-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2014; 4(2): 108-124

doi:10.5923/j.cmaterials.20140402.10

Fracture Toughness of AA2024 Aluminum Fly Ash Metal Matrix Composites

Ajit Bhandakkar1, R C Prasad1, Shankar M L Sastry2

1Department of Metallurgical Engineering and Materials Science, IIT Bombay

2Mechanical, Aerospace and Structural Engineering, Washington University in St. Louis, USA

Correspondence to: Ajit Bhandakkar, Department of Metallurgical Engineering and Materials Science, IIT Bombay.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

The aluminum fly ash metal matrix composites (MMCs) find important applications in automobile and aerospace where high strength and modulus is important. The fly ash by product of coal burning is drawing lot of attention as reinforcement for MMCs due to its low cost and reduction in environmental pollution. The ash particles, generally being hollow in nature, display lower densities while oxides present as constituents make them possess high modulus and strength thereby enhancing specific strength and stiffness along with lower densities compared to many metal based systems. The uses of MMCs are impeded in critical applications due to its low fracture toughness as compare to metals. LEFM (Linear Elastic Fracture Mechanics) has been used by researchers to characterize the plane strain fracture toughness using various specimen geometries and notches. However there were very few studies using EPFM (Elastic Plastic Fracture Toughness) are reported in open literature. In the present paper the influences of weight fraction of fly ash reinforcement on hardness, tensile strength and fracture toughness have been evaluated. Hardness of aluminium fly ash metal matrix composites increases with the addition of fly ash particulate reinforcement. However the tensile strength and fracture toughness KIC and JIC of the aluminum fly ash composite decreases that of base alloy. The fracture toughness of AA2024 varied between 17-18  as compared to 21

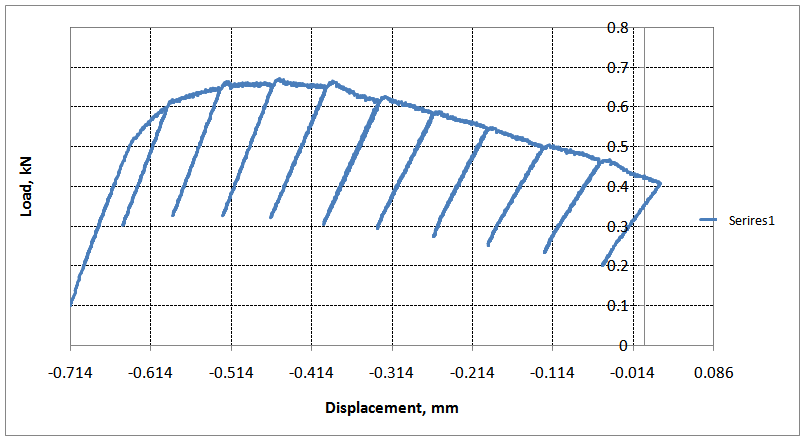

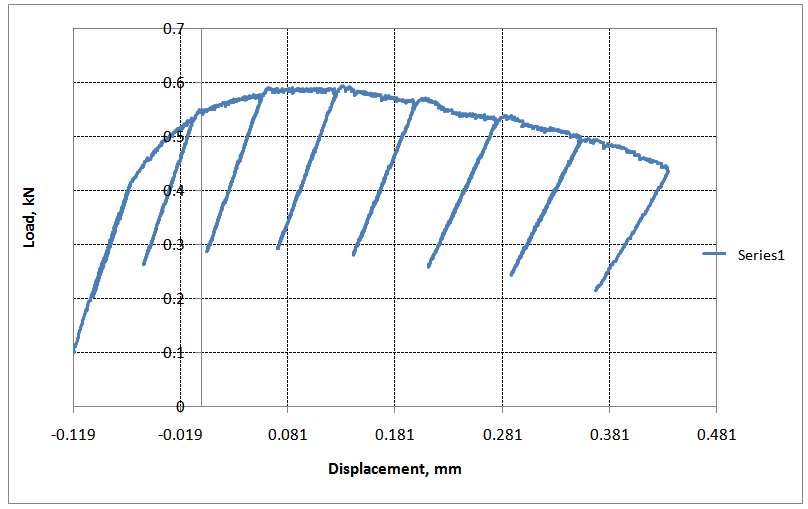

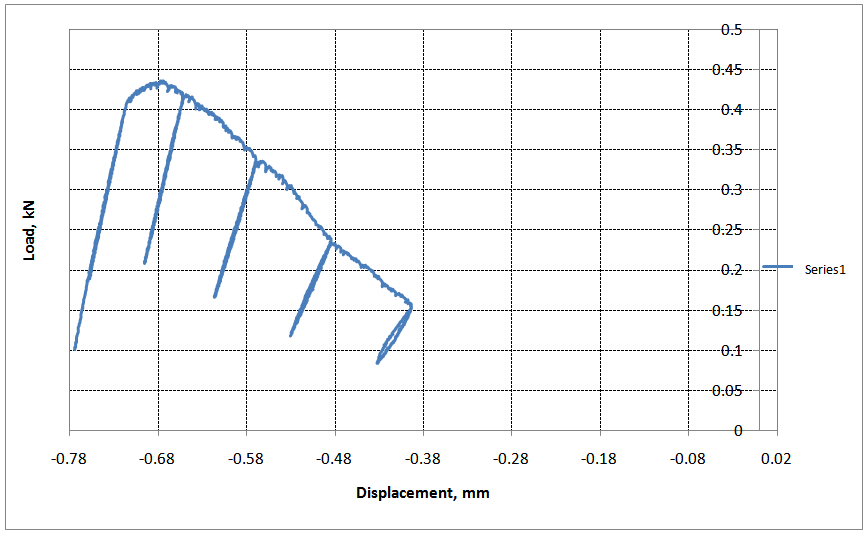

as compared to 21  for remelted base alloy AA2024, which is consistent with the reported data. The JIC fracture toughness of AA2024 fly ash composites varied between 6-15 KJ/m² as compared to 25 KJ/m² for the re melted base alloy AA2024. The load and COD plot shows hysteresis loop in loading and unloading compliance curve. This hysteresis loop is indicative of crack closure due to fly ash particles. The reason for crack closure may be surface roughness resulting from reinforcement particles in the composites. The fracture behavior and micro-mechanism of failure in base alloy and composites have been observed under SEM and optical microscopy.

for remelted base alloy AA2024, which is consistent with the reported data. The JIC fracture toughness of AA2024 fly ash composites varied between 6-15 KJ/m² as compared to 25 KJ/m² for the re melted base alloy AA2024. The load and COD plot shows hysteresis loop in loading and unloading compliance curve. This hysteresis loop is indicative of crack closure due to fly ash particles. The reason for crack closure may be surface roughness resulting from reinforcement particles in the composites. The fracture behavior and micro-mechanism of failure in base alloy and composites have been observed under SEM and optical microscopy.

Keywords: Fracture Toughness, Aluminum Fly Ash Composites, MMCs, Damage Mechanics

Cite this paper: Ajit Bhandakkar, R C Prasad, Shankar M L Sastry, Fracture Toughness of AA2024 Aluminum Fly Ash Metal Matrix Composites, International Journal of Composite Materials, Vol. 4 No. 2, 2014, pp. 108-124. doi: 10.5923/j.cmaterials.20140402.10.

Article Outline

1. Introduction

- The commercial applications of MMCs have been limited due to their higher cost and low fracture toughness as compared to metal alloys. However in spite of higher cost MMCs has emerged as an important class of materials due to high specific strength and stiffness as well as other desirable properties. The Aluminium alloy matrix composites are being used extensively for high performance applications in automobile and aerospace. Because of several advantages, continued efforts are being made to process Aluminum ceramic reinforced metal matrix composites with low cost reinforcement. Fly ash which is by product of coal burning is drawing lot of attention as reinforcement for MMCs due to its low cost and reduction in environmental pollution. The fly ash particles, generally being hollow in nature, display lower densities while oxides present as constituents make them possess high modulus and strength thereby enhancing specific strength and stiffness along with lower densities compared to many metal based systems. The measurement of valid plane strain fracture toughness, (KIC) and Elastic plastic fracture toughness (JIC) for particulate reinforced metal matrix composites is an important step in the process of developing useful products from these materials and increasing confidence in their properties and performance. However limited work has been reported in open literature on influence of fly ash on fracture toughness of aluminum metal matrix composites.The value of the KIC and JIC characterizes the fracture resistance of a material in the presence of a sharp crack under tensile loading, where the state of stress near the crack front is a triaxial plane strain, and the crack-tip plastic region is small compared with the crack size and specimen dimensions [3-6]. In 1977 Barker [7] proposed the short-rod specimen for determining plane strain fracture toughness. Waszczak [8] investigated the applicability of LEFM (KIC) to Boron /Aluminium composites and reported the non linear behavior of load vs COD (crack mouth Opening displacement) curve due to large scale plasticity of AA6061 aluminium alloy.The LEFM method of fracture toughness of Al/SiC metal matrix composites were studied by few researches [9-11] and reported that the fracture toughness of the composites depends on the volume fraction and aspect ratio of the particles. Hong et al. [11] showed that the fracture toughness of SiC/2024 Al alloy composite decreases from 20.16 MPam1/2 to 14.67 MPam1/2 when the volume fraction of the SiC particles increases from 3% to 10%. Hasson and Crowe [12] showed that the KIC value is 15.8 MPam1/2 for a 25 vol.% SiCp reinforced 6061 Al alloy composite in T6 condition, while the value is only 7.1 MPam1/2 for a 20 vol.% SiCw reinforced 6061 Al alloy composite in T6 condition. The uses of MMCs are thus impeded in critical applications. LEFM (Linear Elastic Fracture Mechanics) has been used by researchers to characterize the plane strain fracture toughness using various specimen geometries and notches. [13–23]. However there were very few studies using EPFM (Elastic Plastic Fracture Toughness) are reported in open literature. In this paper, the aluminum fly ash metal matrix composites AA2024 were processed by low cost liquid metallurgy route. The composites were secondary processed by hot extrusion and evaluate the mechanical properties, fracture toughness and micro-mechanisms of failure. The composites in the present investigation showed a stable crack growth therefore JIc test was conducted using three point bend specimens. Typical loading unloading curves for base alloy and composite are plotted and the fracture toughness KQ for AA2024 base alloy and fly ash composites were calculated from J-R curve at maximum load.

2. Experimental

2.1. Material

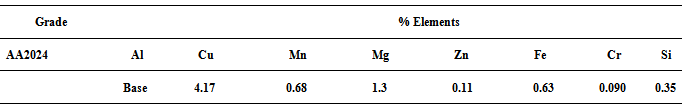

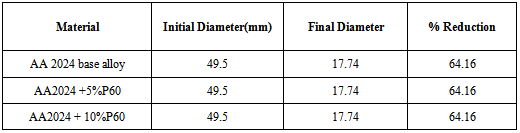

- Aluminum alloy AA 2024 are used as base matrix with composition (weight percent) listed in Table.1 The reinforcement used are silicon carbide and fly ash having particles of sizes 25-45 in 5%, and 10% by weight and the chemical composition of fly ash reinforcement is as per Table.2.

|

|

2.2. Processing of Aluminum Fly Ash Composites

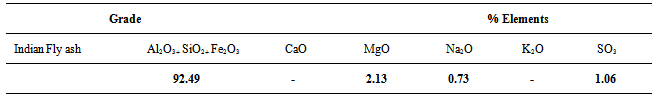

- Fig.1 and Fig.2 shows the experimental setup for fabrication of aluminum metal matrix composite through liquid metallurgy route. About 1 kilograms of the AA 2024 alloy is cleaned and loaded in the silicon carbide crucible and heated to above its liquidus temperature. The temperature was recorded using chromel-alumel thermocouple. To maintain the solid fraction of about 0.4, the temperature of the melt was lowered before stirring. The specially designed mechanical graphite stirrer is introduced into the melt and stirred at ~ 400 rpm as shown in Fig.3. The depth to which the impeller was immersed is approx 1/3rd the heights of the molten melt from the bottom of the crucible. The preheated (800℃) fly ash particulates (25-45μm) were and 900℃ for silicon carbide (1500 grit) added through a preheated pipe by manual tapping into the slurry, while it was being stirred. Table 3 gives the stir casting process details. A post-addition stirring time of 30 min was allowed to enhance the wetting of particulates by the metal. The temperature of the slurry was sufficiently raised above the melting range of the matrix alloy before pouring the composite melt into preheated permanent mould.

| Figure 1. Experimental set up for processing of AA2024/fly ash composites |

| Figure 2. Experimental set up for fabrication of aluminum metal matrix composite |

| Figure 3. Graphite stirrer for uniform distribution of Aluminum metal matrix composite |

|

2.3. Secondary Processing

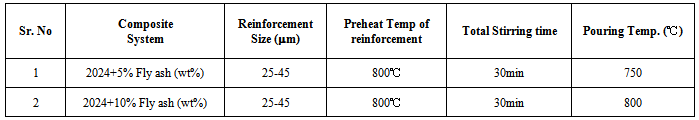

- The as-cast composite billets were extruded/hot rolled at 450 oC (Soaking for 4 hrs) in order to get rid of the porosities induced during primary processing. It also improves the distribution of the reinforcement in the aluminum matrix. Secondary processing improves distribution of fly ash reinforcement in the matrix, imparts directional properties, whereby mechanical properties are improved. The hot extrusion/rolling details of Metal Matrix Composite (AA2024 + fly ash) are shown in Table 4.

|

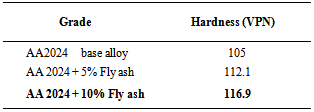

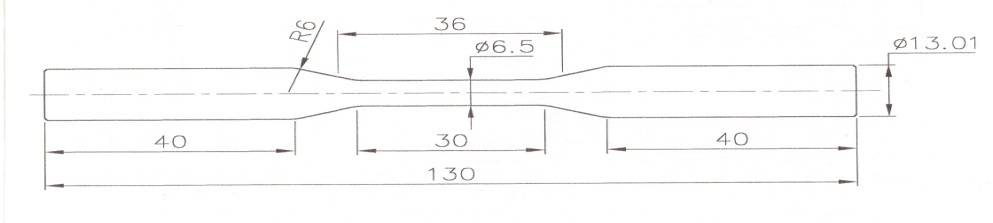

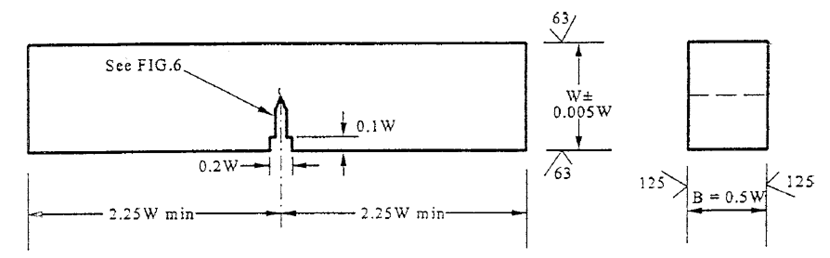

2.4. Specimen Preparation

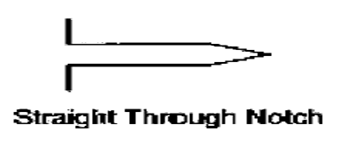

- The tensile specimens were fabricated from the extruded rods of the base metal and composite extrusions. as shown in Fig.4 as per ASTM E8 were used for tensile testing. The SENB specimens for KIC are prepared in LT direction with notch and intended direction perpendicular to the rolling direction as per ASTM E-1820 and ASTM E-647 standards as shown in Fig 5 and Fig.6.

| Figure 4. Tensile test specimen as per ASTM E-8 |

| Figure 5. Fracture toughness test specimen SENB for JIc and FCGR testing |

| Figure 6. Fatigue crack starter notch configuration |

3. Results and Discussion

3.1. Elastic Plastic Fracture Toughness Testing

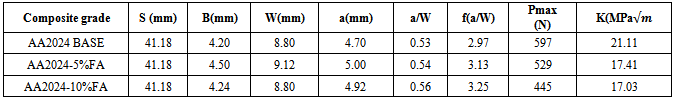

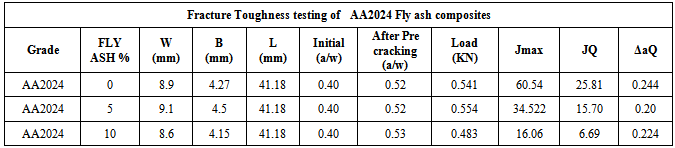

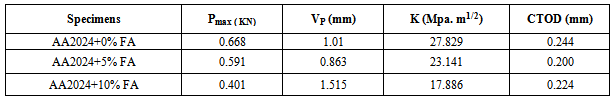

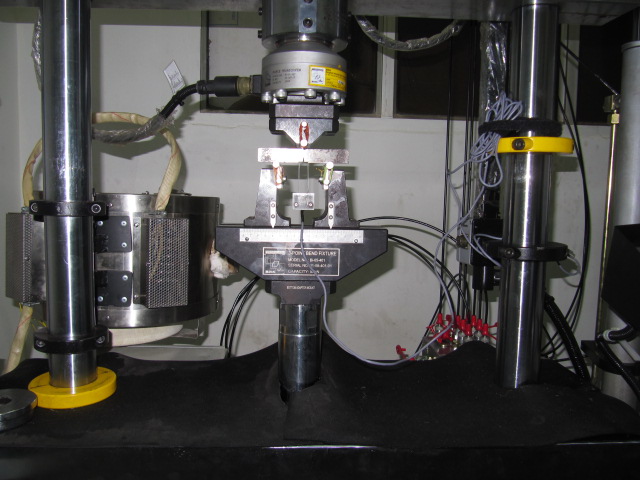

- Elastic plastic fracture toughness JIC tests and fatigue crack growth rate (FCGR) were conducted on BiSS 50 KN servo hydraulic Universal Testing Machine by using SENB test sample as per ASTM E-1820 and as shown in Fig.7. The conditional fracture toughness was calculated using following Eqn.1 and the values of fracture toughness of base alloy and composites are listed in Table.5 and Table.6.

| Figure 7. Test set up for Fracture toughness testing |

|

|

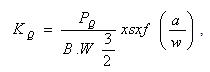

3.2. Equation 1 Fracture Toughness of Composite KQ

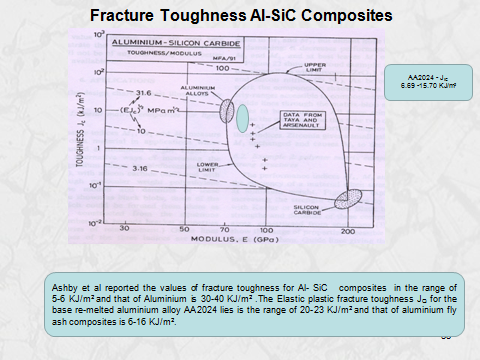

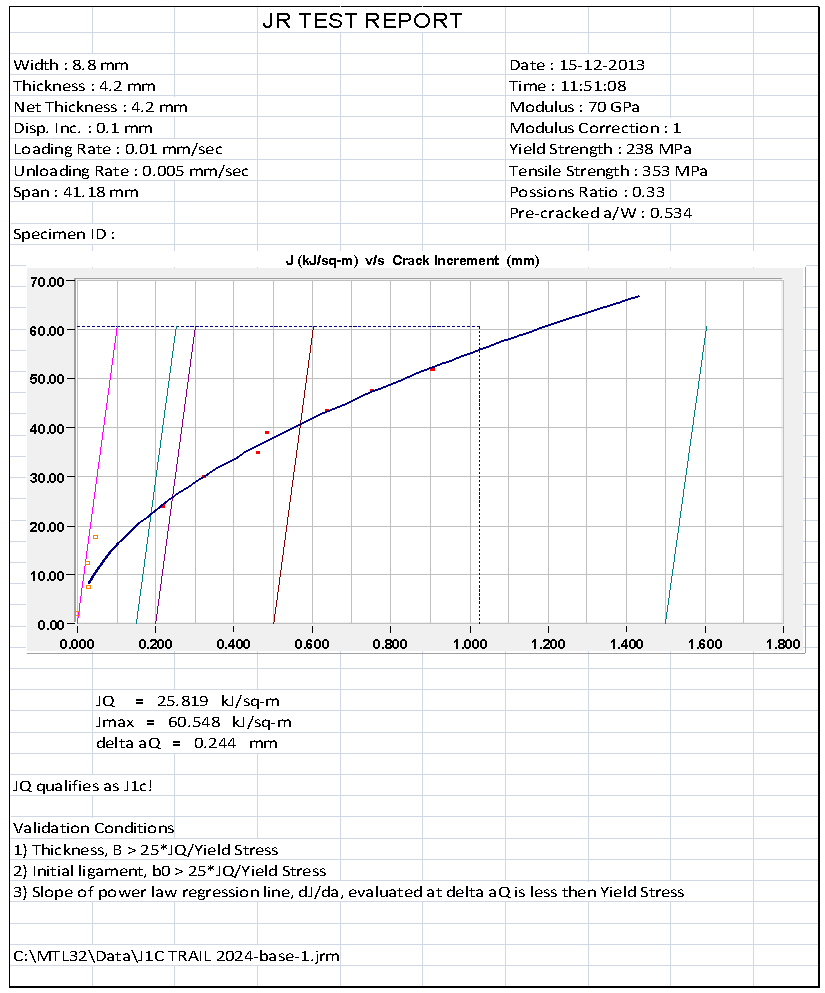

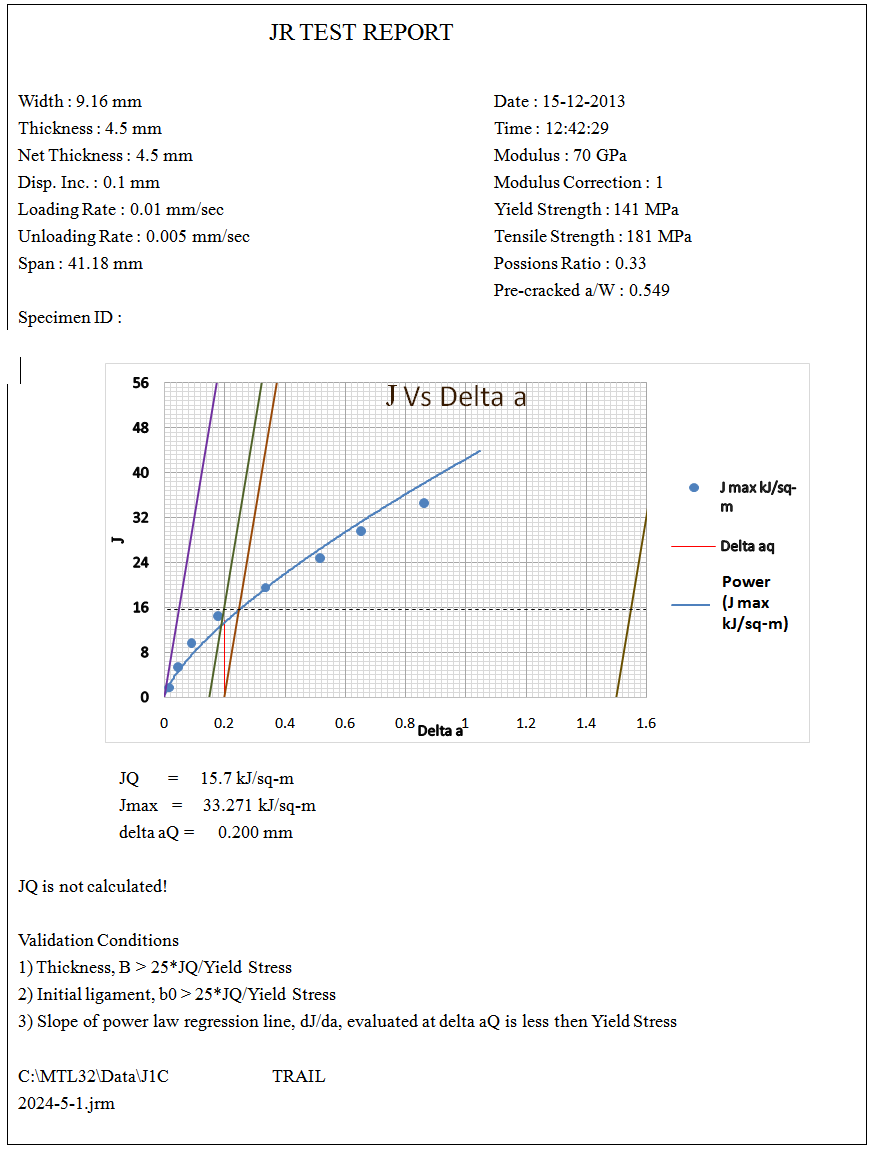

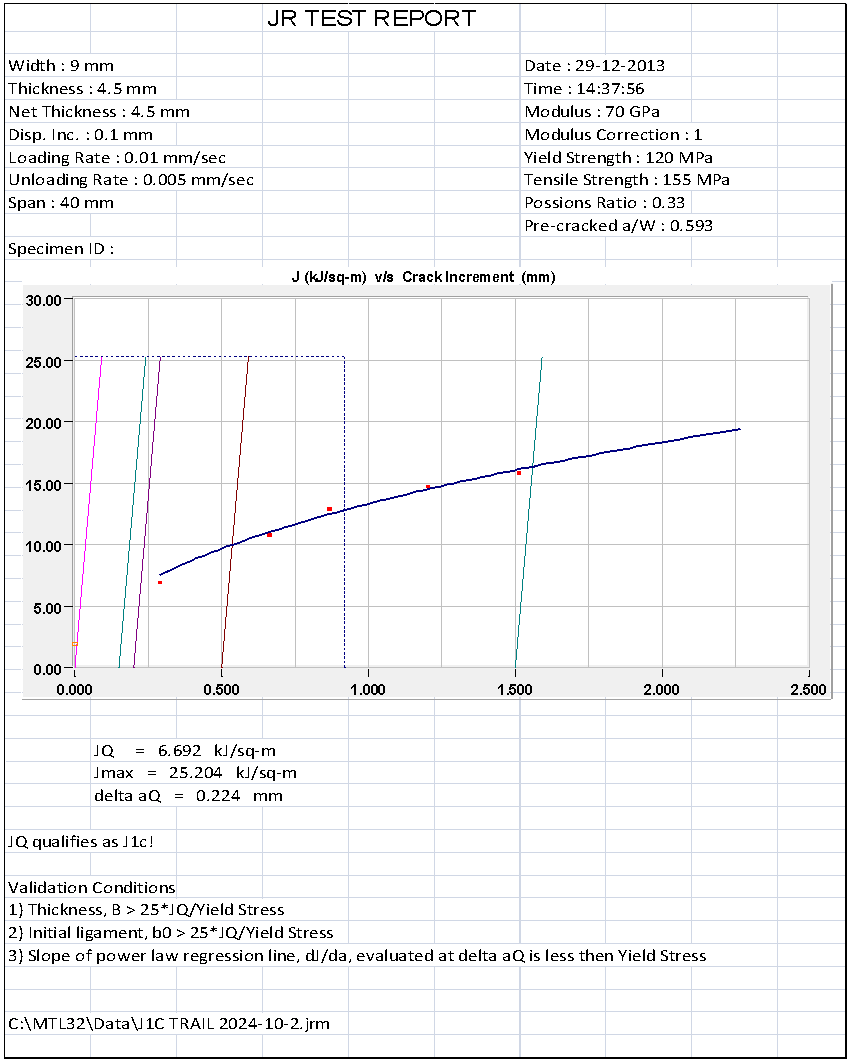

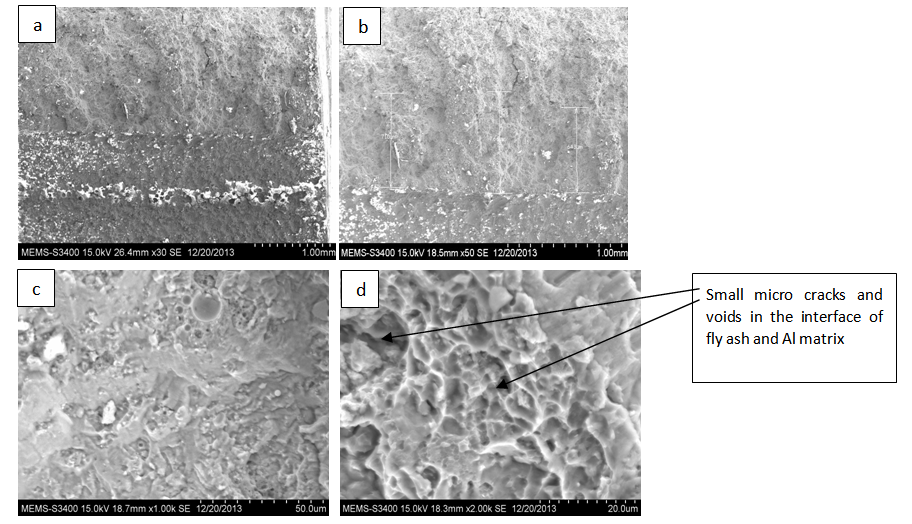

KQ = Conditional Fracture Toughness PQ = Load value obtained by 95% secant line.S = Span lengthA = Crack length W = Width of the specimenThe Elastic plastic fracture toughness JQ for the base alloy AA2024 is 25.81 KJ/m2 and for AA2024-5% FA is 15.70 KJ/m2 and AA2024-10% FA 6.69 KJ/m2 as listed in Table.5.This decrease in the fracture toughness of the composites is due to weak interface between the fly ash reinforcement and aluminum alloy matrix which acts as small micro cracks as shown SEM microstructure in Fig.18. Also during stir casting lot of casting defects such as void, porosity generates during stirring of fly ash reinforcement. The similar results were reported by Ashby et.al for the Aluminum Silicon carbide composites as shown in Fig.8, the fracture toughness of the composites is in the range of 6-10 and that of base alloy is in the range of 10-30 KJ/m2.

KQ = Conditional Fracture Toughness PQ = Load value obtained by 95% secant line.S = Span lengthA = Crack length W = Width of the specimenThe Elastic plastic fracture toughness JQ for the base alloy AA2024 is 25.81 KJ/m2 and for AA2024-5% FA is 15.70 KJ/m2 and AA2024-10% FA 6.69 KJ/m2 as listed in Table.5.This decrease in the fracture toughness of the composites is due to weak interface between the fly ash reinforcement and aluminum alloy matrix which acts as small micro cracks as shown SEM microstructure in Fig.18. Also during stir casting lot of casting defects such as void, porosity generates during stirring of fly ash reinforcement. The similar results were reported by Ashby et.al for the Aluminum Silicon carbide composites as shown in Fig.8, the fracture toughness of the composites is in the range of 6-10 and that of base alloy is in the range of 10-30 KJ/m2.

|

| Figure 8. Elastic Plastic fracture toughness of Composites - Al-SiC |

| Figure 9. J- Δa curve of base alloy AA2024 base alloy |

| Figure 10. J- Δa curve of base alloy 2024 + 5% FA Composite |

| Figure 11. J- Δa curve of base alloy 2024 + 10% FA Composite |

| Figure 12. load V/s COD of AA 2024 base alloy |

| Figure 13. load V/s COD of AA2024-5%FA composites |

| Figure 14. load V/s COD of AA2024-10%FA Composites |

3.3. Influence of Fly ash Reinforcement on Fatigue

- Fatigue is the phenomenon of mechanical property degradation leading to failure of a material or a component under cyclic loading. There are two approches of fatigue testing i.e. conventional approach (the stress vs cycle S−N) curves) and the fatigue crack growth rates using linear elastic fracture mechanics (LEFM).In the conventional approch defect free specimen is subjected to cyclic loading at known stress value and the number of cycles at which specimen fails is recorded. The stress value vs number of cycles the specimen withstand during cyclic loding is plotted to get S-N curve.The significant drawback of such studies is that no distinction can be made between the crack initiation stage and the crack propagation stage. In the second approch a specimen containing crack is subjected to cyclic loading with known crack length (a) and load amplitude. The crack growth rate da/dN vs ΔK (stress intensity factor) is plotted to know the fatigue crack growth rate.

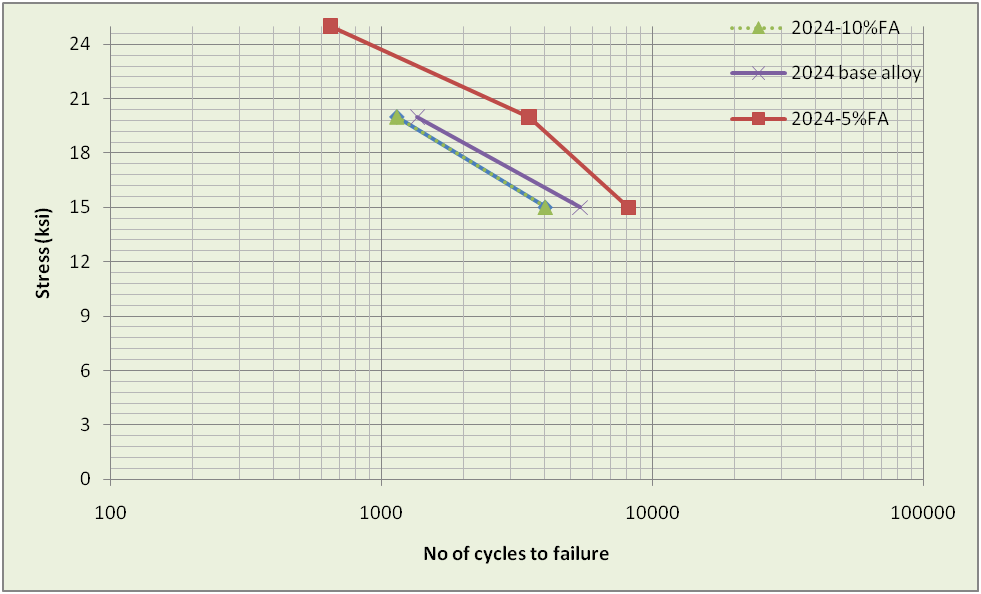

3.4. S-N Curve Approch

- Fatigue strength depends on strength/hardness. The hardness increases with vol % reinforcement, so does the fatigue strength (number of cycles to failure at a given stress). However, AA2024-10vol % FA rendered lower fatigue than AA2024-5 wt.% FA composite and base alloy as shown in Fig.15. This could be due to agglomeration of particles with higher vol % of reinforcement that acts as a metallurgical notch. No definite trend of increase in strength with vol % was observed in this study. In fact in most cases strength was found to decrease. This may arise due to defects in cast composites that render them more notches sensitive.

| Figure 15. S-N plot of AA2024 base alloy and composites |

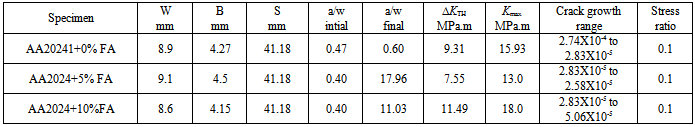

3.5. FCGR Approach

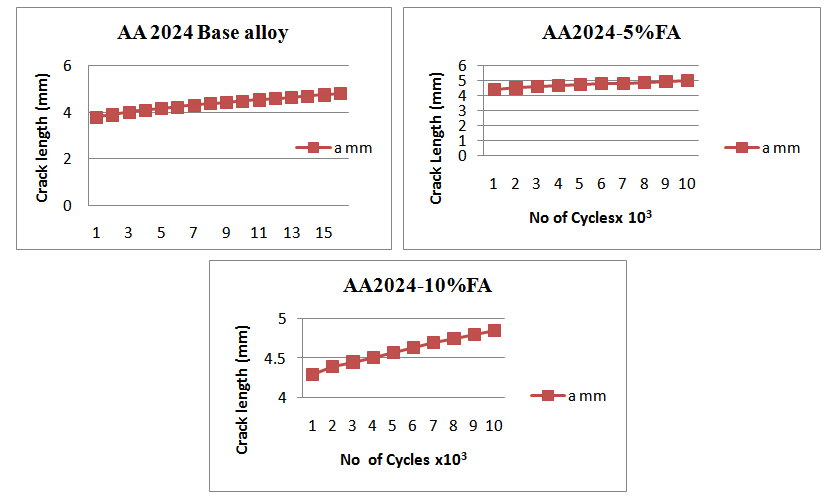

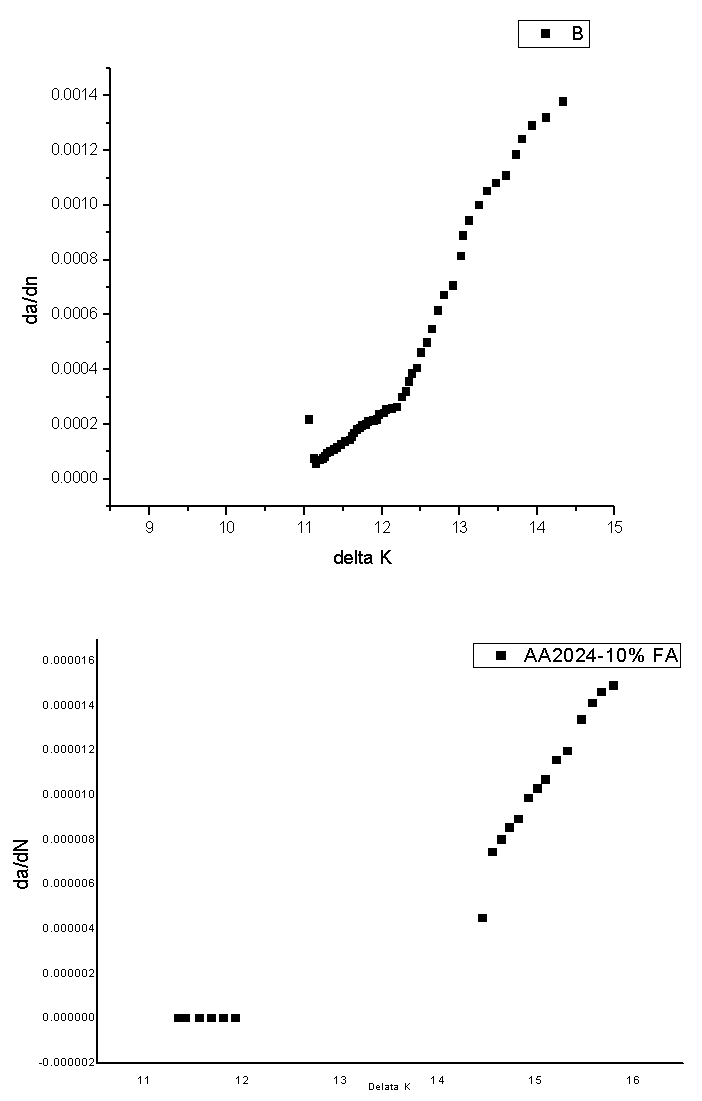

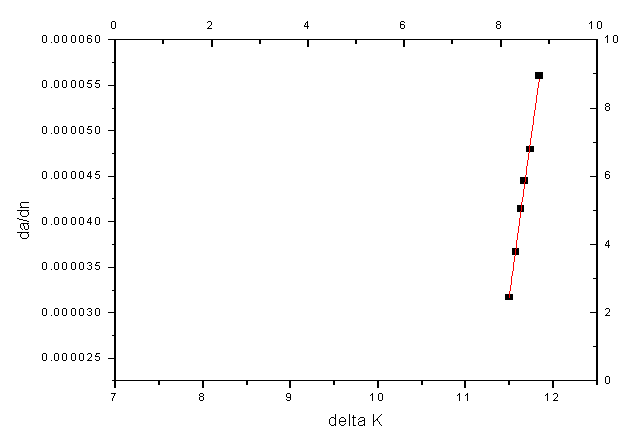

- For many applications resistance to crack propogation under cyclic loading is of significant importance. A typical FCGR curve of matrix alloy and 5% FA and 10% FA compsite is shown in Fig.17. It can be seen that the initial portion of FCGR of composite is less than matrix alloy but ΔKTh is higher. Crack then follows the zig-zag path resulting in surface roughness. Roughness induced crack closure during unloading and crack deflection results in higher ΔKTh. A typical feature of the fatigue crack growth region shows striations Fig.21 and Fig.22 (c) where as overload fracture consists of dimples of various sizes. It can be seen in Fig.21 and Fig.21 (d) that fatigue crack growth results curved crack front. It indicates that even in such a lower thickness of the metal matrix composites the plain strain condition exists in the center where crack grows more and is subsequently arrseted at the surfaces. The FCGR behavior of AA2024 aluminum alloy and composite made out of this alloy exhibit similar trends. The FCGR curve for matrix alloy falls over a delta K range 10 MPa

while the same for composite fall over a narrower stress intensity range. There is no distinction of different regions of da/dN v/s delta k plot is seen as compare to a typical plot for composites material. No Paris regions for composites are identified however Kmax is obtained from plot. FCGR test results for base alloy and its composites are obtained from plots and test results are given in Table 8 and Fig.16.

while the same for composite fall over a narrower stress intensity range. There is no distinction of different regions of da/dN v/s delta k plot is seen as compare to a typical plot for composites material. No Paris regions for composites are identified however Kmax is obtained from plot. FCGR test results for base alloy and its composites are obtained from plots and test results are given in Table 8 and Fig.16.

|

| Figure 16. Crack growth rate V/s no of cycles for AA 2024 base alloy and Composites |

| Figure 17. FCGR for AA 2024 base alloy and Composites |

| Figure 18. da/dn vs delta K plot for AA2024 and FA composites |

4. Mechanical Properties

4.1. Tensile Properties

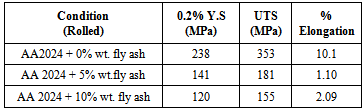

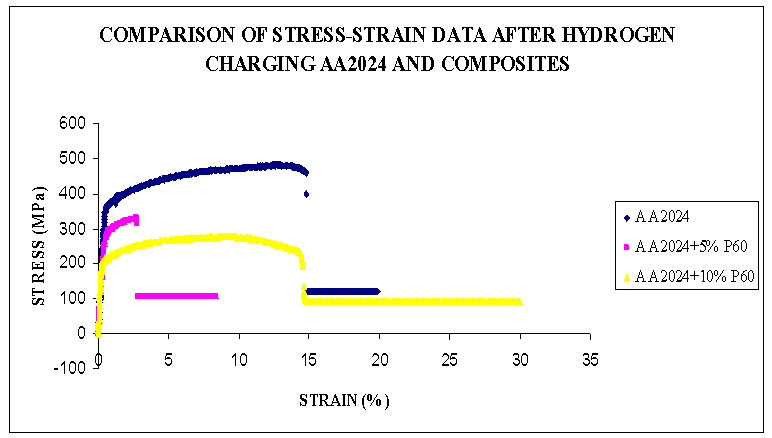

- The mechanical properties such as ultimate tensile strength, 0.2% yield strength and percentage elongation have been evaluated for AA 2024 base alloy and fly ash composites and are listed in Table.9 and shown in Fig.19. The hardness of the base alloy and composite listed in Table.10.

|

|

| Figure 19. Stress vs % Strain plot of AA2024 base alloy and composites |

4.2. Hardness

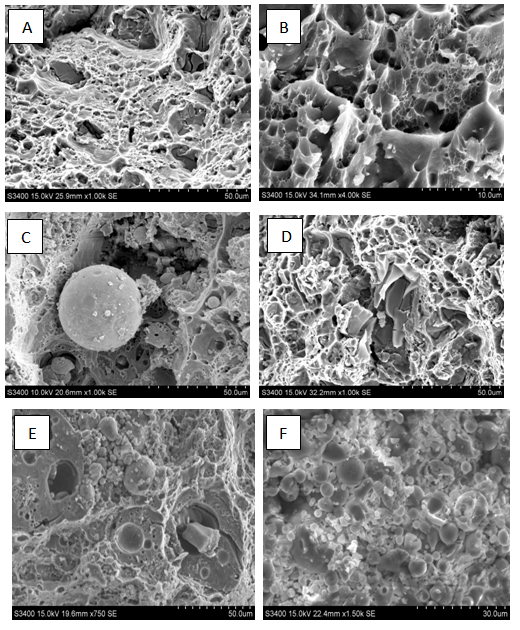

- The hardness have been evaluated for AA2024/fly ash composites with Leco Vickers Micro hardness tester and the hardness values of the base alloy and composites are listed in Table.10 The hardness of the aluminum fly ash composites increase with the fly ash reinforcement. The SEM micrograph in Fig.7a shows uniform distribution of the fly ash reinforcement in the aluminum matrix. The increase in the micro hardness is due strain fields created around fly ash particles because of the difference in the thermal expansion coefficients of aluminum base alloy and fly ash particles. The strain fields’ piles up dislocations and the interaction between dislocations and fly ash particles offer resistance to the propagation of cracks. The grain refinement provided by the fly ash particles during solidification is also responsible for increase in the micro hardness. Tensile test results as listed in Table.9 and Figure.19 of aluminum fly ash composites at room temperature indicates that with the increase in the fly ash reinforcement from 0% to 10% the yield strength decreases from 238 MPa to 120 MPa and the tensile strength decreases from 353 MPa to 155 MPa. This decrease in the yield strength and tensile strength may be attributed due to the presence of casting defects in the fly ash composite during addition of fly ash particulate reinforcement. The tensile fracture surface was observed under SEM to study the modes of fracture as shown in Fig.20 (a-f).The large dimples are associated with the reinforcing particles and small dimples are associated with the fine second phase particles in the matrix. The dimples observed in the aluminum fly ash composites were shallow compared to that observed in unreinforced alloy. The presence of particles in the ductile aluminum alloy matrix promotes low plasticity and condition of high stress triaxiality and voids nucleate at low strain and coalescence is dominated only by their transverse growth. This prevents the extensive growth of voids results in shallow dimples in composites alloy as compared to base alloy.

| Figure 20. SEM factographs of AA2024 base alloy and composites (A-F) |

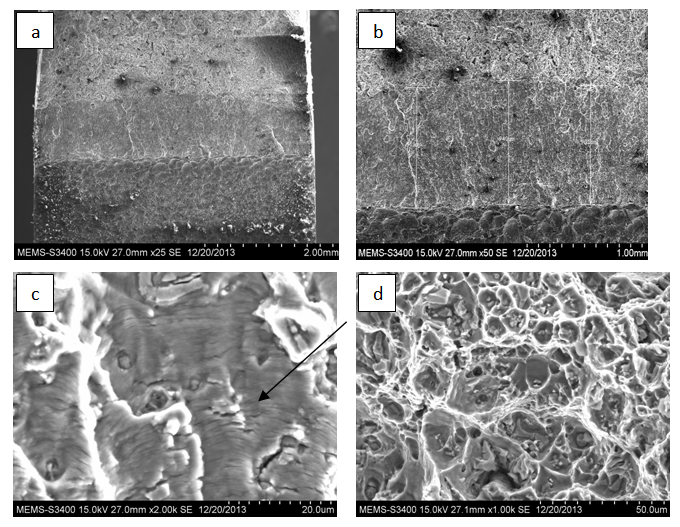

| Figure 21. (a-d) showing the different zones during fracture toughness testing JIC AA2024 Base alloy |

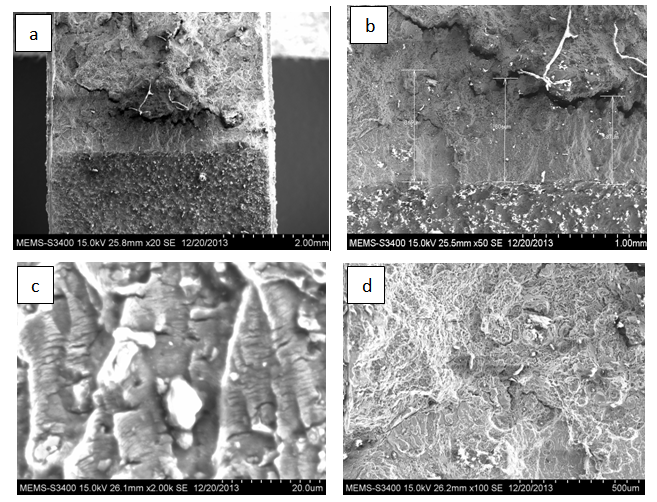

| Figure 22. (a-d) showing the different zones during fracture toughness testing AA2024-5%FA composite |

| Figure 23. (a-d) showing the different zones during fracture toughness testing AA2024-10%FA composite |

5. Conclusions

- 1. Uniform distribution of fly ash and silicon carbide particles in the aluminum matrix was obtained by liquid metallurgy route of stir casting followed by hot extrusion.2. The yield strength, Tensile strength and % elongation of AA2024 fly ash metal matrix composites decreases with the increase in reinforcement.3. The fracture toughness KIC of AA2024 fly ash composite is 17-18

as compared to 21

as compared to 21  for unreinforced and re melted base alloy.4. The Elastic plastic fracture toughness JIc of AA2024 fly ash composites varied between 6-15 KJ/m² as compared to 25 KJ/m² for the re melted base alloy AA2024 as which is consistent with the reported data. 5. The load and COD plot of the composite shows a hysteresis loop in loading and unloading compliance curve. This is indicative of crack closure. The reason for crack closure may be surface roughness resulting from fly ash particles in the composites.6. The FCGR curve for matrix alloy falls over a delta K range 10

for unreinforced and re melted base alloy.4. The Elastic plastic fracture toughness JIc of AA2024 fly ash composites varied between 6-15 KJ/m² as compared to 25 KJ/m² for the re melted base alloy AA2024 as which is consistent with the reported data. 5. The load and COD plot of the composite shows a hysteresis loop in loading and unloading compliance curve. This is indicative of crack closure. The reason for crack closure may be surface roughness resulting from fly ash particles in the composites.6. The FCGR curve for matrix alloy falls over a delta K range 10  while the same for composite fall over a narrower stress intensity range. Hence the composite may therefore, be considered as potential candidate materials for aerospace sectors.

while the same for composite fall over a narrower stress intensity range. Hence the composite may therefore, be considered as potential candidate materials for aerospace sectors.  Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML