-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2016; 6(3): 63-67

doi:10.5923/j.cmaterials.20160603.01

Rheology and Mechanical Studies on Polystyrene/Polyethylene-graft-maleic Anhydride Blend and Cellulose-Clay Based Hybrid

Ayesha Kausar

Nanosciences Division, National Centre for Physics, Quaid-i-Azam University Campus, Islamabad, Pakistan

Correspondence to: Ayesha Kausar , Nanosciences Division, National Centre for Physics, Quaid-i-Azam University Campus, Islamabad, Pakistan.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In this work, novel polyethylene-graft-maleic anhydride (PE-g-MAH) and polystyrene (PS)-based blend was prepared. The cellulose (Cell) and cellulose modified with montmorillonite nanoclay particles (Cell-Clay) were employed as filler. The impartial was to fabricate mechanically stable materials with enhanced morphological, mechanical, and rheological properties. The network morphology was observed by Field Emission Scanning Electron Microscopy (FESEM). The complex viscosity (η*) of the PS/PE-g-MAH/Cell and PS/PE-g-MAH/Cell-Clay was found to increase with the nanofiller contents. The PS/PE-g-MAH matrix reinforced with 5 wt.% cellulose showed tensile strength of 29.5 MPa, while PS/PE-g-MAH/Cell-Clay 5 showed value of 39.2 MPa. The Young’s modulus of PS/PE-g-MAH/Cell 5 was increased to 2.1 GPa, whereas PS/PE-g-MAH/Cell-Clay 5 was improved to 3.6 GPa.

Keywords: Polyethylene-graft-maleic anhydride, Cellulose, Nanoclay, Tensile strength, Complex viscosity

Cite this paper: Ayesha Kausar , Rheology and Mechanical Studies on Polystyrene/Polyethylene-graft-maleic Anhydride Blend and Cellulose-Clay Based Hybrid, International Journal of Composite Materials, Vol. 6 No. 3, 2016, pp. 63-67. doi: 10.5923/j.cmaterials.20160603.01.

Article Outline

1. Introduction

- One of most extensively employed polyolefin polymer is polyethylene (PE). It does not comprise any polar group in backbone therefore promotes uniform dispersal of fillers especially organic fillers [1, 2]. Usually modification of polyethylene is carried out with polar monomer chiefly polyethylene-grafted-maleic anhydride for the improvement in miscibility and compatibility with the fillers [3-5]. For polymeric matrices, cellulose or wood fibers have been utilized as filler for composite strengthening with comparatively low density, biodegradability, and economical accessibility [6]. In spite of numerous desirable features of wood fiber to act as strengthening constituents, its commercial employment in fiber-filled composite has not gained much success. A chief motive is that the two constituents of the composite-fiber and polymeric matrices have incompatible surfaces. The wood fiber has hydrophilic and thermoplastic hydrophobic nature, so limiting the stress transfer at the interface [7]. For enhancement of mechanical features of wood-reinforced thermoplastic composites, outstanding fiber integration and strong adhesion between fiber and matrix are generally needed. For the augmentation of compatibility of polymer/cellulose composite constituents, numerous efforts have been made either by chemical or physical modification of polymer matrix or fiber [8, 9]. The interfacial contact between the reinforcement and matrix has been favored by intensive milling, mixing or grinding for the synthesis of high energy surface [10, 11]. For such systems comprising hydrophobic thermoplastics and hydrophilic fibers, coupling agents are extensively employed for the enhancement of adhesion, dispersion, and compatibility [12-14]. For the modification and improvement of acid-base interaction at fiber-matrix interface and enhancement of composite potential, surface modification of cellulose or polymer matrix could be performed [15-17]. For the integration of polymer and fillers numerous techniques have been employed such as conventional free-radical grafting, polycondensation grafting, and fiber surface grafting [18-20]. All the routes have their own limitations and significances. It was also noted that by graft polymerization the wetting problem of wood fiber can be overcome which will then offer excellent compatibility with matrix. Adhesion will be further increased if the grafted polymer length is beyond critical entanglement length. The potential and features of polymer/cellulose composites are greatly dependent upon type, orientation, dispersion, content, and processing routes. Concerning to microstructure, the clay particles are integrated in polymer matrix in either exfoliated or integrated state [21]. In general, the intercalated polymer/clay nanocomposites are achieved by the dispersion of polymer between layered silicates. Even though the inter-layer spacing enhances, there is still attractive forces exist between the layered silicates for stacking in uniform spacing. Exfoliated nanocomposites are synthesized when layer spacing of composite enhances to the point where there is no enough attraction between silicate layers to sustain uniform layer spacing. Exfoliated or intercalated polystyrene/clay nanocomposites have been extensively investigated [22]. In this attempt, polyethylene-graft-maleic anhydride (PE-g-MAH) and polystyrene (PS)-based blends were prepared. Cellulose (Cell) and cellulose modified with clay particles (Cell-Clay) were employed as filler in novel hybrid materials. The main research objective was to produce mechanically stable materials with improved morphological and rheological properties. To the best of our knowledge, PS/PE-g-MAH/Cell and PS/PE-g-MAH/ Cell-Clay materials have been prepared for the first time and analyzed for the rheological, mechanical, and morphology properties. The effect of filler type and content on interfacial interaction and performance of the resulting composite have been investigated. Cellulose, clay, and cellulose-clay-based composites are natural materials which are cost-effective, biodegradable, and widely used for efficient wastewater treatment. Cellulose or chitosan-based composites are biosorbents having fine adsorption capacity toward chromium and other toxic metals. Montmorillonite or bentonite-based organoclays have also been utilized for the remediation of noxious metals. Novel PS/PE-g-MAH-based cellulose-clay composite materials, therefore, can be employed as effective adsorbent for the removal of chromium and toxic metals from waste water.

2. Experimental

2.1. Materials

- Polyethylene-graft-maleic anhydride (PE-g-MAH), polystyrene (PS, Mw 35,000), montmorillonite (MMT, K 10 powder), cellulose fibers, 2-chloro-1,3-dimethylbenzene (97%), and dimethylacetamide (DMAc, 99%) were purchased from Aldrich.

2.2. Instrumentation

- Rheological measurements were performed using ARES rheometer from TA instrument. Dynamic frequency sweep experiments were performed under continuous nitrogen atmosphere using 25 mm parallel plate fixture at 200°C. The linear viscoelastic limit was determined using strain sweeps at frequency of 10 rad/s at 200°C. The elastic moduli (G') and complex viscosity (η*) of materials were obtained as functions of angular frequency (ranging from 0.1 rad/s to 100 rad/s) at 200°C. Transmission electron microscopy (TEM) was conducted with a JEOL JEM 2100F TEM. The sample was prepared with a Leica UC-6 ultramicrotome with a Diatome diamond knife at room temperature.

2.3. Cellulose Modification (Cell-Clay)

- 1g cellulose was stirred in 100 mL DMAc for 2h. Then 1g sodium montmorillonite was dispersed in DMAc (100 mL) separately and stirred for 2h. The cellulose mixture was poured in clay mixture and stirred overnight at room temperature. The stirred suspension was allowed to settle and the supernatant was discarded. The product was dried at 70°C [23].

2.4. PS/PE-g-MAH/Cell Hybrid Preparation

- Solution-blending method was used to mix PS and PE-g-MAH (1:1), and cellulose (1-5 wt.%) in dimethylbenzene at 130°C for 2h. The resulting precipitate was filtered. Afterward the precipitate was put in a roller mill at 120°C for 0.5 h. The resulting sheet was compression molded at 120°C for 0.5 h into plate with thickness of 4 mm [24].

2.5. PS/PE-g-MAH/Cell-Clay Hybrid Preparation

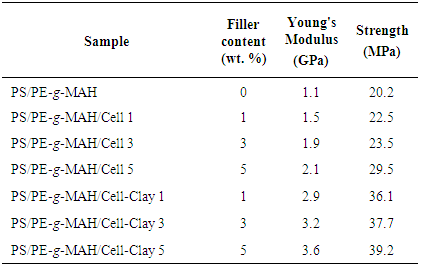

- Here again solution blending method was used to mix PS and PE-g-MAH (1:1), and Cell-Clay (1-5 wt.%) in dimethylbenzene (130°C). The precipitate was filtered and roller pressed at 120°C for 0.5 h. The resulting sheet was compression molded at 120°C for 0.5 h into plate with thickness of 4 mm (Fig. 1).

| Figure 1. Formation of PS/PE-g-MAH/Cell-Clay nanocomposite |

3. Results and Discussion

3.1. Rheological Properties of PS/PE-g-MAH/Cell and PS/PE-g-MAH/Cell-Clay

- The rheological behavior of nanocomposite at various filler loadings have been studied. The complex viscosity (η*) of the PS/PE-g-MAH/Cell and PS/PE-g-MAH/Cell nanocomposite are given in Fig. 2. The η* of the PS/PE-g-MAH/Cell and PS/PE-g-MAH/Cell-Clay samples prepared with different nanofiller contents was studied. According to the results, addition of cellulose and nano-clay modified cellulose has slender influence on the nanocomposite rheological behavior. As can be seen from rheology curves, as the filler content increased, the complex viscosity increased slightly. The increases in η* of PS/PE-g-MAH/ Cell are negligible but effect was prominent in the case of PS/PE-g-MAH/Cell-Clay with various filler loadings. By increasing the cellulose-nanoclay concentrations, the interaction between the nanofiller to polymer chains are perceptibly sturdier. The better matrix-filler interaction contribute to the increase in melt viscosity.

| Figure 2. Complex viscosity (η*) vs. frequency of (A) PS/PE-g-MAH/Cell and (B) PS/PE-g-MAH/Cell-Clay nanocomposites at 200 °C |

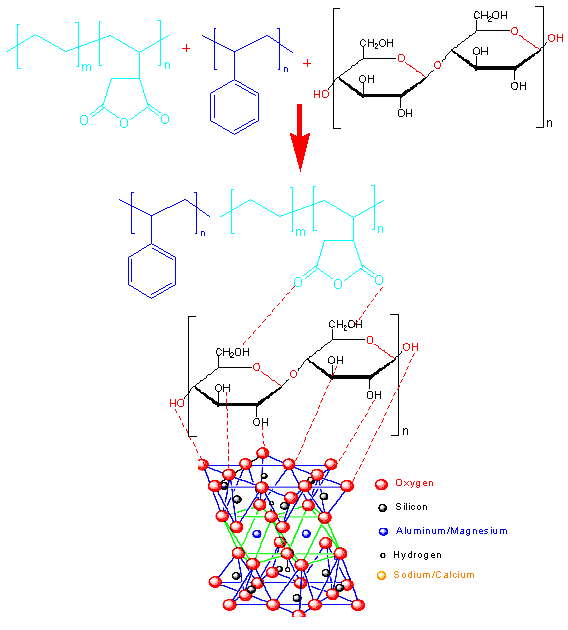

3.2. Microscopic Analysis

- FESEM micrographs of the fracture surfaces of PS/PE-g-MAH/Cell and PS/PE-g-MAH/Cell-Clay hybrids are presented in Fig. 3. Interconnected network morphology was observed in the case of both the composite. In PS/PE-g-MAH/Cell, some closely packed pores or gaps were observed (Fig. 3A). However in the case of PS/PE-g-MAH/Cell-Clay hybrid there was formation of fine network (Fig. 3B). This sort of morphology is usually observed due to non-covalent interaction between the polymer chains and nanofiller [25].

| Figure 3. FESEM micrographs of (A) PS/PE-g-MAH/Cell 1 and (B) PS/PE-g-MAH/Cell-Clay 1 |

3.3. Mechanical Properties

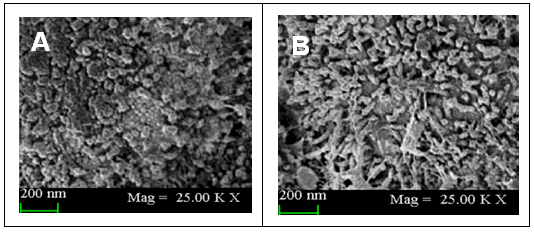

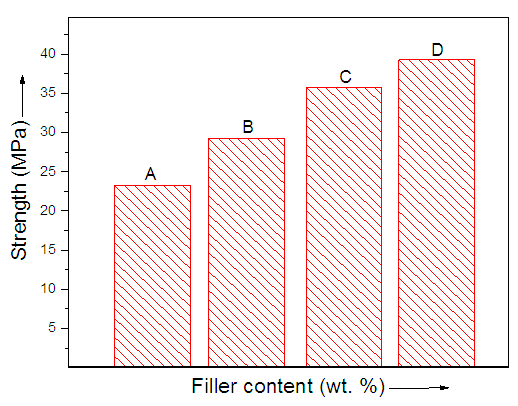

- Mechanical properties of PS/PE-g-MAH/Cell and PS/PE-g-MAH/Cell-Clay composites are given in Table 1. The effect of filler content on tensile strength and modulus of PS/PE-g-MAH/Cell and PS/PE-g-MAH/Cell-Clay composites are shown in Fig. 4.

|

| Figure 4. Tensile strength of (A) PS/PE-g-MAH/Cell 1; (B) PS/PE-g-MAH/Cell 5; (C) PS/PE-g-MAH/Cell-Clay 1; and (D) PS/PE-g-MAH/Cell-Clay 5 nanocomposites |

4. Conclusions

- The improvement in nanocomposite properties were achieved using cellulose and cellulose modified nano-clay into the polystyrene/polyethylene-graft-maleic anhydride blend matrix. The continuous improvement in the properties of the cellulose and cellulose-nano-clay hybrids was observed with increasing concentration up to 5 wt. %. The interaction between blend matrix and cellulose montmorillonite led to better dispersion of the nanofiller, based on SEM observations. The tensile results also indicated high degree of exfoliation of the nano-clay and cellulose (5 wt. %). An enhanced complex viscosity indicated fine rheological behavior. The relationship between nanofiller type and rheological behavior was apparent from the results.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML