S. D. Asgekar1, V. K. Joshi2, Priti S. Futane1, P. S. Joshi1

1Textile and Engineering Institute, Ichalkaranji, India

2Shri Gurugovindsinghji Institute of Engineering and Techology, Nanded, India

Correspondence to: S. D. Asgekar, Textile and Engineering Institute, Ichalkaranji, India.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Sugarcane being the agricultural waste can be effectively used in combination with coir for enhancement of the mechanical properties of composites. The sugarcane fibres/coir reinforced composites were made in phenol formaldehyde resin. Composite sheets were made with three different thickness values, viz. 2.5mm, 6mm and 10mm. Four varieties of sugarcane namely CO86032, COVSI9805, COM265 and COC671 with 14 month maturity period were taken for making the composites. The properties of composites are compared with 100% coir composites. The average tensile strength, Izod impact strength, compressive strength, water holding capacity for sugarcane/coir reinforced composites increases, while flexural strength decreases with thickness of composite sheets. These composites with fairly good mechanical properties can be used as structural materials like false ceiling.

Keywords:

Sugarcane Fibres, Coir Fibres, Phenol Formaldehyde Resin, Composites, False Ceiling

Cite this paper: S. D. Asgekar, V. K. Joshi, Priti S. Futane, P. S. Joshi, Characteristics of Sugarcane/Coir Fibres Reinforced Composites in Phenol Formaldehyde Resin, International Journal of Composite Materials, Vol. 3 No. 6, 2013, pp. 156-162. doi: 10.5923/j.cmaterials.20130306.03.

1. Introduction

Nowadays, the natural fibres reinforced composites have received much attention in producing potential structural materials. The natural fibres such as jute, sisal, coir, banana, sugarcane, hemp have many attractive characteristics like low density, less abrasive, low cost, biodegradability, and renewability over traditional glass and organic fibres[1, 2]. Sugarcane bagasse is a waste product widely generated in high proportion in sugar mill. It is a fibrous residue left over after crushing and extraction of juice from the sugarcane. Sugarcane fibres are extracted from the hard encrusting material of sugarcane plant called as rind, by alkali treatment[3]. Recently many studies have been reported on the bagasse/ sugarcane fibre reinforced composites. Sugarcane being the agricultural waste can be effectively used in combination with coir for enhancement of the mechanical properties of composites. Bagasse based thermoplastic composites can replace wood in applications such as furniture and interior panels[4].In this study we have made an attempt to manufacture the sugarcane /coir fibre reinforced composite in phenol formaldehyde resin and the properties are compared with 100% coir reinforced composite. Also the possibility of its probable use in structural materials such as false ceiling is explored.

2. Experimental

2.1. Materials

In this study four Sugarcane (saccharum officinarum) varieties, namely CO86032, COVSI9805, COM265 and COC671, with maturity period of 14 months were collected from Jawahar Sahakari Sugar Mills limited, Hupari, Maharashtra (India). The coir (cocos nucifera) fibres were collected from Central Institute of Coir Technology, Coir Board, Bangalore (India). Phenol formaldehyde resin was purchased from market.

2.2. Methods

2.2.1. Extraction of Sugar Cane Fibres

The extraction of fibres involved the following steps.i) Mechanical separation:The sugarcane samples of above mentioned varieties were subjected to miniature juice extractor wherein sugarcane juice was separated from bagasse. The soft core part pith was removed from bagasse manually. The hard rind was then cut across the length so that it is free from nodes.ii) Chemical extraction:The rind was then subjected to hot water treatment (material to liquor ratio 1:50). In this process, rind was kept in hot water at around 90°c for one hour, for removal of colouring matters and traces of sugar. It was then dried in the sunlight. Finally, the rind was subjected to 0.1N NaOH treatment. This process was carried out at boiling water temperature for four hours at atmospheric pressure, with material to liquor ratio 1:100(fig 1). A stirring action was used to enhance the fibre separation. The well separated fibres were then sun dried. | Figure 1. Chemical Extraction Process |

2.2.2. Manufacturing of Nonwovens

It involves the following stagesi) Carding:The carding process involves the separation of fibres. The fibres extracted from given varieties were subjected to the Bau Bremen 838 carding machine for effective opening of fibres. | Figure 2. Sugarcane fibres |

| Figure 3. Coir fibres |

ii) Web Formation:The well separated fibres were used for the formation of web. In this process the fibres were mixed with coir in the ratio 4:1. The mixture was then subjected to Besch NR_51 needle punching machine for the formation of web. The needle density used in the formation of web was 800 needles per square feet. The web so formed was then used for manufacturing the composite. | Figure 4. Besch NR_51 needle punching machine |

| Figure 5. Hydraulic hot press |

| Figure 6. Composite sheet |

2.2.3. Composite Manufacturing

Sugarcane/coir and pure coir fibre composites were manufactured by hot press molding machine (US SD, GMD888). In this process fibre web was impregnated in phenol formaldehyde resin, with fibre to resin ratio 1:1. The impregnated web was sun dried for one hour and then pressed by hydraulic hot press at 40kg/sq feet at 130℃ for 6min. Composites sheets were made with three different thickness values, viz. 2.5mm, 6mm and 10mm.

3. Testing

3.1. Fibre Testing

i) Fibre fineness: The fineness of sugarcane fibre was measured by gravimetric method according to ASTM D1577-07 standards. A bundle of fibres was weighed and total length of fibres in a bundle was measured. ii) Tensile Properties: The tensile test was carried out on the Instron5565 tester. This test was conducted according to the ASTMD 3379 standards (specimen length 25cm, speed of testing 2mm/min).

3.2. Composite Testing

The composite sheets were subjected to various mechanical tests. i) Tensile testing:The Tensile test was performed on Universal Tensile Machine (UTM), according to ASTM D638 standards. The test was carried out at cross head speed 50mm/min with span distance of 250mm. ii) Compressive testing:The Compressive test was performed on Universal Tensile Machine (UTM), according to ASTM D695 standards. The test was carried out at cross head speed 1.3mm/min with span distance of 100mm. iii) Flexural testing:The Flexural test was performed on Universal Tensile Machine (UTM) according to ASTM D790 standards. The test was carried out at cross head speed 1.3mm/min with span distance of 100mm. iv) Izod Impact testing:The Izod impact test was performed on Izod impact tester, according to ASTM D256 standards.v) Water absorption testing:This test was conducted according to ASTM D590 standards. The percentage water absorption was calculated by the weight difference between dry and wet samples. The formula for percentage water absorption is given below.∆M (%) = (Mf − Mi / Mi ) X 100Where Mf and Mi are the respective weights of wet and dry samples.

4. Result and Discussion

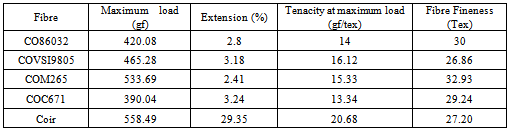

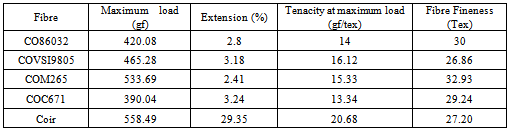

The properties of sugarcane and coir fibres are summarized in the following table 1.Table 1. Tensile properties of sugarcane and coir fibre

|

| |

|

The specifications of composites areS1 = Co86032+ coir, S2 = CoVSI9805+ coir,S3 = Com 265+ coir,S4 = Coc671+ coir,C =100% coir.The results are analysed by two way ANOVA technique.

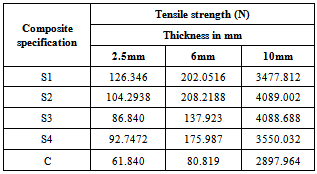

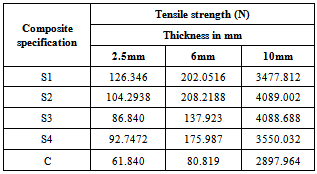

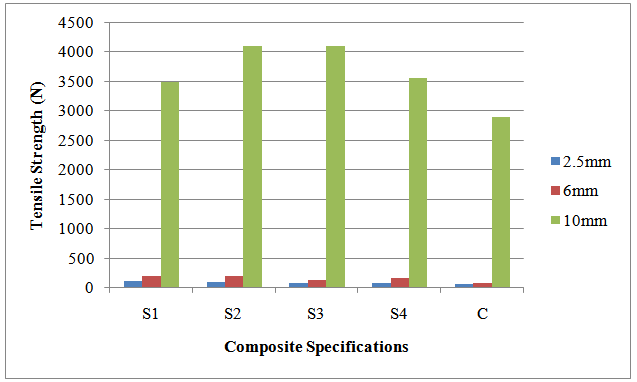

4.1. Tensile Strength

The statistical analysis reveals that there is significant increase in tensile strength of all sugarcane /coir composites compared to 100% coir. Composites made from sugarcane/ coir for all cases shows no significant difference in tensile strength which indicates that the tensile strength is independent of variety. The average tensile strength for all cases increases significantly with thickness. The higher values of sugarcane /coir composite are mainly attributed to the lower density of sugarcane fibres. In the given volume of composite more number of sugarcane fibres are accommodated as compared to the coir fibres. Due to which there is increase in tensile strength of sugarcane/coir reinforced composites. Especially at 10 mm thickness, there is steep rise in tensile strength .usually the structural materials for which tensile strength is important property, the composite sheets with 10 mm thickness can be used exclusively.Table 2. Average tensile strength of composites

|

| |

|

| Graph 1. Tensile strength of composites |

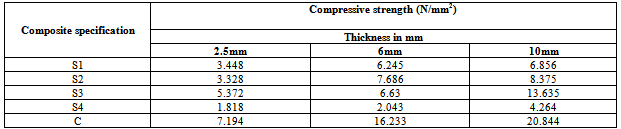

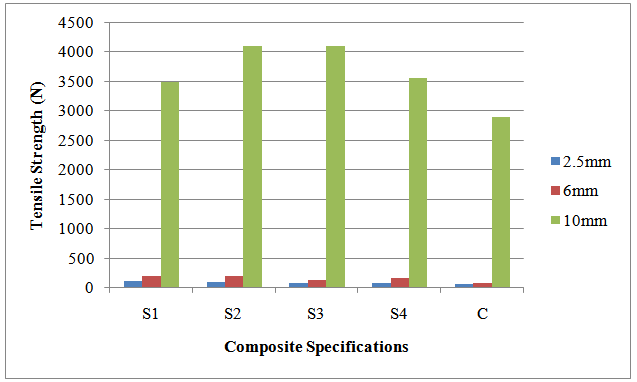

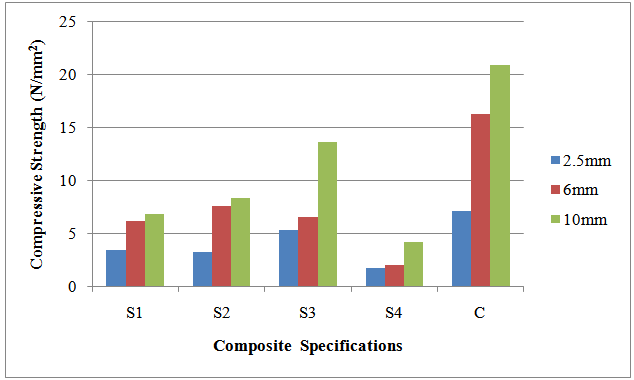

4.2. Compressive Strength

Table 3. Average compressive strength of composites

|

| |

|

The statistical analysis reveals that there is significant decrease in Compressive strength of all sugarcane /coir composites compared to 100% coir composite. The compressive strength of case S4 is lowest while S3 shows higher values. The rest two cases show moderate values of compressive strength. The average Compressive strength for all cases increases significantly with thickness. The high compressive strength of 100% coir composite can be attributed to its high extensibility compared to sugarcane.  | Graph 2. Compressive strength of composites |

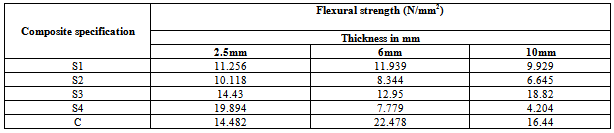

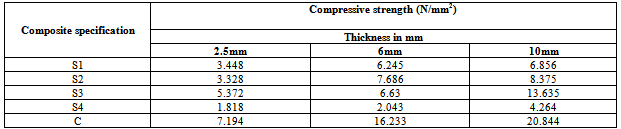

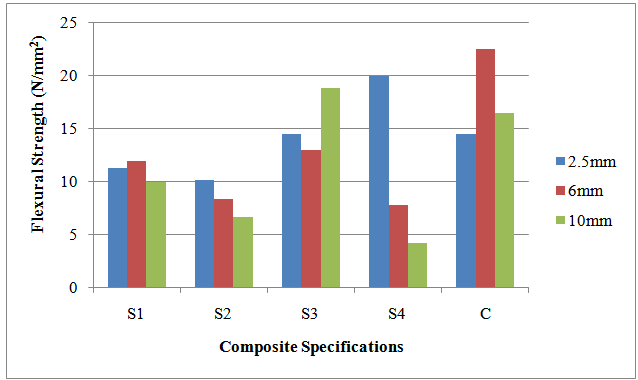

4.3. Flexural Strength

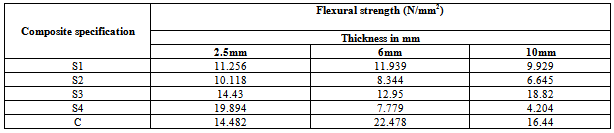

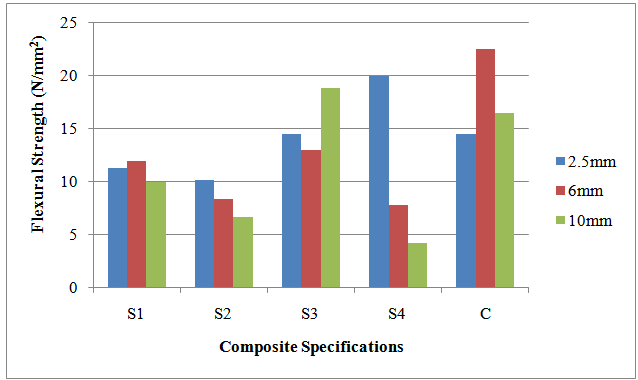

Table 4. Average flexural strength of composites

|

| |

|

The statistical analysis reveals that there is significant difference in flexural strength of all sugarcane /coir composites compared to 100% coir composite. Composites made from sugarcane/coir for all cases shows no significant difference in flexural strength which indicates flexural strength is independent of variety. The average flexural strength at 2.5mm thickness is comparatively better for all cases of sugarcane/coir composites. In general the flexural strength of 100% coir composite is high compared to sugarcane/coir composites. The flexural strength which is the measure of resistance to bending can be related to the extensibility of fibres. Since the extensibility of coir is high in comparison with sugarcane, its flexural strength is high. | Graph 3. Flexural strength of composites |

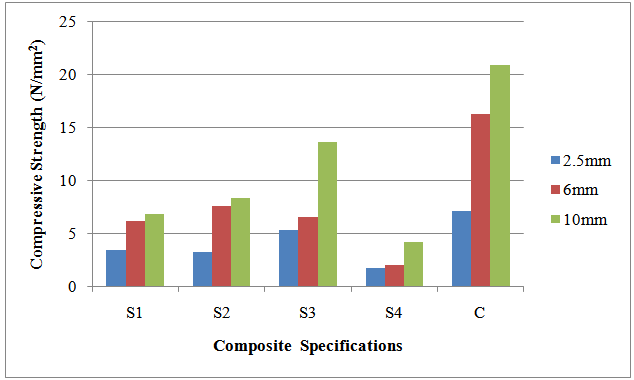

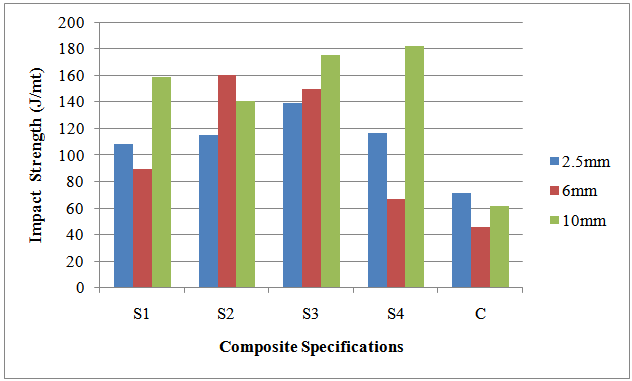

4.4. Impact Strength

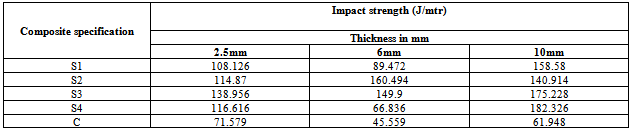

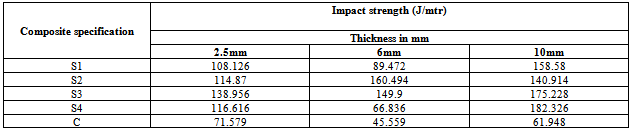

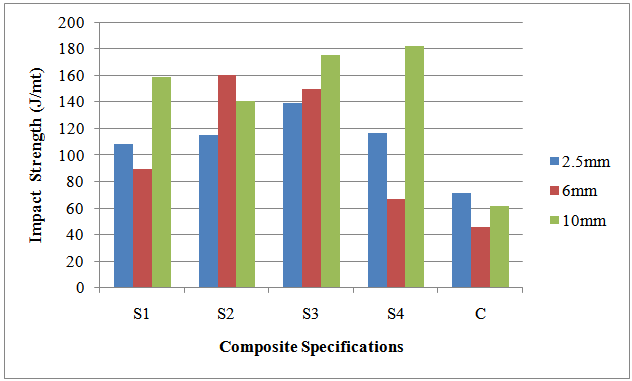

Table 5. Average impact strength of composites

|

| |

|

The statistical analysis reveals that there is significant increase in impact strength of all sugarcane /coir reinforced composites compared to 100% coir composites. Composites made from sugarcane/coir for all cases shows no significant difference in impact strength which indicates that it is independent of variety. The average impact strength shows no specific trend with respect to thickness but impact strength for all cases corresponding to 10 mm thickness is consistently high. The high values of impact strength for sugarcane/coir reinforced composite can be correlated to its tensile strength. | Graph 4. Impact strength of composites |

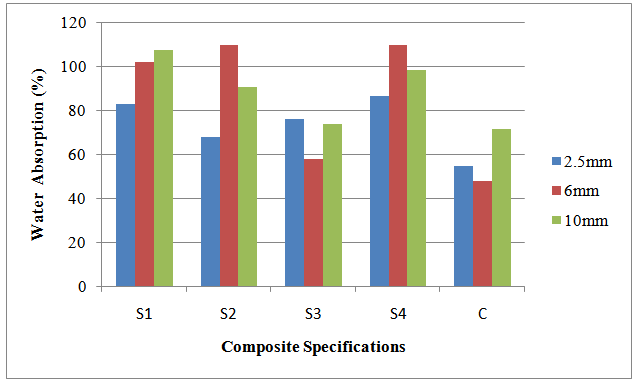

4.5. Water Absorption Test

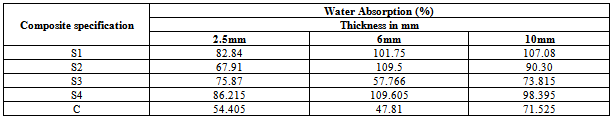

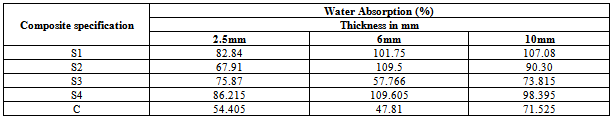

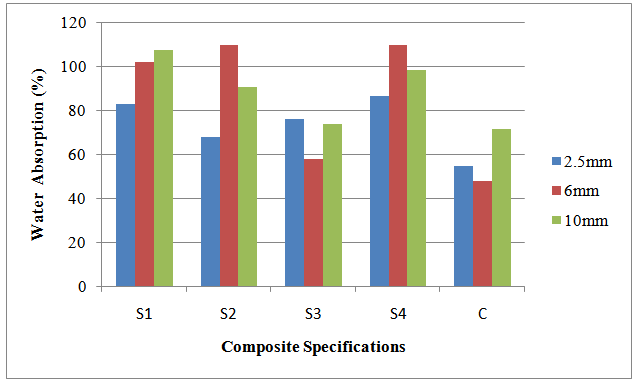

Table 6. Average water absorption in percent

|

| |

|

The statistical analysis reveals that there is significant increase in water absorption for all cases of sugarcane/coir composites compared to 100% coir composite. Composites made from sugarcane/coir for all cases show no significant difference in water absorption which indicates water absorption is independent of variety. The water absorption shows no specific trend with respect to thickness. The higher values of water absorption in case of sugarcane /coir reinforced composites are mainly related to the more number of sugarcane fibres that can be accommodated in the given volume of composite. The high values of water absorption for sugarcane/coir based composites confirm its suitability in the false ceiling which can maintain the moisture level in the hall.  | Graph 5. Water absorption of composites in percentage |

5. Conclusions

The results can be summarized as followsThe average tensile strength for all cases shows significant increase with thickness. The tensile strength increases significantly for sugarcane/coir composites in comparison with 100% coir composites. The average Compressive strength for all cases increases significantly with thickness. Compressive strength of all sugarcane /coir composites shows significant decrease in comparison with 100% coir composite. The average flexural strength of all sugarcane /coir composites shows significant difference compared to 100% coir composite.The average impact strength of all sugarcane /coir composites increases significantly compared to 100% coir composite. The impact strength shows no specific trend with respect to thickness but it is consistently high for all cases corresponding to 10 mm thickness.The water absorption of all sugarcane /coir composites increases significantly compared to 100% coir composite. There is no specific trend for water absorption with respect to thickness. The high values of water absorption for sugarcane/coir based composites confirm its suitability in the false ceiling.As far as the varieties are concerned no significant difference was found in these properties indicating the performance of composites is independent of variety.In general mechanical properties of sugarcane /coir mix reinforced composites corresponding to 10mm thickness are fairly good and can be used as the structural materials.

ACKNOWLEDGEMENTS

Author is thankful to Principal Prof (Dr.) P. V. Kadole and head of the department Prof. (Dr.) U. J. Patil, of Textile and engineering Institute, Ichalkaranji, (India), for their encouragement.

References

| [1] | A. K. Bledzeki and J. Gassan, “Composites reinforced with cellulose based fibre”, Prog. Polym. Sci., 24 (1999), 221. |

| [2] | A. K. Mohanty, M. Mishra and G. Hinrichsen, “Biofibres, biodegradable polymers and biocomposites: An overview”, Macromole. Mater. Eng., 1 (2000), 276/277. |

| [3] | Collier. B., Collier J., Agarwal. P., “Extraction of fibres from sugarcane”, Textile Research Journal, 12, 1992, P 741-748. |

| [4] | Monteiro, S. N. Rodriquez, R. J. S., and De Souza, M. V., “Sugarcane bagasse waste in low cost composites”, Advance Performance Materials, 1998, 5(3), 183-191. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML