-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2014; 4(1): 1-3

doi:10.5923/j.cmaterials.20140401.01

Fourier-IR Spectroscopic Study of the Structure of High-density Polyethylene Composites with Semiconductor Fillers GaAs and GaAs <Te>

Maqsud I. Aliev1, Nushaba N. Gadzhieva2, Gunay B. Ahmadova1

1Institute of Physics of ANAS, Baku, AZ 1143, Azerbaijan

2Institute of Radiation Problems of ANAS, Baku, AZ 1143, Azerbaijan

Correspondence to: Gunay B. Ahmadova, Institute of Physics of ANAS, Baku, AZ 1143, Azerbaijan.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

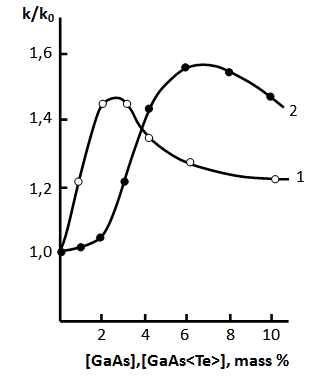

The method of Furrier IR spectroscopy was applied in the study of the structure of high-density polyethylene composites with semiconductor fillers GaAs and GaAs <Te> at room temperature. It was revealed that in case of 2-3 mass % content of GaAs and 5-8 mass % of GaAs <Te> in PE films the maximum degree of crystallinity is obtained. It is shown that GaAs and GaAs <Te> fillers with 50 micron dispersion in polyethylene compositions play a role of structure formers in the increase of the degree of crystallinity and a change in the supramolecular polymer structure.

Keywords: High-density polyethylene, Semiconductor fillers GaAs and GaAs <Te>, Polymer composites, Degree of crystallinity, Fourier-Infrared (IR) spectroscopy, Absorption band, Supramolecular structure

Cite this paper: Maqsud I. Aliev, Nushaba N. Gadzhieva, Gunay B. Ahmadova, Fourier-IR Spectroscopic Study of the Structure of High-density Polyethylene Composites with Semiconductor Fillers GaAs and GaAs <Te>, International Journal of Composite Materials, Vol. 4 No. 1, 2014, pp. 1-3. doi: 10.5923/j.cmaterials.20140401.01.

1. Introduction

- Obtainment of polymeric compositions with interesting electro-physical, strain-sensitive, electret, sensory, spectral-luminescent, optical and other properties largely depends on the nature of the filler, the shape, size and distribution of particles, as well as the degree of interaction between components[1-6]. Usually, new fillers lead to the enhancement of the practical application of the composite material as the nature of the aggregation of the filler particles, conditions of crystallization and a number of other factors change the morphology of the polymeric matrix , and as a result, composite materials obtained on their basis acquire unique properties[1-2]. In this respect, of particular interest are composites based on high density polyethylene (HDPE) with compound semiconductors GaAs and GaAs <Te>. The reason of the fact is that these semiconductors have peculiar crystal and band structures, and are promising materials in micro-and optoelectronics[5-8]. Choice of HDPE (C2nH2n+2) as a binding agent caused a good knowledge of the material[9-10]. It should be noted that actually there exists no literature data on the optical and spectral properties of the composites and HDPE-GaAs and HDPE-GaAs <Te>.Therefore, in this paper we present the results of Fourier-IR spectroscopic studies of composite HDPE films with GaAs and GaAs <T> fillers (the content of which is 1-10 mass %) at room temperature. IR spectroscopy allows us to follow the structural changes caused by the introduction of micro-particles to the polymer matrix, and identify patterns associated with these changes[9, 11].

2. Experimental

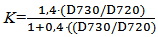

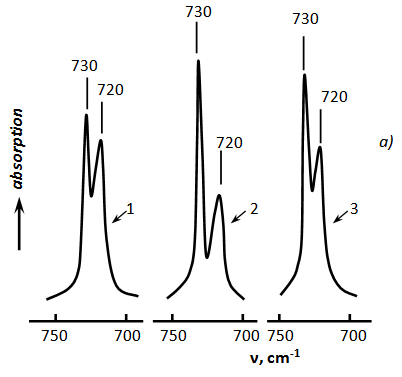

- Of HDPE and GaAs and GaAs <Te> semiconductors powders (with particle size ∼50 micron) there was prepared homogeneous mixture prepared through mechanical mixing. Then homogeneous mixture was within15 minutes exposed to hot pressing at T = 140°C temperature and cooled to room temperature within 30 min. This method allows obtainment of HDPE film with uniform distribution of microparticles in the volume of the polymer, which is a necessary factor for optical studies. The uniform distribution of the microparticles in HDPE films was controlled against Fourier-IR absorption spectra. The thickness of the original and composite films was equal to d = 50-100 microns. The content of GaAs and GaAs <Te> microparticles varied from 1 to 10 mass %. (1,2,3,4,5,6,7,8,9,10 mass %).Fourier-IR absorption spectra of virgin samples of the initial HDPE and its composites were recorded on Varian 640 FT-IR spectrometer at room temperature in the 4000-400 cm-1 frequency range. Structural changes in PE films connected with the introduction of particulate fillers was traced in the frequency range v = 750-700 cm-1 corresponding to pendular oscillations of CH2 group PE, as well as in the deformation (v = l500-1400 cm-1) and valence (v = 3000-2800 cm-1) areas symmetric and asymmetric vibrations of CH2 groups[11].The crystallinity degree of the samples was calculated based on the optical densities by the following formula[7].

| (1) |

3. Results and Discussion

| Figure 1a. Fourier IR-absorption spectra of the initial (1) and composite HDPE films containing 2 (2), and 6 mass% of GaAs microparticles (3) |

| Figure 1b. Fourier IR- absorption spectra of the initial (1) and composite HDPE films containing 2 (2), and 6 mass% of the GaAs <Te> microparticles (3) |

| Figure 2. Dependencies of the relative degree of crystallinity of HDPE + GaAs (1) and HDPE + GaAs <Te> (2) samples on the mass content of the microparticles of GaAs and GaAs •Te> filler in HDPE films |

4. Conclusions

- The possibility of applying the Fourier IR spectroscopy method of study of structural changes connected with the introduction of microparticles in the matrix of the polymer. In the area of concentration of fillers of GaAs up to 2-3 mass%, and GaAs <Te> up to 6-8 mass %, an area of maximum crystallinity of HDPE is observed which is conditioned by the change in the third transition phase of the supramolecular structure (SMS) of the amorphous crystalline polymer. Increase of the concentration of fillers above these values leads to the formation of clusters, decrease in surface energy and stabilization up to the crystallization processes of the polymer.By varying the concentration of fillers and type of the polymer can change the degree of crystallinity and SMS of the polymer matrix. Fillers GaAs and GaAs <Te> with 50 microns dispersed in composites with HDPE play a role of a structure former in the growth of the degree of crystallinity and a change in SMS.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML