-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2015; 5(1): 9-17

doi:10.5923/j.cmaterials.20150501.02

Tensile and Shear Punch Properties of Bamboo Fibers Reinforced Polymer Composites

Agus Edy Pramono1, Indriyani Rebet1, Anne Zulfia2, Subyakto3

1Department of Mechanical Engineering, Politeknik Negeri Jakarta, Depok, Indonesia

2Department of metallurgy and material, faculty of engineering, Universitas Indonesia, Depok, Indonesia

3Research Center for Biomaterials, Indonesian Institute of Sciences, Bogor, Indonesia

Correspondence to: Agus Edy Pramono, Department of Mechanical Engineering, Politeknik Negeri Jakarta, Depok, Indonesia.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Bamboo fibers reinforced polymer composites have been fabricated in the two types of fibers direction, and properties of tensile strength and shear strength of punch has been investigated. Bamboo fibers reinforced polymer composites (BFRP) was fabricated for manufacture of construction materials in as panels. Bamboo fibers with a diameter of <0.5 mm, length of 280mm, weighed in a weight of 50; 75; 100 grams, arranged in a single direction and double direction, in a tray sized 10 x 280 x 280 mm, superimposed liquid phenolic resin by hand lay-up. Both types of composite panels were cut and machined to obtain test standard size. The results of tensile strength test and punch shear test showed that the increase in weight of the bamboo fibers may increase the strength of the composite. Composites with bidirectional fibers has a tensile strength lower than the composite uni direction. Composites with bidirectional fibers has punch shear strength higher than the composite uni direction.

Keywords: Bamboo Fiberss Reinforced Polymer (BFRP), the Mechanical Properties of Composites, Bamboo Fiberss, Phenolic Resin, Uni Direction, Two Direction, Hand Lay-up

Cite this paper: Agus Edy Pramono, Indriyani Rebet, Anne Zulfia, Subyakto, Tensile and Shear Punch Properties of Bamboo Fibers Reinforced Polymer Composites, International Journal of Composite Materials, Vol. 5 No. 1, 2015, pp. 9-17. doi: 10.5923/j.cmaterials.20150501.02.

Article Outline

1. Introduction

- Composite materials are engineering materials (engineered materials) are made from two or more basic material with chemical and physical that differ significantly, that remain distinct at the macro level in the final structure. There are two groups of constituent materials, matrix and reinforcement. Matrix material surrounds and supports the reinforcement material in maintaining their relative positions. The reinforcement material provides the physical properties and mechanical specifically to improve the physical and mechanical properties of the matrix. A collaboration between these two basic materials produce material properties that are not provided for each material element of origins, while the extensive variation in the matrix and reinforcing materials that the designer can choose the product or the structure of the best combination. Engineered composite materials must be fabricated. Matrix material can be incorporated into reinforcing materials, before or after the reinforcement material is placed into the mold or the mold surface. Matrix material melts, after the part is essentially formed. Depending on the state of the matrix material, melting can occur to various ways of chemical polymerization or freezing of the liquid state. This studies utilized bamboo fibers rope types of bamboo as reinforcement of polymer matrix phenolic resin. Fabrication and research what utilizes the natural fibers composites have been done by other researchers. Alomayri T, et al, In the Journal of Asian Ceramic Societies 1 (2013) utilizing the cotton fibers to strengthen the geopolymer composites. This study examined the hardness, impact strength and compressive strength of geopolymer composites reinforced cotton fibers [1]. Fibers composites fabricated from wool and wool fibers treated with chitosan (CH) and a solution of gellan gum (GG) that contain food dyes resulted in increased mechanical characteristics compared to the wool fibers, the study conducted by Khairul Anuar Mat Amin, et al., in the journal Fibers (2013) [2]. D.O. Castro, et al., in Polymer Testing 31 (2012), examined composites fabricated from bio-high-density polyethylene (HDBPE) obtained from ethylene derived from sugarcane ethanol and curauá fibers formed by the internal mixer and mixing followed by thermopressing. This study examines the impact and flexural strength of the composite [3]. Composite polymer PLA (Polylactic acid) which reinforced with natural fibers; bamboo fibers, fibers vetiver grass and coconut fibers have been fabricated and studied by Wiphawee Nu-thong, et al., which was written in Energy Procedia 34 (2013). This study tested the impact strength properties of the composite [4]. Wassamon Sujaritjun, et al., in Energy Procedia 34 (2013), have examined the tensile strength of composites fabricated from PLA (Polylactic acid) which reinforced with bamboo fibers (BF), vetiver grass fibers (VF) and coconut fibers (CCF) [5]. The composites fabricated from bacterial cellulose (BC) as a nano-sized adhesive reinforced with sisal fibers have been investigated by Koon-Yang Lee, et al., which was written in Composites Science and Technology 72 (2012) [6]. Alomayri T., et al., in the Journal of Asian Ceramic Societies (2014), have examined the flexural strength, flexural modulus, impact strength, hardness and fracture toughness of the geopolymer composite reinforced braided cotton fibers, the composite was fabricated by weight of cotton fibers from 4.5; 6.2 and 8.3% [7]. Performance of cement mortar reinforced with fibers bonding percentage variation of palm trees have been studied to assess its feasibility for application structure and non-structure, this study has been conducted by Nesibe Gozde Ozerkan, et al., in International Journal of Sustainable Built Environment (2013) [8]. Composite single direction of poly lactic acid and jute fibers yarn twisted and fabricated using compression molding. Reinforcing fibers aligned with the fibers and the matrix resin was used as a mediator to prepare preform material of single direction. This composite has been investigated by Anin Memon, et al., published in Energy Procedia 34 (2013) [9]. Cement composites reinforced with short flax fibers separately (JFRCC) with variation matrix for the development of concrete and natural fibers reinforced mortar for construction has been investigated by Xiangming Zhou, et al., published in Materials and Design 49 (2013) [10]. Processing and characterization of the composite polyester and aligned long curauá fibers has been done by Sergio Neves Monteiro, et al., which was written in the Journal of Materials Research and Technology (2013). This study has tested the impact and flexural strength of the composite [11]. S. D. Asgekar, et al., in International Journal of Composite Materials, 2013, has fabricated and tested mechanical properties of fibers bagasse and coir - reinforced composites made in phenolic formaldehyde resin [12]. Based on the review of the research journal article above, many researchers have made use of natural fibers as reinforcement in the composite with polymer adhesive or cement. Most researchers have tested mechanical properties of impact strength, flexural strength; most researchers did not test the shear strength of the punch on natural fibers composite, and few researchers who tested for tensile strength. Only a few researchers which have made use of bamboo fibers as reinforcement in composites, and most of the natural fibers materials were provided by the manufacturer. This research work utilized bamboo fibers as reinforcement fibers in phenolic resin-based composite. Composite fabrication was done by hand lay-up in this study. Bamboo fibers arranged in two kinds of directions; single direction (uni direction) and double direction (two directions). The mechanical properties of composite were inspected by testing the tensile strength and shear strength of the punch, the structure of the interface bond between the reinforcing fibers and the matrix was checked by testing the micro structure.

2. Experiment

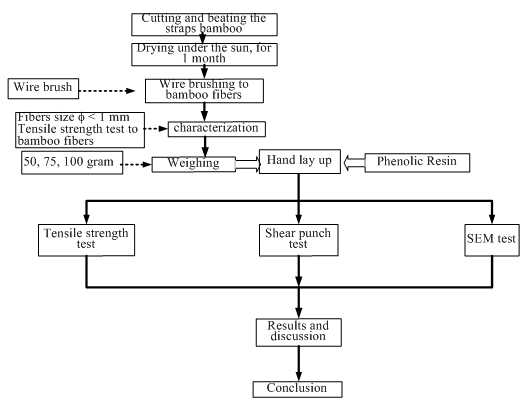

2.1. Flow chart of study

2.2. Preparation of Materials

- The study utilized natural fibers which were the raw bamboo fibers; bamboo fibers used was of type of strap bamboo. Bamboo was cut in 400 mm length, the pieces was hit with a hammer or flat iron, the pieces cracked and the fibers will split each other, the separated fibers were wire brushed to reach a diameter of < 5 mm. The bamboo fibers were then dried under the sun for 1 month.

2.3. Testing the Tensile Strength of Bamboo Fibers

- Tests conducted on 50 sheets of bamboo fibers cross- sectional with a diameter of < 0.5 mm. Preparation of fibers tensile test specimens follows the standard ASTM D 3379-75. The mechanical properties of the fibers tensile strength was tested with standard tensile machine by following the ASTM D-882.

2.4. Fabrication of Uni Direction Composite Specimens

- Dry bamboo fibers were weighed according to the proportion specified 50 grams, 75 grams and 100 grams, appropriate to the volume of mold tray. Bamboo fibers were arranged in the tray in one direction and one layer, the appropriate panel size 10 x 280 x 280 mm, by way of hand lay-up, and then resin phenol poured. The samples identities were 1D1L 50; 1D1L 75; 1D1L 100.

2.5. Fabrication of Two Direction Composite Specimens

- Dry bamboo fibers were arranged perpendicular to each other in the tray in two layers, by way of hand lay-up. The weight of the fibers was 50 grams, 75 grams and 100 grams, appropriate to the volume of the mold tray. The identities of the samples were 2D2L 50; 2D2L 75; 2D2L 100.

2.6. Standardization of Shape and Dimension

- The composites panel were cut perpendicular and parallel to the fiber's orientation [11]. Cutting was done by cutting grinding machine. Panel specimens were cut in the size of 10 x 10 x 160 mm with a milling machine, to achieve the size and shape of tensile test specimens. To achieve the size and shape of the punch shear test specimen, specimen panels was cut in the size of 100 x 100 x 10 mm.

2.7. SEM Testing

- SEM testing was conducted to determine the micro structure of composites, especially at the interface of the fibers / polymer. Test was conducted with the SEM JEOL JSM-6390A.

2.8. Testing the Tensile Strength of Composite

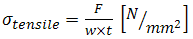

- Testing the tensile strength of bamboo fiber composite was conducted with machine UTM (universal testing machine), Tarnotesting. TARNOGROCKI, GA 0,3V / 483. The tensile strength of the test specimen was calculated with the following formula:

| (1) |

is the tensile strength of composite specimens, F is the tensile test load [N], w is the width of the tensile test specimen cross section [mm], t is the thickness of the tensile test specimen cross section [mm].

is the tensile strength of composite specimens, F is the tensile test load [N], w is the width of the tensile test specimen cross section [mm], t is the thickness of the tensile test specimen cross section [mm].2.9. Punch Shear Strength Testing of Composite

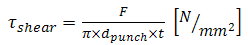

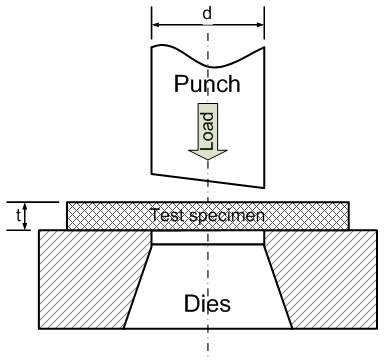

- Testing of punch shear strength of composite specimen was performed with machine UTM (universal testing machine), Tarnotesting, TARNOGROCKI, GA 0,3V / 483. The machine was equipped with a press tool (punches and dies), and the shear strength is calculated by the following formula:

| (2) |

| Figure 2. Press tool of punch shear test |

is punch shear strength of composite specimens, F is the shear punch test load [N], d is the diameter of the punch [mm], t is the thickness of composite test specimen [mm].

is punch shear strength of composite specimens, F is the shear punch test load [N], d is the diameter of the punch [mm], t is the thickness of composite test specimen [mm].3. Result and Discussion

3.1. Testing the Tensile Strength of Bamboo Fiber

- Testing of tensile strength of bamboo fibers was done by following the ASTM standard D-882, the number of test specimens of 50 sheets of bamboo fibers. Test results showed the fibers tensile strength average 359 N/mm2, with a modulus of elasticity of 2508 N/mm2. For comparison, Wiphawee Nuthong, et al., in the journal Energy Procedia 34 (2013) provided data bamboo fibers tensile strength 441 N/mm2 and a modulus of elasticity of 35900 N/mm2 [4] [5]. Graph testing the tensile strength of bamboo fibers is shown in Figure 3.

| Figure 3. Tensile test of bamboo fibers |

3.2. Results of the Composite Tensile Strength Test

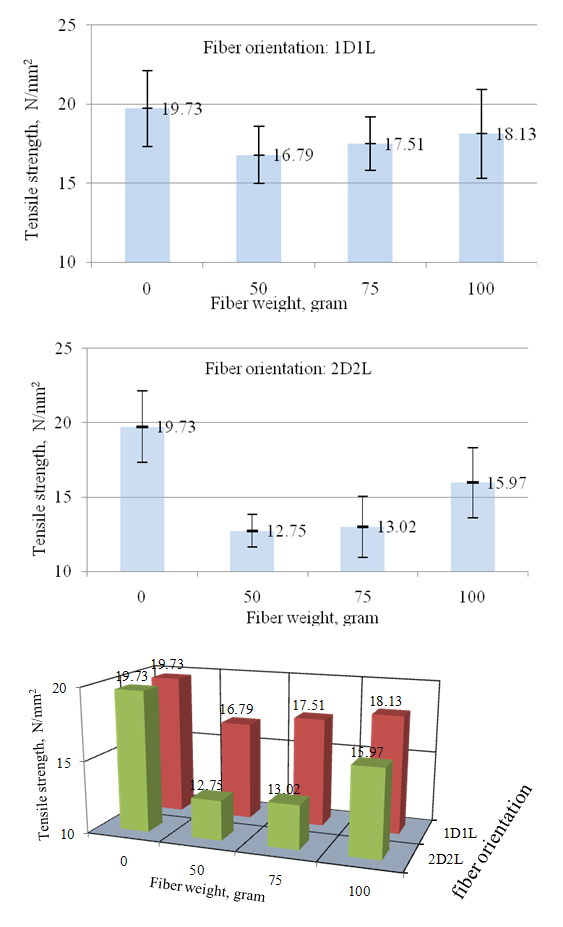

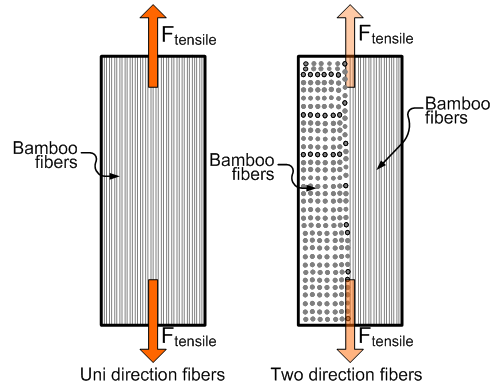

- Composite tensile strength test results showed that the higher the content of bamboo fibers in the composite the higher the tensile strength of composite. This applies to two types of composites, both in uni direction and the two directions. However, the test results also showed that the tensile strength of the phenol resin was not increased by the presence of bamboo fibers in it, from the test results and analysis indicated the tensile strength of phenol resin without fibers was higher than the composite strength of bamboo fibers and phenol resin. This is shown in Figure 4, the results of tensile strength test of phenol resin was 19.73 N/mm2. Meanwhile, phenol resin composites containing 50 grams of bamboo fiber's uni direction yielded tensile strength of 16.79 N/mm2, and the composite of two direction produced tensile strength of 12.73 N/mm2. It thus was also experienced by Wassamon Sujaritjun et al., In Energy Procedia 34 (2013), which stated that the tensile strength of natural fibers reinforced PLA of composite did not show an increase when compared to net PLA [5]. Bamboo fibers composites containing 100 grams of type uni direction yielded tensile strength of 18.13 N/mm2, and the type of two direction yielded tensile strength of 15.97 N/mm2. The results of tensile strength testing of the two types of composites showed that the composite type of uni direction was stronger than the composite type of two directions. Meanwhile, Wassamon Sujaritjun, et al., in the journal Energy Procedia 34 (2013) fabricated PLA composite reinforced bamboo fibers, vetiver grass fibers and coconut fibers. PLA composites with bamboo fibers tensile yielded strength up to 50 MPa, PLA composite with vetiver grass fibers tensile yielded strength up to 45 MPa, and PLA composite with coconut fibers tensile yielded strength of 50 MPa [5]. Composite type of uni direction is more resistant to tensile load than two type of composite direction, because, all bamboo fiber's arrangement of uni direction parallel to the load, while, for arrangement of fibers composite bidirectional split in two, half the fiber's arrangement of parallel to the direction of tensile testing workload and a half arrangement of fibers perpendicular to the direction of the tensile test workload. Sketch of relationships fibers direction and the direction of the tensile test load are shown in Figure 5.

| Figure 4. Relationship of tensile strength, fiber weight and fiber orientation |

| Figure 5. Relationship of tensile force and fibers direction |

3.3. Punch Shear Strength Test Results

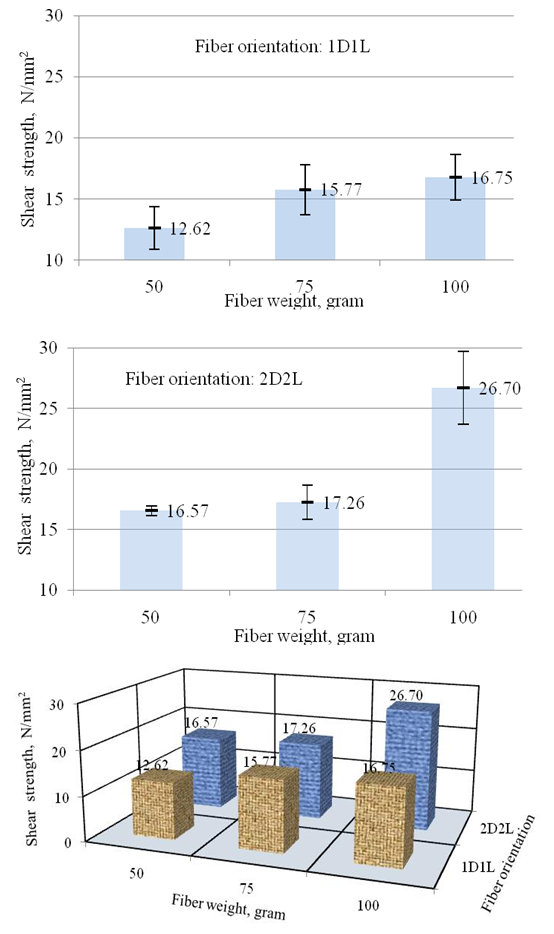

- Punch shear strength test results showed that the higher the bamboo fibers content in the composite, the higher the punch shear strength of the composite. This applied to two type’s composite, both in uni direction and the two directions. Figure 6 shows the punch shear strength values of bamboo fibers / polymer composite. Composite of uni direction type with a content of 50 grams of bamboo fibers showed punch shear strength of 12.62 N/mm2, and a composite of two directions showed the punch shear strength of 16.57 N/mm2. Meanwhile, composite containing 100 grams of bamboo fiber, for this kind of uni direction showed the punch shear strength of 16.75 N/mm2, and the two direction type composite produced the punch shear strength of 26.70 N/mm2. Based on the fibers content, the higher the fibers content the higher the punch shear strength of composite, but the direction of the fiber's arrangement showed that the composite with bidirectional fibers perpendicular produced higher punch shear strength than the composite of uni direction. This was contrary to the results of testing of tensile strength of the composite. Punch shear strength test results could not be compared to the results of other studies, based on the study of the journal article that there were no studies that perform this test.

| Figure 6. Relationship of shear strength, fiber weight and fiber orientation |

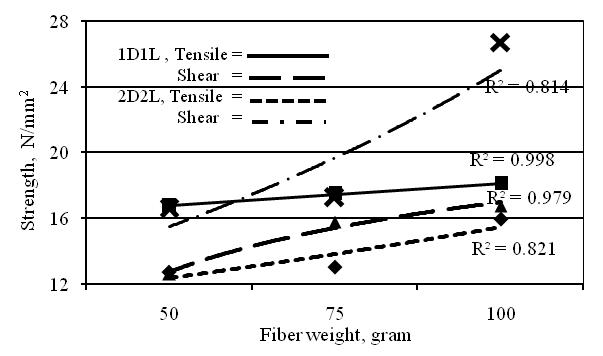

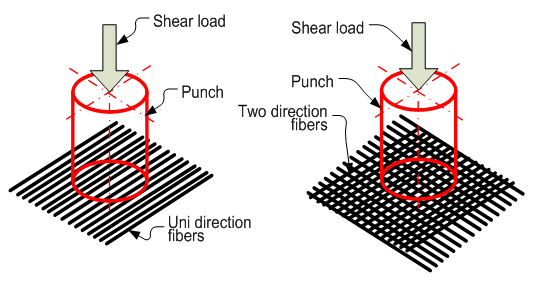

3.4. Relationship Tensile Strength and Shear Strength Punch

- In the process of loading the tensile test, the load pulled out the fibers from polymer adhesiveness of phenol resin, while the shear punch test load trimmed perpendicular to the direction of the fibers. This process produced different types of strength although in the same unit. The Highest punch shear strength shown by composite of two directions (2D2L) was 26.70 N/mm2, while the tensile strength of the composite yielded 15.97 N/mm2. In uni direction composite tensile strength was higher than the punch shear strength. In uni direction composite, containing 100 grams of fibers, yielded tensile strength of 18.13 N/mm2, and the punch shear strength of 16.75 N/mm2. All types of composite in this study showed an increase in tensile and shear strength, concurrent addition of bamboo fiber content, as shown in Figure 7. Punch shear strength of composite bidirectional was higher than the tensile strength. Meanwhile, the punch shear strength of the uni direction composite was lower than the tensile strength. This was caused by fiber's defence against the direction of punch shear test load. Composite types of uni direction maintain direction of shear loads only in two opposite directions. Meanwhile, the composite types of bidirectional sustained the load direction in four directions perpendicular to each other. As shown in Figure 8.

| Figure 7. Relationship of shear and tensile strength |

| Figure 8. Sketch shear load on the fiber direction |

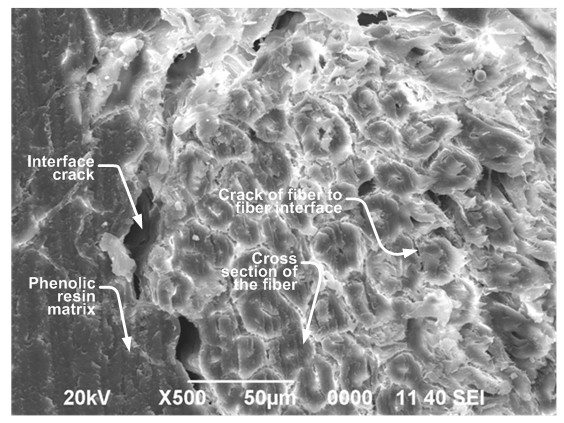

3.5. Interfacial between Bamboo Fibers to the Polymer Matrix

- Wiphawee Nuthong, et al., in the journal Energy Procedia 34 (2013), stated that the decrease in impact strength or mechanical properties of the composite was a result of the interfacial bond between the fiber and the matrix [4]. Likewise, expressed by Wassamon Sujaritjun, et al., in the journal Energy Procedia 34 (2013) that the increase in the tensile strength of the composite due to the better interfacial adhesion between the fibers to matrix. Interfacial bonding between the fiber and the matrix played an important role on the mechanical properties of natural fiber reinforced composites [5]. It so occurred that tensile strength and punch shear strength of the composite in this study, which is shown in the SEM test results. Figure 9 shows the state of the micro structure of the bamboo fibers / phenol resin composite. The micro structure of the composite showed a crack at the interface between the matrix and bamboo fibers. Cracks also occurred between adjacent bamboo fibers. Cracks or cavities can occur may be caused by the evaporation of the water content of bamboo fiber when it reacts with phenol resin. Cavities cracks caused weakness mechanical properties of the composite as a whole, because the loads transfer between the matrix to the fiber was interrupted by crack's cavity. Load transfer between the fibers to fibers next to them is also interrupted by crack's cavity. Thus, these conditions triggered the weakening of the mechanical strength of the composite.

| Figure 9. The state of composite microstructure interface |

4. Conclusions

- Bamboo fibers-reinforced polymer composites (BFRP) have been fabricated in two types, uni direction and two directions, for the purpose of manufacture of construction materials in the form of panels. Composite of bamboo fibers / phenol resin of uni direction type (1D1L) produced tensile strength of 17 – 18 N/mm2, and punch shear strength of 13 – 17 N / mm2. Composite of bamboo fibers / phenol resin of two direction type (2D2L) produced tensile strength of 13 – 16 N/mm2, and punch shear strength of 17 – 27 N/mm2. Composite of uni direction types (1D1L) produced greater tensile strength than the composite of two direction type (2D2L). Composite of two direction type (2D2L) produced punch shear strength greater than any kind of uni direction (1D1L).Fabrication of composite of phenol resin reinforced bamboo fibers potentially formed interface cracks cavity between fibers to the matrix, and the fibers to fibers.

ACKNOWLEDGMENTS

- The authors wish to thank the directorate of research and community service, the directorate general of higher education, ministry of education and culture of the Republic of Indonesia for funding this research work. This research was funded through a national strategy research scheme with the contract number: 41 / PL3.B / SPK / 2014, April 29, 2014.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML