-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Composite Materials

p-ISSN: 2166-479X e-ISSN: 2166-4919

2013; 3(1): 1-6

doi:10.5923/j.cmaterials.20130301.01

Hydration Characteristics of Bagasse in Cement-Bonded Composites

Omoniyi T. E, Akinyemi B. A

Department of Agricultural and Environmental Engineering, University of Ibadan, Oyo State, Nigeria

Correspondence to: Omoniyi T. E, Department of Agricultural and Environmental Engineering, University of Ibadan, Oyo State, Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

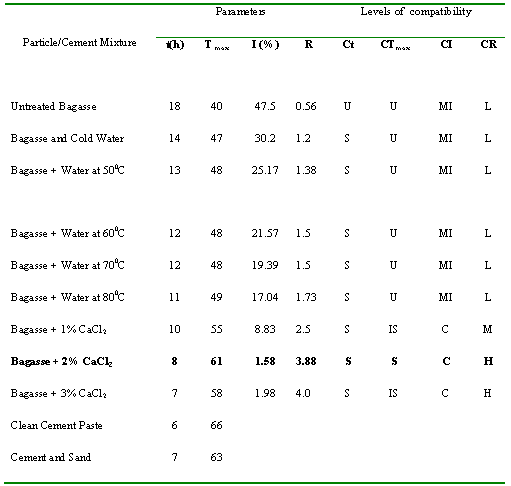

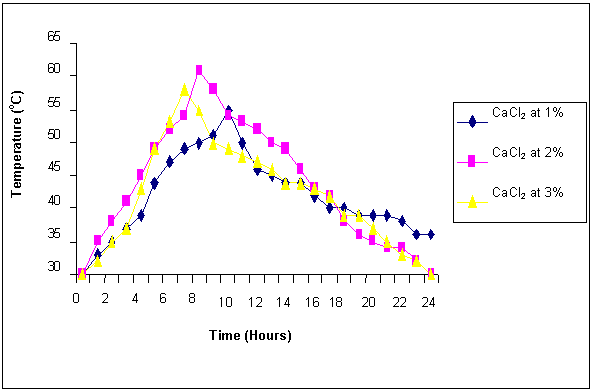

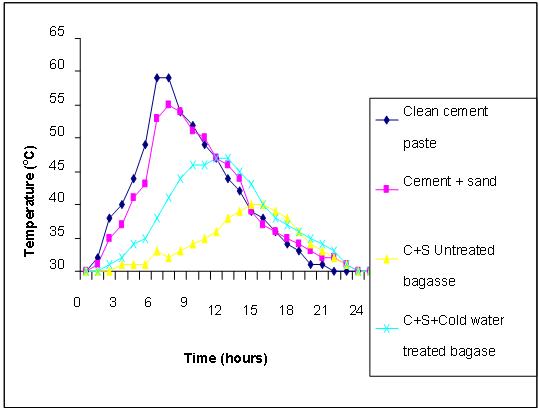

Four compatibility assessment methods were used to ascertain the compatibility of bagasse with cement composite. The time to reach maximum hydration temperature was achieved when CaCl2 and water above 60℃ were used as treatment agents. Maximum hydration temperature between 55℃ – 61℃ were achieved when treated with 1 – 3% CaCl2. The inhibitory index value of 1.58% - 8.83% were achieved when treated with bagasse while others have value greater than the acceptable parameter standard for exterior use. The maximum hydration rate of 4.0 was achieved when the bagasse fiber was treated with 3% CaCl2 and this was closely followed by 2% CaCl2 at 3.38. These results showed that all the different compatibility assessment parameters adopted indicated that bagasse was incompatible with Portland cement without pre-treatment. Treatment of bagasse with cold water and addition of 2% CaCl2 satisfied all requirements for compatibility in terms of time to reach maximum temperature, the maximum hydration temperature and the inhibitory index value. Treatment with CaCl2 gave the best result probably due to its capacity to minimize the adverse effect of the soluble sugars and extractives and also to accelerate cement hardening and setting. This result shows that treated bagasse is compatible with cement bonded composite for construction purposes.

Keywords: Hydration Index, Bagasse, Treatment, Temperature ,Time

Cite this paper: Omoniyi T. E, Akinyemi B. A, Hydration Characteristics of Bagasse in Cement-Bonded Composites, International Journal of Composite Materials, Vol. 3 No. 1, 2013, pp. 1-6. doi: 10.5923/j.cmaterials.20130301.01.

Article Outline

1. Introduction

- Increasing attention should be given to the use of natural fibre with a view to conserving energy and protecting the environment and because of basic engineering properties of crack resistance, ductility and energy absorption that it impacts on cement particleboard (CPB). In the past, wood was the main aggregate employed in CPB. However economic and environmental pressures have led to other lignocelluloses being considered for use. A range of substitute materials, such as agricultural and wood processing residues, tree barks and weeds, has been tested. Examples include rice straw and giant ipil-ipil, oil palm shell and cork granules[1]. Several other candidates are available, including rattan cane, coconut husk, banana, bagasse, bamboo, and oil palm. These materials are available in abundance and present as waste in West Africa. Natural fibres cement composite is useful because of eco-friendly nature and provide the most economic and socially useful outlet for natural fibre chips, residues and agricultural wastes. Coconut is one of the most economically useful palms in tropical Asia and Africa[2]. All parts of the palm are useful and local people use it for lumber and as source of food. Coconut husk however is of limited commercial use at present. Rattan, a non timber forest product used for manufacturing cane furniture, grows as a spiny climber in the tropics and sub-tropics. Following harvesting, rattan is stripped of its spines and leaf sheaths before drying. Unfortunately much of the cane material becomes discoloured by staining fungi during this part of the process[1]. This material cannot be processed for furniture and is considered waste. At present 20 – 30 % of the processed rattan is waste.The major challenges facing the development of durable natural fibre cement composite are the inherent weakness of the natural fibre particles themselves such as low elastic modulus, high water absorption, susceptibility to fungal and insect attack and lack of durability in alkaline environment. And also because of the influence of botanical components (hemi-cellulose, starch, tannin, phenols, and lignin) all which are known to inhibit the normal setting and strength development properties of cement matrix. This work examines the compatibility of bagasse with ordinary Portland cement using hydration tests.

2. Materials and Methods

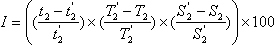

- The hydration test method used was the same as described by[3] and[4] . This test investigated the suitability of bagasse in wood-cement manufacture. Bagasse was hammer-milled, sieved and dried for two weeks. Only particles that passed through 850 μm sieve and retained on a 600 μm were used. The bagasse/water/cement mixtures comprised 15 g bagasse particles, 200 g ordinary Portland cement and 90.5 ml distilled water (as in[5] and[2] ). Each 15g bagasse sample was gradually mixed with 200g of cement in a polythene bag thereafter distilled water was added to the mixture and stirred until homogenous paste was obtained. Required quantity of CaCl2 (at four concentrations by weight 0, 1, 2, and 3% respectively) were added to the paste. The mixture was transferred to a Dewar flask and a thermocouple was inserted to enable temperature measurement at 1 – min intervals over a 23 – h period. The time taken to attain maximum temperature was assessed. Three replicates were used. The experiments were carried out at room temperature of 25 ± 2℃. The same procedure was followed for bagasse pre-treated with cold and hot water.To calculate the inhibitory index (l), the following equation was used:

[6]Where:t2 is the time to reach maximum temperature of the inhibited cement (bagasse-cement-water mixture )t’2 is the time to reach maximum temperature of the uninhibited cement (cement-water mixture)T2 is the maximum hydration temperature of the inhibited cement (bagasse-cement-water mixture)T’2 is the maximum hydration temperature of the uninhibited cement (cement-water mixture)S2 is the maximum temperature – time slope of the inhibited cement (bagasse-cement-water mixture)S’2 is the maximum temperature – time slope of the uninhibited cement (cement-water mixture).

[6]Where:t2 is the time to reach maximum temperature of the inhibited cement (bagasse-cement-water mixture )t’2 is the time to reach maximum temperature of the uninhibited cement (cement-water mixture)T2 is the maximum hydration temperature of the inhibited cement (bagasse-cement-water mixture)T’2 is the maximum hydration temperature of the uninhibited cement (cement-water mixture)S2 is the maximum temperature – time slope of the inhibited cement (bagasse-cement-water mixture)S’2 is the maximum temperature – time slope of the uninhibited cement (cement-water mixture).3. Results and Discussion

3.1. Hydration Test Results

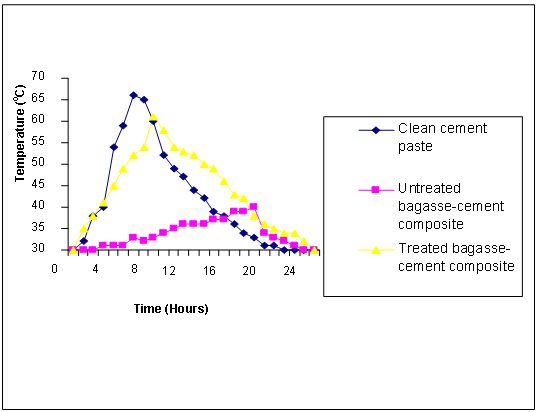

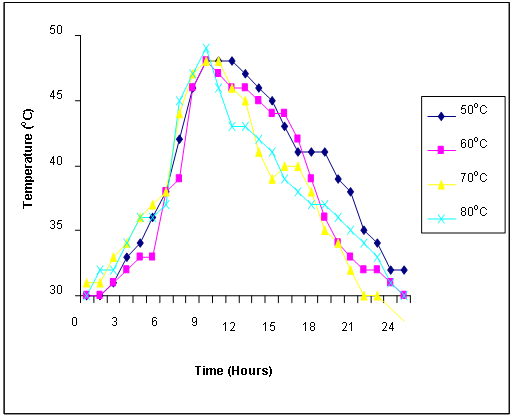

3.1.1. Time Taken by the Bagasse-Cement to Attain Maximum Temperature

|

3.1.2. Maximum Hydration Temperatures of the Mixtures

- The maximum hydration temperatures (Tmax) of the different aggregate-cement mixtures are shown in Table 1. The values ranged from 400C for the untreated bagasse/cement/sand mixture to 660C for neat cement. Using Tmax as the criterion for compatibility, the cold and hot water treated mixture could be considered unsuitable for cement board production since they reduced hydration temperature to values below 500C, the value recommended by[8] , and[9] . Addition of 1% and 3% CaCl2 however increased Tmax from 40℃ for the untreated bagasse/cement mixture to 55℃ and 61℃respectively.t = time to reach maximum temperature Tmax = maximum hydration temperature of the inhibited cement.T’max = maximum hydration temperature of the uninhibited cement.I = inhibitory indexR = hydration rateCt = compatibility level based on time to maximum temperatureCTmax = compatibility level based on maximum hydration temperature CI = compatibility level based on inhibitory index CR = compatibility level based on hydration rateC = compatible; S = suitable; U = unsuitable; IS = intermediately suitable; MI = moderately inhibitory; L = low; M = medium; H = high hydration rate

| Figure 1. Effects of Chemical Treatments at Different Levels of CaCl2 Concentration on Hydration Behaviour of Bagasse Composite |

| Figure 2. Effects of Cold Water Treatment on Hydration Behaviour of Bagasse Composite |

| Figure 3. Effects of Chemical Treatment on Hydration Behaviour of Bagasse Composite |

| Figure 4. Effects of Hot Water Treatment on Hydration Behaviour of Bagasse Cement Composite |

3.2. Inhibitory Index

- The inhibitory index (I) values for the different treatments are shown in Table 1. The values ranged from 1.58% for bagasse treated with 2% CaCl2 to 47.50% for the untreated bagasse cement mixture. The untreated bagasse-cement/sand mixture that had the longest time (18 h) to maximum temperature and lowest hydration temperature value (400C) also had the highest I value of 47.5% and the least hydration rate of 0.56. These results show that all the different compatibility assessment parameters adopted indicated that the bagasse was incompatible with Portland cement without pre-treatment. Treatment of bagasse with cold water and addition of 2% CaCl2 satisfied all requirements for compatibility in terms of time to reach maximum temperature, the maximum hydration temperature and the inhibitory index value. Treatment with CaCl2 gave the best result probably due to its capacity to minimize the adverse effect of the soluble sugars and extractives and also to accelerate cement hardening and setting. Comparable data in the literature for the inhibition index of bagasse flakes and particles in cement matrices were not found. Other wood species in mixture with cement that gave moderate inhibition similar to bagasse include Eucalyptus[10], Cypress[4] and Pseudoacacia[8].Summary and Conclusion: Hydration characteristics of bagasse cement composite have been determined. The influence of compatibility based on time, temperatures, hydration index and rate were examined for different treatments. It was concluded that bagasse treated with CaCl2 at 2% is compatible with ordinary Portland cement.The following conclusions were drawn from the hydration test;1. Untreated bagasse is not compatible with ordinary Portland cement.2. Addition of 2% CaCl2 improved the temperature and reduced the setting time.3. Addition of 2% CaCl2 also gave the least inhibitory index and the highest hydration rate.This showed that when bagasse cement composite is treated with 2% CaCl2 the result is compatible and suitable for construction purposes.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML