-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Computer Science and Engineering

p-ISSN: 2163-1484 e-ISSN: 2163-1492

2023; 13(1): 8-14

doi:10.5923/j.computer.20231301.02

Received: Nov. 28, 2023; Accepted: Dec. 20, 2023; Published: Dec. 23, 2023

SAP - ERP Software’s Pivotal Role in Shaping Industry 4.0: Transforming the Future of Enterprise Operations

Moyinuddeen Shaik

Manager- Business Process Applications, Mine Safety Appliances, Cranberry Twp, USA

Correspondence to: Moyinuddeen Shaik, Manager- Business Process Applications, Mine Safety Appliances, Cranberry Twp, USA.

| Email: |  |

Copyright © 2023 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The advent of Industry 4.0 marks a paradigm shift in the realms of digital transformation, with SAP (Systems, Applications, and Products in Data Processing) positioned as a pioneering force at the forefront of this revolution. This article meticulously explores the profound influence by SAP on the landscape of Industry 4.0, analyzing the intricate ways in which its cutting-edge technologies and solutions contribute to the evolution of manufacturing and business operations. As industries embrace the convergence of physical and digital domains, SAP's prominence becomes increasingly evident. This examination serves as a testament to SAP's pivotal role in steering and defining the trajectory of Industry 4.0.

Keywords: SAP, Industry 4.0, HANA, IoT, AI, Optimization, Cybersecurity, Collaboration, Digital Transformation

Cite this paper: Moyinuddeen Shaik, SAP - ERP Software’s Pivotal Role in Shaping Industry 4.0: Transforming the Future of Enterprise Operations, Computer Science and Engineering, Vol. 13 No. 1, 2023, pp. 8-14. doi: 10.5923/j.computer.20231301.02.

Article Outline

1. Introduction

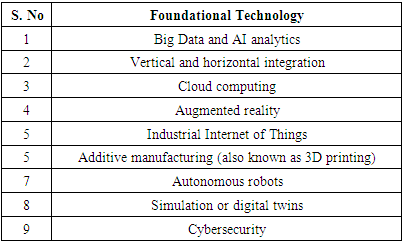

- Industry 4.0 represents the convergence of physical and digital technologies to create a smart, connected, and automated ecosystem. At the heart of this transformation lies SAP, a leading provider of enterprise software that is instrumental in integrating and optimizing the diverse elements of Industry 4.0.Industry 4.0 is built on a framework of nine key technology pillars. These innovations serve as the connectors between the physical and digital realms, enabling the development of intelligent and autonomous systems. While certain advanced technologies within this framework are already in use across various industries and supply chains, the true power of Industry 4.0 emerges when these technologies are seamlessly integrated and utilized collectively. Among these transformative pillars are:

|

2. Industry 4.0 Concepts and Technologies

- Industry 4.0 represents a revolutionary paradigm in manufacturing and business processes, marked by the convergence of digital technologies, automation, and data exchange. Let us review the core principles of Industry 4.0 and the technologies driving this transformation, with a specific focus on the integration of the Internet of Things (IoT), Artificial Intelligence (AI), and the notable synergy with SAP ERP. Industry 4.0 is characterized by several foundational principles that redefine the nature of production and organizational processes. These principles include:

2.1. Interoperability and Interconnectivity

- Seamless communication and data exchange among diverse devices, machines, and systems are imperative for Industry 4.0. This facilitates real-time data synchronization and collaboration across different facets of the production process. Standardized protocols and interfaces, such as Industrial Ethernet, OPC UA, and MQTT, ensure compatibility between various technologies and vendors, streamlining integration and reducing complexity.

2.2. Information Transparency

- Accessing and leveraging real-time data is pivotal for optimizing operations and informed decision-making within Industry 4.0. Industry 4.0 systems aggregate data from sensors, machines, and production processes, which is subsequently analysed and visualized. This process yields valuable insights into process efficiency, machine performance, and potential issues. Enabling technologies include data analytics platforms, cloud computing, and Industrial IoT platforms.

2.3. Decentralization and Autonomous Decisions

- Empowering machines and systems to make autonomous decisions based on real-time data is essential for achieving faster response times and enhanced process flexibility. This autonomy is realized through edge computing, where data is processed and analysed closer to the source, enabling real-time decision-making without dependence on centralized control systems. Enabling technologies encompass intelligent agents, edge computing platforms, and machine learning algorithms.

2.4. Real-time Capability

- Industry 4.0 systems must possess the capability to respond to changes in real-time to uphold optimal efficiency and product quality. This necessitates high-performance communication networks, robust computing resources, and efficient data processing algorithms. Enabling technologies include 5G networks, real-time databases, and in-memory computing.

2.5. Technical Assistance and Service Orientation

- Industry 4.0 systems should be designed with a focus on providing users with the requisite information and support for effective operation and maintenance. Features such as remote monitoring, predictive maintenance, and augmented reality support contribute to comprehensive technical assistance, ensuring the seamless operation and continuous improvement of Industry 4.0 implementations.

2.6. Modularity

- Building systems with modular components enhances flexibility and scalability, allowing for easy adaptation to changing needs and the integration of emerging technologies. Modular systems can be customized effortlessly to meet the specific requirements of diverse applications and industries. This modularity fosters adaptability and futureproofing of Industry 4.0 implementations.

3. Beyond the Assembly Line: Industry 4.0's Impact Across Sectors

- In the era of Industry 4.0, the impact of technological advancements extends far beyond traditional manufacturing, reaching into diverse sectors such as healthcare, automotive, and retail. Industry 4.0 is not just about robots replacing humans in factories. It is a broader movement encompassing the digitization and automation of entire industries. Its impact stretches far beyond the assembly line, affecting various sectors in profound ways.

3.1. Manufacturing

- 3.1.1. Smart factories: Automation, robotics, and intelligent machines are transforming production lines, making them more efficient, flexible, and adaptable to changing demands.3.1.2. Predictive maintenance: Sensor-equipped machines and advanced analytics enable real-time monitoring and predictive maintenance, reducing downtime and optimizing resource utilization.3.1.3. Customization and mass personalization: Advanced technologies such as 3D printing and AI-powered design tools allow for mass customization and production of personalized products.

3.2. Logistics and Supply Chain

- 3.2.1. Internet of Things (IoT) and connected devices: Real-time tracking of goods and materials throughout the supply chain improves transparency, efficiency, and responsiveness.3.2.2. Automated warehouses and transportation: Robots and automated systems handle warehousing and transportation tasks, increasing speed, accuracy, and safety.3.2.3. Predictive logistics: Data-driven insights help predict demand fluctuations and optimize transportation routes, reducing costs and environmental impact.

3.3. Retail

- 3.3.1. Omnichannel experiences: Digital platforms and customer data enable seamless shopping experiences across online and offline channels.3.3.2. Personalized marketing and recommendations: AI-powered marketing tools personalize offers and recommendations based on individual customer preferences and purchase history.3.3.3. Smart stores: Advanced technology is used to enhance the shopping experience with interactive displays, self-checkout options, and personalized product recommendations.

3.4. Healthcare

- 3.4.1. Telemedicine and remote care: Digital tools and technologies enable remote diagnosis, treatment, and monitoring of patients, improving access to healthcare, and reducing costs.3.4.2. Precision medicine and genomics: AI and data analysis tools help personalize medical treatments and therapies based on individual patient genetics and health data.3.4.3. Robot-assisted surgery: Minimally invasive procedures performed by robots improve accuracy, precision, and patient outcomes.

3.5. Agriculture

- 3.5.1. Precision agriculture: Sensors and data analytics enable farmers to optimize resource usage, monitor crop health, and predict yield, leading to increased productivity and sustainability.3.5.2. Automated farming equipment: Robots and autonomous vehicles perform tasks such as planting, harvesting, and weed control, reducing labor costs, and improving efficiency.3.5.3. Vertical farming: Controlled-environment agriculture technologies increase food production in urban areas and reduce reliance on traditional land-based farming.

4. Evolution of SAP ERP: Historical Development and Key Milestones

- The evolution of SAP ERP software is a remarkable journey that spans several decades, marked by transformative developments and technological advancements. This section offers a detailed exploration of the historical trajectory of SAP ERP, focusing on key milestones that have shaped its evolution up to the present-day SAP S/4HANA platform.

4.1. Early Beginnings

- SAP, founded in 1972 by five engineers in Germany, initially focused on developing software solutions for enterprise resource planning. The company's early forays into ERP were characterized by a commitment to streamlining business processes and integrating various organizational functions.

4.2. R/2 to R/3 Transition

- The 1980s witnessed a significant milestone with the introduction of SAP R/2, the first integrated ERP suite. This marked a departure from traditional mainframe-based systems, offering a more modular and flexible architecture. The transition to R/3 in the early 1990s represented a paradigm shift, introducing a client-server model and further enhancing the scalability and functionality of SAP ERP.

4.3. Global Expansion and Standardization

- As SAP ERP gained prominence, the 1990s saw the company expanding its global footprint. Standardization of business processes became a focal point, allowing organizations to implement SAP solutions across diverse industries. This era laid the groundwork for SAP's ascendancy as a leading ERP provider.

4.4. SAP S/4HANA Revolution

- A pivotal moment in SAP's history occurred with the introduction of SAP S/4HANA in 2015. This marked a shift towards a digital core, leveraging in-memory computing to enable real-time data processing. The S/4HANA platform embraced cloud computing, mobile capabilities, and advanced analytics, ushering in a new era of intelligent enterprise solutions.

4.5. Integration of Emerging Technologies

- In recent years, SAP ERP has continually evolved by embracing emerging technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT). This integration underscores SAP's commitment to staying at the forefront of technological innovation and providing cutting-edge solutions to its user base.

4.6. SAP's Position in the ERP Market

- Analysing SAP's position in the ERP market reveals a narrative of consistent leadership and innovation. As of [current year], SAP stands as a dominant force, holding a substantial market share globally.• Global Reach: SAP's ERP solutions are deployed across diverse industries and geographies, highlighting a truly global reach. The company's international presence ensures that its ERP offerings cater to the unique needs of businesses operating in various cultural and regulatory contexts.• Market Share: SAP has consistently held a significant share of the ERP market, with a strong competitive edge. The reliability, scalability, and comprehensive nature of SAP ERP solutions contribute to the company's sustained market leadership.• Customer Base: SAP's ERP customer base is extensive and diverse, encompassing small and medium enterprises (SMEs) to large multinational corporations. The broad applicability of SAP ERP across industries, coupled with a focus on user-centric design, has resulted in a loyal and expanding customer community.

5. SAP Solutions for Industry 4.0

- SAP's ERP solutions significantly contribute to shaping Industry 4.0 by providing businesses with the tools and capabilities necessary for increased automation, data-driven decision-making, and intelligent operations. This hypothesis proposes a positive influence of SAP on Industry 4.0.SAP offers a comprehensive suite of solutions that cater to various approaches for implementing the key pillars of Industry 4.0. Here is a breakdown of these pillars and how SAP can address them:

5.1. Interoperability and Interconnectivity

- 5.1.1. SAP Cloud Platform Integration: This platform enables seamless data exchange between different applications, systems, and devices, regardless of vendor or technology.5.1.2. SAP HANA Cloud Connect: This service provides secure and reliable connectivity between on-premise systems and the cloud, facilitating data integration and real-time collaboration.5.1.3. SAP Standardized protocols and interfaces: SAP supports various industry-standard protocols and interfaces, ensuring compatibility and seamless integration with other systems.5.1.4. SAP Business Technology Platform (BTP): SAP Business Technology Platform (SAP BTP) brings together application development and automation, data and analytics, integration, and AI capabilities in one unified environment. Create personalised experiences across business processes, build applications, analytics, and integrations faster, and run mission-critical innovation confidently on major cloud providers' infrastructure fully managed by SAP.

5.2. Information Transparency

- 5.2.1. SAP S/4HANA: This ERP system provides a centralized platform for collecting, storing, and analyzing data from various sources across the organization.5.2.2. SAP Analytics Cloud: This cloud-based analytics platform offers pre-built dashboards and reports for visualizing key performance indicators (KPIs) and generating real-time insights.5.2.3. SAP Cloud for Manufacturing: This solution provides industry-specific applications for tracking production processes, monitoring equipment performance, and analyzing quality data.

5.3. Decentralization and Autonomous Decisions

- 5.3.1. Edge computing: SAP offers edge computing solutions that enable data processing and decision-making closer to the source, allowing for faster response times and increased autonomy.5.3.2. Internet of Things (IoT): SAP integrates with various IoT platforms and devices, enabling real-time data collection and analysis for decentralized decision-making.5.3.3. Machine Learning: SAP provides machine learning algorithms that can be embedded into applications and systems, allowing them to learn and adapt to changing conditions and make autonomous decisions.

5.4. Real-time Capability

- 5.4.1. SAP S/4HANA: This in-memory database provides high-performance data processing capabilities, enabling real-time monitoring and analysis of operational data.5.4.2. SAP Leonardo IoT Suite: This suite offers solutions for real-time data collection, analysis, and visualization, enabling organizations to respond to changes and events in real-time.5.4.3. Predictive analytics: SAP offers predictive analytics solutions that leverage historical data and machine learning to predict future trends and events, allowing for proactive decision-making.

5.5. Technical Assistance and Service Orientation

- 5.5.1. SAP Intelligent Robotic Process Automation (RPA): RPA bots can automate repetitive tasks, freeing up human employees to focus on higher-value activities.5.5.2. SAP Leonardo Digital Assistant: This AI-powered assistant provides users with personalized recommendations, answers to questions, and assistance with tasks.5.5.3. SAP Customer Experience solutions: These solutions offer tools for managing customer interactions, providing personalized support, and resolving issues efficiently.

5.6. Modularization

- 5.6.1. SAP Business One: This ERP solution is designed for small and medium-sized businesses, offering a modular design that can be customized to meet specific needs.5.6.2. SAP Cloud Platform: This platform provides a set of pre-built services and modules that can be easily integrated to build customized applications and workflows.5.6.3. SAP Industry Cloud Solutions: These solutions offer industry-specific modules that can be added to SAP core applications to tailor them to the needs of different industries.

5.7. Additional Solutions

- 5.7.1. Security: SAP offers robust security features and tools to protect sensitive data and ensure the integrity of systems.5.7.2. Sustainability: SAP solutions can help organizations reduce their environmental impact by optimizing resource utilization and minimizing waste.5.7.3. Workforce Development: SAP provides training and development programs to help organizations prepare their employees for the changing nature of work in the Industry 4.0 era.

6. SAP's Impact on the Modern Enterprise

- SAP's impact on the modern enterprise extends far beyond simple software solutions. By providing a comprehensive ecosystem of tools, technologies, and services, SAP empowers businesses to:

6.1. Streamlined Processes

- SAP ERP integration often leads to streamlined business processes. Automation and standardized workflows reduce manual effort, minimizing errors and enhancing operational efficiency. SAP provides a comprehensive suite of applications that integrate various business processes, fostering seamless communication and collaboration. Modules like SAP S/4HANA serve as a digital core, unifying data, and processes across an organization.

6.2. Real-time Visibility

- SAP ERP provides real-time visibility into various aspects of operations, from supply chain management to financial transactions. This visibility enables informed decision-making and proactive problem-solving. SAP's in-memory computing capabilities, exemplified by SAP HANA, enable real-time data processing and analytics. Businesses can make informed decisions based on up-to-the-minute insights, enhancing agility and responsiveness.

6.3. Resource Optimization

- Organizations witness resource optimization as SAP ERP efficiently allocates resources based on real-time demand, reducing unnecessary costs, and improving overall resource utilization.

6.4. Adaptive Planning

- SAP ERP equips organizations with tools for adaptive planning. The system's real-time data and forecasting capabilities enable agile responses to market fluctuations and changing customer demands.

6.5. Quick Decision-Making

- With data readily available, organizations can make quicker and more informed decisions. SAP ERP's analytical features empower leaders to respond promptly to market dynamics, gaining a competitive edge.

6.6. Supply Chain Resilience

- SAP ERP enhances supply chain resilience by providing end-to-end visibility. This enables organizations to identify potential disruptions and implement agile strategies to mitigate risks.

7. Case Studies: Highlighting Successful Transformations

- SAP plays a pivotal role in facilitating Industry 4.0 by providing a comprehensive ecosystem of solutions that support the key principles of this revolution. The following real-world case studies illustrate the effectiveness of SAP solutions in driving digital transformation and achieving significant benefits across various industries.

7.1. Bosch Rexroth: Transforming Manufacturing with SAP S/4HANA

- • 25% reduction in production lead time.• 20% increase in overall equipment effectiveness (OEE).• Improved inventory management and forecasting accuracy. • Real-time visibility into production processes.

7.2. Henkel: Embracing Predictive Maintenance with SAP Predictive Asset Insights

- • Reduced downtime by 30%.• Optimized maintenance schedules and resource allocation.• Extended asset lifespan and improved operational efficiency. • Data-driven decision-making for proactive maintenance.

7.3. Colgate-Palmolive: Driving Supply Chain Agility with SAP Integrated Business Planning

- • Improved demand forecasting accuracy and planning.• Enhanced collaboration between sales, production, and logistics teams.• Reduced inventory levels and waste.• Increased responsiveness to market changes and customer demands.

7.4. Siemens: Building a Digital Twin with SAP Leonardo

- • Improved product quality and consistency.• Reduced production costs and cycle times.• Enhanced operational efficiency and flexibility.• Data-driven insights for continuous improvement.

7.5. BASF: Optimizing Energy Management with SAP S/4HANA Cloud

- • Reduced energy consumption and costs.• Improved energy efficiency and sustainability.• Real-time insights into energy usage patterns.• Data-driven decision-making for energy optimization.

7.6. Coca-Cola HBC – Digital Transformation with SAP IBP

- • Enhanced demand and supply planning processes.• Demand forecasting and inventory optimization.• Improved agility in responding to market demand fluctuations.• Enhanced collaboration across the supply chain ecosystem.These case studies showcase the diverse ways SAP empowers companies across industries to leverage Industry 4.0. By providing a comprehensive suite of solutions, SAP allows businesses to become more connected, intelligent, and efficient, driving competitive advantage and success in the digital age.

8. Ethical Considerations

8.1. Data Privacy and Security

- The collection and utilization of vast amounts of data raise concerns about the privacy and security of individuals' information. For instance, the exponential growth of interconnected devices and sensors within the Industrial Internet of Things (IIoT) landscape necessitates a heightened focus on data privacy and security. Organizations must prioritize robust data encryption, access controls, and transparency in data usage. Clear consent mechanisms and compliance with data protection regulations are crucial.

8.2. Algorithmic Bias and Fairness

- AI algorithms may inadvertently perpetuate biases present in training data, leading to unfair treatment of certain groups. Ethical AI design requires continuous monitoring for biases, transparency in algorithmic decision-making, and efforts to ensure fairness and equity. Despite advancements in AI technologies, human oversight remains crucial for ensuring ethical and responsible decision-making.

8.3. Job Displacement and Reskilling

- Automation and AI can lead to job displacement, potentially causing economic and social challenges. Ethical implementation involves proactive measures for reskilling and upskilling the workforce, as well as addressing societal impacts through policies supporting job transition and education. Studies suggest that up to 30% of jobs in the United States alone could be susceptible to automation by 2030. This trend is particularly evident in sectors like manufacturing, transportation, and administrative support, where repetitive tasks are readily automated.

8.4. Transparency and Accountability

- The opacity of AI algorithms may hinder understanding and accountability in decision-making processes. Ensuring transparency in algorithmic decisions, providing explanations (explainable AI), and establishing accountability mechanisms are critical for ethical practices.

8.5. Environmental Impact

- The increased reliance on data centers for processing Big Data and AI computations can have significant environmental consequences. Implementing sustainable practices, optimizing energy usage, and exploring green technologies are essential to minimize the environmental footprint.

8.6. Autonomous Systems and Decision-Making

- The deployment of autonomous systems may raise questions about accountability in case of unintended consequences or errors. Establishing clear lines of responsibility, incorporating fail-safe mechanisms, and ensuring human oversight are crucial for ethical deployment.

9. Challenges

9.1. Integration Complexity

- Integrating diverse Industry 4.0 technologies can be complex, leading to technical challenges and compatibility issues. Strategic planning, collaboration between different stakeholders, and ongoing system maintenance are vital for successful integration.

9.2. High Implementation Costs

- Implementing Industry 4.0 technologies often involves significant upfront costs. Organizations need to carefully assess the return on investment (ROI) and explore cost-effective implementation strategies while considering long-term benefits.

9.3. Resistance to Change

- Employees may resist adopting modern technologies, impacting the success of implementation. Consideration: Effective change management strategies, user training, and transparent communication about the benefits of transformation are essential to overcome resistance.

9.4. Lack of Standardization

- The absence of standardized protocols may hider interoperability between different technologies and systems. Consideration: Industry collaboration, the development of standards, and adherence to existing frameworks are necessary for ensuring seamless integration.

9.5. Regulatory Compliance

- The evolving nature of technology may outpace regulatory frameworks, leading to compliance challenges. Organizations must stay informed about relevant regulations, actively engage with regulators, and ensure compliance with ethical and legal standards.

9.6. Cybersecurity Threats

- The increased connectivity and reliance on digital technologies expose systems to potential cybersecurity threats. Prioritizing robust cybersecurity measures, conducting regular audits, and staying abreast of emerging threats are critical for mitigating risks.Addressing the above ethical considerations and potential challenges is essential to ensure that Industry 4.0 technologies are deployed responsibly, ethically, and with a positive impact on society and the workforce. Organizations, policymakers, and technology developers must collaborate to establish ethical frameworks and best practices for the evolving landscape of Industry 4.0.

10. Conclusions

- In conclusion, SAP's influence on Industry 4.0 is transformative, aligning seamlessly with the principles of intelligent manufacturing. As organizations worldwide embrace the fourth industrial revolution, SAP stands as a strategic ally, empowering businesses to thrive in the dynamic landscape of Industry 4.0. By fostering intelligent manufacturing through cutting-edge solutions, SAP empowers businesses to unlock unprecedented levels of efficiency, agility, and innovation.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML