exit to include extra input for CW quantity. This is a technical configuration (possibly requiring an ABAP enhancement if standard RF screens don’t support it). This ensures mobile users can comply with catch weight processes without paper.

5.8. Quality Management and Catch Weight

- If SAP QM is in scope (for example, goods receipt creates inspection lots), and samples are taken that affect weight (like moisture tests), consider how QM results might interface with catch weight. There isn’t a direct config to link QM to weight adjustment, but a process can be configured: e.g., if an inspection finds items underweight, a QM usage decision could trigger a correction (scrap or rework). This is more process design, but ensure any QM integration doesn’t conflict.One area to check: if using Quality Inspection in EWM, see that it can show the parallel UoM. EWM’s QI documents likely reference the batch/handling units which have the weight recorded, so usually fine.

5.9. Financial Settings

- From a configuration perspective, if using moving average price for catch weight materials, be cautious. Each goods movement with actual weight will post a proportional value. For standard price, variances might occur if actual total weight differs from planned. In Controlling (CO-PC settings), ensure that variance calculation is set appropriately (for example, if producing catch weight materials in a process order, decide how yield is recorded – by weight or pieces – and how variances are assigned). This isn’t a single config switch but a set of practices: e.g., if weight is valuation, then yield in production confirmation should be in weight to avoid large variances.

6. Business Benefits of Advanced Catch Weight Management

- Despite the challenges discussed, the advantages of implementing advanced catch weight management in SAP EWM are compelling, particularly for the food and meat industries. Key business benefits include:

6.1. Improved Pricing and Revenue Accuracy

- By capturing the exact weight of products shipped, companies can invoice customers with precision. In variable-weight scenarios, this prevents revenue leakage that occurs when flat pricing is used to approximate weight. A study of industry practices notes that using catch weight eliminates scenarios where one customer might inadvertently receive more product (by weight) for the same price as another, simply due to weight variability. This fairness in pricing not only boosts revenue (the company gets paid for every pound/kilogram delivered) but also improves customer trust, because customers are confident, they pay only for what they get. It also reduces the need for post-sale adjustments or credits due to weight discrepancies, simplifying financial reconciliation.

6.2. Enhanced Inventory Visibility and Planning

- Catch weight management provides a more granular view of inventory. Instead of just knowing how many cases or units are on hand, the company also knows the total weight on hand. This is crucial for planning in industries where orders or production recipes are weight-based. For example, a meat processor planning a shipment needs to ensure it has, say, 1000 kg of chicken breasts in stock – if inventory were only tracked by cases, they’d have to estimate. With catch weight, they can query the system directly for weight availability. SAP’s unified database ensures the weight stays associated with the stock through all movements. As a result, material requirements planning (MRP) and available-to-promise (ATP) checks become more reliable for catch weight items, reducing stockouts or short shipments. It also helps in yield analysis – comparing how much weight was received vs. shipped can identify process losses (like dehydration or trim waste), enabling continuous improvement in operations.

6.3. Regulatory Compliance and Consumer Safety

- In many jurisdictions, regulations require accurate net weight labeling on food packages. Companies using catch weight can more easily comply since their system inherently manages actual weight data. If a regulator audits the records to see if the weights on labels match what was shipped, the SAP system can produce evidence (each batch, HU recorded with actual weight). For items sold at retail by weight, mislabeling weight is a serious offense; catch weight processes reduce that risk significantly. Additionally, traceability is improved – if there’s a recall, knowing the weights can matter (for example, dosage of a contaminant might depend on weight, etc.). While weight is not the only factor in safety, having detailed records contributes to a culture of precision that aligns with quality and safety management.

6.4. Financial Accuracy in Valuation and Costing

- When the parallel (catch) weight unit is used as the valuation unit, inventory accounting reflects reality more closely. Each goods receipt is valued exactly at the received weight * standard price per weight. This prevents cumulative distortions. In contrast, if one were to use an average conversion, over time the errors could accumulate causing inventory value to drift from actual. With CWM, at any point the total inventory value in General Ledger should tie to the actual total weight * price. This also simplifies cost of goods sold calculation – when goods issue happens, the system knows the exact weight shipped, so the COGS posted is proportional. In a moving average price scenario, catch weight postings keep the moving average stable because the correct quantity is issued. Financial controllers benefit from fewer manual adjustments or suspense entries. In short, the books are cleaner and audits are smoother (auditors can see quantity in dual units and be assured that the valuation is on the right basis). One specific innovation is integration with Margin Analysis: companies can analyze profit per pound/kilo sold, which is often more meaningful than per unit if units vary in size. This granular profitability insight can inform pricing strategy and procurement.

6.5. Operational Efficiency Gains

- At first glance, adding weighing might seem like an efficiency loss, but in the bigger picture it can simplify processes and reduce errors. For example, consider the previous method some companies used: receiving would record an estimated weight, then later an accounting clerk might reconcile invoice weights and adjust inventory or billing. With catch weight captured at source, those later reconciliation steps can be eliminated or minimized. Scanco, a warehouse technology firm, points out that catch weight automation “minimizes human error” and reduces time spent on corrections. Additionally, by integrating weight capture into normal workflow (with scanners/scales), the effort becomes routine and less burdensome than periodic large reconciliations or inventory counts. Over time, companies often streamline the weighing process (finding optimal methods), and it simply becomes part of standard work with negligible impact on throughput. Meanwhile, the elimination of separate weight-tracking spreadsheets or systems means less duplicate data entry and fewer mistakes. The warehouse management now happens in one system (SAP EWM), improving data integrity.

6.6. Customer Satisfaction and Transparency

- With advanced catch weight capabilities, companies can offer greater transparency to their customers. Delivery notes and invoices can show both the number of units and the weight delivered, which customers in food service or retail appreciate for their own inventory control. If a customer questions a shipment’s weight, the supplier can confidently refer to the recorded data (even down to each box’s weight, if needed). Some companies even share catch weight data via EDI or on shipping labels (e.g., a label might say “Net Weight = X kg”). This level of transparency can be a competitive differentiator when vying for contracts with large buyers who audit supplier accuracy. It demonstrates a commitment to fairness and accuracy. In scenarios like contract manufacturing or toll processing (where payment might be based on output weight), having an SAP-driven single source of truth for weights can avoid disputes and strengthen partnerships.

6.7. Enabling Advanced Analytics and Optimization

- Once weight data is consistently captured, the company can leverage it for advanced analytics. For example, analyzing weight variance by supplier can identify which suppliers deliver product that consistently undershoots or overshoots expected weight – leading to better negotiating (paying for actual yield, not just count). Analytics might reveal process inefficiencies, like certain plant lines yielding less net weight than others for the same input (indicating higher waste). By having detailed weight data, companies can move towards yield management and optimization, a critical aspect in food processing profitability. It also enables more accurate carbon footprint calculations (since weight is related to volume shipped, etc.), which can feed into sustainability reporting.

6.8. Scalability and Digital Foundation

- Implementing catch weight in SAP EWM lays a foundation for future digital innovations. For instance, it becomes easier to implement IoT weight sensors, machine learning for weight predictions, or blockchain for supply chain transparency (recording exact attributes of each item). In a way, CWM is an early step towards the Internet of Things – treating each item as a uniquely measured object. Companies that have mastered this can more readily adopt automation like automated picking with built-in weighing, because their systems and processes are already oriented to handle variable data per item. It’s preparing the enterprise for more advanced Industry 4.0 initiatives. In summary, the business benefits span financial, operational, and strategic realms. SAP’s catch weight management is not merely a module to tick a compliance box; it actively contributes to performance improvements. It can help in “transforming the food industry” by saving money and time through accuracy and efficiency. Companies that have implemented it often report clearer insight into their business – they know exactly how much product they are buying, storing, and selling at all times, which is a cornerstone of good supply chain management.

7. Integration Considerations (EWM, S/4HANA, and Beyond)

- Advanced catch weight management does not exist in isolation; it touches various components of the SAP landscape and possibly external systems. Key integration considerations include:

7.1. EWM and Core S/4HANA Integration

- In an embedded EWM scenario (which is the norm in S/4HANA), integration is largely seamless. EWM uses the same database as the core (MM and SD), so a catch weight material in the material master is directly understood in EWM processes. The integration consideration here is mostly to ensure configurations align (as noted, EWM reuses the customizing for catch weight profiles and tolerance from S/4). For decentralized EWM, integration is more complex: one must ensure the Core Interface (CIF) or other master data transfer sends the parallel unit and relevant flags to the EWM system. Also, any transactional data transfer (deliveries) needs to carry the catch weight quantities. According to SAP, connectivity between CWM and decentralized EWM is supported, but one should test key transactions thoroughly. For instance, when an outbound delivery is sent to a decentralized EWM, does it include the parallel quantity? Usually, the ERP delivery would include both and the EWM system must store it. Integration mapping might require an enhancement if standard IDoc types didn’t initially account for it (though by EWM 9.5 this was standard). So, project teams should not assume it works out-of-box without confirming via integration testing.

7.2. Integration with SAP Sales and Distribution (SD)

- Catch weight affects SD in pricing and ordering. If a sales order is created for a catch weight item, the order might be in base units (pieces/cases) but pricing needs to be in weight unit (for example, price per KG). SAP allows pricing units different from sales units; the condition records can be maintained per LB/KG, and the order line will use the parallel quantity for pricing calculation.

7.3. Integration with SAP Materials Management (MM) / Procurement

- On the procurement side, purchase orders for catch weight items should specify both units as well. Typically, the PO is in base unit (like ordering 50 carcasses) but the pricing from vendor is per KG. SAP supports dual units in POs for CWM materials: the PO line can have an “alternate quantity” or catch weight quantity field. The GR posting then uses actual weight. Integration point: ensure that the vendor’s invoice (SAP LIV – Logistics Invoice Verification) matches up. The invoice will likely come as “X KG at price Y = total Z”. The SAP system, having recorded the GR in KG and pieces, can automatically verify the invoice quantity in KG. This reduces invoice mismatches.

7.4. Integration with Production (SAP PP/QM)

- In meat/food processing, production orders or process orders yield catch weight materials. SAP PP can integrate with CWM such that the production confirmation allows input of yield in both units. Integration consideration: when a process order for salami (for example) is confirmed, the user can specify produced 100 sticks = 120 kg. The goods receipt into EWM would then already have 120 kg as catch weight for those 100 pieces. If using SAP Process Integration (PI) or a Manufacturing Execution System (MES) interfaced with SAP, that MES should capture weights on the line and send them with confirmations. In SAP S/4, it’s ideal to use the PP-PM interface that supports CWM, rather than doing two-step updates. If QM is active, integration between QM and EWM for catch weight might include sending quality inspection results (e.g., moisture content measured might be used to adjust expected weight loss – although not standard, some integration can be designed where QM results influence allowed weight range or trigger reweigh requirement). At minimum, ensure QM inspection lots for CWM materials show both quantities so that quality inspectors are aware (for example, if a sample is taken, the system might need to deduct weight of sample from inventory – a small detail, but relevant in pharmaceutical or expensive ingredients).

7.5. Financial Integration (Controlling/FI)

- We touched on valuation – integration here means how the material ledger and CO processes handle dual units. Luckily, in S/4HANA the material ledger is always active, which can record movements in multiple units. Ensure that integration to CO-PA (Profitability Analysis) is set up such that it can capture either the weight or the revenue per weight if needed for analysis. In classic CO-PA, you might add a characteristic or value field for quantity in parallel UoM. In the new Margin Analysis (in SAP Analytics), perhaps just ensuring the measure of quantity can be in different units for different materials. It’s more an analytical integration than transactional.

7.6. Upgrades and Patches

- Integration also involves keeping the system updated to support CWM. If SAP releases patches that fix or enhance catch weight processes, those need to be applied. For example, earlier versions might have some limitations that are lifted in a support package; keeping an eye on SAP Notes related to CWM/EWM integration is important. The integration between modules is improved over time (like the removal of redundant customizing in embedded scenario was a big improvement). Being on a current release ensures you get these enhancements, which smooth out integration wrinkles (for instance, S/4HANA 2020+ had better integration of EWM with production for catch weight, etc., compared to initial 1610 release which had more restrictions). In summary, integration considerations revolve around ensuring all parts of the SAP environment (and connected systems) handle the dual-unit nature of catch weight materials gracefully. SAP’s strategy has been to integrate CWM deeply into core processes rather than leaving it as a bolt-on. This is evident in S/4HANA where catch weight is part of the standard data model. However, it’s up to the implementation team to configure and sometimes customize the integration points, especially when dealing with physical device data and external partners. Done correctly, the integration will be seamless and the catch weight information will flow from procurement through warehouse to sales and finance without loss or manual reentry – fulfilling the promise of a unified system.

8. Innovations and Future Outlook

- The field of catch weight management, while niche, continues to evolve with technological innovations and changing business needs. SAP’s advanced catch weight features in EWM have laid a strong foundation, and we can anticipate further developments and best practices shaping the future:

8.1. Automation and Industry 4.0

- The integration of IoT (Internet of Things) devices with SAP EWM is an emerging area of innovation for catch weight. Weighing devices are becoming smarter and more connected. For example, pallet jacks and forklifts with built-in scales can automatically record the weight of goods as they are moved. In the future, such devices could interface directly with EWM through SAP’s IoT services or Edge Services. This would allow weight capture to be entirely handsfree – imagine a forklift picks up a pallet of meat, the forklift’s sensor reads 500 kg, and via a Bluetooth or Wi-Fi connection, it updates the EWM transaction in real time. This eliminates even the scanning step, truly accelerating weighing. Some solutions of this kind are already in pilot stages in large cold storage warehouses. The innovation here is combining mobile equipment telemetry with EWM’s APIs to create a cyber-physical system.

8.2. Machine Learning for Weight Estimation

- Another innovative angle is using machine learning to predict or validate weights. For instance, in industries like poultry, the weight of a box might correlate with other variables (like the production line it came from, time of day, etc.). A machine learning model could flag anomalies – if a certain box’s weight is out of pattern compared to its peers even if within tolerance, it might indicate a mistake (like a missing product). Conversely, ML could help fill gaps when weights aren’t captured, by providing an estimated weight to use until actual can be updated. SAP’s Leonardo AI (now embedded in SAP Business Technology Platform) could be leveraged to analyze historical catch weight data and optimize processes (e.g., suggesting ideal batch sizes to minimize weight variance, or optimizing trim cuts to hit target weights more consistently). While these are not out-of-the-box SAP features yet, the data being collected via CWM is an enabler for applying data science.

8.3. Blockchain and Transparency Initiatives

- There’s growing interest in farm-to-fork traceability and transparency. For high-value food items, companies are exploring blockchain to record each transaction. Catch weight info can be part of that record. For example, a tuna supply chain on blockchain might log the weight of each tuna at catch, after processing, and at sale, to ensure no tampering or misrepresentation. The innovation is not in catch weight per se, but in using catch weight data as one attribute in a tamper-proof ledger that multiple parties can trust. SAP has blockchain adapters and has showcased pilots in agriculture; integrating EWM’s catch weight events with such distributed ledgers could become a value-add, particularly for proof of sustainability (showing yields, waste, etc., across the chain).

8.4. Mobile and User Experience Improvements

- SAP Fiori and mobile apps can make catch weight tasks much more user-friendly. Instead of using SAPGUI or RF screens, Fiori apps could guide users with visuals and sensor integration. For example, a tablet app for receiving might show the product image, expected weight range, and a live scale reading—making the process intuitive and reducing errors.SAP or partners could develop these specialized UIs, cutting down training time. Additionally, Fiori analytical apps could track metrics like daily weight variance or out-of-tolerance HUs, giving supervisors real-time dashboards to monitor performance.

8.5. Cloud Deployment and Extensibility

- As SAP pushes S/4HANA Cloud, they will eventually incorporate catch weight into the public cloud edition as well (especially because many mid-market food companies would want it). The innovation there will be making CWM available in a standardized way with perhaps pre-configured profiles for industries. Cloud customers might get easy toggles like “activate catch weight for material X” without deep config knowledge. SAP might also deliver API endpoints for catch weight operations (allowing cloud integration easily). Extensibility in cloud (e.g., using SAP’s Business Technology Platform) could allow quick development of custom weight capture apps or IoT integration without modifying the core, which is an innovation in how we approach enhancement – e.g., an event in EWM (HU created) could trigger an extension app that awaits a weight reading from a sensor, then writes back the valuation quantity via API.In conclusion, advanced catch weight management is set to become even more integrated, automated, and intelligent. The fundamental problem – products vary, we need to manage that – remains, but solutions will become more seamless. SAP EWM’s current capabilities already position companies to take advantage of these trends, because having structured weight data is the first step to any advanced digital initiative in this space. The innovations on the horizon promise to further reduce manual effort (through automation), increase accuracy (through smart systems and checks), and derive more strategic value from what was once considered just a nitty-gritty detail of warehouse operations.

9. Conclusions

- SAP’s Advanced Catch Weight Management (CWM) in S/4HANA EWM addresses the challenges of managing variable-weight products, especially in industries like food and meat processing. CWM allows tracking inventory in two units—such as pieces and weight—ensuring accuracy where standard weights don’t apply.SAP evolved from basic batch-specific UoMs to a robust CWM system. Key components include material master settings, catch weight profiles, and tolerance groups. Real-world examples—like weighing meat cartons or tracking cheese weight loss—show how CWM improves billing, compliance, and efficiency.Implementation requires careful planning: activating features, configuring units and tolerances, and embedding weighing into warehouse workflows. Embedded EWM simplifies this by avoiding data duplication, while decentralized setups need extra integration. Though CWM introduces complexity and change management needs, it brings better control and accuracy.CWM delivers clear business value: accurate pricing, transparent inventory, legal compliance, and reduced rework. It aligns financials with actual weight and supports traceability. Integration across procurement, sales, production, and finance is essential to realize these benefits.Looking ahead, automation (e.g., IoT scales, machine learning) will enhance CWM further. What’s advanced today may soon be standard. For industries with variable-weight products, adopting CWM is becoming essential—not just beneficial.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML