-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2020; 10(2): 40-49

doi:10.5923/j.cmaterials.20201002.03

Received: June 26, 2020; Accepted: August 11, 2020; Published: August 26, 2020

Impact Analysis of Honeycomb Core Sandwich Panels

Shah Alam , Babatope Adegbesan , Damodar Khanal

Department of Mechanical Engineering, Texas A&M University-Kingsville, Kingsville, TX, USA

Correspondence to: Shah Alam , Department of Mechanical Engineering, Texas A&M University-Kingsville, Kingsville, TX, USA.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Over time, man have struggled to cope with the modern-day types of ballistic threats. Consequently, it became important to understand the principles behind the design of the armor systems. The objectives of this study are to analyze and improve on the performance of sandwich-structured armor systems upon ballistic impact load. The model of the armor was in the form of sandwich structure with fiber reinforced polymers FRP as the skin and Aluminum Alloy Al3003 as the core. The core was filled with Silicon Carbide (SiC) and Aluminum Oxide (AL2O3). The uniqueness of the design is to use prismatic shaped ceramic blocks to erode the projectile and to use the 3D truss cores with Kevlar 29 and T1000G/epoxy for composite armors. Though in previous armor systems, ceramic powder and composite materials are used, the prismatic shaped ceramic particulate reinforced by metallic truss is a completely new concept. The ballistic impact was carried out using a 7.62 mm armor piercing projectile (APM2) at a striking velocity ranges of 1000 m/s -1600 m/s. The dynamic analysis is carried out in terms of residual velocity and energy absorption capacity. The skin thickness, material composition, velocity etc., was varied to get their influence on the impact resistance of the armor system. Finite element analysis, using ABAQUS CAE was performed on the designed armors upon an impactor at a velocity starting at 1200m/s until the velocity penetrates the armor. The effect of face sheet material, thickness and core material on the energy absorption capacity of the armors were observed. The difference in energy absorption values was observed to be minimal for the two face sheet materials used in this research. Validations of the simulation results were carried-out for Kevlar-29/Epoxy laminate using experimental results obtained using inhouse testing. Upon completion of all the analysis, it was found that these specific designed armors are strong enough to protect against relatively high ballistics threats, up to 1500m/s impact velocity.

Keywords: Composite, Armor, Impact, Finite element method

Cite this paper: Shah Alam , Babatope Adegbesan , Damodar Khanal , Impact Analysis of Honeycomb Core Sandwich Panels, International Journal of Composite Materials, Vol. 10 No. 2, 2020, pp. 40-49. doi: 10.5923/j.cmaterials.20201002.03.

Article Outline

1. Introduction

- Since the beginning of civilization, humans have protected itself from different kinds of threats such as arrows, swords, and other combative materials. Peoples wore clothes made of different kinds of primitive and old age materials such as animal skin (leather), woods, stones, copper, steel etc. to protect themselves from various kinds of threats [1]. As time moves past, in the early years of industrial revolution and the experience of continuously escalating threats, it became essential even for small armies to be fully be equipped with armor. In summary, the need for ballistic protection was felt [2]. Later, as military, and paramilitary operations got further modernized with highly technology-driven war and ammunition tactics, this led to the increase in demand for improvement in armor materials to be lighter, damaged resistant, flexible, and high energy absorbing. This gave birth to the use of composite materials in armor.To further meet the demands of the armor industries, it is important to understand the principles of the science behind the design of sandwich armor structures. While huge amount of work has been done in understanding these principles, especially armor fabrics and composite, the industry still faces major challenges such as mobility and protection. When it comes to armor materials, mobility and protection are the two major demands by its users. Ballistic armors demand for the lightest possible armor materials to aid mobility. On a contrary, protective properties increase with increase in weight of armor materials which consequently impedes mobility. Today, research into armor materials mainly focuses on weight reduction and strength improvement to enhance mobility and save energy for users. As a result, a lightweight, flexible, and high energy absorbing materials became attraction of the field. Sandwich composite gave a new light because of its lightweight and high stiffness structure. The wide range of reinforcing materials provision and the advancement of new processing techniques are drawing attention to composite materials enabling large-scale production [3]. Today, there are many ongoing researches on the how to improve on composite structure performance. Researchers are analyzing various conditions for sandwich composites materials, combining different materials to optimize the energy absorbing properties of the structures without losing focus on the overall weight. Material properties and thickness, core properties are other properties that can be varied to optimize the performance of sandwich composite structure.The application of advanced materials in the manufacturing of armor systems has assisted in optimizing the performance of ballistic armors. Garcia-Avila et al [16], carried-out studies on how composite armor systems show superior ballistic performance to both NIJ-Type III and IV threats. Their design allowed the composite metal foam to absorb the ballistic kinetic energy effectively, where the CMF layer accounted for 60–70% of the total energy absorbed by the armor system. Similarly, CMF was investigated for its effectiveness against 0.5 large caliber ballistic threats. With a composite structure design consisting of a ceramic faceplate, CMF core, a thin aluminum back plate and ballistic impact velocity of between 500-885m/s. CMF was found to absorb 73-76% of the kinetic energy [5]. CMF was found to offer the needed weight saving without compromising protection. Again, weight reduction has been one of the most important parameters in the search for new armor materials. Different armor materials exhibit different ballistic energy absorption mechanisms which need to be studied to improve the performance and energy absorbing properties. Lakshmi L and Nandakumar C stated that materials such as composites and fabrics has replaced high density metals and alloys which limited mobility and offered less protection [5]. Pawar MJ. et. al, considered the impact of bullets on ceramic/aluminum AL2O3/Al5083 and AlN /Al 5083 bi-layer hybrids composites and observed that AlN ceramics has superior performance in overcoming the bullet when compared to AL2O3 ceramics. This study will aid the development of efficient structure for protection against ballistics [17].Jefferson et al. showed the most critical factors that restricts the vast use of fiber reinforced polymer matrix composite materials is the damage caused by induced impact load. Considering the behavior of the composite under transient impact loading and ways to improve their properties to withstand these types of load might be a critical success most especially in the aerospace industries. Their study includes reviews on what was termed four key parameters: material, geometry, events and environmental conditions. Their review observed and recommended that composite materials can be permanently and reversibly damaged by exposure to different environmental conditions. Other notable conclusions were factors that affect the strength of composite materials such fiber orientation, bond strength between the matrix and fiber [18].Many studies have been carried out to investigate the effect of core thickness and intermediate layers on mechanical properties of armor composite. Arbaoui J. et al, investigation on the effect of core thickness (between 10 – 40mm) and intermediate layers from single to quadruple, on the mechanical properties of a polypropylene honeycomb core facing multilayer sandwich structure under three points bending. Their results from the bending test showed that the mechanical properties increase with increasing core thickness and intermediate layers [19]. Similarly, Weilan L. et al. explored the design of the composite backplates combined with the ceramic cylinder layer to construct a high-performance armor system. With their consideration of gradual ignoring investigation of the third layer material which is widely accepted sandwich construction. Their result showed that the composite backplates, Ti6Al4V provided a strong support role to the first layer and simultaneously enhanced the energy balance function from the middle layer of UHMWPE, showing a great bulletproof property [20]. Furthermore, the methods of manufacture have been proven to affect mechanical properties of sandwich structure polymer composites. Aneta K. et al., investigates how mechanical properties of polymer composites are affected by method of manufacture – hand lay-up, press method and autoclave – under the impact of load. The sandwich with similar manufacture process were studied for structural analysis of adhesive between panels and core. They were able to show that pressure while forming sandwich panels influences some mechanical properties of sandwich structured polymer composites such as flexural strength, impact strength, and compressive strength [21].Study of ballistic impact mechanism is a highly complex mechanical process which mainly depends on the thickness, strength, toughness, ductility and density of the target materials and projectile parameters [1]. The modern advances of in developing of tough, high-strength and high-modulus fibers such as fabrics and their composite laminates has led to their use as armor applications. Mulat et al. reviewed how different ballistic material properties such as weave design fabric type and density, fiber etc., affect the composite performance. They found that almost all the parameters that affect the ballistic penetration resistance of materials are interrelated. Therefore, studies that attempt to single out an individual effect cannot yield conclusive results unless all the other parameters are explicitly presented. They concluded that a combined, detailed, and high-level research approach needs to be carried out in order to better understand the vibrant deformation and failure mechanisms of ballistic materials [1]. Chang Qi et al., carried out a finite element analysis to study the dynamic responses of honeycomb sandwich panels (HSPs) subjected to in-plane projectile impact. The honeycomb used had three core configurations to determine high of the HSP had the best ballistic resistance and to clarify the influence of macroscopic parameters such as factsheets, core thickness and core relative density. Their results found the perforation resistance capacities of the HSPs increases with increase in the macroscopic parameters. However, the mesoscopic parameters showed no effects on sandwich ballistic properties [22].Ian Crouch claims to have timely reviewed the body armor materials and systems as new test standards are currently being written and new innovative products are being released. He claimed that evolution of body armor is highly dependent upon, not only new armor materials but also on the well-informed, and judicious, use of strict, and evolving design principles. The developments of armor materials across fibers, fabrics, and strike-face will continue to refine, and improve body armor systems. However only in small, incremental steps. The latest generation of UHMWPE materials reflects the successful development of armor concepts such as the stacked systems. He later suggested that lessons from the reduction in the size of the soft vests, without changing the size of the hard armor plates should help in the informed design-decisions made in future. Researches should be targeted towards development of smart textiles that will enable worn fabrics for health monitoring and increased levels of protection [9].From above literature reviews, it is noted that studies have been carried out on the mechanical properties of composite materials that affect the performance of sandwich structures. It was also noticed that the different composite materials reviewed are mostly targeted towards the test of ceramic composites. Only few works carried out used the newly developed carbon fiber reinforced polymers. Also, not many works have been done on the combination of different core structures heights to analysis its effect on the performance of sandwich structures. And finally, works on the energy absorption of sandwich capacity under repeated, high ballistic impact at a single strike point is still at the elementary stage. Therefore, this study will assist in further understanding of the performance of composite sandwich armor filled will ceramic.

2. Methodology

- This research was carried out using finite element method on the sandwich composite armor using commercial software ABAQUS. A step by step approach was used in developing the armor model for the analysis. First geometry parts are created in the part module, followed by assigning material properties to the parts. These parts are then assembled in the assembly module, followed by creating boundary conditions, interactions, steps, mesh and loading the ballistic with a velocity charge. The model parameters are then varied with different design matrix to achieve the objectives of this research. The main steps of the Finite Element analysis are discussed below.

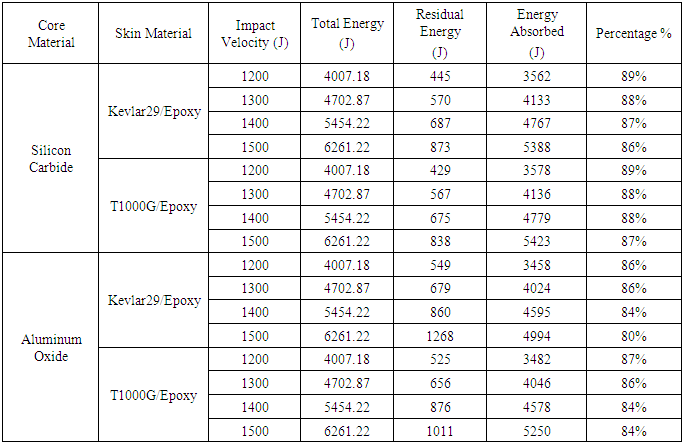

2.1. Bullet

- The bullet is designed with a cylindrical base and a conical top. This is referenced to a standard ballistic with a 19mm length and an 8mm diameter [23]. It is assigned with a steel property making the overall mass to be 10g. Figure 1 is the penetrator used for the finite element analysis.

| Figure 1. Steel Bullet |

2.2. Armor Skin Layer

- The top and bottom layer of the armor are designed with Kevlar-29/epoxy and carbon fiber T1000G/epoxy. They are constructed as a 3D rectangular laminates with dimensions of 120mm by 120mm. It was extruded to a thickness of 2mm to analysis the armor performance. These laminates are made up 4 plies with each ply thickness of 0.5mm. The plies are stacked in sequence of [0/90]2 orientation.

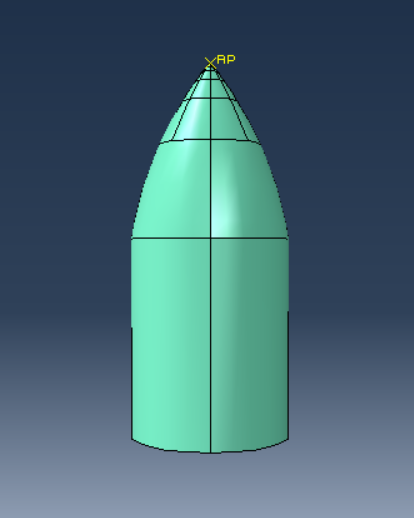

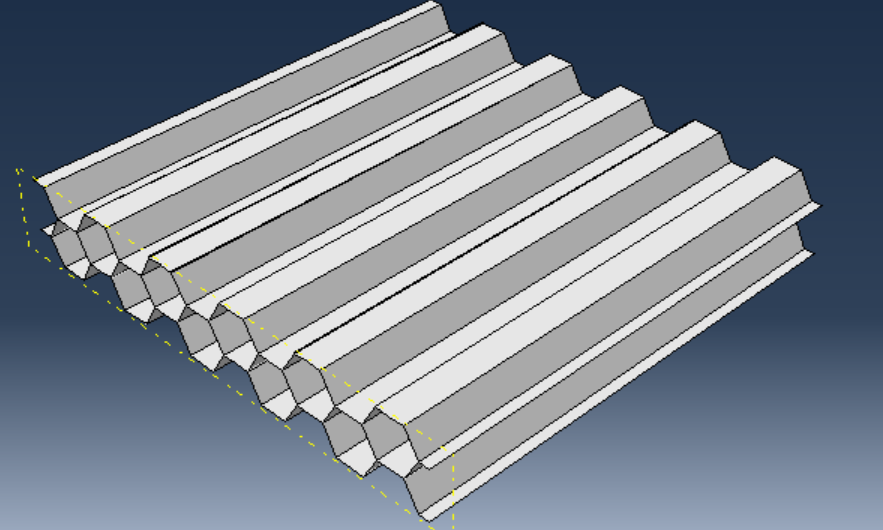

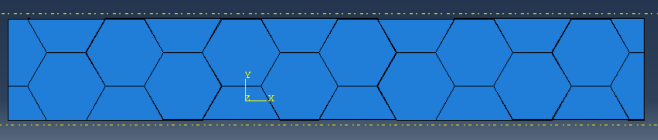

2.3. Armor Honeycomb Core

- The core is a honeycomb structure made of Aluminum alloy, Al3003. It was constructed with a 3D deformable shell with dimensions 120 x 120mm and height of 19.05mm. the cell size is 12.7mm and cell thickness of 0.3m. Figure 2 below shows the honeycomb structure in Abaqus software.

| Figure 2. Aluminum Honeycomb Core |

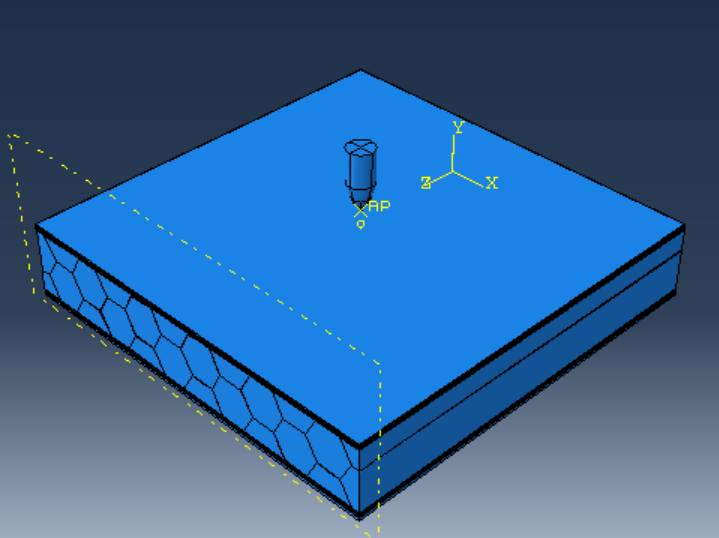

2.4. Armor Center Piece Core

- The centerpieces are constructed made of silicon carbide and aluminum oxide. They are designed with a size of 12.4mm to tightly fill the open gaps of the aluminum honeycomb core. To create uniformity and alignment, the centerpieces takes the shape of the aluminum honeycomb and are easily fit into the core. Figure 3 shows the picture of a unit centerpiece and Figure 4 shows the filled the aluminum honeycomb with ceramic.

| Figure 3. Hexagonal ceramic |

| Figure 4. Silicon Carbide/Aluminum Oxide Filled Core |

2.5. Armor Assembly

- All the geometric parts are assembled as shown in the figure 5 below. A gap of 2mm was assigned between the projectile and top skin to allow initiation of the steel bullet.

| Figure 5. Armor Assembly |

2.6. Armor Material Properties

- Material mechanical properties was defined to all geometric part that makes up the armor. These properties as discussed in chapter one can be found in detail in the tables below. Failure criterion governing the damaging of these materials were assigned to each geometric part. Assigning material properties was carried out in the properties window. This was followed by assigning a section for the ceramic centerpieces, steel bullet and the aluminum honeycomb core. A different process was used for the top and bottom layer. A composite layup was created as an alternative. To complete property definition, the created property sections were assigned to each geometric part, respectively. Mechanical Properties of High Tensile Strength Kevlar 29/Epoxy [24], T1000G/Epoxy [25], Aluminum alloy (AL3003) [26], Ceramics SiC [27], Aluminum oxide [27] and steel alloy AISI 4140 [28] are used in the model.

2.7. Composite Layup

- In this study, the quasi isotropic Kevlar 29/epoxy ply with [0-0-0-0] orientation and unidirectional T1000G/epoxy ply with [0-90-0-90] orientation is used. Since the properties of the quasi isotropic T1000G/epoxy were not found, T1000G/epoxy at [0-90-0-90] orientation is used. It is assumed that this configuration is equivalent to quasi isotropic configuration. The results presented in this thesis are based on this assumption.

2.8. Mesh and Mesh Convergence

- Mesh convergence check was done before carrying out FEA on the constructed sandwich models in this research. The reason is to obtain accurate results for the finite element analysis of these models. This was achieved by plotting the residual velocity against the mesh sizes of 0.6, 0.8, 1.0, and 1.2 mm using the Kevlar-29/epoxy sandwich panel with face sheet thickness of 2mm. The result showed a variance of approximately 4% between the 0.6 – 0.8mm mesh to confirm its convergence. Though a mesh convergence is considered when the variation of the results from one mesh size to another is near zero % theoretically, but in reality, for a complex structure it is not possible. It is industrial practice that a variation of the results from one mesh size to another lower than 5% is considered as mesh convergence. A mesh size of 0.7mm was used for the fine mesh at the center of the sandwich panels and coarse mesh of 3.5mm at the edges in this analysis. The reason for the choice of mesh sizes is because of the complexity of the panels. The combination of the fine and coarse mesh on the sandwich panels was used to reduce computation time.

2.9. Failure Mechanism

- Understanding damage or failure plays an important role in the study and analysis of finite element analysis of fiber reinforced composite materials and other geometric parts used in this research. This section discusses the theory of failures of the different materials used in this research.

2.9.1. Deformation and Failure of Metal Alloy

- When the metals are subjected to load, it undergoes an elastic deformation and with more load it undergoes plastic deformation and finally it fails and break. The honeycomb core material Aluminum alloy (Al3003) is expected to undergo elastic-plastic deformation and eventually break. A stress strain diagram that describes the mode of failure is used in the model [23].

2.9.2. Failure Criteria of Ceramic

- Drucker-Prager failure criterion is capable of modelling stress and strain behavior of pressure sensitive materials such as rock, soil, and concrete. Like other plastic models, its accuracy depends largely on its evaluation of parameters that determine its flow rule, yield criterion and hardening or softening rule. The failure criterion for ceramic material (Silicon Carbide and Aluminum Oxide) used in this research was modeled using Drucker Prager failure criteria [27].

2.9.3. Progressive Damage Modelling in Fiber-Reinforced Material

- Composite materials have highly desirable mechanical properties; however, these materials could also be fragile and susceptible to damage during impact. Damages are inevitable, it is therefore important to study the effect of damages on the reduction of strength of composite materials after impact [28].

2.9.4. Damage Initiation and Failure Criteria

- Damage initiation can be described by the onset of failure at a point in the material [25]. damage initiation criteria proposed by Hashin and Rotem [29] are used in this analysis. These criteria recognize material damage mechanism at four different modes which are fiber tension, fiber compression, matrix tension and matrix compression. Hashin’s damage failure criteria described in [30] are used in this analysis.

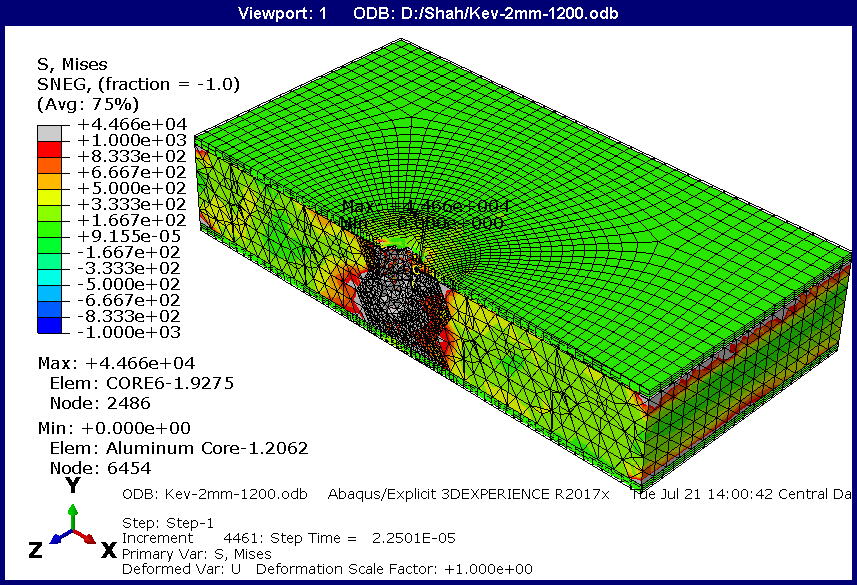

3. Results and Discussions

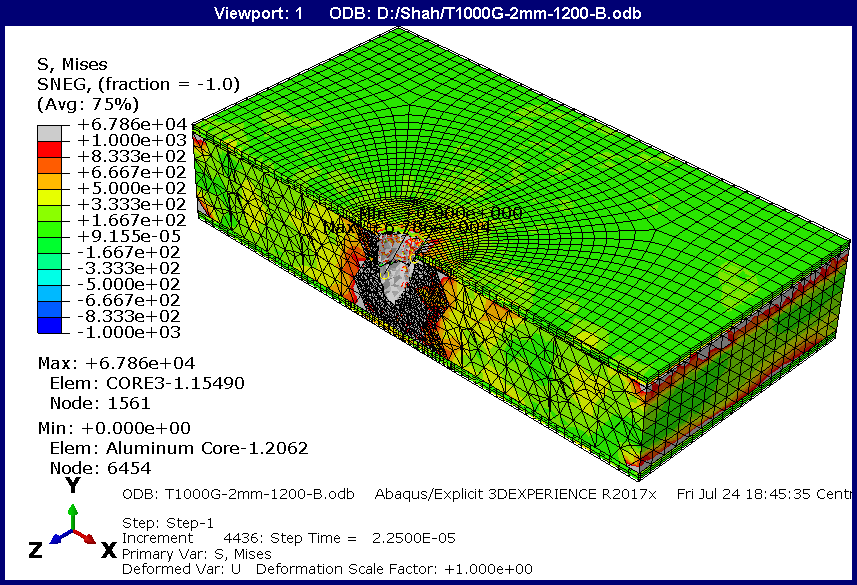

- To determine the impact behavior of the sandwich panels, finite element analysis using Abaqus software was utilized to analyze the different parametric configuration panels at four different impact velocities such as 1200, 1300, 1400 and 1500m/s. A base model of the composite sandwich with face sheet thickness of F1-2mm was impacted with a velocity of 1200m/s to calculate the energy absorption capacity and residual velocity of the panel. Similar processes were carried out using velocity 1300, 1400 and 1500m/s. The resulting energy absorption and residual velocity were obtained. Finally, the process was repeated for different composite panel of face sheet thickness of F2-3mm and F3-4mm. Figure 6 and 7 show the Von Mises stress distribution for Kevlar-29/epoxy and T1000G/epoxy with face F1-2mm sheets thickness at 1300m/s. The grey areas show stress more than 1000 psi and the 1000 psi filtering value is used to show the relative stress contour to be more visible. Higher filtering values make the contour to be localize at the center and less visible. It can be observed that maximum stresses are mostly concentrated at the bullet impact and in the boundary constraint areas. This is reasonable because the part of the impact load is absorbed by the impact areas and the rest is balanced by the constraint areas.

| Figure 6. Von Mises stress distribution of Kevlar-29 skinned armor at 1200m/s |

| Figure 7. Von Mises stress distribution of T1000G skinned armor at 1200m/s |

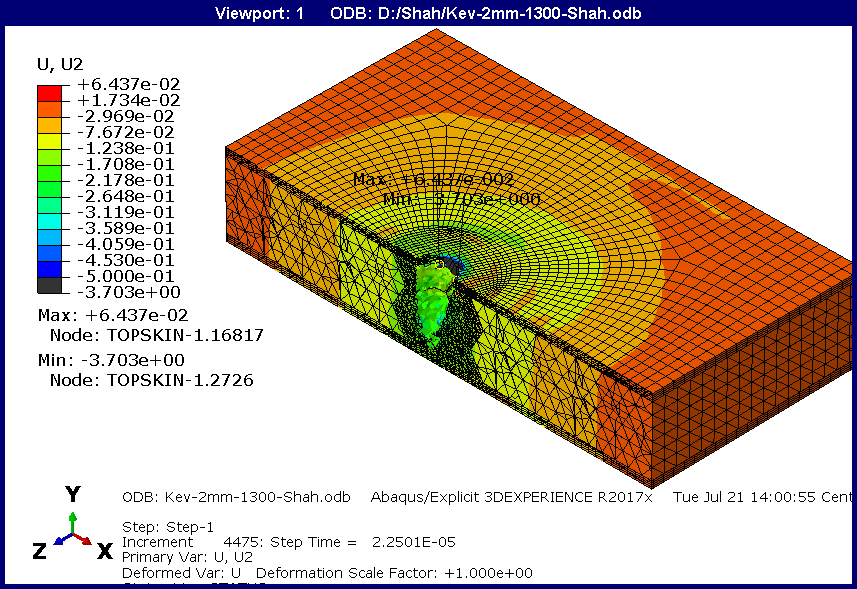

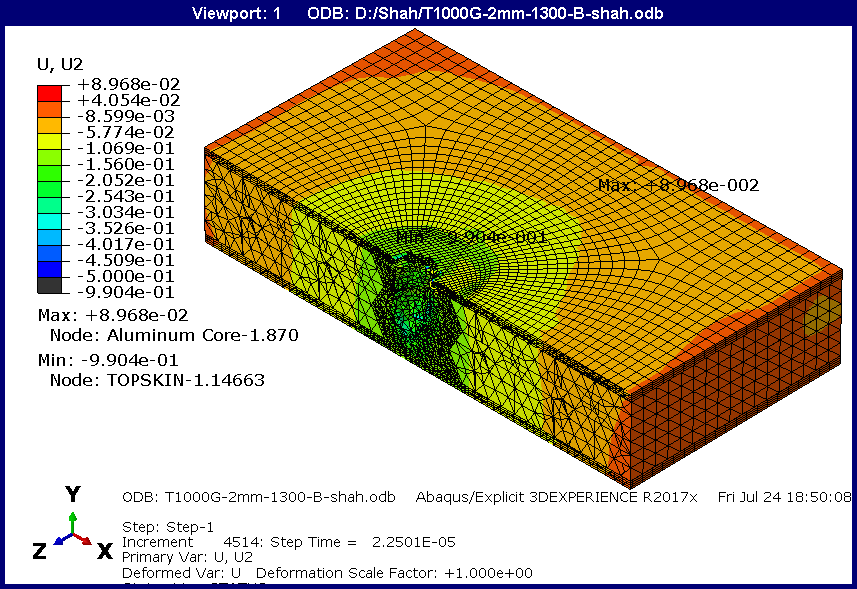

| Figure 8. Deformation of F1-2mm Kevlar-29 skinned armor at 1300m/s |

| Figure 9. Deformation of F1-2mm T1000G skinned armor at 1300m/s |

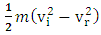

Where, m is the mass of the impactor,

Where, m is the mass of the impactor, is the initial velocity of the impactor,

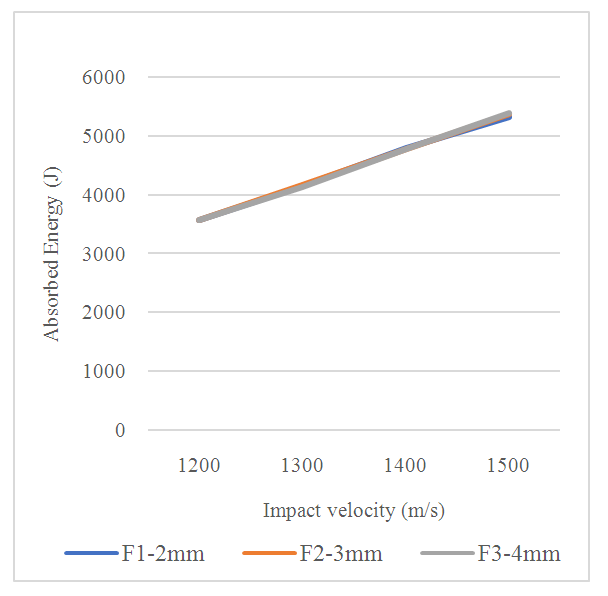

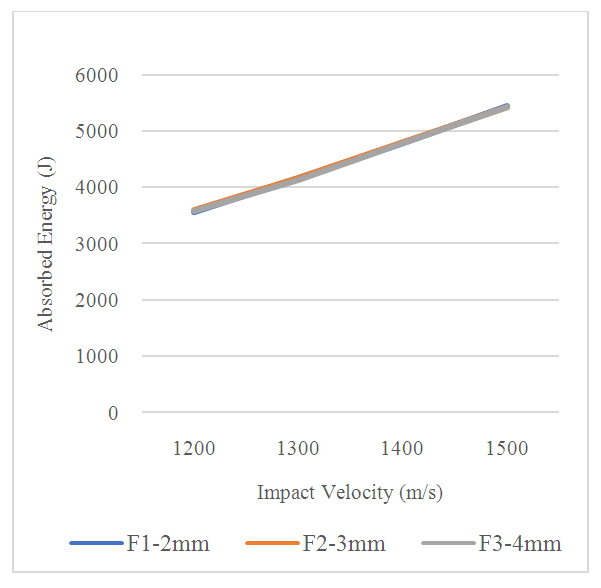

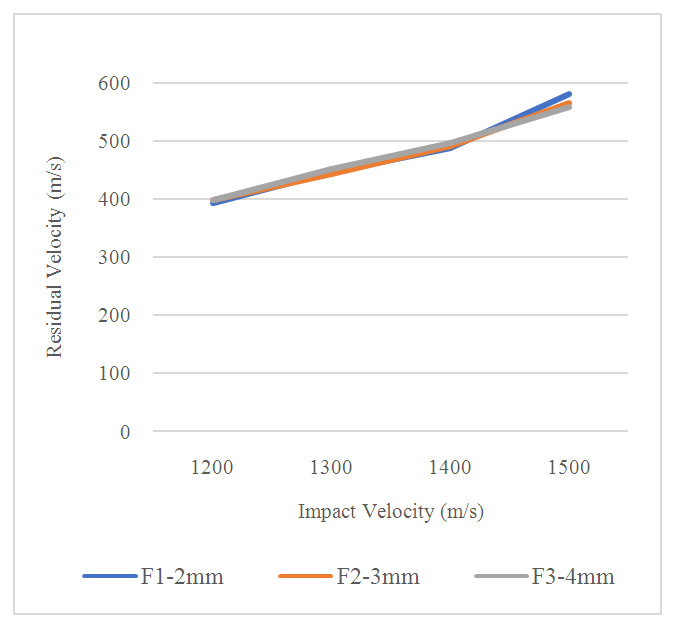

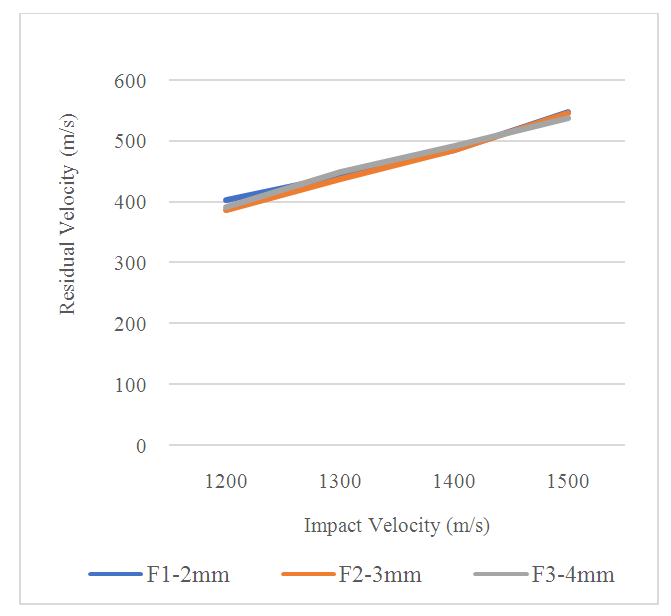

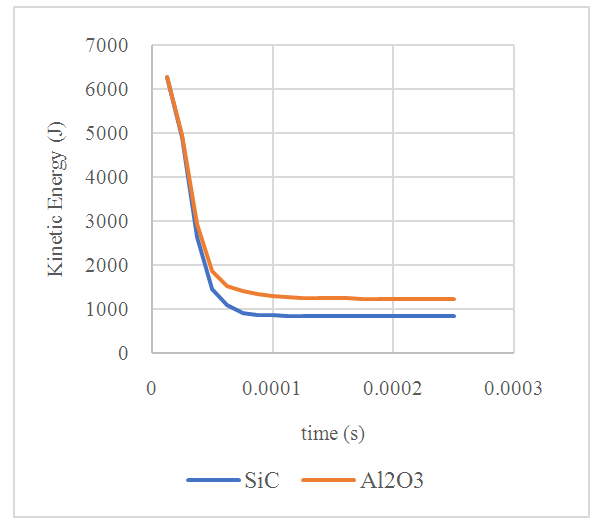

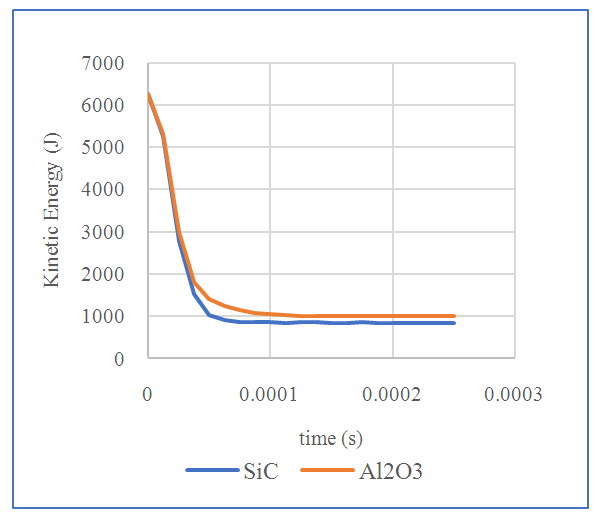

is the initial velocity of the impactor,  is the residual velocity of the impactor. From figure 10 and 11, it can be seen that the energy absorption capacity of the sandwich panels for all configurations improved with increase in the thickness of the face sheet.

is the residual velocity of the impactor. From figure 10 and 11, it can be seen that the energy absorption capacity of the sandwich panels for all configurations improved with increase in the thickness of the face sheet.  | Figure 10. Kinetic energy absorption at different impact velocity of Kevlar 29 skin and SiC core armor |

| Figure 11. Kinetic energy absorption at different impact velocity of T1000G skin and Al2O3 core armor |

| Figure 12. Residual velocity at different impact velocity of Kevlar 29 skin and SiC core armor |

| Figure 13. Residual velocity at different impact velocity of 1000G skin and Al2O3 core armor |

| Figure 14. Comparing of Kinetic Energy of F2-3mm Kevlar 29 skin and core filled with SiC and Al2O3 at impact velocity 15 m/s |

| Figure 15. Comparing of Kinetic Energy of F3-4mm Kevlar 29 skin and core filled with SiC and Al2O3 at impact velocity 15 m/s |

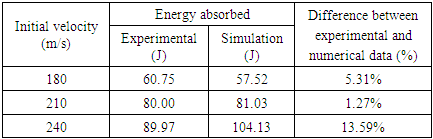

|

3.1. Validation

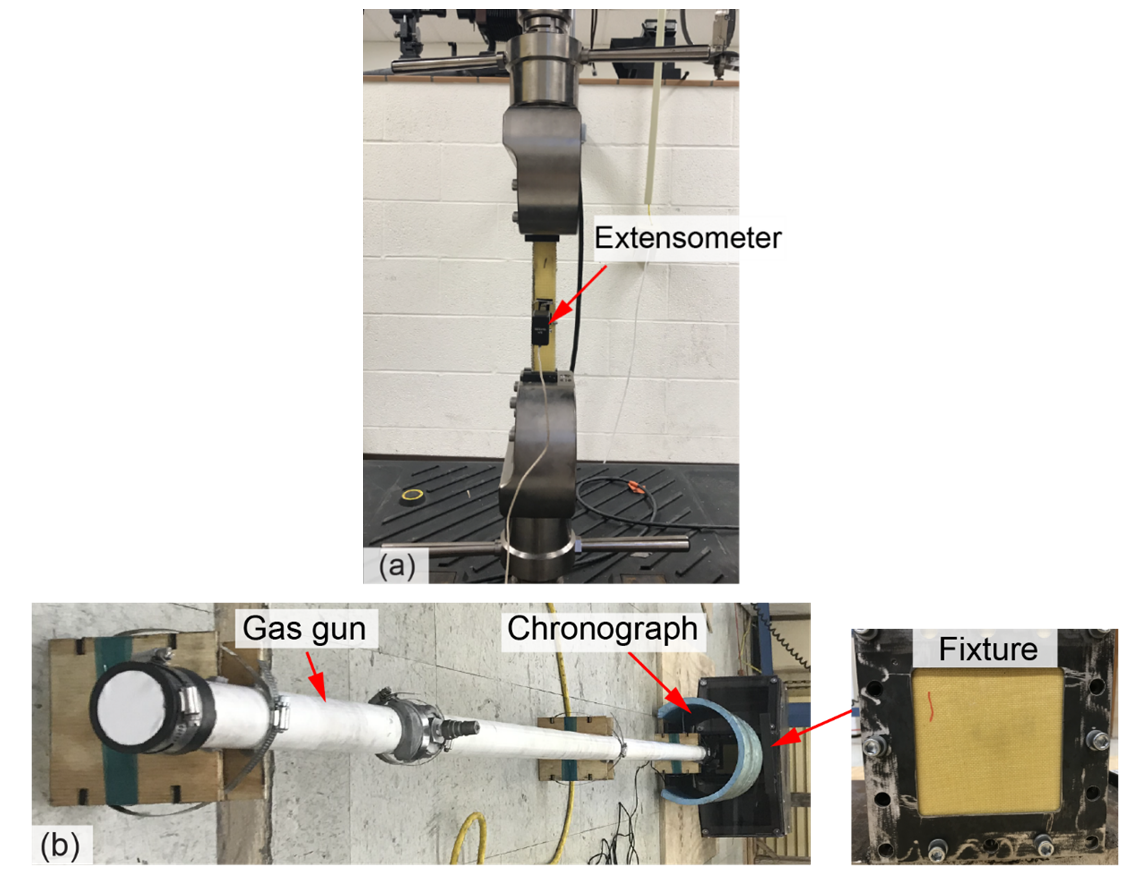

- To validate the Kevlar-29 composite model, a quasi-static tensile test was first conducted to measure the basic mechanical properties of the material. Three tests were performed on an MTS C45.105 universal testing machine, as shown in Fig. 16a. The dimensions of the samples were prepared according to ASTM D-3039 standard [32]. According to the standard, the length of the specimen was 250 mm, overall gauge length was 150 mm, and gauge length of extensometer was 25 mm. The thickness of the specimen was in the range of 1.8-2.2 mm, consisting of 4 layers of Kevlar-29 style 745 ballistic grade fabrics from Fiberglass Supply. The measured tensile modulus and tensile strength were 10.05 GPa and 586 MPa, respectively. These quantities are very close to what measured by Concli et at. [33] are used in this analysis.In addition, using an in-house developed gas gun, four ballistic impact tests were conducted on specimens with a dimension of 120 × 120 mm, as shown in Fig. 16b. The impact velocity was measured using a chronograph to be in the range of 50m/s-90m/s. In these tests, the specimens were either penetrated or non-penetrated. The ballistic limit was found to be lie in the range of 60m/s-78m/s. From the FE simulation, the ballistic limit of the specimen was found to be 75m/s. It shows a very good agreement with the experimental results. Therefore, in this way the FE model of the Kevlar-29 composite is validated.

| Figure 16. (a) MTS cross head holding a Kevlar-29 specimen for tensile testing, (b) a gas gun facility for impact testing of a Kevlar-29 specimen |

|

4. Conclusions

- The effect of face sheet materials on the performance of sandwich armors were analyzed. The analysis also considered how the face sheet thicknesses and materials of the ceramic core impact the strength and performance of sandwich panels for the purpose of armor protection. Series of finite element analysis (FEA) at a range of impact velocities of 1200-1500m/s were carried out. The effect of ceramic core materials on the analysis carried out showed silicon carbide had better absorption capacity than the aluminum oxide. The Kevlar-29 sandwich panel with silicon carbide absorbed approximately 86% of the total kinetic energy while the aluminum oxide panel absorbed 80% of the total kinetic energy. This was also similar for corresponding panels with the T1000G face sheet. Analyzing the T1000G/Epoxy showed to have a slightly better performance compared with the Kevlar-29/Epoxy with respect to energy absorption capacity and residual velocities of the impactor. However, the energy absorption capacity of both materials proved to be good materials for high ballistic armor. At velocities below 1400, the kinetic energy of the penetrator was not high enough to completely penetrate through the sandwich panels. At 1500m/s, the penetrator was observed to completely penetrate through the Kevlar-29/Epoxy panel. However, the penetrator was not able to completely penetrate through the T1000G/Epoxy sandwich panels. Finally, it can be said that these specific designed panels are capable of armor protection for high ballistic impact velocity range up to 1500m/s and would not be reliable for higher ballistics threats.

ACKNOWLEDGEMENTS

- This work is supported by the Army Research Office (ARO) Grant Award Number W911NF-18-1-0478.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML