Marília da Silva Bertolini1, Cristiane Inácio de Campos2, Amós Magalhães de Souza1, Tulio Hallak Panzera3, André Luis Christoforo4, Francisco Antonio Rocco Lahr5

1Department of Materials Engineering, Engineering School of São Carlos (EESC/USP), São Carlos, 13566-590, Brazil

2Department of Wood Engineering, Paulista State University, Campus of Itapeva, Itapeva, 18409-010, Brazil

3Centre for Innovation and Technology in Composites – CITeC, Department of Mechanical Engineering, Federal University of São João del-Rei, São João del-Rei, 36307-352, Brazil

4Centre for Innovation and Technology in Composites – CITeC, Department of Engineering Civil, São Carlos Federal University, São Carlos, 13565-905, Brazil

5Department of Structural Engineering, Engineering School of São Carlos (EESC/USP), São Carlos, 13566-590, Brazil

Correspondence to: André Luis Christoforo, Centre for Innovation and Technology in Composites – CITeC, Department of Engineering Civil, São Carlos Federal University, São Carlos, 13565-905, Brazil.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Abstract

The aim of this research was to produce and evaluate mechanical performance in compression parallel to the grain for composites made with wastes from Pinus sp. and Portland cement. To obtain the composites were used treated and untreated wood particles, average size 1.7mm, and Portland cement-II-E-32, determining a ratio for cement/wood/water of 1: 0.21: 0.6. Treatment of particles was based on thermal bath in water for a period of 6 hours. Effect of treatment on density and mechanical properties of these composites was analyzed, according to NBR 7215:1996. Results showed that inclusion of treated wood particles in manufacture of wood-cement composite was significant in all properties investigated, by reducing density (7%); increasing modulus of elasticity (126%) and compressive strength (70%). Large gains in these properties demonstrate the feasibility of wood-cement composites manufacture.

Keywords:

Composites, Wood wastes, Particles treatment, Portland cement, Physical-mechanical properties

Cite this paper: Marília da Silva Bertolini, Cristiane Inácio de Campos, Amós Magalhães de Souza, Tulio Hallak Panzera, André Luis Christoforo, Francisco Antonio Rocco Lahr, Wood-Cement Composites from Wastes of Pinus Sp. Wood: Effect of Particles Treatment, International Journal of Composite Materials, Vol. 4 No. 2, 2014, pp. 146-149. doi: 10.5923/j.cmaterials.20140402.14.

1. Introduction

Nowadays, one can note increasing the concern for recycling, reuse and rational exploitation of natural resources, since most of the raw materials are becoming scarce due to poor planning in relation to their use. Another issue is the negative environmental impact caused by many materials, such as asbestos and various types of polymers, which triggered the search for environmentally friendly inputs. [1].Cement-wood composites are constituted of fibers/vegetal particles, mineral type binder, water and chemical additives, which are consolidated under pressure at room temperature [2]. These products have many advantages such as no emission of toxic during their manufacture and reduced cost due to cure without applying high temperatures [3, 4]. Moreover, panels made from these composites have high versatility in terms of finish, may be sawn, nailed, screwed, glued and towed; allowing wide application [5] as flat roofing, prefabricated structures, mobile homes, permanent formwork, cladding, sound barriers and paving, because they work as structural insulation panels [6].Wood wastes have been potential materials for application in these composites, such as Eucalyptus grandis [7], wood preserved with pesticide containing creosote [8], tropical woods [9], Jack pine (Pinus banksiana) wood chips [10], among others. Karade [6] cites the possibility of using various lignocellulosic wastes as rice straw, coir, cork granules, hazelnut shell, oil palm, arhar stalks, bagasse; as well as residues from wood products - construction demolition wastes and furniture industry (waste MDF, timber, barks).In this context, this study aimed to produce and characterize wood-cement composites reinforced with Pinus sp. wastes.

2. Material and Methods

Manufacture of composites and testsPinus sp. were obtained in sad sawmills in form of shavings, from Itapeva region, São Paulo State, Brazil. Distilled water was used for composites hydration and Portland cement II-32 as a binder. Wood wastes were converted into particles (Figure 1) in a knife mill Marconi model MA-680. Particles retained between sieves with openings of 10 and 20 mesh were selected, with dimensions closed to 1.7 mm. | Figure 1. Wastes from Pinus sp. wood (a) and particles obtained (b) |

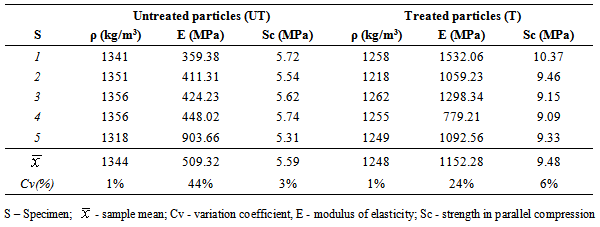

Treatment of particles aimed at removing extractives which could inhibit cement curing. Adapting procedure used by Beraldo e Carvalho [11], particles were immersed in distilled water at 80°C, using a thermal bath QUIMIS Q 250-E. Immersion was performed in three cycles (2 hours each), with subsequent washing of the particles in cold water. After, particles were dried in a drying oven at 105 (±) 1°C to remove moisture.Proportion of cement/biomass/water used in the composites was 1/0.21/0.6. Experimental conditions were obtained according to type of biomass and treatment. Composites production consisted of mixture of the dry components - cement and particles, and after added to water. Six specimens were produced for each condition, cylindrical format and with dimensions of 50 x 100 mm (Figure 2). Specimens were removed from their molds after 48 hours, stored for 5 days in a plastic bag, to prevent cracking and 21 days outdoors, totalizing 28 days curing. Process of manufacturing and curing of specimens was adapted from Beraldo et al. [12], with some adjustments. | Figure 2. Specimens made with untreated wood (a) and with treated wood particles (b) |

Properties of composites such as strength and modulus of elasticity in compression parallel to the grain were determined according to NBR 7215 [13] and NBR 8522 [14]. Density of composites was obtained by the ratio between mass and volume of specimens.Statistical AnalysisTo investigate the influence of treated particles on properties of density (ρ), modulus of elasticity (E) and strength (Sc) in parallel compression of wood-cement composites, analysis of variance (ANOVA) - Kruskal-Wallis (non parametric) and Student-Newman-Keuls - multiple comparisons test, by BioEstat ® version 5.0 software, were used. The significance level (α) set for ANOVA was 5%. The null hypothesis (H0) was the equivalence between means and alternative hypothesis (H1) was related to non-equivalence of averages. P-value from Kruskal-Wallis test below the significance level implies rejecting H0, accepting it otherwise.

3. Results and Discussions

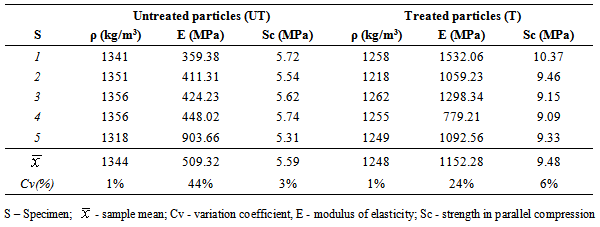

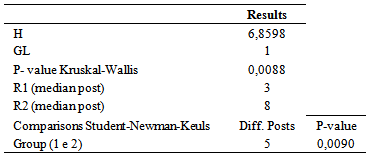

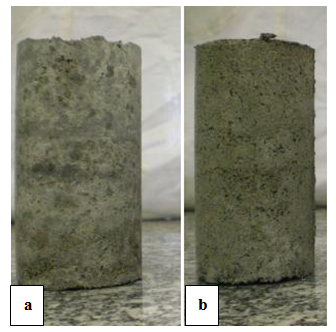

Table 1 shows results of physical and mechanical properties for composite cement-wood, with and without fiber treatment.Table 1. Results of physical and mechanical properties for composite cement-wood

|

| |

|

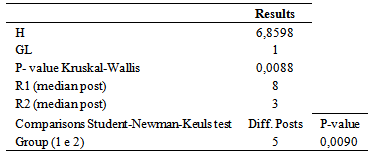

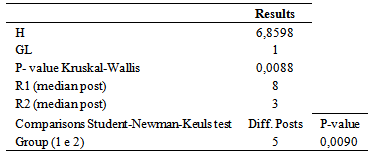

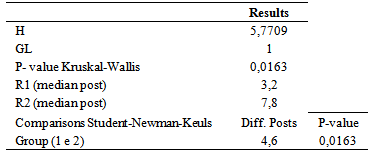

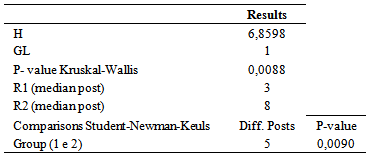

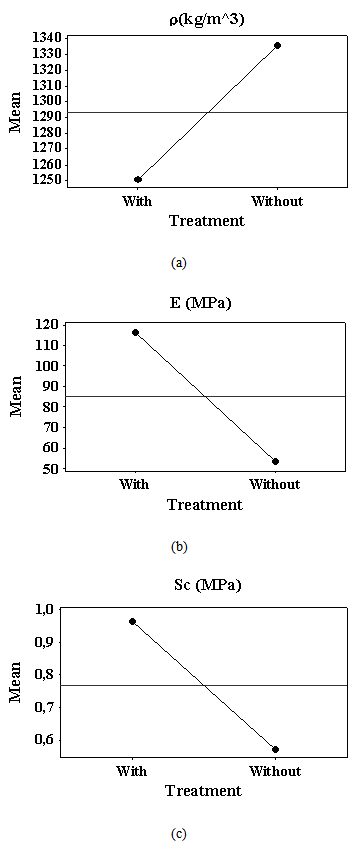

Regarding the density, it was noted that values found are consistent with literature, compared to similar composites of 1.20 g/cm³ reinforced with 20% of Eucalyptus grandis particles [7]. After treatment of Pinus sp. particles, composites showed a lower density, possibly due to extractives removal.Torkaman et al. [15] obtained compression strength to cementitious composites, containing 25% wood, approximately, 1.6 MPa in compression. It should be emphasized the values obtained in present study, with quantities of reinforcing fibers (≈ 20%), resulting in Sc around 5MPa for non-treated particles (UT) and approximately 10 MPa for treated particles (T). In addition to particles treatment, longer cure times can increase this property, according to a study involving composites of this type [16], which compared cure times of 28 and 90 days. In terms of elasticity (E), treatment of wood particles used as reinforcement resulted in increases of 126%.Tables 2 to 4 present results of ANOVA Kruskal-Wallis test of properties investigated for two treatments evaluated. GL are degrees of freedom R1 and R2 median posts related to particles untreated and treated, respectively.Table 2. Results of ANOVA Kruskal-Wallis for density

|

| |

|

Table 3. Results of ANOVA Kruskal-Wallis for modulus of elasticity in parallel compression

|

| |

|

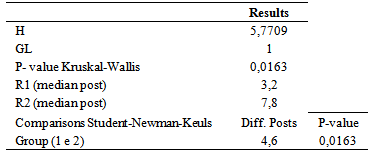

Table 4. Results of ANOVA Kruskal-Wallis for strength in parallel compression

|

| |

|

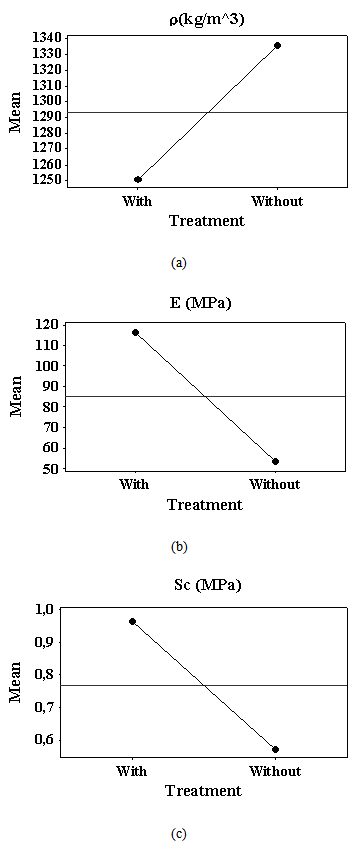

From Tables 2 to 4 it was noted that wood particles treatment was significant in the three properties (P-value <0.05). Particles treatment was responsible for reduction of 7% in composites density and increased values of strength and elasticity in parallel compression at 126% and 70%, respectively, as can be seen in Figure 3. | Figure 3. Graphs of main effects: density (a), modulus of elasticity in compression (b) and compression strength (c) |

Studies of Lima [17] showed that thermal bath of wood particles can provide a positive effect on the compressive strength, and result in a lower loss value for the consistency (final-initial consistency) and, consequently, greater fluidity mortar.

4. Conclusions

Inclusion of treated wood particles in the manufacture of wood-cement composite was significant in all three properties investigated, by reducing the density values (7%) and increase values of modulus of elasticity (126%) and compressive strength (70%) compared to composites made from untreated wood. Large gains in these properties demonstrate the feasibility of wood-cement composites manufacture.

References

| [1] | M. S. Bertolini. Produção e avaliação das propriedades físico-mecânicas de compósitos lignocelulósicos produzidos a partir de madeira de Pinus sp., bambu da espécie Dendrocalamus giganteus e cimento Portland [monograph]. Itapeva (SP): São Paulo State Univesity “Júlio de Mesquita Filho”, 2009. |

| [2] | V. A. Sá, L. Bufalino, V. C. S. Albino, A. A. Corrêa, L. M. Mendes, N. A. Almeida. Mixture of three reforestation species on the cement-wood panels production. Revista Árvore, Vol.36, n.3 (2012), p.549-557. |

| [3] | A. J. M. Lima, S. Iwakiri, M. G. Lomelí-Ramirez. Use the residue of Pinus spp. high reactivity metakaolin and residue of ceramic calcined in wood-cement composites. Madera Y Bosques, Vol. 17, n.2 (2011), p.47-65. |

| [4] | S. Iwakiri: Painéis de Madeira Reconstituída (FUPEF, Curitiba 2005). |

| [5] | A. MATOSKI. Utilização de pó de madeira com granulometria controlada na produção de painéis de cimento-madeira [PhD thesis]. Curitiba (PR): Federal University of Paraná, 2005. |

| [6] | S. R. Karade. Cement-bonded composites from lignocellulosic wastes. Construction and Building Materials, 24, 1323–1330, 2010. |

| [7] | R. M. Ronquim, F. S. Ferro, F. H. Icimoto, C. I. Campos, M. S. Bertolini, A. L. Christoforo, F. A. Rocco Lahr. Physical and Mechanical Properties of Wood-Cement Composite with Lignocellulosic Grading Waste Variation. International Journal of Composite Materials, 4(2): 69-72, 2014. |

| [8] | A. Ashoria, T. Tabarsab, F. Amosib. Evaluation of using waste timber railway sleepers in wood–cement composite materials. Construction and Building Materials, 27 (1), 126–129, 2012. |

| [9] | M. Fan, M. K. Ndikontar, X. Zhou, J. N. Ngamveng. Cement-bonded composites made from tropical woods: Compatibility of wood and cement. Construction and Building Materials, 36, 135–140, 2012. |

| [10] | P. Tittelein, A. Cloutier, B. Bissonnette. Design of a low-density wood–cement particleboard for interior wall finish. Cement & Concrete Composites, 34, 218–222, 2012. |

| [11] | A. L. Beraldo, J. V. Carvalho. Portland cement – Eucalyptus grandis composite. Scientia Forestalis, n. 65, p. 150-161, jun. 2004. |

| [12] | A. L. Beraldo, A. C. Arruda, A. C. Stancato, C. A. P. Sampaio, O. P. Fernandes Filho, V. M. Leonel. Vegetable waste Portland cement composite, in: Brazilian Meeting on Timber and Timber Structures - EBRAMEM, 8, MG (2002), CD-ROOM. |

| [13] | ABNT. Brazilian Technical Standards Association. NBR 7215: Portland cement - Determination of compressive strength. Rio de Janeiro, 1996. |

| [14] | ABNT. Brazilian Technical Standards Association. NBR 8522: Concrete - Determination of the elasticity modulus by compression. Rio de Janeiro, 1984. |

| [15] | J. Torkaman, A. Ashori, A. S. Momtazi. Using wood fiber waste, rice husk ash, and limestone powder waste as cement replacement materials for lightweight concrete blocks. Construction and Building Materials, 50, 432–436, 2014. |

| [16] | A. N. Givi, S. A. Rashid, F. N. A. Aziz, M. A. M. Salleh. Assessment of the effects of rice husk ash particle size on strength, water permeability and workability of binary blended concrete. Construction and Building Materials, 24, 2145–2150, 2010. |

| [17] | A. M. Lima. Influência de três tipos de tratamentos físicos na resistência à compressão de compósitos cimento-madeira à base de resíduos de serraria [dissertation]. Belém (PA): Federal University of Pará, 2005. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML