-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2023; 13(1): 1-6

doi:10.5923/j.cmaterials.20231301.01

Received: Mar. 13, 2023; Accepted: Apr. 16, 2023; Published: May 12, 2023

Elaboration of a Composite Material Based on Fabrics Waste and Polystyrenes: Effect of Polystyrene Resin on the Strengths of the Composite

Brahiman Traoré, Obré Sery Paul Jolissaint, Koffi Clement Kouadio, Conand Honoré Kouakou, Edjikeme Emeruwa

Laboratory of Soils, Water and Geomaterials, Felix Houphouët Boigny University, Cocody-Abidjan, Ivory Coast

Correspondence to: Brahiman Traoré, Laboratory of Soils, Water and Geomaterials, Felix Houphouët Boigny University, Cocody-Abidjan, Ivory Coast.

| Email: |  |

Copyright © 2023 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

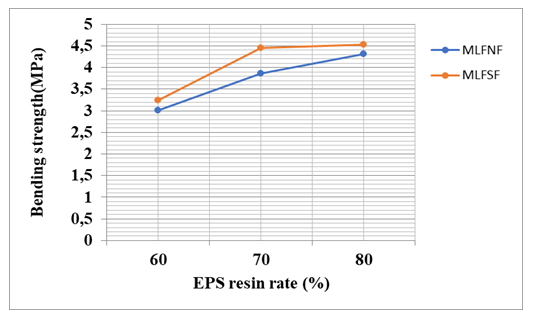

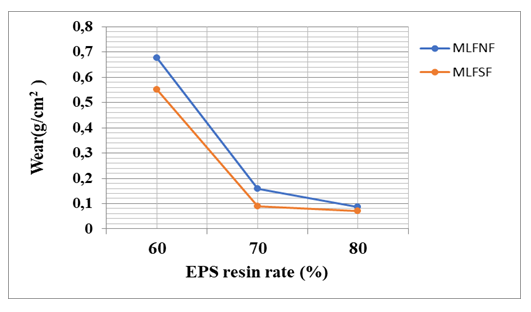

This study consists in proposing a recycling method for sewing fabrics and polystyrene waste. One way of valorization such waste is through its use as a new raw material resource in materials. The objective of this work is the development of new materials based on sewing fabrics waste and expanded polystyrene. For the elaboration of the samples, two types of fabrics, LFNF (loincloth fabrics based on natural fibers) and LFSF (loincloth fabrics based on synthetic fiber) were selected because they are the most accessible. The samples were made by varying the rate of fabric and expanded polystyrene (EPS). Tests were made on these samples to determine their physical (density and absorption) and mechanical (wear resistance and three-point bending strength) properties. The results obtained showed that the density of two types of composites decrease with increasing rate of EPS. Water absorption also decreases from 5.12% to 1.15% for MLFSF (materials with loincloth fabrics based synthetic fiber) and from 15.02% to 2.68% for MLFNF (materials with loincloth fabrics based natural fiber) with an increase in the PSE resin content. Finally, the bending strength increases from 3.23 MPa to 4.53 MPa for the MLTSF and from 3.01 MPa to 4.32 MPa for the MLTNF with a variation in the rate of the EPS resin ranging from 60 to 80%. Wear strength also decreases with increasing resin. The use of EPS as a binder in composites gives it encouraging physical and mechanical properties. The use of EPS and fabrics waste as a new raw material resource in manufacturing of new materials is therefore a way of recovering this waste.

Keywords: Sewing fabrics, Waste, Expanded polystyrene, Valorization, Composite

Cite this paper: Brahiman Traoré, Obré Sery Paul Jolissaint, Koffi Clement Kouadio, Conand Honoré Kouakou, Edjikeme Emeruwa, Elaboration of a Composite Material Based on Fabrics Waste and Polystyrenes: Effect of Polystyrene Resin on the Strengths of the Composite, International Journal of Composite Materials, Vol. 13 No. 1, 2023, pp. 1-6. doi: 10.5923/j.cmaterials.20231301.01.

Article Outline

1. Introduction

- The proliferation of industrial waste such as sewing and polystyrene waste contributes enormously to environmental pollution. It is therefore necessary to recover this waste by considering it as a new raw material resource in manufacturing of new materials in order to reduce the use of natural raw material. The valorization of this waste could constitute an interesting environmental and economic alternative, by eliminating it from cumbersome and polluting landfills. The literature mentions that there are several ways of recovering polystyrene waste through several production methods [1-4]. Similarly, the recycling of fabrics waste is the subject of several studies [5-7]. It is with this in mind that a recycling method including these two types of waste was initiated. The general objective of this work is then to develop new materials using expanded polystyrene (EPS) in the form of resin as a binder and sewing fabric waste as reinforcement.

2. Materials and Method

2.1. Raw Materials

2.1.1. Expanded Polystyrene

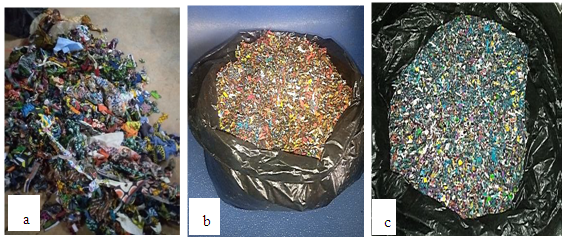

- The polymer used for the development of the matrix is recycled expanded polystyrene shows in Figure 1. It comes from the recovery of packaging material and other plastic products collected throughout the city of Abidjan. It represents a significant quantity left behind in our environment.

| Figure 1. Expanded polystyrene waste |

2.1.2. Sewing Fabrics Waste

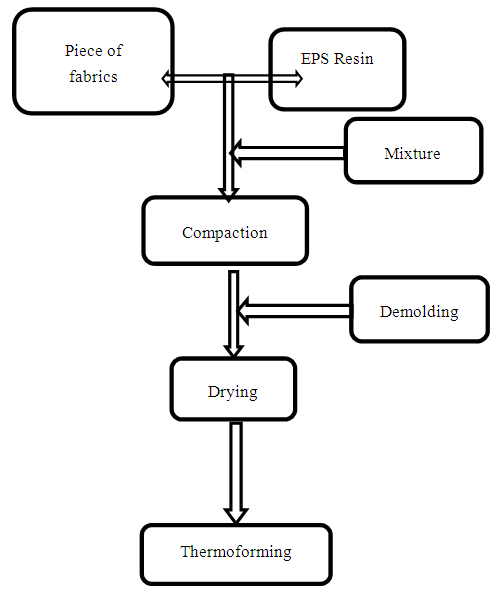

- Sewing tissue waste is generally leftover fabric discarded after being used by different fashion designer. This tissue waste is mainly made up of natural and synthetic fibers.Among these fabrics the choice fell on loincloths because they are the most used and the most rejected in our environment. The fabrics waste shows in Figure 2a used for this study comes from the various sewing workshops in the city of Abidjan. This waste is sorted, classified by constituent, and then shredded into small pieces (Figure 2b and 2c) in order to facilitate the homogeneity of the fabrics-resin mixture.

| Figure 2. Sewing fabrics waste; (a) fabrics bulk, (b) synthetic fiber fabrics shredded; (c) natural fiber fabrics shredded |

2.2. Experimental Method

2.2.1. Polystyrene Resin Production Method

- Expanded polystyrene at the end of its life is recycled and used as a binder for making composites. For this study, a solvent (acetone) was used to melt the expanded polystyrene. During the elaboration of this resin (Figure 3) one liter (1l) of acetone was used to melt 0.7 kg of polystyrene.

| Figure 3. Expanded polystyrene (EPS) resin |

2.2.2. Formulation and Elaboration

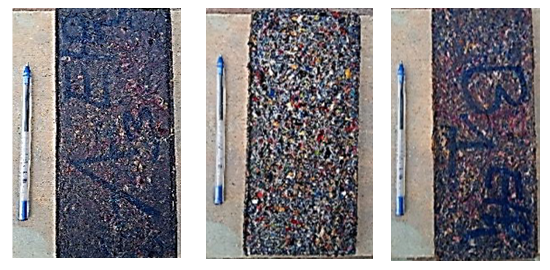

- For manufacturing of the materials, the pieces of fabrics and the polystyrene resin were mixed according to the variable mass proportions. The quantity of EPS used for the elaboration of the materials varies between 60% and 80% with an increment of 10. It should be noted that it is from 60% PSE resin that consolidated samples are obtained. After mixing (EPS resin and fabrics) in a container, the assembly is introduced into an extruder for mixing for 3 minutes. For the shaping of the samples, the mixture obtained is introduced into the mold of a static manual press and then compressed. After compaction, the samples are removed from the mold and then dried. After drying, the samples are then subjected to thermoforming. Thermoforming is a process that consists of softening the sample by put it in an electric oven at a temperature of 230°C for 30 min. The sample, once flexible and malleable, is introduced into the mold of the static manual press and then compressed. After compression, the final material is obtained. The methodology adopted for the elaboration of materials is summarized on the Figure 4.

| Figure 4. Diagram of sample development procedure |

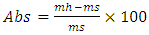

| Figure 5. Picture of samples obtained |

2.3. Characterizations of the Samples Produced

2.3.1. Physical Characterizations

2.3.1.1. Density

- After thermoforming, the samples are weighed. The different dimensions (length, width and thickness) are measured. From the dimensions, the volume of the samples is calculated, then the density is obtained by the Equation (1).

| (1) |

2.3.1.2. Water Absorption Test

- The penetration of water into a material is done by absorption. This absorption influences the durability of the material and is responsible for several damages. There are several types of absorption test. The immersion absorption test carried out during this study is determined according to the directives of standard NBN B 15-215:1989 [8]. After thermoforming the samples are weighed (ms). Then the samples are immersed in water for 24 hours and then weighed again (mh). The water absorption by immersion expressed as a percentage is obtained by the Equation (2).

| (2) |

2.3.2. Mechanical Characterization of Samples

2.3.2.1. Bending Strength

- The mechanical strength of building materials is one of the most important properties for their use. The bending test was carried out according to standard NF B 51-008 [9] on samples measuring 150 x 100.8 x 10.5 mm3. The three (3) point bending strength is expressed in MPa or N/mm2 and is given by the Equation (3).

| (3) |

2.3.2.2. Wear Test

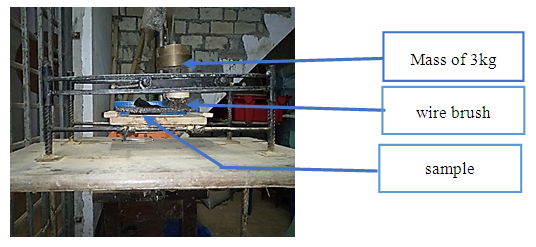

- The hardness of an object is its ability to scratch another object or to be scratched by it. Surface hardness makes it possible to know the durability of a material, to estimate the importance of some types of alteration and to appreciate the ability of materials to resist surface abrasion. The wear test characterizes the abrasion resistance of the faces of the samples. For this, samples with different contents of tissue residue and EPS resin are subjected to mechanical erosion applied by friction using a metal brush. To measure wear, we used the device shows on Figure 6, produced by the Geomaterials team [10].

| Figure 6. Wear measuring device |

| (4) |

3. Results and Discussion

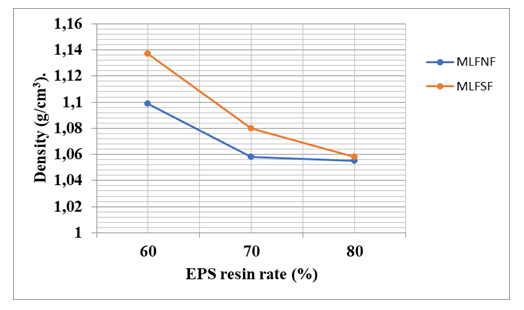

3.1. Influence of Polystyrene Resin on Density

- Figure 7 shows the density variation as a function of EPS resin content.

| Figure 7. Density variation function resin content of EPS. |

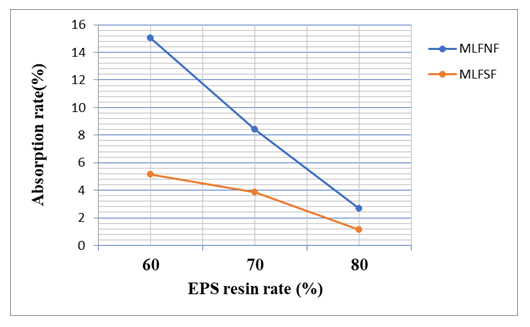

3.2. Influence of the Polystyrene Rate on Water Absorption by Total Immersion

- Figure 8 shows the variation of the absorption rate as a function of the EPS resin content

| Figure 8. Variation of the absorption rate as a function of the EPS resin content |

3.3. Influence of Polystyrene Content on Bending Strength

- Figure 9 shows the results of varying the 3-point bending strength.

| Figure 9. Variation of strength as a function of the EPS resin content in the material |

3.4. Influence of Polystyrene Content on Wear Strength

- Figure 10 shows the variation of wear as a function of EPS resin content.

| Figure 10. Variation of wear as a function of EPS resin content |

4. Conclusions

- The objective of this study was to recover sewing and polystyrene waste by developing a composite material using in construction. The experimental results allow to say that the strengths increase with the rate of EPS. The rate of water absorption also decreases with the rate of EPS. By comparing the results obtained with some standards that relate to coating materials, we can then say that these materials can be used as flooring materials. This method of developing materials turns out to be one of the solutions for recycling this industrial waste.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML