-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2014; 4(2): 52-55

doi:10.5923/j.cmaterials.20140402.02

Mechanical Properties of Particleboards Manufactured with Schizolobium amazonicum and Castor oil Based Polyurethane Resin: Influence of Proportion Polyol/Pre-Polymer

Fabiane Salles Ferro1, Felipe Hideyoshi Icimoto1, Diego Henrique de Almeida1, Amós Magalhães de Souza1, Luciano Donizeti Varanda1, André Luis Chritoforo2, Francisco Antonio Rocco Lahr1

1Wood and Timber Structures Laboratory (LaMEM), Department of Structures Engineering (SET), São Carlos Engineering School (EESC), São Paulo University (USP), Brazil

2Federal University of São Carlos, Civil Engineering Department (DECiv), Washington Luís highway, km 235 - SP 310 – Guanabara garden, São Carlos - SP, Brazil

Correspondence to: André Luis Chritoforo, Federal University of São Carlos, Civil Engineering Department (DECiv), Washington Luís highway, km 235 - SP 310 – Guanabara garden, São Carlos - SP, Brazil.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

With a worldwide trend looking for biodegradable materials, non-polluting and biomass products, the Castor oil based polyurethane resin is an alternative to formaldehyde based resins. The Castor oil based polyurethane resin is bicomponent type, formed from a polyol component derived from the castor beans (Ricinus comunalis) and a pre-polymer resin. The aim of this research was to evaluate the influence of castor-oil based polyurethane resin formulation (particularly proportion of pre-polymer/polyol) in static bending properties (modulus of elasticity and modulus of rupture) of particleboards produced with Paricá (Schizolobium amazonicum) wood specie. Four proportions of components (polyol/pre-polymer) were evaluated: 0.75:1; 1:1; 1:1.25 and 1:1.5. Results showed significant improvements in the modulus of elasticity with increasing the pre-polymer component. Modulus of rupture property was not affected significantly by the different proportions of the components of the resin, providing equivalent results. The proportion of 1:1 (polyol/pre-polymer) could be considered the best solution for delivering better mechanical performance and use the least amount of the derivative component of the petroleum.

Keywords: Schizolobium amazonicum, Particleboards, Castor oil based polyurethane resin

Cite this paper: Fabiane Salles Ferro, Felipe Hideyoshi Icimoto, Diego Henrique de Almeida, Amós Magalhães de Souza, Luciano Donizeti Varanda, André Luis Chritoforo, Francisco Antonio Rocco Lahr, Mechanical Properties of Particleboards Manufactured with Schizolobium amazonicum and Castor oil Based Polyurethane Resin: Influence of Proportion Polyol/Pre-Polymer, International Journal of Composite Materials, Vol. 4 No. 2, 2014, pp. 52-55. doi: 10.5923/j.cmaterials.20140402.02.

1. Introduction

- The technological process of the wood sector, coupled with availability of planted forests has enabled a number of alternatives to the use of forest wood refuse, among them, the production of panels [1]. The particleboards are produced with wooden elements, with the addition of adhesives and consolidated by hot pressing by applying temperature and pressure [2].In relation to the quality and properties of the panels, there are many factors that contribute to the characteristics of the final product. The adhesive is one of the factors that should be considered in the production process of panels, it is directly related to the conditions of product, use and costs. Setting the correct type and amount of resin to be used is very important to optimize the cost benefit, because the adhesive is the major cost component [3-4].The synthetic origin adhesive are the most currently used, due to its better adhesion properties and resistance to attack by micro-organisms, when compared to adhesives from natural sources. The main adhesives employed in panel industries have formaldehyde in the composition, which when released may come to cause problems to the environment and human health. In addition, these adhesives require high temperature pressing (above 160℃), which causes a high power consumption [5-6].With a worldwide trend to use of biodegradable products, non-polluting and sourced from renewable inputs, many investments are being made in order to get a free formaldehyde adhesive, but presenting the same efficiency. The castor oil based polyurethane resin is an alternative to formaldehyde-based adhesives [7-8].The castor oil based polyurethane resin is the bicomponent type, composed by a polyol and a prepolymer. Castor-oil, extracted of Ricinus communis seed found in tropical and subtropical regions, is very abundant in Brazil. The prepolymer is obtained from petroleum. Mixture of these components origin the polyuretane resin, which viscosity is defined by ratio polyol/pre-polymer [9].The Castor oil based polyurethane resin had its technical potential shown in several studies of wood based panels, like: Bertolini [10], Ferro [11], Nascimento e Morales [12], Souza [13] e Varanda [14].Despite the promising market, the use of castor oil based polyurethane, developed by the Institute of Chemistry of São Carlos, University of São Paulo [15], is not used commercially by the industry of particleboard yet. The competitiveness of polyurethane adhesive in relation to other existing polymers implies in the fact that it originates from natural raw materials and renewable, in reasonable prices of diisocyanates available in Brazil, and for not being aggressive to humans and the environment [16].For the purpose of using higher amount of resin component derived from renewable sources (polyol), the aim of this research is to evaluate the influence of castor-oil based polyurethane resin formulation, particularly proportion pre-polymer/polyol, in static bending properties of particleboards produced with Schizolobium amazonicum.

2. Material and Methods

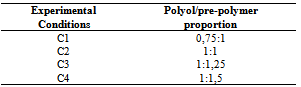

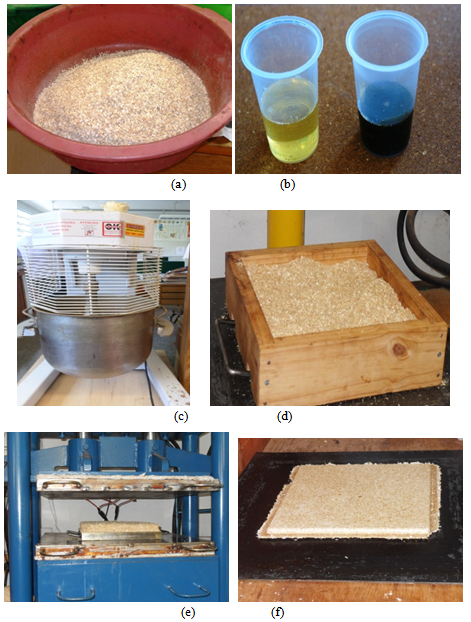

- Tests were carried out in Wood and Timber Structures Laboratory (LaMEM), Structural Engineering Department (SET), São Carlos Engineering School (EESC), São Paulo University (USP).For this research, Schizolobium amazonicum residues obtained in LaMEM were used. After, they were processed in mill to obtain particles (Fig. 1a).Particles were bonded with castor-oil based polyurethane resin, with 100% solids content (Fig. 1b). (A) component is the polyol (castor oil derivate), density 1.20g/cm³; (B) component is the petroleum-derivate diisocyanates, density 1.24 g/cm³ (Fig. 1c).Four proportions between polyol and pre-polymer were evaluated, and are presented in Table 1. Two panels with nominal dimensions 28×28×1cm, density 0.80g/cm3, were fabricated for each experimental conditions. Adhesive content used were 12% based on dry weight of particles [12].

|

| Figure 1. Particleboards production process |

3. Results and Discussions

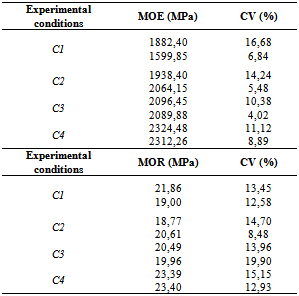

- Table 2 presents the results of the mean values and coefficient of variation (CV) obtained for MOE and MOR in static bending for the panels produced.

|

|

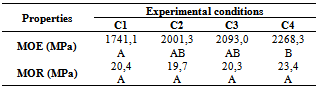

4. Conclusions

- It is possible to conclude that ratio polyol/prepolymer, components castor-oil based polyurethane resin, significantly influenced the modulus of elasticity in static bending of the particleboard evaluated in this research. The increase in cited ratio resulted in higher mean values for the investigated properties. For the modulus of rupture, mean values were statistically equivalent.Ratio 1:1 (polyol/pre-polymer) can be considered the best solution, considering the mechanical performance and the use of the least amount of petroleum-derivate component.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML