Muhammad Jahidul Hoque1, Suvra Chakraborty1, Monon Mahbub1, Md. Abdul Gafur2

1Department of Mechanical Engineering, Bangladesh University of Engineering & Technology, Dhaka, 1000, Bangladesh

2Department of Materials & Metallurgical Engineering, Bangladesh University of Engineering & Technology, Dhaka, 1000, Bangladesh

Correspondence to: Muhammad Jahidul Hoque, Department of Mechanical Engineering, Bangladesh University of Engineering & Technology, Dhaka, 1000, Bangladesh.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

The thermal conductivity of systems based on polypropylene, filled graphite and carbon black have been studied. Graphite and carbon black having different particle shapes were used as fillers. The PP-Gr & PP-CB composites were prepared using extrusion and the hot compression mold technique. The composite preparation conditions allowed the formation of a random distribution of filler particles in the polymer matrix. LEES method was followed for thermal conductivity measurement . Different weight percentage analysis for both type of filler in a single matrix were allowed. Analysis by varying total mass of the composite were also performed. The concentration dependence of the thermal conductivity shows no significant jump for the percolation threshold. Experimental results showed promising trend as described by Lichtenecker proposal and shows almost well-disposed accordance with theoretical values.

Keywords:

Polymer Composites, Compression Molding, Percolation Threshold, Packing Factor, Thermal Conductivity

Cite this paper: Muhammad Jahidul Hoque, Suvra Chakraborty, Monon Mahbub, Md. Abdul Gafur, Thermal Conductivity of Polypropylene Based Composite Materials Filled with Graphite and Carbon Black, International Journal of Composite Materials, Vol. 3 No. 5, 2013, pp. 136-140. doi: 10.5923/j.cmaterials.20130305.04.

1. Introduction

Composite materials are made by combining reinforcement (fiber) with matrix (resin), and this combination of the fiber and matrix provide characteristics superior to either of the materials alone. The term composite material is used to describe the macroscopic combination of two or more materials. The fundamental goal in the production and application of composite materials is to achieve a desired performance from the composite that is not obtainable from the separate constituents or from other single phase materials.Nowadays, the use of composite materials in different fields of engineering (microelectronics, aeronautics and space, transport, etc.) is continually increasing[1]. The interest for these materials arises from the fact that it is possible to develop new materials with properties adapted to specific applications. Moreover, in some cases, composite materials allow the physical properties of each component used in the manufacturing process to be combined.Polymer composite are now an important class of engineering materials. The properties of composites are largely influenced by the properties of their constituents and the distribution and interactions among them. The constituents usually interact in a synergic way, providing properties that are not accounted for by a simple volume - fraction of the components. Along with the volume fraction and the distribution of discrete units in the continuous phase, the interfacial area plays an important role in determining the extent of interaction between the reinforcement and the matrix and in this way the final properties of the composite.Versatile combination of the matrix and filler can be possible to improve and develop different properties of the composite materials. Such as polymer composites filled with metal are of interest for many fields of engineering. Carbon based (graphite, carbon black) composites have exceptional mechanical properties which are unequaled by other materials. The material is strong, stiff, and lightweight, corrosion resistive. Graphite composite is the material of choice for applications where lightweight & superior performance is paramount, such as components for spacecrafts, fighter aircrafts, and racecars[2].Today the composite marketplace is widespread. As reported recently by the SPI Composites Institute, the largest market is still in transportation (31%), but construction (19.7%), marine(12.4%), electrical/electronic equipment (9.9%), consumer(5.8%), and appliance/business equipment are also large markets. The aircraft/airspace market represents only 0.8% which is surprising with regard to its importance in the origins of composite. The purpose of this study is to measure the thermal conductivity of polymer composite using a newer combination of polypropylene - graphite, polypropylene- carbon black. And to provide general information and specifications on graphite composite materials and carbon black composite materials for designing lightweight, thermal conductive or resistive , high performance products with graphite and carbon black composites.In our study we prepared sample through several steps such as particle treatment, extruding(initial mixing of polymer & filler), hot pressing (final sample),sample preparation. A common polymer materials polypropylene is used as matrix for both of the filler graphite and carbon black. Using standard procedure of preparing sample the thermal conductivity of the matrix is measured with the help of LEES apparatus. It was intended to find out the trend of the thermal conductivity of polymer composite for different percentage content of graphite and carbon black as filler in certain weight of polymer composite and also by varying the total weight content of single polymer composite. Comparison of the experimental result with theoretical model result and analyze any degree of divergence of these result and to find out the reason of any discrepancy if any was also studied.

2. Thermal Conductivity of the Composite

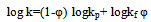

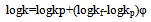

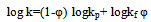

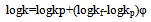

Several investigations of polymer composites with dispersed fillers show the absence of percolation behavior of the thermal conductivity k with increasing dispersed filler concentration[3-6]. The realistic filler geometric characteristics connected with the packing factor F value have not been taken into account[7]. This is due to the fact that the thermal conductivities of the dispersed filler kf and of the polymer matrix kp are comparable to each other, their ratio not being more than 103, whereas the filler electrical conductivity ϭf is 1010–1020 times larger than the polymer conductivity ϭp. The model[8] predicts the percolation threshold appearance only if the ratio of filler conductivity to polymer conductivity is larger than 105. In fact, the percolation theory is applied only to systems having conductive sites (or bonds) in a non-conductive medium[9].Lichtenecker proposed such a dependence, that the same function describes both the conductivity and resistance: k= f( kp; kf ;φ); 1/k = f (1/kp; 1/kf ;φ)[10] . The following function fulfills the above conditions: | (1) |

Taking the logarithm, we get: or

or | (2) |

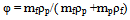

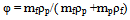

where φ is the content of the filler in the polymer composite wheremf = Mass of the fillermp = Mass of the polymerρp = Density of the fillerρf = Density of the polymerTopological peculiarities of the systems filled with dispersed filler has not taken into account in Eqs. (1)–(2). When such systems are filled, the thermal conductivity of the composites increases from kp to the largest kF value within the 0 < φ < F concentration interval. An equation describing the concentration dependence of thermal conductivity has been proposed for that case in[7] ,

wheremf = Mass of the fillermp = Mass of the polymerρp = Density of the fillerρf = Density of the polymerTopological peculiarities of the systems filled with dispersed filler has not taken into account in Eqs. (1)–(2). When such systems are filled, the thermal conductivity of the composites increases from kp to the largest kF value within the 0 < φ < F concentration interval. An equation describing the concentration dependence of thermal conductivity has been proposed for that case in[7] , | (3) |

Evidently, if F=1 and N=1, then Eq.(3) is identical to Eq. (2) and the behavior of the system follows Lichtenecker’s dependence. The value of F=1 means that the filler phase possesses such properties that it fills up all composite volume at φ=F (limit content), i.e. the filler content changes from 0 to 1 volume portion and kF=kf . This case is realized for systems having continuous second phase, for example, alloys or solutions. If the second phase is a dispersed filler, then the F value is taken into account by φ/F, which also changes from 0 to 1.This evaluation of F can help further to determine the value of N and trend of the findings[9].

3. Test for Thermal Conductivity

According to ASTM Method C 201 the thermal conductivity can be measured[11].An alternative method for the test of thermal conductivity is LEES and Chorlton’s method[12]. The thermal conductivity of a poorly conductive polymer composite having thin layer is measured by this method. Difficulty in maintaining the face at uniform temperature overcame by placing a good conductor copper, of exactly the same diameter as the experimental slab on each side of poor conductor and in measuring that temperature.If T1= Temperature of top copper plate at steady state.T2= Temperature of bottom copper plate at steady state.A= Cross sectional area of polymer composite sample.K= Thermal conductivity of polymer composite sample.d= Thickness of the slab polymer composite sample.then the quantity of heat conducted per second through composite sample is  | (4) |

At the steady state this heat Q is radiated per second from bottom copper plate. If m and s be the mass and specific heat of bottom copper plate and dT/dt be its cooling rate at temperature T2, then the heat loss (radiated per second from bottom copper plate ) is | (5) |

dT/dt is determined by performing a subsidiary experiment. From equation (4) and (5) the thermal conductivity of polymer composite is | (6) |

4. Experimental

4.1. Materials

4.1.1. Polymer

The polymer used in this study is polypropylene (PP) and it is isotactic(Melting point 176°C ) type PP. Density: 850 kg/m3 . Thermal conductivity 0.1~0.22 W/mK. In isotactic PP all methyl groups positioned at the same side with respect to the backbone of the polymer chain without any branching [13].

4.1.2. The Fillers

The fillers used are graphite and carbon black.Graphite(gr): Graphite powder with the average particle size ranging from 10 to 20 µm. Black in color, density: 2160 kg / m3 ,thermal conductivity: 119~165 W/mK, Carbon -graphite%=30-70.Carbon black(CB): CB is furnace black type, has density 1800~2100 Kg/m3, thermal conductivity is 0.141for grade 6, 0.182for grade 6 spheron.

4.2. Sample Preparation

For sample of pure polypropylene, moisture removal of polymer is done by placing required amount of PP in a furnace at 50℃ for 3 hours. PP-GR, PP-CB mixtures were prepared by extrusion process, by gradually adding the appropriate amount of the filler in the polymer matrix.The matrix-filler mixing was performed at a temperature slightly above the melting point of the polymer. And the moderate speed of the rotor is maintained. For homogeneous mixing of the polymer and filler this mixing process is repeated for at least 3 times. Then noodles from the extruder turned into small tablet for compression molding.Compression molding is done at sufficient temperature and liver oil pressure and special water cooling arrangement were maintained with water jacket. Square sample from compression molding is then grinded for making circular shape with required dimension and treated to prepare it for measuring thermal conductivity using LEES apparatus.

4.3. Characterization

LEES apparatus was used for thermal conductivity measurement. It consist of two copper disc. Oil bath, oil supplying pump, oil heating arrangement and digital temperature measurement arrangement .Polymer composite was placed between two good conducting copper disc in the LEES apparatus. Hot silicon oil is supplied by centrifugal pump for heating the tested sample and then cooling rate is measured by using cooling temperature for a certain time limit. At steady state conduction heat from the sample equals the heat radiation and convection with the surrounding from copper disc. Then thermal conductivity of the polymer composite is measured by equalizing Fourier’s law of conduction and Newton’s cooling law.

5. Results and Discussion

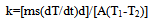

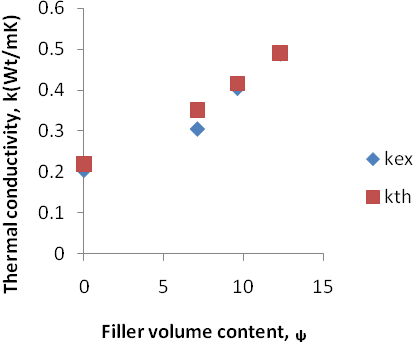

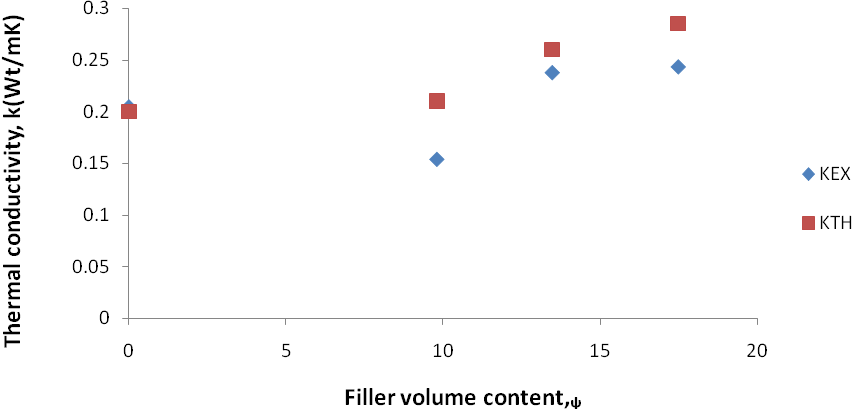

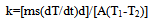

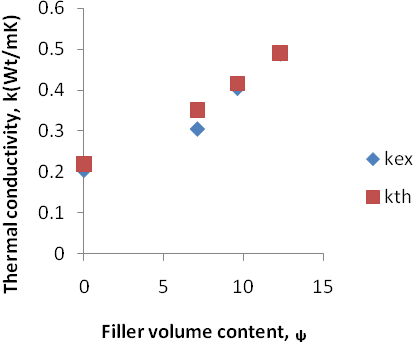

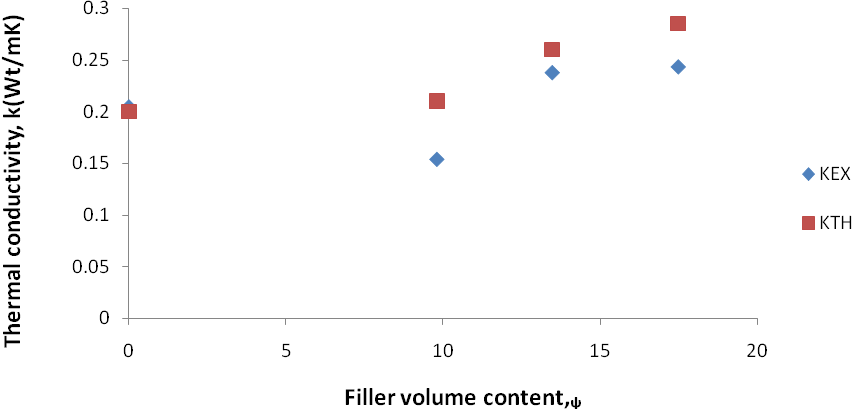

All findings of theoretical(literature) and experimental results are compared for different combination. Dependence of the thermal conductivity on filler volume content for the composites of carbon black studied are shown in Figure1. & Figure2. | Figure 1. Concentration dependence of the thermal conductivity of the composite: PP-CB(grade 6): square -theoretical conductivity, rombos- experimental conductivity |

| Figure 2. Concentration dependence of the thermal conductivity of the composite: PP-CB(grade 6- spheron) square -theoretical conductivity, rombos- experimental conductivity |

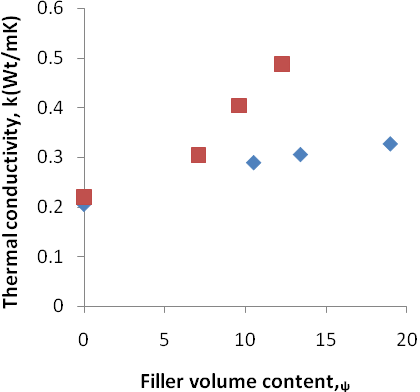

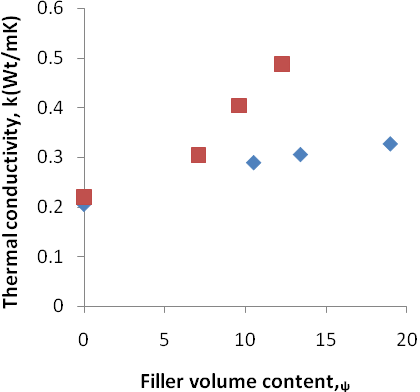

| Figure 3. Concentration dependence of the thermal conductivity of the composite: PP-Graphite with high carbon content |

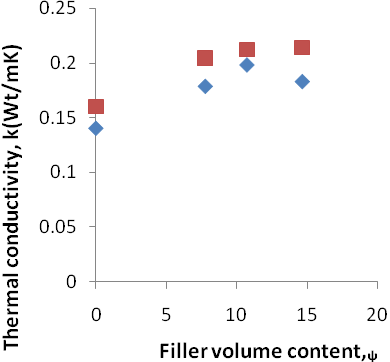

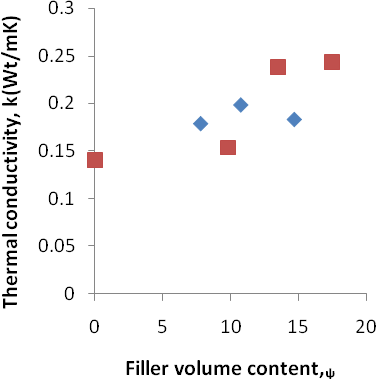

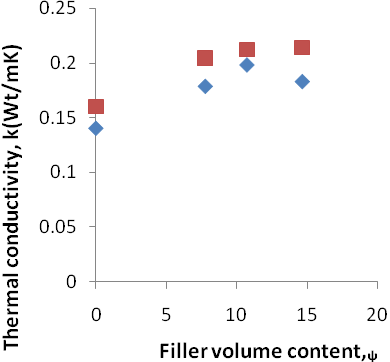

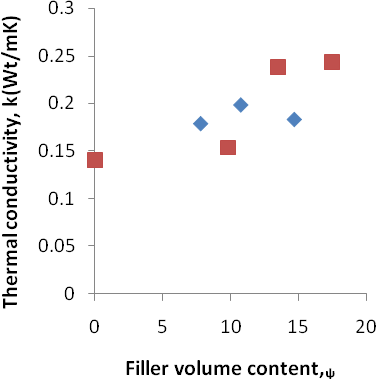

Dependence of the thermal conductivity on filler volume content for the composites of graphite studied are shown in Figure3. & Figure4. Comparison of both the experimental and theoretical observation.Polymer composite filled with high carbon content graphite shows less discrepancy of experimental & theoretical observation than low carbon content graphite filled composite. And in some filler volume content theoretical proposal leads experimental conductivity for composite material having graphite with low carbon content. | Figure 4. Concentration dependence of the thermal conductivity of the composite: PP-Graphite with low carbon content |

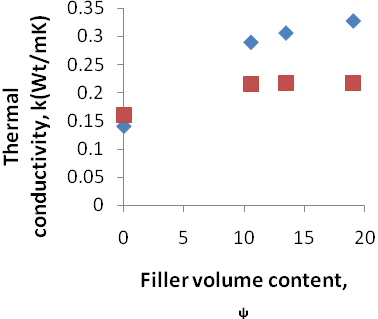

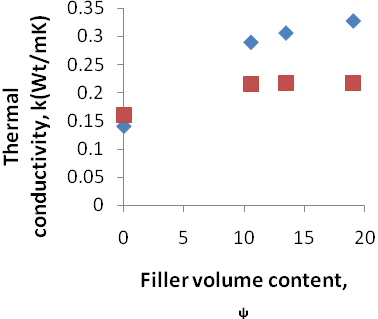

Low carbon content graphite filled polymer composite shows steady trend after certain filler content, which is absent in PP-Graphite (HCC) composite. Spheron Carbon black has higher thermal conductivity in comparison witn grade 6 carbon black, but much less than PP-Graphite composite as seen from both Figure5.& Figure6. for most of the filler volume content | Figure 5. Comparison of thermal conductivity of PP-Graphite(HCC) & PP- CB(grade6 spheron) . Square: PP-Gr, Rombos: PP-CB |

| Figure 6. Comparison of thermal conductivity of PP-Graphite(lCC) & PP- CB(grade6 ) . Square: PP-Gr, Rombos: PP-CB |

6. Conclusions

The result obtained with the investigation of polymer composite filled with graphite and carbon black allow us to draw the following conclusion.In explaining the concentration dependence of thermal conductivity of polymer composite filled with carbon black of grade 6 exhibit more convenient result by following the proposal of theoretical model. Both type graphite filled composite shows increasing trend of thermal conductivity, where sample having graphite of high carbon percentage shows more increment. But after 19% filler content PP-Graphite(LCC) composite shows steady trend violating the absence of percolation behavior of the thermal conductivity with increasing dispersed filler concentration.

References

| [1] | Abderrahim Boudenne, Laurent Ibos, Magali Fois, Evelyne Gehin, Jean-Charles Majeste, “Thermo-physical Properties Of Polypropylene/Aluminum Composites”. |

| [2] | Performance composite.com. |

| [3] | Progelhof RC,Throne JL, Ruetsch RR. Polym Eng Sci 1976;16:615 |

| [4] | kusy RP, Corneliussen RD. Polym Eng Sci 1975;15:107–12 |

| [5] | Bigg DM. Adv Polym Sci 1995;119:1–30. |

| [6] | Sundstrom DW, Lee Y-D. J Appl Polym Sci 1972; 16: 3159–67. |

| [7] | Mamunya EP. Funct Mater 1998;5:410–2. |

| [8] | Rymarenko NL, Voitenko AI, Novikov VV, Privalko VP. Ukrain Polym J 1992;1:259–66.998;5:410–2. |

| [9] | Ye.P. Mamunya , V.V. Davydenko , P. Pissis , E.V. Lebedev ,“Electrical and thermal conductivity of polymers filled with metal powders”, European Polymer Journal 38 (2002) 1887–1897 |

| [10] | Dulnev GN, Zarichnyak YuP. Thermal conductivity of compounds and composite materials. Leningrad: Energija; 1974 (in Russian). |

| [11] | ASTM designation c 201-68 “ Standard test methods for Thermal conductivity of refractories” |

| [12] | Ahamed Giasuddin and shabuddin, practical physics, 2nd edition 155. |

| [13] | A. Akinci, “Mechanical and structural properties of polypropylene composites filled with graphite flakes”, Received 20.11.2008; published in revised form 01.02.2009. |

or

or

wheremf = Mass of the fillermp = Mass of the polymerρp = Density of the fillerρf = Density of the polymerTopological peculiarities of the systems filled with dispersed filler has not taken into account in Eqs. (1)–(2). When such systems are filled, the thermal conductivity of the composites increases from kp to the largest kF value within the 0 < φ < F concentration interval. An equation describing the concentration dependence of thermal conductivity has been proposed for that case in[7] ,

wheremf = Mass of the fillermp = Mass of the polymerρp = Density of the fillerρf = Density of the polymerTopological peculiarities of the systems filled with dispersed filler has not taken into account in Eqs. (1)–(2). When such systems are filled, the thermal conductivity of the composites increases from kp to the largest kF value within the 0 < φ < F concentration interval. An equation describing the concentration dependence of thermal conductivity has been proposed for that case in[7] ,

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML