-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2016; 6(5): 145-151

doi:10.5923/j.cmaterials.20160605.01

Dielectric, Conductance and Pyroelectric Characterization of MWCNT:PVDF Nanocomposite Thin Films for Multiple Device Applications

Padmaja Guggilla, Matthew Edwards

Department of Physics, Chemistry & Mathematics, Alabama A&M University, Normal, USA

Correspondence to: Padmaja Guggilla, Department of Physics, Chemistry & Mathematics, Alabama A&M University, Normal, USA.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Through this communication dielectric, pyroelectric, and conductance properties of polyvinylidene fluoride (PVDF) nanocomposite thin films with multi-wall carbon nanotubes (MWCNT) embedded in it, as a function of temperature and frequency are reported. Samples, ranging from 15 – 280 microns in thickness, were measured in the temperature range of 20 to 90°C and in frequencies range of 50Hz to 110MHz. The samples were prepared by the cost effective and yet simple, solution casting technique. Measurements indicate that at constant temperatures, the real dielectric constant decreases at lower frequencies, stays steady at low frequencies but rises at higher frequencies towards the strong resonance. The dielectric loss, a particular concern as it is inversely related to the conductance, decreases also at lower frequencies but rise at higher frequencies with a steeper slope in each case. Additionally, pyroelectric coefficient is measured in the same temperature range and results show higher values compared to addition of silver nano particles in PVDF thin films and provided preliminary evidence of the causative microscopic response mechanism. Our MWCNT:PVDF thin films yield higher figures of merit than that indicated by pure PVDF thin films and results indicate a usage of MWCNT:PVDF thin films in infrared uncooled sensors and vidicon technology.

Keywords: Multi-wall carbon nanotubes (MWCNT), Polymer nanocomposite thin film slabs, Dielectric properties, Energy storage, Pyroelectrics

Cite this paper: Padmaja Guggilla, Matthew Edwards, Dielectric, Conductance and Pyroelectric Characterization of MWCNT:PVDF Nanocomposite Thin Films for Multiple Device Applications, International Journal of Composite Materials, Vol. 6 No. 5, 2016, pp. 145-151. doi: 10.5923/j.cmaterials.20160605.01.

Article Outline

1. Introduction

- The frequency response of materials and the effects of temperature on physical systems have been of high interest for material scientists for more than two centuries. Resulting from the advances in the fields of nanophysics and microelectronics as well as advances in high-speed data processing techniques, thermal sensing and imaging have become useful diagnostic tools in the health (medical) industries, military arenas and environmental protection aids [1]. Smart materials are solid-state transducers having electrochromic, piezoelectric, pyroelectric, electrostrictive, electroactive, or other actuating and sensing functions. Available smart materials, for use in infrared detector or vidicon and in tensile/pressure sensing systems so far are: triglycine sulfate (TGS), lithium niobate (LN), lithium tantalate (LT), lead titanate (PT), lead zirconate titanate (PZT), polyvinylidene fluoride (PVDF), polyvinylidene fluoride-trifluoroethylene copolymer (P(VDF-TrFE)) and others [2-4]. In particular, the man-made polymer material PVDF, besides being mechanically flexible with solvent and chemical resistance, has a number of attractive dielectric and pyroelectric properties. PVDF has fast, dynamic response for use in touch/tactile sensors and infrared detection or vidicon imaging devices [5]. Multi-wall Carbon Nanotubes (MWCNTs) of outside diameter × length (7-15nm × 0.5-10μm, respectively) exhibit excellent mechanical and electrical properties. As polymers present high flexibility and transparency, ease of processing and low cost, the combining of polymers with CNTs would be promising for sensor materials [7]. Composite materials containing metal nanoparticles have attracted great attention due to their unique chemical and physical properties, which make such materials applicable for use in molecular detection [9], near field optical microscopy [10] and in optoelectronic devices such as light emitting diodes and photovoltaic devices [11]. Researchers have reported that with the addition of Ag in composite films, as opposed to using pure polymer thin films, the sample would promote electron transport, resulting in higher pyroelectric currents [12]. The demand for flexible electronic devices, which can be folded and bent in three dimensions, has led scientists to focus on composite films, which can reduce the possibility of failures arising from mechanical bending by absorbing internal stresses generated during processing. Since polymers have high merits except for their inherent low dielectric constant, such conventional polymeric dielectric materials usually used as composites contain high dielectric ceramic powders such as lithium tantalate. In this paper we focus on the individual and interrelated dielectric and pyroelectric properties of 0-3 nanocomposite thin films.

1.1. Pyroelectrics

- Pyroelectric materials respond to change in temperature resulting in spontaneous polarization (Ps) of the materials. To effectuate large pyroelectricity with change in temperature, the prototype materials for pyroelectric sensing should have low density, a small specific heat, small dimensions, a large IR absorption coefficient, high Curie temperature, high pyroelectric coefficient, as well as, low real dielectric constant and low dielectric loss (the imaginary part of the complex dielectric constant) [3]. In low frequency ranges, the temperature dependent dipolar polarization slightly modifies the position of atoms or molecules within certain crystals and polymer thin films, thus producing charge separation, with a corresponding voltage development across the material, whereas piezoelectric materials produce voltage due to pressure [3, 4]. The pyroelectric and piezoelectric sensor systems simultaneously react to temperature and pressure changes, making discrimination between temperature and pressure changes impossible. Sensors that show both piezoelectricity and pyroelectricity can thus be used only in devices where one parameter, either temperature or pressure, is kept constant. Graz et al [6] proposed that by designing nanocomposites via two-step poling sequence, sensitivity to pressure and temperature could be selectively and spatially controlled. Thus, one can obtain two distinct sensory modes from a single composite material. PVDF has a number of attractive properties as used in touch and tactile sensors and in vidicon/imaging applications. Besides high lateral thermal resolution, desirable conditions are due to PVDF low weight. PVDF’s formability occurs into thin sheets between 5µm and 2mm in thickness, with accommodating mechanical properties that provide its usefulness as a material. Nevertheless, there is a need to enhance further PVDF’s performance both as a sensor and target for vidicons/imagers. The polymeric, composite films containing dispersed electric conductive fillers such as Ag and MWCNTs are desirable candidates for dielectric materials. Oltean et al [14] studied some electrical properties of metallic iron reinforced polymeric composite materials subjected to stress state of electric field, temperature variation or mechanical load, and researchers have reported that CNTs increase the dielectric constant more than carbon black in the microwave frequency due to their high aspect ratio [12, 13]. Scientists have also reported that the dielectric constant of the composite films with CNTs and Ag particles is proportional to the thickness of CNTs as well as the weight percentage of them.Multi-walled nanotubes (MWCNT) consist of multiple layers of graphite, rolled in onto themselves to form a tube shape structure. In the present work, an effort has been made to disperse multi-walled carbon nanotubes(s) via stirring or ultrasonic processing in a PVDF matrix to form 0-3 nanocomposites. The pyroelectric properties of the resultant composites were measured. After using the foregoing parameters to assess their use as pyroelectric infrared detectors and as vidicons, various figures-of-merit of composite films have been calculated and compared with pure PVDF film.

1.2. Dielectrics

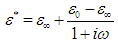

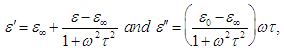

- Materials having both advantageous dielectric and pyroelectric properties are particularly significant for a myriad of technologies. Advantageous dielectric nanocomposites would be materials having a high dielectric constant and lower dielectric loss for energy storage or insulation purposes; advantageous pyroelectrics would yield higher electrical currents in an external electrical circuit for a small change in the temperature for pyroelectric sensor or vidicon. However, complications of “dielectric anomalies” [19-23] can exist when making measurements on dielectrics, especially when the measurement is made with a nanocomposite dielectric slab placed in between parallel condenser plates [24]. Not only is it likely that unaccounted for air gaps exists on each side of the slab, but the expected polarization charge effect will be diminished by apparent free charge flow onto the surfaces of the dielectric. Ideally, the air gap can be removed by using sputtered electrodes in the case of dielectric crystals and by electric conductive paint on the front and back surfaces for thin film polymer composites. Nevertheless, dielectric anomalies still exist that can diminish the polarization charge resulting from concentrations of impurities and small flaws in the dielectric where charge can accumulate. In addition, the idea of interfacial or space charge polarization is suggested as a contribution to polarization due to charge migration.Vikram S. Yadav et al [25] report measures of the dielectric constant of PVDF thin films in the temperature range from 21 to 80°C and in frequencies from 10Hz to 1MHz. As a part of this work, we have preliminarily measured the dielectric constant spectrum of 0-3 nanocomposites of lithium tantalate PVDF thin film slabs in the temperature range from 21 to 90°C and in frequencies from 50Hz to 110MHz. To remove the chance of dielectric anomalies due to parallel-plate assembly, measurements were made with conductive paint on the front and back surfaces of the thin film sample slabs and samples were fitted with electrodes to the Agilent’s 4294A Impedance Analyzer through the 16047E connection fixture, using the Global Specialties Calibration standard.In addition to describing the above experimental techniques, we present a brief presentation of the theory of dipolar dielectrics as the initial point to begin understanding the dielectric properties of nanocomposite thin films. In this regard, Debye’s classical picture of polarization with a single relaxation [25], having a set of non-interacting dipoles that are able to rotate in opposition to some viscous resistance, yields the equation for the complex permittivity ɛ* as

| (1) |

relaxation time.The real and imaginary part of the dielectric constant are given by

relaxation time.The real and imaginary part of the dielectric constant are given by | (2) |

| (3) |

| (4) |

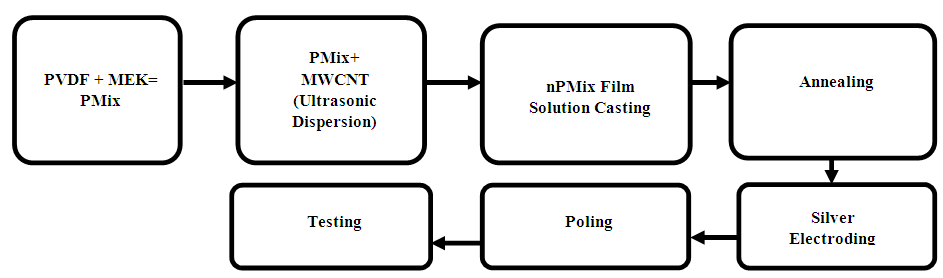

2. Experiment

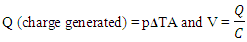

- PVDF and MWCNT were purchased from Sigma-Aldrich. PVDF films, made of pure form and 0-3 connectivity nanocomposite of MWCNT using the solution cast technique [15]. The first step in the preparation of the PVDF solution (Pmix) was to dissolve a suitable amount of PVDF in methyl-ethyl-ketone (MEK) at 60°C. A requisite amount of MWCNT solution or lithium tantalate was then added to form nPMix and this mixture was stirred, for several hours, to break-up the agglomerates and disperse the MWCNT or lithium tantalate uniformly in the nPmix. The length and diameter of the multi-walled carbon nanotubes were of an outside diameter x Length of 7-15nm x 0.5-10μm, respectively. The obtained nPMix composite solution was kept in a suitable container for the solvent to evaporate. The films were annealed for 2-3 hours in the air, at 110°C for the present case. The final samples were each extracted from the respective dried films, coated with conductive paint (front and back faces); then the film was cut into typically 10mm X 10mm sized elements for measurement. The samples intended for dielectric measurements were tested without further processing; the samples for pyroelectric determination were poled at 100°C using 50kV/cm for 2 hours. After the poling process, the samples were short circuited and annealed at 50°C for 2 hours. The flowchart of the fabrication processes is depicted in Figure 1. The real (ε') and imaginary (ε") parts of dielectric constant were calculated by measuring capacitance and dielectric loss and the conductance was measured directly. To measure the dynamic pyroelectric current, a direct measurement technique was used. The detailed measurement procedures of these parameters were described in an earlier publication [7]. The pyroelectric current Ip was measured and the pyroelectric coefficient (p) was calculated using the relationship:

| (5) |

| Figure 1. Summary of Composite Film Fabrication Process |

| (6) |

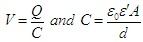

| (7) |

where p is the pyroelectric coefficient, c΄ is the volume specific heat, ε' is the dielectric constant and ε'' is the dielectric loss (the imaginary part of dielectric constant). In our calculations, it was assumed that the specific heat is the same in both PVDF and composite films. Regarding dielectric characterization, the Agilent 4294A Impedance Analyzer was used with an electrode fixture while the texture was inside a thermostat-temperature controlled oven. The dielectric constant ε΄ was determined from measuring the capacitance C, and the dielectric loss with the conductance were measured directly as a function of temperature and frequency.

where p is the pyroelectric coefficient, c΄ is the volume specific heat, ε' is the dielectric constant and ε'' is the dielectric loss (the imaginary part of dielectric constant). In our calculations, it was assumed that the specific heat is the same in both PVDF and composite films. Regarding dielectric characterization, the Agilent 4294A Impedance Analyzer was used with an electrode fixture while the texture was inside a thermostat-temperature controlled oven. The dielectric constant ε΄ was determined from measuring the capacitance C, and the dielectric loss with the conductance were measured directly as a function of temperature and frequency. 3. Results and Discussion

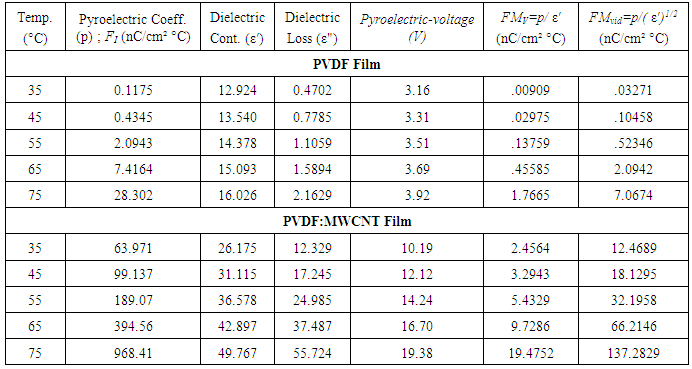

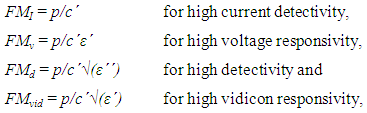

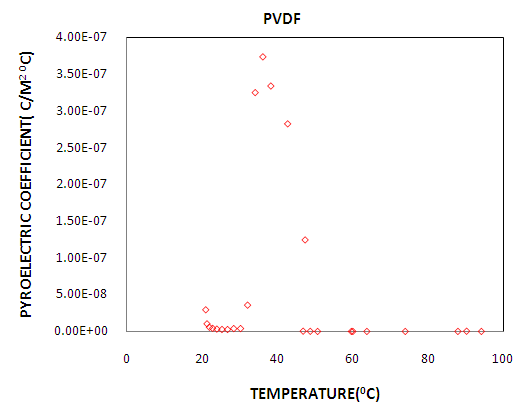

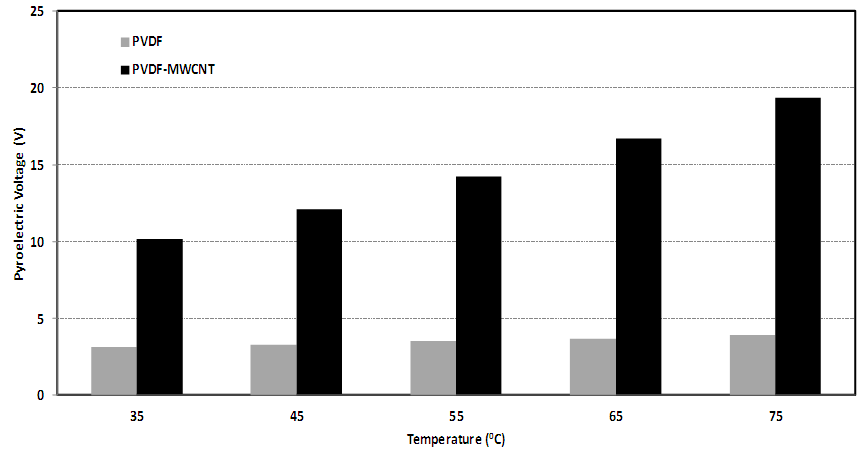

- Figures 1 and 2 show the temperature dependence of the pyroelectric coefficient p, of PVDF and nanocomposite films. As expected in ferroelectrics, these parameters increase with the increase in temperature. The variation of the pyroelectric coefficient of the films is depicted. The authors have previously calculated related figures of merit (see reference 1, Edwards et al). In addition, a theoretical model had been developed, which explains the effect of the matrix’s electrical conductivities on the electrical properties and poling behaviors of the 0-3 ferroelectric composites [8-9]. Zhang et al [8] developed a comprehensive analysis for the pyroelectric activity of 0-3 ferroelectric composites, which includes additional contributions from the electrical conductivity of the constituents. According to Wong’s model [9], the increment of conductivity of the matrix increases the poling degree of the ceramic and hence pyroelectric properties are enhanced. The increment of the matrix’s electrical conductivity will increase the leakage current and the dielectric loss ε", which will be harmful to the poling process. Our data are in agreement with the expected results [9].

| Figure 2. Pyroelectric Coefficient Vs Temperature of Pure PVDF Film |

| Figure 3. Pyroelectric Coefficient Vs Temperature of PVDF+MWCNT Film |

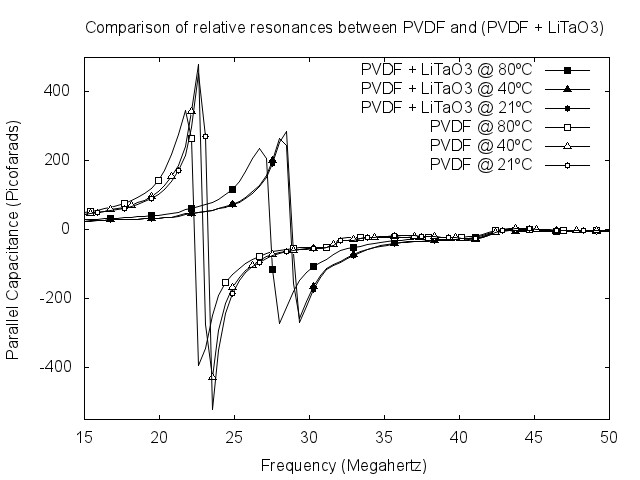

| Figure 4. Capacitance Versus Frequency |

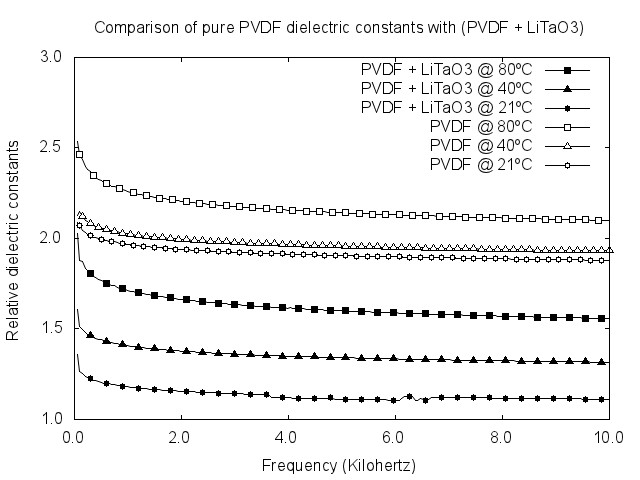

| Figure 5. Relative Dielectric Constants Versus Frequency |

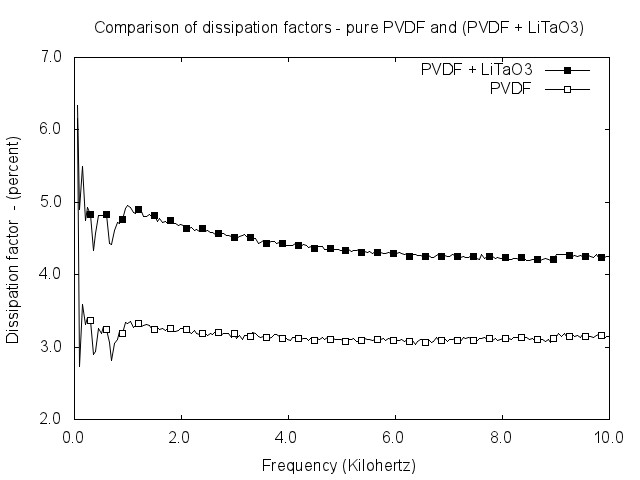

| Figure 6. Dissipation Factor Versus Frequency |

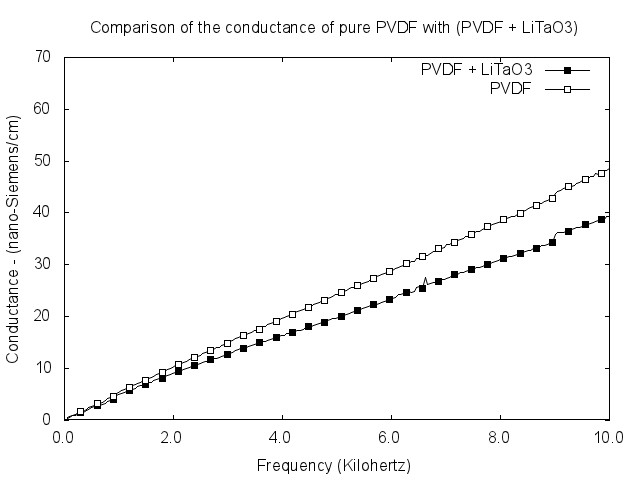

| Figure 7. Conductance Versus Frequency |

|

| Figure 8. Comparison of Pyro-Voltage Generated for PVDF and PVDF- via 1°C Increase in Temperature |

4. Conclusions

- The experimental results obtained of nanocomposite films (PVDF, PVDF-MWCNT) and Lithium tantalate ceramic particles films can be summarized as follows:• Films of PVDF and PVDF:MWCNT have been fabricated using a solution cast method. This technique is a very useful and inexpensive technique for manufacturing nanocomposite pyroelectric sensors because films can be fabricated with less energy, time and effort as compared to ceramic and single crystal fabrication. • The films were characterized for their dielectric and pyroelectric properties, in order to determine their usefulness in un-cooled infrared detector and vidicon tactile applications.• The calculated pyroelectric figures-of-merit (FMv, FMd and FMvid) of the nanocomposite films were found to be higher than pure PVDF films. • Results show that the pyrovoltage generated by the addition of the MWCNTs with an increase in temperature. • PVDF:MWCNT films, based on preliminary results obtained, are attractive for use in un-cooled thermal and pressure sensing elements especially in medical and environmental applications where flexible and curved-surface based sensors are required. • The relative dielectric constant measurements reveal a characteristic decrease in value at frequencies from 50Hz to 300Hz and remain essentially constant thereafter at that lower value until the material’s resonance occurs in the range of 10 to 50MHz.• The relative dielectric constant spectrum values are greater in value at higher temperatures than at lower temperatures.• The dielectric constant spectrum values are significantly lower with lithium tantalate dopants.• The resonance frequency decreases with lithium tantalate dopant from about 28MHz to 22MHz and there is a small resonance frequency decrease with increase in temperature as well. Further work is in progress to ascertain the mechanisms for enhancement of the dielectric and pyroelectric properties of nanocomposites films.

ACKNOWLEDGEMENTS

- This work has been partially supported by Physics DHS-BS Award #2010-ST-062-000034 and Evans Allen grant number 105-25-5670. Thanks are extended to Dr. Ashok Batra for helping the authors and providing invaluable discussions. The authors thank Jade Douglas for her assistance with sample preparation and measurement monitoring.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML