-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2019; 9(2): 44-52

doi:10.5923/j.cmaterials.20190902.03

Automotive Application of Hybrid Composites of Aluminium Alloy Matrix: A Review of Rice Husk Ash Based Reinforcements

A. A. Yekinni1, 2, M. O. Durowoju2, J. O. Agunsoye3, L. O. Mudashiru2, L. A. Animashaun1, O. D. Sogunro1

1Department of Mechanical Engineering, Lagos State Polytechnic, Ikorodu, Lagos, Nigeria

2Department of Mechanical Engineering, Ladoke Akintola University of Technology, Ogbomoso, Nigeria

3Department of Metallurgical and Materials Engineering, University of Lagos, Akoka, Nigeria

Correspondence to: A. A. Yekinni, Department of Mechanical Engineering, Lagos State Polytechnic, Ikorodu, Lagos, Nigeria.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In view of the enormous interest and high demand for Aluminium/Rice Husk Ash (Al/RHA) based composites with improved thermal, tribological and physico-mechanical properties for automotive applications, an exhaustive and all-encompassing review of the data on morphology, properties and processing methods of different hybrid composites of Al/RHA based seems timely. Hybrid Aluminum Matrix Composites (HAMCs) are the most recent generation of composites that have potential to replace monolithic aluminium alloys and single reinforced composites due to improved properties. This paper is aimed at reviewing current researches and development in RHA based Al hybrid composites and identifying the possibility of developing a novel low cost-improved property of RHA hybrid composites of aluminium for automotive applications. Hybrid composites of aluminium reviewed in this study include; rice husk ash/alumina, rice husk ash/silicon carbide, rice husk ash/fly ash and rice husk ash/bagasse. Based on the database for material properties, the application area of HAMCs has been proposed in the present review. It has been concluded that the hybrid composites offer more flexibility and reliability in the design of possible automotive components depending upon the reinforcement's combination and composition. As a result of some observables in the properties of rice husk ash, it is recommended that low concentration rice husk ash reinforcement could be used to solve the dispersion challenges of graphene in molten aluminium to produce hybrid composites free of harmful intermetallic compound like aluminium carbide.

Keywords: Hybrid, Rice Husk Ash, Reinforcement, Stir Casting, Graphene

Cite this paper: A. A. Yekinni, M. O. Durowoju, J. O. Agunsoye, L. O. Mudashiru, L. A. Animashaun, O. D. Sogunro, Automotive Application of Hybrid Composites of Aluminium Alloy Matrix: A Review of Rice Husk Ash Based Reinforcements, International Journal of Composite Materials, Vol. 9 No. 2, 2019, pp. 44-52. doi: 10.5923/j.cmaterials.20190902.03.

Article Outline

1. Introduction

- The demands made on materials for excellent performance are so many and diverse that no single material can satisfy them. That eventually led to a resurgence of the now popular concept of combining different materials in an integral composite material system that results in a performance unachievable by the individual constituent and provides the great advantage of a flexible design. This implies that, a composite material that meets the need of several engineering applications with most efficient design be developed [1].Aluminium based matrices is preferred for use in the production of composites being the cheapest among other different matrix materials and are also tailorable to processing by adopting conventional techniques for the production of its metals and alloys [2-4]. There is growing interest by researchers in providing alternative sources of reinforcements that offer the potential of producing Aluminium matrix composites (AMCs) at reduced cost while maintaining high performance levels [4-6]. Aluminium metal matrix composites derives the unique properties from the material characteristics of both the matrix and the reinforcing phases [7]. The reinforcements provide the improved mechanical, wear, and high thermal properties for the AMCs [4,8,9].Over the years, there have been a major concern of solid waste recycling of agricultural and industrial wastes. However, the use of such wastes will provide cheaper source of matrix materials such as waste beverages cans, damaged aluminum roofing sheets etc., and for reinforcements such as industrial wastes (fly ash, red mud) Naresh, [10]; Bienia, et al., [11] and agro wastes (rice husk ash, bamboo leaf ash, coconut shell ash) for AMCs development [4,12].As a result of high demand for AMCs with better physical, mechanical, thermal and tribological properties, there is growing concern in the production of hybrid composites of aluminium by reinforcing aluminium matrix with two reinforcements. However, recent research investigations have revealed that agro/industrial waste materials such as fly ash, graphite, rice husk ash, bagasse, eggshell, snail shell, coconut shell, bamboo leave ash etc., can be successfully used as a complementary reinforcement in AMCs [13-18]. In addition to this, two ceramic phases can also be used for development of hybrid composites of aluminium [19]. Furthermore, the benefits in the use of hybrid composite is not limited to improving the performance of the composites by introducing new features. Also, these agro/industrial wastes materials can reduce the production cost of aluminum composites [13,14]. In addition, drastic reduction in density of the composites is achieved by replacing the aluminium of higher density with reinforcing materials of lower density [16,18].The paper is aimed at reviewing experimental background related to the characterization and mechanical performance of aluminum/rice husk ash based hybrid composites developed by various processing methods and report various results achieved in this field. The potential of different types of primary and secondary reinforcements has been thoroughly explored for the production of HAMCs and suggestion on new application of rice husk ash to produce hybrid composites of aluminium with improved properties for automotive applications proffered.

2. Review of Literature

2.1. Strengthening Mechanisms in Metal Matrix Composites

- Several strengthening mechanisms as summarized by Casati, and Vedani, [20] may include load transfer effect, Hall-Petch strengthening, Orowan strengthening coefficient of thermal expansion (CTE) and elastic modulus (EM) mismatch Zhang, Z.; Chen, [21]; Zhang, and Chen, [22]; Sanaty-Zadeh, [23]; Luo [24] are responsible for the high mechanical resistance of metal matrix composites. The first three strengthening methods that are discussed below.

2.1.1. Load Transfer Effect

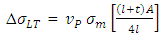

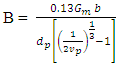

- Under an applied external load, the load transfer from the soft and compliant matrix to the stiff and hard particles contributes to the strengthening of the base material. However, a modified Shear Lag model is now commonly being used to predict the contribution in strengthening due to load transfer in particulate-reinforced composites [20-23].Load transfer effect is as expressed in equation 1

| (1) |

is the volume fraction of the particles,

is the volume fraction of the particles,  is the yield strength of the unreinforced matrix, l and t are the size of the particulate parallel and perpendicular to the loading direction, respectively. Sanaty-Zadeh [23] modified equation 1 to equation 2 or the case of equiaxed particles as shown below:

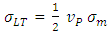

is the yield strength of the unreinforced matrix, l and t are the size of the particulate parallel and perpendicular to the loading direction, respectively. Sanaty-Zadeh [23] modified equation 1 to equation 2 or the case of equiaxed particles as shown below: | (2) |

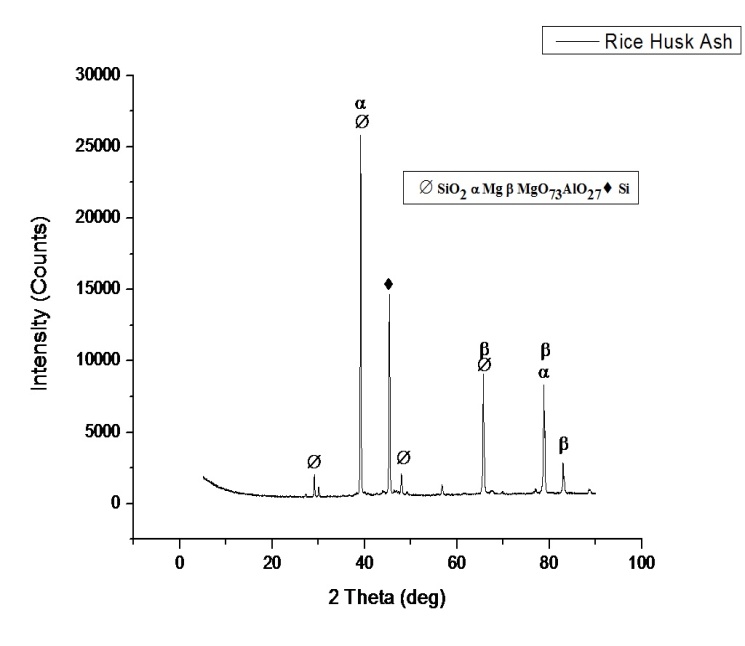

2.1.2. Hall-Petch Strengthening

- According to Hull and Bacon [25], different orientations of adjacent grains and high lattice disorder behaviour of the regions could prevent the dislocation from moving in a continuous slip plane. Therefore, grain size has a strong influence on strength of the metal since the dislocation movement can hinder the grain boundaries.The Hall-Petch equation formulated by Hull and Bacon [26] relates the strength with its average grain size (d) as shown in equation 3

| (3) |

is the strengthening coefficient (characteristic constant of each material).Since the particles interact with grain boundaries by acting as pinning points, retarding or stopping their growth they play a significant role in determining the final grain size found in metal matrices of composites. However, the increase of

is the strengthening coefficient (characteristic constant of each material).Since the particles interact with grain boundaries by acting as pinning points, retarding or stopping their growth they play a significant role in determining the final grain size found in metal matrices of composites. However, the increase of  (volume fraction) and the decrease of

(volume fraction) and the decrease of  (particle diameter) result in a finer grain structure, which has been theoretically modeled by the Zener equation 4 [23].

(particle diameter) result in a finer grain structure, which has been theoretically modeled by the Zener equation 4 [23]. | (4) |

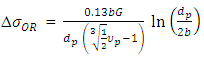

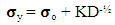

2.1.3. Orowan Strengthening

- Orowan mechanism discussed the interaction of nano-particles with dislocations. Hull and Bacon [25] stressed that the external load could cause the non-shearable ceramic reinforcement particles to pin the crossing dislocations and promote dislocations bowing around the particles (Orowan loops). This Orowan effect is expressed in equation 5

| (5) |

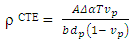

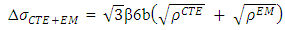

2.1.4. Coefficient of Thermal Expansion (CTE) and Elastic Modulus (EM) Mismatch

- Sanaty-Zadeh [23] affirmed that material cooling and straining due to formation of Geometrically Necessary Dislocations (GNDs) accommodates the mismatch in Coefficient of Thermal Expansion (CTE) and in Elastic Modulus (EM) between the reinforcements and the metal matrix. The density of such mismatch can be accounted for by equation 6 and 7.

| (6) |

| (7) |

| (8) |

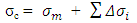

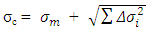

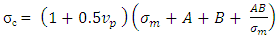

2.1.5. Sum of Contributions

- Summing the above contributions, that is, single strengthening effects, Δσi, with the original yield strength of the unreinforced matrix, σm, gives the final strength of the composite, σc, shown in equation 9

| (9) |

| (10) |

| (11) |

| (12a) |

| (12b) |

2.2. Production and Characterization of Rice Husk Ash

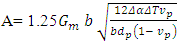

- Souza et al., [28] used three different methods to obtain silica having high specific surface area from burned pre-treated rice hulls. In the first method, the hull was treated with hot organic acid solutions and then burned into ash. In the next method, the hull was boiled in water with an autoclave at temperatures close to 150°C, while the third method involves treating the hull at 250°C in order to render it fragile and later reduce it to a fine powder before burning it to ash. The first two methods resulted in white amorphous silica of approximately 500 m2/g of specific surface area. While the last method showed that alkaline elements were not removed from the hull, thereby, producing an amorphous gray carbon-free powder in which specific surface area can be up to 250 m2/g. However, investigation of the specific surface area of the prepared silica revealed that such alkaline elements will not mix with silica in the hulls or combine as insoluble compounds.Olamide and Oyawale [29] studied the characterization of local rice husk to determine its chemical constituents using Atomic Absorption Spectrophotometer. Rice husk (RH) obtained from two methods (raw RH and leached RH) were both subjected to calcination for within temperature range of 50 – 750°C to establish its characterization temperature. Characterization temperature was investigated via the temperature at which the highest specific surface area and highest amount of silica which took place at 700°C were observed. Parameters characterized include: Na2O, K2O, Fe2O3, MnO, CaO, loss on ignition (LOI) and specific surface area. However, the results revealed that the optimal temperature and maximum amount of silica was obtained at 700°C with highest specific surface area. It was also observed that at 750°C, there was decrease in the amount of silica content obtained. Characterization temperature of 700°C was therefore recommended to be the best to obtain optimal silica. It was also concluded that rice husk ash obtained by leaching was superior and very rich in silica.Kumar and Singh [30] prepared a composite of aluminium by synthesizing SiC from rice hush and consolidated the prepared SiC with Al matrix by powder metallurgy route. The powder was sintered at a temperature of 550°C with holding time of one hr. X-ray diffraction, SEM, EDX were used to characterize the composites and microstructural analysis by optical microscopy. Hardness and wear rate were the major responses obtained from assessment of mechanical properties. The results revealed that conventional sintering method is a potential way for synthesizing new high strength commercial Al/SiC metal matrix composites.Issagulov et al., [31] studied the physical and chemical properties of rice husk (a silicon-carbonic raw material), thermophysical characteristics of the process of rice-husk by pyrolysis in nonreactive and oxidizing environment; in interval of temperatures 150 – 850°С and high temperature pyrolysis in interval of temperatures 900 – 1500°С. The process defines silicon-carbon production that compares favourably with the technical production of silicon and silicon carbide.Martı´nez et al., [32] studied the production of short fibres and fine particles β – SiC by pyrolysis of Colombia rice husk in gas furnaces. The SiC was synthesized in a gas furnace while a mathematical model was designed and developed to build the equipment. Optimization of the process parameters from design of experiment included variables such as temperature, pyrolysis time, type of catalyst, and process atmosphere. The material was characterized using FTTR, DRX and SEM for microstructural characterization and EDX was used for chemical analysis. Yekinni et al., [33]; Yekinni et al., [34] and Durowoju, et al., [35] produced rice husk ash by carbonization of rice husk. The mixture was first blown manually to separate the husk from rice grain. The blown and washed rice husk was then dried under sun rays for three days. The rice husk was placed inside a crucible pot, well-lagged with cotton wool and then burnt at 700°C for two hours inside the muffle furnace to ensure proper carbonization. It was sieved and graded into three different particle sizes. X-ray diffractometric profiles of RHA particulate is shown in Figure 1. Major diffraction peaks occurred at diffracting angles (2θ) of 29.60°, 39.65°, 43.40° and 48.73° with inter-planar distance of 3.02 Å, 2.27 Å, 2.09 Å and 1.91 Å and relative X-Ray diffracting intensities of 1256.10, 355.38, 341.56 and 515.81. The respective phases at these peaks are SiO2, Si, SiO2 and SiO2 respectively. The diffraction peaks of SiO2 which is the major constituent of RHA particle and others are clearly seen [36].

| Figure 1. XRD of Rice Husk Ash (Source: Yekinni et al., [36]) |

2.3. Hybrid Composites of Rice Husk Ash based Reinforcement

- Reinforcement of a metal matrix with more than one reinforcement is referred to as hybrid composites. Such reinforcements combination includes, RHA with alumina, silicon carbide, fly ash and bagasse.

2.3.1. Microstructural Characterization

- Jaswinder and Amit [37] stressed that it is essential during fabrication of composites to obtain a uniform distribution of reinforcing particles in the matrix alloy and to ensure that segregation/agglomeration of particles during the progress of solidification is prevented. Mechanical stirring is usually applied during melt preparation or holding. When investigating this phenomenon, the stirring condition, melt temperature, and the type, quantity and nature of the particles are some of the other factors to consider [38,39]. External force provided by the stirrer helps to mix a non-wettable reinforcement phase into a liquid melt, and also create a uniform and homogeneous suspension in the melt. The uniformity of particle dispersion in a melt before solidification is aided by the dynamics of the particle movement in agitated containing vessels. Therefore, the study of microstructure using different microscopic equipment is quite useful in evaluating the distribution of reinforcing particles in metal matrix alloy.Alaneme et al., [40] aimed at determining the possibility of developing high performance Al matrix composites at reduced cost from alumina (Al2O3) and rice husk ash using two-step stir casting technique. The optical micrographs show evidence of high visibility of RHA and Al2O3 particulates with best dispersion for the hybrid composite containing 4 wt.% of RHA. Scanning electron microscopy of the same composites according to Alaneme and Olubambi [17], was used to establish the corrosion and wear mechanisms of the composite. The SEM images confirmed that preferential dissolution of the more anodic Al matrix occurs in place of the cathodic RHA/Al2O3 particles with single reinforced Al-Mg-Si/10 wt.% Al2O3 composite having a better corrosion resistance (figure 2c and d).Composites of Al/RHA- SiC were produced by stir casting technique and characterized by Chinta et al., [41]. The microscopic observations revealed that grain size increases significantly with increase in concentration of SiC in hybrid metal matrix composite which was largely responsible for difference in physical and mechanical properties of the composites at different percent weight fraction of reinforcements. Alaneme and Adewale [4] revealed micrographs that showed good dispersion of the RHA and SiC particulates in the Al alloy matrix with little particle clusters observed such that segregation or sedimentation problems did not manifest. Moulleswaran et al., [42] observed that with RHA kept at 2 wt.% and SiC varied from 5 – 20 wt.%, there was formation of network of SiC at low magnification while a non-continous network was observed at high magnification. However, a better network was formed with 10 wt.% SiC in Al matrix.

2.4. Density

- Addition of ceramic reinforcements increase the density of the base alloy during fabrication of composites. But when lightweight reinforcements like agricultural wastes are added, it results in overall reduction of the density of the hybrid composites [3,40].Alaneme et al., [40] observed slight porosity less than 2.3% when compared the experimental and theoretical densities of Al/RHA-Al2O3 composites which also confirmed the reliability of the two step stir casting process used in producing the hybrid composites. The densities of the hybrid composites reduce with increase in weight percent of reinforcements with highest reduction of 5.91% at 4 wt.% RHA and 6 wt.% Al2O3. Similar observations were made by Alaneme and Adewale [4] with hybrid composites of Al/RHA-SiC. The authors stressed further that increase in RHA content of lower density (0.31 g/cm3) in comparison to SiC of higher density (3.6 g/cm3) favours reduction of density. Usman et al., [43] studies of Al/rice husk ash-bagasse showed that the composites produced with addition of BA with low density of 238.26 kg/m3 have better decreasing ability as BA decreases the density of the alloy by 19% compared with RHA with density of 397.114 kg/m3 and 15% decrease. This outcome is also in line with results of Prasad and Krishna [5], who varied RHA from 2% to 8% in Al alloy matrix and Usman et al, [44]. The decrease in densities is believed to have resulted from the hard and low density RHA and other reinforcement which replace the soft and higher-density Al matrix thereby giving the composites overall reduction in densities. Therefore, the use of hybrid composite is most suitable for use where combinations of improved mechanical properties and light weight of aluminium composites is a necessity.

2.5. Mechanical Properties

2.5.1. Hardness

- The particulate reinforcements with low aspect ratio is believed generally to provide more hardness on the metal matrix composites than the reinforcements with high aspect ratio. The particulate reinforcements such as SiC, Al2O3, graphene and aluminide are harder reinforcement and therefore improve the hardness composites than the whisker and fibre reinforced metal matrix composites [38,45,46].Rice Husk Ash containing mainly SiO2, will result in composites having lower hardness value [47]. This was confirmed by Alaneme et al., [40] which observed percent reduction in hardness of hybrid composites of Al/RHA-Al2O3 by 4.58%, 8.14% and 10.94% at 2, 4 and 6 wt.% RHA respectively when compared with Al/Al2O3. Contrary results were obtained by Subrahmanyam et al., [48] from Al/rice husk ash-fly ash composites where RHA contains 1.23 wt.% carbon with 92.30 wt.% SiO2. Hardness of the composites was observed to increase linearly with increase in RHA particles. Usman et al., [44] obtained the same results with rice husk ash and bagasse. Chinta et al., [42] observed increase in hardness value of Al composites with increase in SiC from 2-4 wt.% due to formation of intermetallic bonding between Al and 5 wt.% RHA. However, increase in hardness value ceases at 6 wt.% SiC. Moulleswaran et al., [41] produced four different hybrid composites of Al/RHA-SiC aimed at replacing the existing cast iron drum with aluminum hybrid composite. Maximum hardness was obtained at Al 2024 + 15% SiC + 2% RHA.Observations clearly showed that the hardness of the composite increases with increase in weight fraction of the two reinforcements. This reason is attributed to increases in surface area of the matrix which then reduces the grain sizes. Also, the presence of reinforcing particles with such hard surface area offers more resistance to plastic deformation and then, increase hardness. It can also be inferred that the resistance of the composites to surface indentation increased with increased addition of the reinforcements within the Al matrix.

2.5.2. Tensile Strength

- The straining effect together with barriers to dislocation movement is required for improvement in the tensile properties of a metal matrix composite. According to Bello et al., [49], the hindrance to dislocation movement could become more effective as the packing density of the reinforcements increase and this could result in piling up of dislocation at the grain boundaries and new compounds’ sites to the extent that any further dislocation movement would be induced by additional force application. Hence, the composites become more strengthened. Saravanan and Senthilkumar [50] suggested that RHA particles could act as barriers to the dislocations when taking up the load applied. Basavarajappa et al., [51] also has similar observations using fly ash particles as reinforcement for the Al alloy matrix.Also, as grains are refined, the area to resist the external force and the number of boundaries increase. This is because the rate of dislocation is reduced due to frequent change in direction of dislocations at grain boundaries. The strong bonding and defect free interface prevent the dissociation of RHA particles from the aluminium matrix during tensile loading. Therefore, the applied tensile load is adequately transferred to the RHA particle. The distribution of RHA particles all over the entire matrix provides the requisite Orowan strengthening for the composites [22,52]. These submissions are in agreement with the Hall-Petch relationship (equation 13), that the grain size is inversely proportional to tensile strength.

| (13) |

is the yield stress of the material;

is the yield stress of the material;  is a materials constant for the starting stress for dislocation movement of the material; K is a measure of resistance to dislocation and D is the diameter of the particulate size. As D decreases, that is decrease in particulate size, the repulsion stress felt by a grain boundary dislocation decreased and the applied stress needed to propagate dislocations through the material increased. Observations from various researchers on Al-RHA based hybrid composites are discussed below.Alaneme et al., [44] observed a slight reduction in tensile strength of 3.7%, 8% and 13% for the hybrid composites containing 2, 3 and 4 wt.% RHA in the reinforcement relative to the single reinforced Al-Mg-Si matrix-10wt.% Al2O3. This trend was attributed to a slight reduction in the expected strengthening carrying capacity from load transfer from the matrix to the particulates. The load carrying capacity of the hybrid composite of Al/RHA/Al2O3 will be dependent on the amount of Al2O3 rather than RHA. Similar results were obtained by Alaneme and Adewale [4]; Prasad et al., [5] with RHA and SiC as reinforcements in aluminium matrix. Such that RHA played the roles of indirect strengthening while SiC provided direct strengthening of the composites. Alaneme and Aluko [7] noted that when hard particulates are used as reinforcement in metal matrix composites, there is tendency to be an increase in the strength due to the synergy of direct and indirect strengthening mechanisms. Mathpathi and Kodli [53] obtained similar trend with rice husk and SiC.Subrahmanyam et al., [48] successfully incorporated rice husk ash and fly ash in Al 356.2 by stir casting technique to produce composites of Al/RHA/FA at ratio 4:6, 5:5 and 6:4 of RHA: FA. Tensile strength increases as weight percentage of RHA increases with maximum ultimate tensile strength achieved at 6% RHA and 4% FA. RHA particles is believed to have acted as barriers to the dislocations while taking up the applied load. Therefore, the improvement in tensile strength of the composite as a result of RHA reinforcement is due to the fact that the filler ash possesses higher strength to offer more resistance in the composite than FA.

is a materials constant for the starting stress for dislocation movement of the material; K is a measure of resistance to dislocation and D is the diameter of the particulate size. As D decreases, that is decrease in particulate size, the repulsion stress felt by a grain boundary dislocation decreased and the applied stress needed to propagate dislocations through the material increased. Observations from various researchers on Al-RHA based hybrid composites are discussed below.Alaneme et al., [44] observed a slight reduction in tensile strength of 3.7%, 8% and 13% for the hybrid composites containing 2, 3 and 4 wt.% RHA in the reinforcement relative to the single reinforced Al-Mg-Si matrix-10wt.% Al2O3. This trend was attributed to a slight reduction in the expected strengthening carrying capacity from load transfer from the matrix to the particulates. The load carrying capacity of the hybrid composite of Al/RHA/Al2O3 will be dependent on the amount of Al2O3 rather than RHA. Similar results were obtained by Alaneme and Adewale [4]; Prasad et al., [5] with RHA and SiC as reinforcements in aluminium matrix. Such that RHA played the roles of indirect strengthening while SiC provided direct strengthening of the composites. Alaneme and Aluko [7] noted that when hard particulates are used as reinforcement in metal matrix composites, there is tendency to be an increase in the strength due to the synergy of direct and indirect strengthening mechanisms. Mathpathi and Kodli [53] obtained similar trend with rice husk and SiC.Subrahmanyam et al., [48] successfully incorporated rice husk ash and fly ash in Al 356.2 by stir casting technique to produce composites of Al/RHA/FA at ratio 4:6, 5:5 and 6:4 of RHA: FA. Tensile strength increases as weight percentage of RHA increases with maximum ultimate tensile strength achieved at 6% RHA and 4% FA. RHA particles is believed to have acted as barriers to the dislocations while taking up the applied load. Therefore, the improvement in tensile strength of the composite as a result of RHA reinforcement is due to the fact that the filler ash possesses higher strength to offer more resistance in the composite than FA.2.5.3. Fracture Toughness

- Alaneme et al., [44] determined the fracture toughness values using circumferential notch tensile (CNT) specimens of Al/RHA-Al2O3 hybrid composites. It was reported that the RHA reinforcement played a significant role in improving the fracture toughness of the composites. Higher fracture toughness was observed in composites containing 2 and 3 wt.% RHA when compared with single Al2O3 reinforced composite. The primary mechanism of fracture toughness according to Alaneme and Aluko [7] was due to such effects as particle cracking, interfacial cracking or particle debonding. However, Alaneme et al., [44] stressed that further studies would be required to explain the slight improvement the fracture toughness observed in the 2 and 3 wt.% RHA containing composites. Alaneme and Adewale [4] reported decrease in fracture toughness with increase in the weight percent of the composites for Al/RHA-SiC at different weight ratio. Even though, the fracture toughness of composites compositions RHA improved when compared with the single SiC reinforced composites.

2.5.4. Impact Energy

- Impact energy is a measure of energy or work done to fracture a specimen. Subrahmanyam et al., [48] carried out Izod impact test for Al alloy composites with rice husk ash (RHA) and fly ash (FA) as reinforcements. Impact energy increases as percent weight fraction of reinforcements increase. Maximum impact strength of 7.5 J was obtained at 4 wt.% FA and 6 wt.% RHA corresponding to 174.4% increase when compared with pure aluminium with impact strength of 4.3 J. The increase in impact strength was attributed more to the influence of hard RHA. Moulleswaran et al., [43] conducted Charpy impact test for Al/RHA/SiC composites for improvement of automobile brake drum. Impact energy decreases with increase in weight ratio of reinforcements. This result negates the trends obtained by Subrahmanyam et al., [51] but agrees with Usman et al., [46] using 7 wt.% rice husk ash and 7 wt.% bagasse with the impact strength increased by 84.4% (from 84.020 J/m2 to 155.244 J/m2) when compared to the control sample. The increase in impact strength of the composite is believed to have been influenced by RHA. This is because composites with high contents of bagasse showed reduction in impact strength.The decrease in impact energy may be attributable to extreme hardness of the new phases which imparts brittleness to the Al matrix. Also, the porosity free-coarse fibrous grain microstructure of the unreinforced Al alloy (without reinforcements) inhibited crack growth, leading to absorption of higher impact energy than at reinforced composites. Hence, the addition of reinforcements to the Al matrix enhanced the strength and grain refinement but reduced the impact energy. However, increase in impact strength upon addition of reinforcement(s) have not been clearly justified in the literature. It has been observed that the effect of particle sizes RHA based reinforcements on impact strength is rare reported and discussed.

2.5.5. Compressive Strength

- With rice husk ash and fly ash reinforced with aluminium alloy, Subrahmanyam et al., [48] reported the effect of these reinforcements on compressive strength. The compression strength increases as percent weight fraction of reinforcements increase with maximum strength obtained at 6 wt.% RHA and 4 wt.% FA. Because RHA particles act as barriers while taking up the load, thus increases hardness. Chinta et al., [41] studied the compressive strength of Al/RHA-SiC, and reported that for a constant percentage of deformation, there was increased in compressive strength of the composites upto 4 wt.% SiC, whereas, the compressive strength decreases as from 4 wt. SiC upward.

3. Discussion

- Rice husk ash is one of the most silica rich raw materials containing about 80-98% silica which can be produced by carbonization (burning in the absence of air) and decarbonization (burning in the presence of air). The ash has good wettability and can absorb upto 12 wt.% in molten aluminium. It combines and mixes easily with many other reinforcements particles at different weight ratios to produce hybrid composites of aluminium. The improved mechanical performance of Al/RHA based hybrid composites is as a result of combined strengthening mechanisms provided by the reinforcing particles in aluminium matrix. Such strengthening of the base aluminium metal matrix could be the result of load transfer from the soft and willing Al matrix to stiff and hard particles under external load. Hall-Petch strengthening is another factor which describes the influence of grain size on Al strength since the grain boundaries can hinder the dislocation movement due to different orientation of the adjacent grains and to the high lattice disorder characteristics of these region, which prevent the dislocations from moving in a continuous slip plane [25]. Another contributor to strengthening by reinforcement is Orowan mechanism which has to do with interaction of reinforcements at nano level with dislocation. Under external load, non-shearable reinforcing particles pin the crossing dislocations and promote dislocation bowing around particles. Coefficient of thermal expansion and in elastic modulus mismatch which occurs between the reinforcements and aluminium matrix is accommodated during material cooling and straining by the formation of geometrically necessary dislocation.The ultimate tensile strength, yield strength, hardness, impact strength of most automotive parts most especially the engine piston ranges between 150 MPa-250 MPa, 80 MPa-210 MPa, 20 HRB-40 HRB respectively [54-57]. It is obvious from the results of physical and mechanical properties of the RHA based hybrid composites reported that the composites are suitable in the production of automotive engine pistons, cylinders, cardan shaft, pushrods, connecting rods, brake caliper assembly, gears, valves, brake systems etc. However, Al/RHA-Al2O3 hybrid composites results appeared to be the best. Better results could be achieved with reinforcements of better mechanical and tribological properties than those that have been reported. Some other particulates such as graphite, fullerene, graphene, mica, B4C have also proved to have better potential as a secondary reinforcement for development of RHA hybrid based composites. It has also been observed that the physical, tribological and mechanical behavior of the reported composites are influenced by composition and type of the reinforcements (hard or soft). Results also showed that several modifications can be adopted to improve the properties of these composites (by reinforcing Al/RHA composite with suitable combination of reinforcements).For advancement in composite materials development, amorphous carbon present in the rice husk ash can be enriched by nanocarbon like fullerene, graphene, nanotubes, nanodiamond and activated carbon. This blend can be used to produce hybrid composites of aluminium alloy and therefore could be an important area of research interest. With proven potentials of these carbon structures they have the tendency to revolutionize wide range of automobile parts and applications globally. Basically, such nanocarbon can be classified as zero-dimensional (0D) fullerenes, one-dimensional (1D) carbon nanotubes, two-dimensional (2D) graphene and three-dimensional (3D) graphite, with the main building block being carbon [58-60].From the foregoing, properties like density, tensile strength, compressive strength, hardness, fracture toughness and impact strength can be optimized for design and development of various automotive components by selecting appropriate reinforcements.

4. Conclusions

- The following conclusions can be drawn from the study:1. Reinforcements are selected based on their effects on the metal matrix and suitability in the area of application. 2. Stir casting route was found to predominate in processing RHA based hybrid composites of aluminium because it is cost effective and processing parameters could easily be varied and monitored. 3. Rice husk ash mixes and blends easily with many other reinforcements in molten aluminium to produce hybrid composites with good properties.4. The ultimate tensile strength, yield strength, hardness, impact strength of most rice husk ash based hybrid composites are greater than 200 MPa, 180 MPa, 35 HRB respectively and are adequate enough to develop most automotive components and parts.5. With appropriate processing method and choice of process parameters, addition of carbonized rice husk with other carbon nanoparticles could further enhance the mechanical properties and widen the areas of automotive applications of the aluminium composite.

ACKNOWLEDGEMENTS

- The authors would wish to express their appreciations to the entire staff of Mechanical Engineering Department of Ladoke Akintola University of Technology, Ogbomoso, Nigeria and Lagos State Polytechnic, Ikorodu, Nigeria for their contributions in the course of this study.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML