-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2014; 4(4): 179-184

doi:10.5923/j.cmaterials.20140404.01

Investigation of Hardness and Wear Behavior of Dental Composite Resins

Omer Sagsoz1, Nurcan Ozakar Ilday1, Nurdan Polat Sagsoz2, Yusuf Ziya Bayindir1, Akgun Alsaran3

1Department of Restorative Treatment, Faculty of Dentistry, Ataturk University, Erzurum, 25240, Turkey

2Department of Prosthodontics, Faculty of Dentistry, Ataturk University, Erzurum, 25240, Turkey

3Department of Mechanical Engineering, Ataturk University, Erzurum, 25240, Turkey

Correspondence to: Omer Sagsoz, Department of Restorative Treatment, Faculty of Dentistry, Ataturk University, Erzurum, 25240, Turkey.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Aim: To investigate wear and microhardness of different dental composite materials and to examine their relevance.Materials and Methods: Seven different composite materials (three micro-hybrid: Filtek Silorane, Filtek Z250, Clearfil APX; two nano-filled: Filtek Supreme XT, Majesty Posterior; a nano-hybrid: Grandio; a nano-ceramic: Ceram X duo) were used. Cylindrical specimens from each material were prepared (n=5). Microhardness of the specimens was measured using a Vickers hardness tester. Wear tests were performed on a conventional pin-on-disk tribometer. Wear was measured with a surface perthometer. The samples have been studied by using a scanning electron microscopy. Data were analyzed statistically.Results: There were significant differences between groups in terms of wear performance and microhardness values. Conclusion: Composites' hardness values did not reflect improved wear performance.

Keywords: Two-body abrasion, Polymer-matrix composite, Hardness, Contact mechanics, Electron microscopy

Cite this paper: Omer Sagsoz, Nurcan Ozakar Ilday, Nurdan Polat Sagsoz, Yusuf Ziya Bayindir, Akgun Alsaran, Investigation of Hardness and Wear Behavior of Dental Composite Resins, International Journal of Composite Materials, Vol. 4 No. 4, 2014, pp. 179-184. doi: 10.5923/j.cmaterials.20140404.01.

1. Introduction

- Since composite materials have been used instead of amalgam it has become a matter of concern for manu-facturers to achieve ideal composite properties. There are many restorative composite brands available, and these vary according to their area of use on the tooth and dental arch (anterior, posterior, cervical, etc.). Modern composites have excellent mechanical properties and are suitable for all restorations, even on the posterior of the dental arch [1], but they are still not perfect materials [2]. While development of composite materials is proceeding, insufficient material properties can reduce their longevity [3]. Wear and hardness are important factors in materials used in dentistry. Dental materials must be durable to have long-term functions. Masticatory forces may alter the anatomic form of restorations with inadequate wear resistance. Wear performance of restorations is crucial, as occlusion has to be continuous. This property directly affects the restoration life [4]. The wear mechanism is affected by different filler loads and resin matrix [5, 6]. Generally, wear is closely associated with the mechanical properties of materials, such as hardness and flexural strength [7].Clinical wear is a complex mechanism. However, wear resistance of materials is determined using different techniques in vitro. Simulation techniques are performed with tooth brushing machines, two-body wear machines and three-body wear machines [8]. The working principle of tooth brushing machines is to bring toothbrushes into contact with specimens and for these to move along programmed paths. Generally a pin-on-disk design is used for two-body wear. Abrasive material contacts with specimens under load and circular or linear reciprocating movements are performed [9]. In three-body wear, an abrasive slurry acts as a substitute for food and causes wear between opposing surfaces [9, 10]. All these tech-niques accurately correspond to clinical wear but are used to estimate material properties.The purpose of this study was to evaluate wear characteristics and microhardness of different composite resins and to investigate any correlation between these properties.

2. Methods

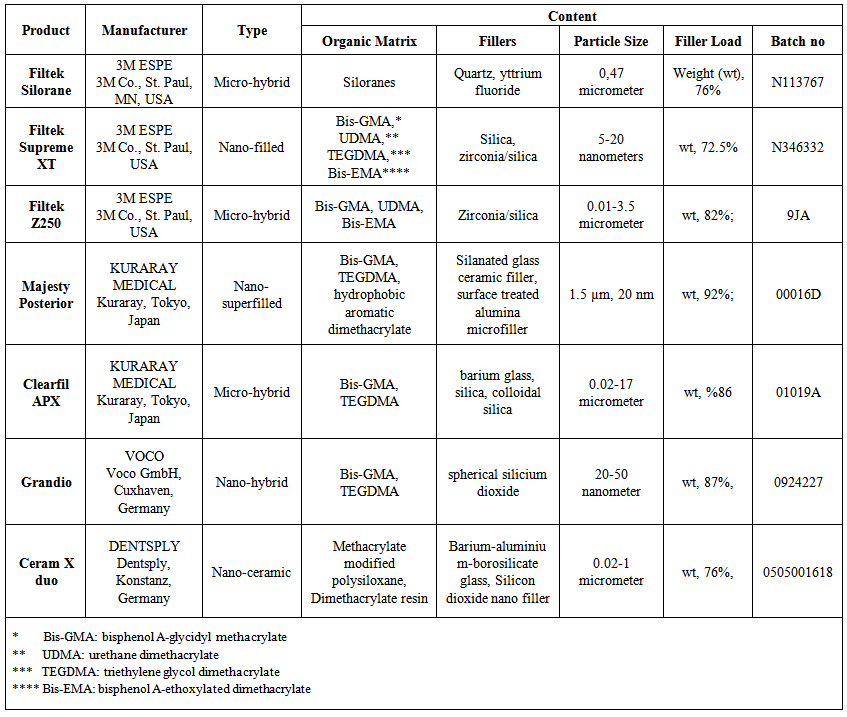

- The tested materials were 7 different commercially available composite restorative resins (Grandio, Clearfil Majesty Posterior, Filtek Supreme XT, Clearfil APX, Filtek Z 250, Filtek Silorane and Ceram X duo) (Table 1).

| Table 1. Composition of test composites (provided by manufacturers) |

3. Results

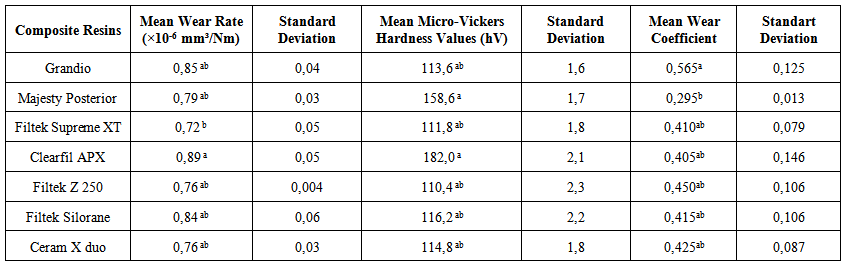

- Vickers hardness values for Clearfil Majesty Posterior and Clearfil APX were significantly higher than those for the other groups (p<0.05). All mean hardness values are listed in Table 2. The highest mean hardness value was obtained from Clearfil APX (182 hV [hardness Vickers]) and the lowest from Filtek Z 250 (110,4 hV).

| Table 2. Composite wear rate, wear coefficient, and Vickers hardness values (means within columns with the same superscript were not different) |

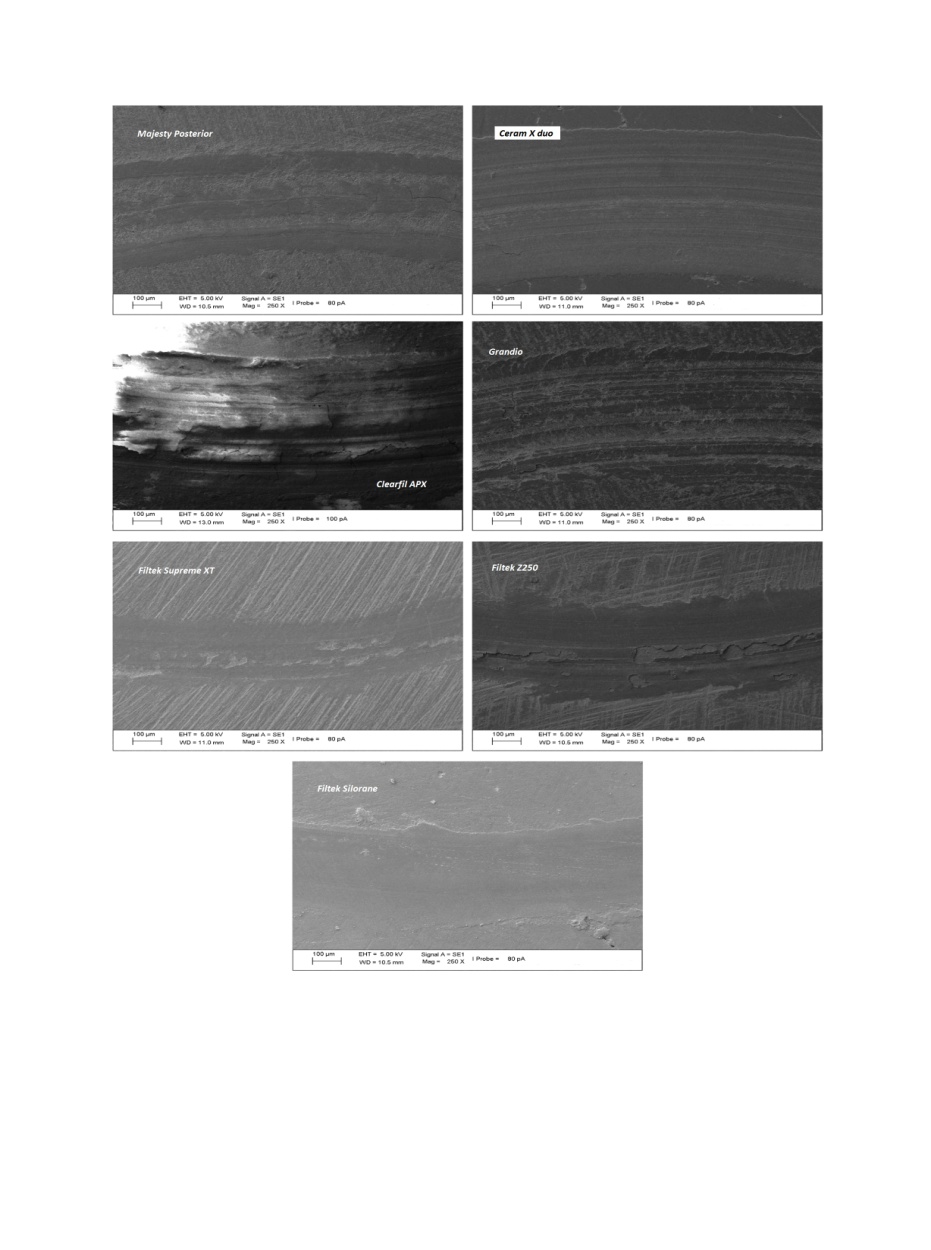

| Figure 1. Scanning electron microscope images of weared composite resins |

- Pearson correlation analysis of surface hardness and wear resistance showed no correlations between these properties.

4. Discussion

- This in vitro study investigated wear and hardness properties of different composite restorative resins. A pin-on-disk tribometer was used to perform wear tests. The contact load was 10 N, within the limits described by Lambrechts et al. [8] The antagonist diameter was 6 mm, which replicates that of the molar cusp [11].The wear distance was 20 m, which was 16.6% of that used by Hahnel et al. (120,000 cycles, 1 mm lateral movement); 8.3% of a 120,000 wear cycle has been demonstrated to be adequate to show a material’s wear performance [12].Hardness plays an important role in characterizing and comparing dental restorative materials [13, 14]. This property is affected by material content. Particle type, level and size of filler and type of resin matrix are all associated with hardness [15, 16]. Degree of polymerization is also associated with hardness [17]. In this study, Vicker’s hardness values were calculated for all composite groups (Table II). The results for Silorane, Supreme XT and Z250 were well-matched with findings reported by Hahnel et al. [18] However, Topcu et al. [19] reported different results for hardness values; in descending order, Majesty Posterior, Clearfil APX, Z 250, Supreme XT and Ceram X. Curing methods may generate these differences with changes in degree of conversion having a positive correlation with hardness [20].The wear of dental composites is a complex combination of wear mechanisms [21]. Clinically, two-body wear occurs indirectly on proximal contact areas [22], and on occlusal surfaces during swallowing, mastication and parafunctions [21, 23]. In three-body wear, progress of the food bolus acts as an abrasive between occlusal surfaces of opposing teeth or restorations. Direct contact between opposing surfaces generally means attrition in two-body wear, whereas in three-body wear, food being forced over opposing surfaces causes abrasion [24]. However, interactions of attrition and abrasion take place in the wear mechanism in vivo [25]. In vitro tests cannot identically mimic in vivo conditions, but exhibit parallelism with prediction of materials’ performance. The wear mechanisms of the composite materials were initially started as adhesive wear, and progressed as abrasive wear. Generally, abrasive particles are clear in wear tracks. While observing Filtek Z250, there seems to be layer separation in wear tracks as delamination (Fig.1) Results from this study showed that Filtek Supreme XT had the lowest wear and Clearfil APX the highest among the groups. Kawai et al. studied different experimental resins containing Bis-GMA, UDMA, TMPT and TEGDMA and reported that wear rose with increasing amounts of Bis-GMA [26]. Comparing Clearfil APX and Supreme XT in our study, the difference in wear loss may be the result of resin matrix content. Unlike Clearfil APX, Supreme XT includes not only Bis-GMA and TEGDMA, but also UDMA and Bis-EMA in the resin matrix, so the amount of Bis-GMA may be reduced. Hu et al. that evaluated the effect of filler loading on two-body wear and reported dramatically increased wear above an 80 wt% filler load [27]. In our study, Clearfil APX had an 86 wt% filler load and the highest wear value, whereas Filtek Supreme XT had a 72.5 wt% filler load and the lowest wear value. However, Majesty Posterior with its 92 wt% filler load did not differ significantly in terms of wear values from Filtek Silorane, which has a 76 wt% filler load. One possible explanation is that different filler types and sizes of composites affect wear resistance. The relationship between wear and hardness has also been studied, and different authors have reported incompatible results. Two-body and three-body wear tests are used to simulate in vivo conditions, and one may produce totally different outcomes to the other. Hu et al. [28] observed different results with same composite material under different test conditions with two-body and three-body wear. The wear of materials is generally considered to be related to their mechanical properties [7]. Freidrich [29] describes a relationship between mechanical properties and wear resistance, with composite hardness inversely affecting wear resistance. Compatibly, Nagarajan et al. [30] reported that harder composites suffer higher wear than softer composites. Tamura et al. [7] also found that the worn volume of different composites rose in line with the increase in Vicker’s hardness. Ramalho and Antunes, [31] however, suggested that hardness is a function of wear resistance. Faria et al. [32] investigated the relationship between the surface hardness and wear resistance of indirect composites and reported that material wear decreases as its hardness increases. In this study, however, the correlation between hardness and wear properties was poor. In the same way, Hahnel et al. [18] determined no significant correlations between wear and Vicker’s hardness in two-body wear research. Different wear test methods may account for the inconsistent results in the literature. Conflicting wear results with two- and three-body wear tests were obtained by Koottathape et al. [33] for the same composites. Mayworm et al. [34] suggested that abrasive wear, which is a result of three-body wear test, is inversely proportional to hardness. However, Nagarajan et al. [30] and Hahnel et al. [18] studied two-body wear of composites and determined a direct correlation between wear and hardness.Although the correlation was statistically poor in this study, hardness values of composite resins appear to follow wear volumes, with the exception of Grandio. Clearfil APX was the hardest of all composites. It was also the most worn material. Supreme XT and Z 250 had the lowest hardness and wear values. These results may be attributed to detached particles acting as abrasives, as discussed for enamel wear by Eisenburger and Addy [35]. Particles detached from harder composites may collaborate with antagonists to make the wear process more effective.

5. Conclusions

- Teeth and restorations are frequently exposed to mechanical forces in the oral environment. Restoration wear is an increasing problem, and extensive wear over many years often ends in restoration renewal. There is no ideal material currently available to satisfy patients who are expecting restorations to last a life time. We conclude that hardness value is not an indicator of wear behavior for all materials. Further studies should be performed to evaluate the correlation between wear and hardness, comparing different wear tests and curing methods.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML