Anna V. Shchutska

Kyiv College of Light Industry, Kyiv, Ukraine

Correspondence to: Anna V. Shchutska, Kyiv College of Light Industry, Kyiv, Ukraine.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Abstract

This paper develops the novel approach to problems arising at the study of permeability for the textile fabrics, natural leathers, thin layers of polymers and other thin porous structures (PS). There is serious gap between the experimental investigation of such PS and the relevant different models proposed to imitate the heat-mass-transfer (HMT) of moist air through the small thickness of PS. The formers are based on the water-vapor-transmission (WVT) rate dynamical parameter, which is not, as a matter of fact, the characteristic of PS itself. The same is true for the uncontrolled in the majority of experiments quantity termed as the gradient of partial moisture pressure. The well-established methodology proposed in this paper provides the reliable estimate of the generalized diffusion coefficient. It characterizes just the properties of PS itself.

Keywords:

Water-vapor-transmission rate’s, Porous structure, Generalized diffusion coefficient

Cite this paper: Anna V. Shchutska, Some Fundamental Problems of Heat-Mass-Transfer through the Thin Materials, International Journal of Composite Materials, Vol. 4 No. 5A, 2014, pp. 35-40. doi: 10.5923/j.cmaterials.201401.05.

1. Introduction

The specific property of a thin porous structure (PS) is two strong inequalities:  between its linear sizes l,b determining the normal test area

between its linear sizes l,b determining the normal test area  (

(  m2, for example) and its thickness δ (

m2, for example) and its thickness δ (  m, in the most cases). The water vapor transmission (WVT) rate of any PS and the textile fabrics, in particular, is of considerable interest for many branches of the practice and science. Such materials provide, for example, the steady moisture transfer from the skin of the weaver through the textile layers into the environment during heavy work or in hot climate conditions.There is a variety of methods to measure WVT (Δm is mass change):

m, in the most cases). The water vapor transmission (WVT) rate of any PS and the textile fabrics, in particular, is of considerable interest for many branches of the practice and science. Such materials provide, for example, the steady moisture transfer from the skin of the weaver through the textile layers into the environment during heavy work or in hot climate conditions.There is a variety of methods to measure WVT (Δm is mass change): | (1) |

which give, however, the quite different results for the same fabric, or, more generally, the same thin PS. The obvious reason of such situation is an absence of the general conception of treatment and interpretation of the experimental data obtained by the different test methodologies, which vary with respect to construction mechanisms, test conditions and measurement parameters.The aim of this paper is to demonstrate that the general approach to the WVT-problem becomes still possible if one rejects its physically incorrect but widespread interpretation as the property of PS itself. In contrast, it is considered here as the standard density of flow:  (i.e. the dynamical parameter) determined for the quasicontinuous PS-media by the non-equilibrium thermodynamics:

(i.e. the dynamical parameter) determined for the quasicontinuous PS-media by the non-equilibrium thermodynamics: | (2) |

where  is the local density of a moist vapor while

is the local density of a moist vapor while  is the effective local kinematic velocity. The main problem of this interpretation is the reliable estimate of both quantities ρ and

is the effective local kinematic velocity. The main problem of this interpretation is the reliable estimate of both quantities ρ and  separately raking into account the netto-mass

separately raking into account the netto-mass  and the respective density

and the respective density  of a PS- material (M) itself. During the water vapor transport process its brutto-mass

of a PS- material (M) itself. During the water vapor transport process its brutto-mass  is increased due to the sorption ability (

is increased due to the sorption ability (  ) of any PS. Of course, these corrections are very different for the hydrophobic or weakly hydrophilic fabrics, on the one hand, and hydrophilic fabrics, on the other hand.Another fundamental problem of the proposed below approach based on the generalized for PS Fick’s law of diffusion:

) of any PS. Of course, these corrections are very different for the hydrophobic or weakly hydrophilic fabrics, on the one hand, and hydrophilic fabrics, on the other hand.Another fundamental problem of the proposed below approach based on the generalized for PS Fick’s law of diffusion: | (3) |

is the reliable estimate of the generalized diffusion coefficient  which has the dimensionality of time. Indeed the comparison (1) and (3) leads to the interesting possibility to calculate

which has the dimensionality of time. Indeed the comparison (1) and (3) leads to the interesting possibility to calculate  from (2)

from (2) | (4) |

is the difference of partial pressures ΔP across PS can be specified (or measured) by experiment. Unfortunately, this is not the case for a majority of WVT-measurements. Our goal below is to demonstrate that some progress can be achieved in the framework of proposed approach too if one measures the same fabric sample by the different test methods.

2. Physical Concepts of Approach

The gradient of partial pressure grad P for a moist vapor in the postulated linear transport equation (3) is, as a rule, uncontrolled by the experimentalist parameter. Its formal definition for the steady process is based on the following reasonable assumption. One supposes the linear decrease of partial pressure on the path from the source moisture 1 (usually it is the saturated water existing in an admitted equilibrium with its saturated vapor at  ) through the tested fabric’s layer 1-2 with the thickness δ up to the presumably zero pressure

) through the tested fabric’s layer 1-2 with the thickness δ up to the presumably zero pressure  of an experimental vessel 2. Of course, the atmospheric pressure

of an experimental vessel 2. Of course, the atmospheric pressure  can be added to the both limiting values of the finite difference

can be added to the both limiting values of the finite difference  to make the realistic estimate of its magnitude in terms of the measurable pressure.Nevertheless the fundamental question remains: Is the saturated vapor pressure of water divided by an arbitrary total width of layers the actual thermodynamic force to provide the respective flow of a moisture j through the fabric in accordance with (1)?

to make the realistic estimate of its magnitude in terms of the measurable pressure.Nevertheless the fundamental question remains: Is the saturated vapor pressure of water divided by an arbitrary total width of layers the actual thermodynamic force to provide the respective flow of a moisture j through the fabric in accordance with (1)? | (5) |

where  is the measurable width of an air layer between the source of moisture and the internal surface 1 of a tested fabric while

is the measurable width of an air layer between the source of moisture and the internal surface 1 of a tested fabric while  for an outside air layer is a bad-defined parameter for any experiment or model.To elucidate the problem of an effective local kinematic velocity

for an outside air layer is a bad-defined parameter for any experiment or model.To elucidate the problem of an effective local kinematic velocity  (of its definition, first of all) in total, let us remind the main specific features of the standard permeability test. The most relevant one is, of course, the sweating guarded hot plate test specified in ISO 11092 [2]. Its detailed description and results can be found elsewhere [1] and only the main working equation should be discussed now:

(of its definition, first of all) in total, let us remind the main specific features of the standard permeability test. The most relevant one is, of course, the sweating guarded hot plate test specified in ISO 11092 [2]. Its detailed description and results can be found elsewhere [1] and only the main working equation should be discussed now: | (6) |

where  is the total evaporative resistance provided by the porous metal plate (imitated the body skin at 35ºC) fabric and boundary air layer

is the total evaporative resistance provided by the porous metal plate (imitated the body skin at 35ºC) fabric and boundary air layer  in (5);

in (5);  - test area,

- test area,  ;

;  - the water vapor pressure of the above plate surface, Pa;

- the water vapor pressure of the above plate surface, Pa;  - the water vapor pressure of the air, i.e. of the undetermined layer of

- the water vapor pressure of the air, i.e. of the undetermined layer of  in (5); H – the heating power, W;

in (5); H – the heating power, W;  - the correction evaporative term for heating power, i.e. latent heat of vaporization, W. The intrinsic evaporative resistance of the fabric

- the correction evaporative term for heating power, i.e. latent heat of vaporization, W. The intrinsic evaporative resistance of the fabric  can be found as the difference:

can be found as the difference: | (7) |

where  is the evaporative resistance of the porous plate and boundary air layer

is the evaporative resistance of the porous plate and boundary air layer  . Just the reciprocal

. Just the reciprocal  -value provides in this arrangement, which drives heat and moisture transfer upward only along the specimen thickness direction, the appropriate value of

-value provides in this arrangement, which drives heat and moisture transfer upward only along the specimen thickness direction, the appropriate value of  :

: | (8) |

Huang and Qian [3] have proposed the rather informative methodology to test, simultaneously,  - and WVT-values. It is based on the change of relative humidity, i.e. measurable water vapor concentration gradient considered as thermodynamic force for the moist vapor transfer. This HQ-approach is closer to the main concept of Fick’s law for selfdiffusion formulated originally for the dilute gases:

- and WVT-values. It is based on the change of relative humidity, i.e. measurable water vapor concentration gradient considered as thermodynamic force for the moist vapor transfer. This HQ-approach is closer to the main concept of Fick’s law for selfdiffusion formulated originally for the dilute gases: | (9) |

where the approximate equality demonstrates its possible extension on the thin PS and  is the molecular-based diffusion coefficient:

is the molecular-based diffusion coefficient: | (10) |

It is expressed here in terms of the average free path of particles (between two neighboring collisions) and  - the average velocity of molecular motion in any transport process realized in the pure dilute gas [4]:

- the average velocity of molecular motion in any transport process realized in the pure dilute gas [4]: | (11) |

where  - concentration of particles with the molecular mass

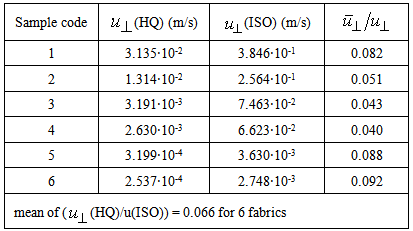

- concentration of particles with the molecular mass  and σ – effective diameter of particles.It is worthwhile to note that the authors of HQ-method [3] themselves did not consider its generalized molecular interpretation for PS based on (9-11). However, the remarkable correlation between their measurements obtained by two different (HQ and ISO 11092) methods confirms completely the possibility of such analysis. It is found by us in terms of the reciprocal resistances (8), i.e. the effective diffusion velocities and is shown in Table 1.

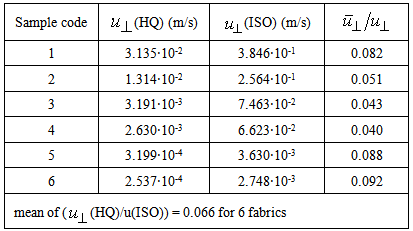

and σ – effective diameter of particles.It is worthwhile to note that the authors of HQ-method [3] themselves did not consider its generalized molecular interpretation for PS based on (9-11). However, the remarkable correlation between their measurements obtained by two different (HQ and ISO 11092) methods confirms completely the possibility of such analysis. It is found by us in terms of the reciprocal resistances (8), i.e. the effective diffusion velocities and is shown in Table 1.Table 1. Correlation of Intrinsic Diffusion Reciprocal (8) Resistances for Six Fabrics Measured in [1]

|

| |

|

While the absolute magnitudes are different in two orders for the both columns, their ratio is the oscillating value near its mean level 0.066. The Pearson correlation test was performed also to demonstrate the quite high level of correlation (0.999) between two discussed methods.It is interesting to remind here the works of Chyjkova et al [5] dated by 1980 and published only in Russian journal KOP. These authors studied the so-called capillar model of porosity in terms of Fick’s law (3). The following molecular-based equations [4] have been used for the small ( ) and large (

) and large ( ) mean diameters of capillars, i.e. model of pores:

) mean diameters of capillars, i.e. model of pores: | (12) |

| (13) |

where D is the diffusion coefficient (10) for a mixture, M [kg/mol] – the molar mass of air ( ) and water (

) and water ( ),

), - the universal gas constant and g – porosity determined by the common area of the surface pores

- the universal gas constant and g – porosity determined by the common area of the surface pores  , i.e.

, i.e.  . Unfortunately, the respective molecular approximations of generalized diffusion coefficient

. Unfortunately, the respective molecular approximations of generalized diffusion coefficient  :

: | (14) |

| (15) |

are rather uncertain ones because the enormous number  and the very small

and the very small  either should be a priori given or should be measured by the quite formidable experiment [5]. Besides, Chyjkova et al [5] have not measured the grad P-value in (12,13) but have predicted it on the base of some unreliable, to our mind, estimates for

either should be a priori given or should be measured by the quite formidable experiment [5]. Besides, Chyjkova et al [5] have not measured the grad P-value in (12,13) but have predicted it on the base of some unreliable, to our mind, estimates for  in (14,15) and calculated

in (14,15) and calculated  -values.There are several rather reliable testing equipments (see, for example UTX-3360) for the so-called air permeability (AP) which is simply the velocity of a dry air u flowing through the thickness of PS:

-values.There are several rather reliable testing equipments (see, for example UTX-3360) for the so-called air permeability (AP) which is simply the velocity of a dry air u flowing through the thickness of PS: | (16) |

where V is the measurable volume change and t – time during which ΔV occurred,  - the measurable volume of a porous material (M). At first sight, one obtains from (16) the alternative to (4) variant for determination of a kinematic velocity if the condition

- the measurable volume of a porous material (M). At first sight, one obtains from (16) the alternative to (4) variant for determination of a kinematic velocity if the condition  is fulfilled:

is fulfilled: | (17) |

However, just this condition for the volume density  of an air stream becomes questionable when the certain mass of a moist vapor remains in PS due to the sorption phenomenon. One should take into account the discontinuity of a relative humidity and the respective density “jump” between the ingoing 1 and outgoing 2 flows of a moving through fabric vapor.Another serious problem of the relevant experimental WVT-methodologies is itself their interpretation. One considers the WVT-quantity as the fabric’s characteristic parameter. Evidently, that this concept is an elusive one because the density of flow

of an air stream becomes questionable when the certain mass of a moist vapor remains in PS due to the sorption phenomenon. One should take into account the discontinuity of a relative humidity and the respective density “jump” between the ingoing 1 and outgoing 2 flows of a moving through fabric vapor.Another serious problem of the relevant experimental WVT-methodologies is itself their interpretation. One considers the WVT-quantity as the fabric’s characteristic parameter. Evidently, that this concept is an elusive one because the density of flow  (1) is a typical dynamic parameter of the linear non-equilibrium thermodynamics. In the formalism of a continuous media, it is simply a reply of system to the action of a thermodynamic force, which is the appropriate gradient. In other words, only the effective coefficient

(1) is a typical dynamic parameter of the linear non-equilibrium thermodynamics. In the formalism of a continuous media, it is simply a reply of system to the action of a thermodynamic force, which is the appropriate gradient. In other words, only the effective coefficient  can be the fabric’s parameter.The non-equilibrium thermodynamics states that the actual diffusion coefficient

can be the fabric’s parameter.The non-equilibrium thermodynamics states that the actual diffusion coefficient  from (9) plays also the role of kinematic velocity and/or temperature-conductivity in the Newton’s and Fourier’s laws, respectively (

from (9) plays also the role of kinematic velocity and/or temperature-conductivity in the Newton’s and Fourier’s laws, respectively (  ) at least, for a diluted gas:

) at least, for a diluted gas: | (18) |

where  is the specific isochoric heat capacity.We assumed now that the discussed here well-established formalism for the small densities of bulk gases can be extended and applied to the dense fluid (most vapor) states and, even, to the gas-liquid-transition states if the following conditions are fulfilled:1) the density profile ρ(x) along the chosen direction of a mass-transfer process should be given to determine the stationary (or, about the equilibrium for a phase-transition state) grad ρ in (9);2) the density of a mass-flow

is the specific isochoric heat capacity.We assumed now that the discussed here well-established formalism for the small densities of bulk gases can be extended and applied to the dense fluid (most vapor) states and, even, to the gas-liquid-transition states if the following conditions are fulfilled:1) the density profile ρ(x) along the chosen direction of a mass-transfer process should be given to determine the stationary (or, about the equilibrium for a phase-transition state) grad ρ in (9);2) the density of a mass-flow  along the same direction should be measured by experiment to evaluate then the diffusion coefficient D;3) the dynamical viscosity η in (18a) as well as the heat transfer coefficient

along the same direction should be measured by experiment to evaluate then the diffusion coefficient D;3) the dynamical viscosity η in (18a) as well as the heat transfer coefficient  in (18b) have to be calculated from the measurable value of the heat capacity

in (18b) have to be calculated from the measurable value of the heat capacity  and the above estimates of D- and ρ(x)-values;4) the effective modified quantity ρ from (18) determined for the special thin δ-layer along the x-direction becomes in the proposed here methodology the main parameter if the divergence of its profile ρ(x) is locally possible just in this layer;5) accordingly to the statement 4) the thin layer of any fabric with the surface

and the above estimates of D- and ρ(x)-values;4) the effective modified quantity ρ from (18) determined for the special thin δ-layer along the x-direction becomes in the proposed here methodology the main parameter if the divergence of its profile ρ(x) is locally possible just in this layer;5) accordingly to the statement 4) the thin layer of any fabric with the surface  located normally to the x-direction of a mass-heat transfer is a reason to change sharply the local value of density ρ taking into account the porous (fractal) structure of its distribution.

located normally to the x-direction of a mass-heat transfer is a reason to change sharply the local value of density ρ taking into account the porous (fractal) structure of its distribution.

3. Generalized Diffusion Coefficient of Fabrics

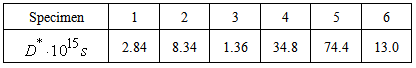

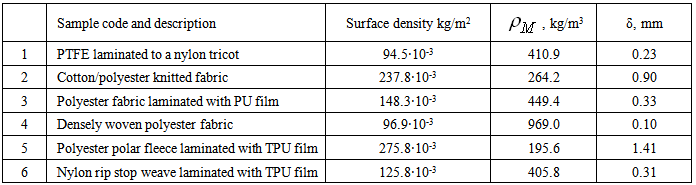

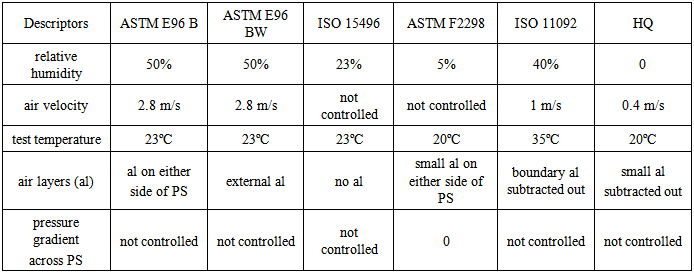

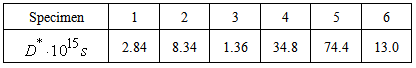

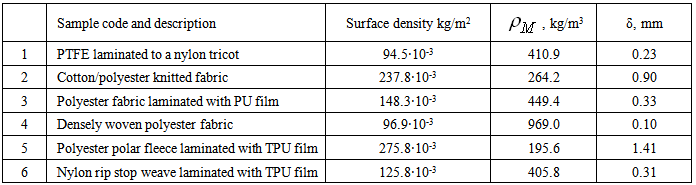

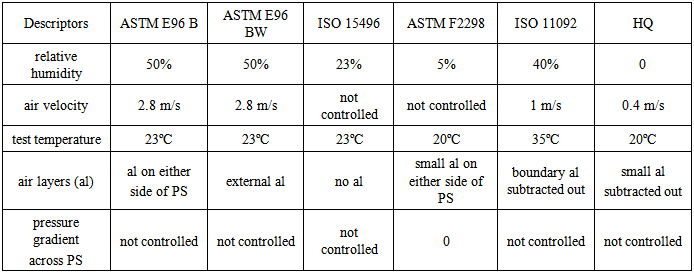

To illustrate the usefulness of the proposed in this work approach (Section 2) the following (see also Table 1) set of six fabrics (Table 2) studied experimentally [1] by six different test methods (Table 3) have been chosen below.Table 2. Specification of the Fabrics

|

| |

|

Table 3. Comparison of Experimental Setup for Six Test Methods

|

| |

|

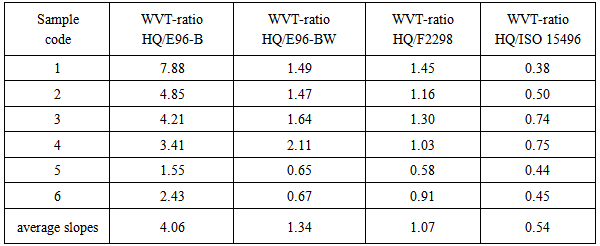

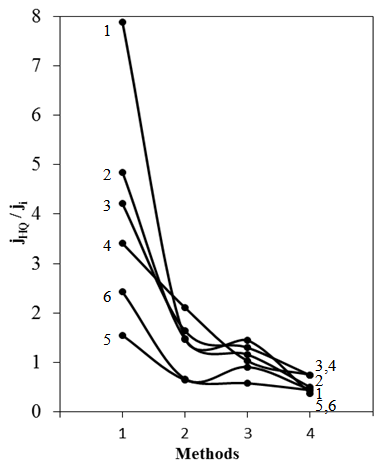

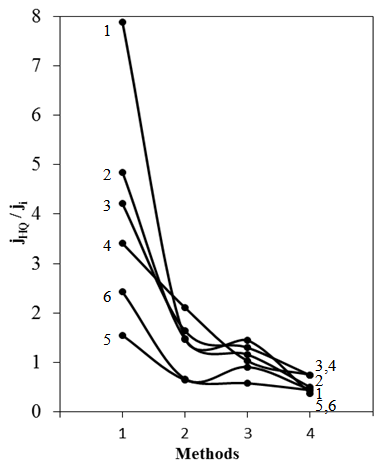

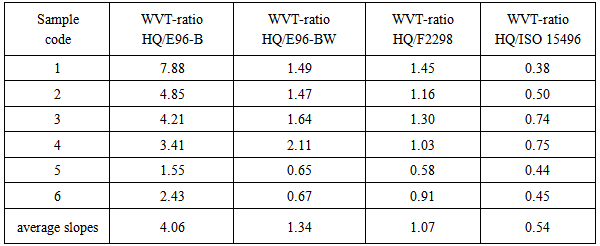

Huang and Qian represented graphically the comparison of other five methods 1)-5) with that 6) developed in [3]. There were: 1) the upright cup method used according to ASTM E96, Procedure B [6]; 2) the inverted cup method used according to ASTM E96, Procedure BW [6]; 3) the desiccant inverted cup method used according to ISO standard [7]; 4) the dynamic moisture permeation cell (DMPC) method used according to ASTM F2298 [8]; 5) the sweating guarded hot plate method used according to ISO 11092 [2].The results of latter one 5) has been analyzed in Section 2 (see Table 1). We have used below in Table 4 the same technique to test the reciprocal by ratio of WVT-values 1)-4) derived by the WVT-standard obtained by HQ-method. The only result of such comparison is the rather rough (in accuracy) confirmation of the linear Fick’s law. Besides, the such approximate graphic analysis contains an unphysical feature because the average slopes from Table 4 as well as in Figure 1 [1] do not provide the correct limiting passing through the point at the coordinate origin ( when grad P = 0).

when grad P = 0).Table 4. Ratio of the WVT-value from HQ-method 6) to those following from 1)-4) methods

|

| |

|

In opposite to the above-discussed comparison we propose the next steps to estimate the realistic  -value:1) It follows from (1) and (3) that an WVT-ratio (see Table 4) represents also the ratio of the respective gradients:

-value:1) It follows from (1) and (3) that an WVT-ratio (see Table 4) represents also the ratio of the respective gradients: | (19) |

2) as a result, one must estimate only one method-dependent gradient of pressure  to predict the others (effective)

to predict the others (effective)  -values for the different methods from the WVT-ratio:

-values for the different methods from the WVT-ratio: | (20) |

3) then, the generalized diffusion coefficient of fabric can be estimated accordingly to (3): | (21) |

4) we have used for the simplicity the standard change of pressure for the basic HQ-method:  to calculate the

to calculate the  -values represented in Table 5.

-values represented in Table 5.Table 5. Generalized Diffusion Coefficient

for Six Fabrics 1-6 from Table 2 for Six Fabrics 1-6 from Table 2

|

| |

|

Nevertheless, Fig.1 demonstrates that the experimental WVT-ratio changes its values mainly monotonically but nonlinearly from one method to another one. The supposed here generalized reason of such behavior is the respective monotonic but non-regular change of the respective thermodynamic force i.e. of the gradient of partial pressure. | Figure 1. Non-linearity of WVT-ratio for the chain of regular changes in the sequence of test methods1) |

4. Conclusions

This work is an attempt to classify the set of standard methods directed usually to estimate WVT. The purpose is to modify approach, in general, and to study the thin PS-property  itself instead of the dynamic WVT-characteristic which is mainly determined by the appropriate thermodynamic force in the variants (1,3) of the generalized linear Fick’s law, formulated for PS.Obviously that the remaining problem is the measurement of pressure drop across the sample. An absence of such experimental parameter cannot be compensated, from our viewpoint, by its theoretical estimates. This arbitrary estimate may cause a large shift in diffusion resistance even if the WVT-value is reliably measured. A combination of AP- and WVT-measurements of the same sample at the same conditions may be essential to solve independently this fundamental problem.

itself instead of the dynamic WVT-characteristic which is mainly determined by the appropriate thermodynamic force in the variants (1,3) of the generalized linear Fick’s law, formulated for PS.Obviously that the remaining problem is the measurement of pressure drop across the sample. An absence of such experimental parameter cannot be compensated, from our viewpoint, by its theoretical estimates. This arbitrary estimate may cause a large shift in diffusion resistance even if the WVT-value is reliably measured. A combination of AP- and WVT-measurements of the same sample at the same conditions may be essential to solve independently this fundamental problem.

References

| [1] | J. Huang and X. Qian “Comparison of Test Methods for Measuring Water Vapor Permeability of Fabrics” Textile Research Journal, vol. 78(4), pp.342-352, 2008. |

| [2] | ISO 11092 1993 “Textiles-Physiological Effects – Measurement of Thermal and Water Vapor Resistance under Steady-state Conditions (Sweating Guarded Hot Plate Test)” International Organization for Standardization, Geneva, Switzerland (1993). |

| [3] | J. Huang and X. Qian “A new test method for measuring water vapor permeability of fabrics” Meas.Sci.Technol., vol. 18(9), pp.3043-3047, 2007. |

| [4] | A.K. Kikoin and I.K. Kikoin, Molecular Physics, M., Nature, 1976 (in Russian). |

| [5] | L.A. Grivtzova, I.V. Gnevysheva, L.F.Chyjkova and B.V.Saytin “About water vapor mechanism of permeability through hydrophobic porous materials”, Kogevenno- obyvnaya promushlennost (KOP), vol. 4, pp.48-49, 1980; L.F. Chyjkova, I.V.Gnevysheva, L.A. Grivtzova, N.L. Tankova, T.K. Shaposhnikova, B.V. Saytin and V.G. Kalashnikov “Interconnection between sorption of moisture and permeability materials”, KOP, vol. 9, pp.47-50, 1980; L.A.Grivtzova, I.V.Gnevysheva, N.L. Tankova, L.F. Chyjkova and B.V. Saytin “Influence of porosity on permeability of polymer materials”, KOP, vol. 10, pp.44-46, 1980. |

| [6] | ASTM E96, 1995. Standard Test Methods for Water Vapor Transmission of Materials, in “Annual Book of ASTM Standards 4.06” American Society for Testing and Materials. West Conshohochen, PA, 1995. |

| [7] | ISO 15496 2004 “Test Measurement of Water Vapor Permeability of Textiles for the purpose of Quality Control” International Organization for Standardization, Geneva, Switzerland, 2004. |

| [8] | ASTM F2298 2003. Standard Test Methods for Water Vapor Diffusion Resistance and Air Flow Resistance of Clothing Materials Using the Dynamic Moisture Permeation Cell in “Annual Book of ASTM Standards 11.03” American Society for Testing and Materials. West Conshohochen, PA, 2003. |

between its linear sizes l,b determining the normal test area

between its linear sizes l,b determining the normal test area  (

(  m2, for example) and its thickness δ (

m2, for example) and its thickness δ (  m, in the most cases). The water vapor transmission (WVT) rate of any PS and the textile fabrics, in particular, is of considerable interest for many branches of the practice and science. Such materials provide, for example, the steady moisture transfer from the skin of the weaver through the textile layers into the environment during heavy work or in hot climate conditions.There is a variety of methods to measure WVT (Δm is mass change):

m, in the most cases). The water vapor transmission (WVT) rate of any PS and the textile fabrics, in particular, is of considerable interest for many branches of the practice and science. Such materials provide, for example, the steady moisture transfer from the skin of the weaver through the textile layers into the environment during heavy work or in hot climate conditions.There is a variety of methods to measure WVT (Δm is mass change):

(i.e. the dynamical parameter) determined for the quasicontinuous PS-media by the non-equilibrium thermodynamics:

(i.e. the dynamical parameter) determined for the quasicontinuous PS-media by the non-equilibrium thermodynamics:

is the local density of a moist vapor while

is the local density of a moist vapor while  is the effective local kinematic velocity. The main problem of this interpretation is the reliable estimate of both quantities ρ and

is the effective local kinematic velocity. The main problem of this interpretation is the reliable estimate of both quantities ρ and  separately raking into account the netto-mass

separately raking into account the netto-mass  and the respective density

and the respective density  of a PS- material (M) itself. During the water vapor transport process its brutto-mass

of a PS- material (M) itself. During the water vapor transport process its brutto-mass  is increased due to the sorption ability (

is increased due to the sorption ability (  ) of any PS. Of course, these corrections are very different for the hydrophobic or weakly hydrophilic fabrics, on the one hand, and hydrophilic fabrics, on the other hand.Another fundamental problem of the proposed below approach based on the generalized for PS Fick’s law of diffusion:

) of any PS. Of course, these corrections are very different for the hydrophobic or weakly hydrophilic fabrics, on the one hand, and hydrophilic fabrics, on the other hand.Another fundamental problem of the proposed below approach based on the generalized for PS Fick’s law of diffusion:

which has the dimensionality of time. Indeed the comparison (1) and (3) leads to the interesting possibility to calculate

which has the dimensionality of time. Indeed the comparison (1) and (3) leads to the interesting possibility to calculate  from (2)

from (2)

) through the tested fabric’s layer 1-2 with the thickness δ up to the presumably zero pressure

) through the tested fabric’s layer 1-2 with the thickness δ up to the presumably zero pressure  of an experimental vessel 2. Of course, the atmospheric pressure

of an experimental vessel 2. Of course, the atmospheric pressure  can be added to the both limiting values of the finite difference

can be added to the both limiting values of the finite difference  to make the realistic estimate of its magnitude in terms of the measurable pressure.Nevertheless the fundamental question remains: Is the saturated vapor pressure of water divided by an arbitrary total width of layers the actual thermodynamic force to provide the respective flow of a moisture j through the fabric in accordance with (1)?

to make the realistic estimate of its magnitude in terms of the measurable pressure.Nevertheless the fundamental question remains: Is the saturated vapor pressure of water divided by an arbitrary total width of layers the actual thermodynamic force to provide the respective flow of a moisture j through the fabric in accordance with (1)?

is the measurable width of an air layer between the source of moisture and the internal surface 1 of a tested fabric while

is the measurable width of an air layer between the source of moisture and the internal surface 1 of a tested fabric while  for an outside air layer is a bad-defined parameter for any experiment or model.To elucidate the problem of an effective local kinematic velocity

for an outside air layer is a bad-defined parameter for any experiment or model.To elucidate the problem of an effective local kinematic velocity  (of its definition, first of all) in total, let us remind the main specific features of the standard permeability test. The most relevant one is, of course, the sweating guarded hot plate test specified in ISO 11092 [2]. Its detailed description and results can be found elsewhere [1] and only the main working equation should be discussed now:

(of its definition, first of all) in total, let us remind the main specific features of the standard permeability test. The most relevant one is, of course, the sweating guarded hot plate test specified in ISO 11092 [2]. Its detailed description and results can be found elsewhere [1] and only the main working equation should be discussed now:

is the total evaporative resistance provided by the porous metal plate (imitated the body skin at 35ºC) fabric and boundary air layer

is the total evaporative resistance provided by the porous metal plate (imitated the body skin at 35ºC) fabric and boundary air layer  in (5);

in (5);  - test area,

- test area,  ;

;  - the water vapor pressure of the above plate surface, Pa;

- the water vapor pressure of the above plate surface, Pa;  - the water vapor pressure of the air, i.e. of the undetermined layer of

- the water vapor pressure of the air, i.e. of the undetermined layer of  in (5); H – the heating power, W;

in (5); H – the heating power, W;  - the correction evaporative term for heating power, i.e. latent heat of vaporization, W. The intrinsic evaporative resistance of the fabric

- the correction evaporative term for heating power, i.e. latent heat of vaporization, W. The intrinsic evaporative resistance of the fabric  can be found as the difference:

can be found as the difference:

is the evaporative resistance of the porous plate and boundary air layer

is the evaporative resistance of the porous plate and boundary air layer  . Just the reciprocal

. Just the reciprocal  -value provides in this arrangement, which drives heat and moisture transfer upward only along the specimen thickness direction, the appropriate value of

-value provides in this arrangement, which drives heat and moisture transfer upward only along the specimen thickness direction, the appropriate value of  :

:

- and WVT-values. It is based on the change of relative humidity, i.e. measurable water vapor concentration gradient considered as thermodynamic force for the moist vapor transfer. This HQ-approach is closer to the main concept of Fick’s law for selfdiffusion formulated originally for the dilute gases:

- and WVT-values. It is based on the change of relative humidity, i.e. measurable water vapor concentration gradient considered as thermodynamic force for the moist vapor transfer. This HQ-approach is closer to the main concept of Fick’s law for selfdiffusion formulated originally for the dilute gases:

is the molecular-based diffusion coefficient:

is the molecular-based diffusion coefficient:

- the average velocity of molecular motion in any transport process realized in the pure dilute gas [4]:

- the average velocity of molecular motion in any transport process realized in the pure dilute gas [4]:

- concentration of particles with the molecular mass

- concentration of particles with the molecular mass  and σ – effective diameter of particles.It is worthwhile to note that the authors of HQ-method [3] themselves did not consider its generalized molecular interpretation for PS based on (9-11). However, the remarkable correlation between their measurements obtained by two different (HQ and ISO 11092) methods confirms completely the possibility of such analysis. It is found by us in terms of the reciprocal resistances (8), i.e. the effective diffusion velocities and is shown in Table 1.

and σ – effective diameter of particles.It is worthwhile to note that the authors of HQ-method [3] themselves did not consider its generalized molecular interpretation for PS based on (9-11). However, the remarkable correlation between their measurements obtained by two different (HQ and ISO 11092) methods confirms completely the possibility of such analysis. It is found by us in terms of the reciprocal resistances (8), i.e. the effective diffusion velocities and is shown in Table 1. ) and large (

) and large ( ) mean diameters of capillars, i.e. model of pores:

) mean diameters of capillars, i.e. model of pores:

) and water (

) and water ( ),

), - the universal gas constant and g – porosity determined by the common area of the surface pores

- the universal gas constant and g – porosity determined by the common area of the surface pores  , i.e.

, i.e.  . Unfortunately, the respective molecular approximations of generalized diffusion coefficient

. Unfortunately, the respective molecular approximations of generalized diffusion coefficient  :

:

and the very small

and the very small  either should be a priori given or should be measured by the quite formidable experiment [5]. Besides, Chyjkova et al [5] have not measured the grad P-value in (12,13) but have predicted it on the base of some unreliable, to our mind, estimates for

either should be a priori given or should be measured by the quite formidable experiment [5]. Besides, Chyjkova et al [5] have not measured the grad P-value in (12,13) but have predicted it on the base of some unreliable, to our mind, estimates for  in (14,15) and calculated

in (14,15) and calculated  -values.There are several rather reliable testing equipments (see, for example UTX-3360) for the so-called air permeability (AP) which is simply the velocity of a dry air u flowing through the thickness of PS:

-values.There are several rather reliable testing equipments (see, for example UTX-3360) for the so-called air permeability (AP) which is simply the velocity of a dry air u flowing through the thickness of PS:

- the measurable volume of a porous material (M). At first sight, one obtains from (16) the alternative to (4) variant for determination of a kinematic velocity if the condition

- the measurable volume of a porous material (M). At first sight, one obtains from (16) the alternative to (4) variant for determination of a kinematic velocity if the condition  is fulfilled:

is fulfilled:

of an air stream becomes questionable when the certain mass of a moist vapor remains in PS due to the sorption phenomenon. One should take into account the discontinuity of a relative humidity and the respective density “jump” between the ingoing 1 and outgoing 2 flows of a moving through fabric vapor.Another serious problem of the relevant experimental WVT-methodologies is itself their interpretation. One considers the WVT-quantity as the fabric’s characteristic parameter. Evidently, that this concept is an elusive one because the density of flow

of an air stream becomes questionable when the certain mass of a moist vapor remains in PS due to the sorption phenomenon. One should take into account the discontinuity of a relative humidity and the respective density “jump” between the ingoing 1 and outgoing 2 flows of a moving through fabric vapor.Another serious problem of the relevant experimental WVT-methodologies is itself their interpretation. One considers the WVT-quantity as the fabric’s characteristic parameter. Evidently, that this concept is an elusive one because the density of flow  (1) is a typical dynamic parameter of the linear non-equilibrium thermodynamics. In the formalism of a continuous media, it is simply a reply of system to the action of a thermodynamic force, which is the appropriate gradient. In other words, only the effective coefficient

(1) is a typical dynamic parameter of the linear non-equilibrium thermodynamics. In the formalism of a continuous media, it is simply a reply of system to the action of a thermodynamic force, which is the appropriate gradient. In other words, only the effective coefficient  can be the fabric’s parameter.The non-equilibrium thermodynamics states that the actual diffusion coefficient

can be the fabric’s parameter.The non-equilibrium thermodynamics states that the actual diffusion coefficient  from (9) plays also the role of kinematic velocity and/or temperature-conductivity in the Newton’s and Fourier’s laws, respectively (

from (9) plays also the role of kinematic velocity and/or temperature-conductivity in the Newton’s and Fourier’s laws, respectively (  ) at least, for a diluted gas:

) at least, for a diluted gas:

is the specific isochoric heat capacity.We assumed now that the discussed here well-established formalism for the small densities of bulk gases can be extended and applied to the dense fluid (most vapor) states and, even, to the gas-liquid-transition states if the following conditions are fulfilled:1) the density profile ρ(x) along the chosen direction of a mass-transfer process should be given to determine the stationary (or, about the equilibrium for a phase-transition state) grad ρ in (9);2) the density of a mass-flow

is the specific isochoric heat capacity.We assumed now that the discussed here well-established formalism for the small densities of bulk gases can be extended and applied to the dense fluid (most vapor) states and, even, to the gas-liquid-transition states if the following conditions are fulfilled:1) the density profile ρ(x) along the chosen direction of a mass-transfer process should be given to determine the stationary (or, about the equilibrium for a phase-transition state) grad ρ in (9);2) the density of a mass-flow  along the same direction should be measured by experiment to evaluate then the diffusion coefficient D;3) the dynamical viscosity η in (18a) as well as the heat transfer coefficient

along the same direction should be measured by experiment to evaluate then the diffusion coefficient D;3) the dynamical viscosity η in (18a) as well as the heat transfer coefficient  in (18b) have to be calculated from the measurable value of the heat capacity

in (18b) have to be calculated from the measurable value of the heat capacity  and the above estimates of D- and ρ(x)-values;4) the effective modified quantity ρ from (18) determined for the special thin δ-layer along the x-direction becomes in the proposed here methodology the main parameter if the divergence of its profile ρ(x) is locally possible just in this layer;5) accordingly to the statement 4) the thin layer of any fabric with the surface

and the above estimates of D- and ρ(x)-values;4) the effective modified quantity ρ from (18) determined for the special thin δ-layer along the x-direction becomes in the proposed here methodology the main parameter if the divergence of its profile ρ(x) is locally possible just in this layer;5) accordingly to the statement 4) the thin layer of any fabric with the surface  located normally to the x-direction of a mass-heat transfer is a reason to change sharply the local value of density ρ taking into account the porous (fractal) structure of its distribution.

located normally to the x-direction of a mass-heat transfer is a reason to change sharply the local value of density ρ taking into account the porous (fractal) structure of its distribution. when grad P = 0).

when grad P = 0). -value:1) It follows from (1) and (3) that an WVT-ratio (see Table 4) represents also the ratio of the respective gradients:

-value:1) It follows from (1) and (3) that an WVT-ratio (see Table 4) represents also the ratio of the respective gradients:

to predict the others (effective)

to predict the others (effective)  -values for the different methods from the WVT-ratio:

-values for the different methods from the WVT-ratio:

to calculate the

to calculate the  -values represented in Table 5.

-values represented in Table 5.

itself instead of the dynamic WVT-characteristic which is mainly determined by the appropriate thermodynamic force in the variants (1,3) of the generalized linear Fick’s law, formulated for PS.Obviously that the remaining problem is the measurement of pressure drop across the sample. An absence of such experimental parameter cannot be compensated, from our viewpoint, by its theoretical estimates. This arbitrary estimate may cause a large shift in diffusion resistance even if the WVT-value is reliably measured. A combination of AP- and WVT-measurements of the same sample at the same conditions may be essential to solve independently this fundamental problem.

itself instead of the dynamic WVT-characteristic which is mainly determined by the appropriate thermodynamic force in the variants (1,3) of the generalized linear Fick’s law, formulated for PS.Obviously that the remaining problem is the measurement of pressure drop across the sample. An absence of such experimental parameter cannot be compensated, from our viewpoint, by its theoretical estimates. This arbitrary estimate may cause a large shift in diffusion resistance even if the WVT-value is reliably measured. A combination of AP- and WVT-measurements of the same sample at the same conditions may be essential to solve independently this fundamental problem. Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML

for Six Fabrics 1-6 from Table 2

for Six Fabrics 1-6 from Table 2