| [1] | S. Ahmed, S. Ikram, S. Kanchi, and K. Bisetty Ed., Biocomposites: Biomedical and Environmental Applications, New York, USA: Jenny Stanford Publishing, 2018. https://doi.org/10.1201/9781315110806. |

| [2] | Garlotta, D., 2001, A literature review of poly (lactic acid),, Journal of Polymers and the Environment, 9, 63–84. https://doi.org/10.1023/A:1020200822435. |

| [3] | Chilakamarry, C.R., Sakinah, A.M.M., Zularisam, A.W. et al., 2021, Glycerol waste to value added products and its potential applications., Systems Microbiology and Biomanufacturing, 1, 378–396. https://doi.org/10.1007/s43393-021-00036-w. |

| [4] | Liu, Y., Zhong, B., and Lawal, A., 2022, Recovery and utilization of crude glycerol, a biodiesel byproduct., RSC Advances, 12, 27997. DOI: 10.1039/d2ra05090k. |

| [5] | Das, A., Kodgire, P., Li, H., Basumatary, S., Baskar, G., and Lalthazuala Rokhum, S., 2023, Recent Advances in Conversion of Glycerol: A Byproduct of Biodiesel Production to Glycerol Carbonate., Journal of Chemistry, 2023, 8730221, 36 pages. https://doi.org/10.1155/2023/8730221. |

| [6] | Elsayed, M., Eraky, M., Osman, A.I., Wang, J., Farghali, M., Rashwan, A.K., Yacoub, I.H., Hanelt, D., and Abomohra, A., 2024, Sustainable valorization of waste glycerol into bioethanol and biodiesel through biocircular approaches: a Review., Environmental Chemistry Letters, 22, 609–634. https://doi.org/10.1007/s10311-023-01671-6. |

| [7] | Goyal, S., Hernández, N.B., and Cochran, E.W., 2020, An update on the future prospects pf glycerol polymers., Polymer International, 70, 911-917. DOI 10.1002/pi.6209. |

| [8] | Fiorani, G., Perosa, A., and Selva, M., 2017, Dimethyl carbonate: A versatile reagent for a Sustainable valorization of renewables., Green Chemistry, 2018, 20, 288-322. https://doi.org/10.1039/C7GC02118F. |

| [9] | Usman, M., Rehman, A., Saleem, F., Abbas, A., Eze, V.C., and Harvey, A., 2023, Synthesis of cyclic carbonates from CO2 cycloaddition to bio-based epoxides and glycerol: an overview of recent development., RSC Advances, 13, 22717. https://doi.org/10.1039/D3RA03028H. |

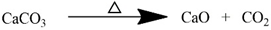

| [10] | Saouza Junior, R.L., Eira, L.C., Detoni, Ch., and Souza, M.M.V.M., 2024, Glycerol carbonate production via transesterification: the effect of support porosity and catalyst basicity., Process, 12, 2256, 20 pp. https://doi.org/10.3390/pr12102256. |

| [11] | Clements, J.H., 2003, Reactive applications of cyclic alkylene carbonates., Industrial & Engineering Chemistry Research, 42(4), 663-674. https://doi.org/10.1021/ie020678i. |

| [12] | Munshi, M.K., Gade, S.M., Rane, V.H., and Kelkar, A.A., 2014, Role of cation-anion cooperation in the selective synthesis of glycidol from glycerol using DABCO-DMC ionic liquid as catalyst., RSC Advances, 4(61), 32127-32133. DOI: 10.1039/c4ra04290e. |

| [13] | Selva, M., Perosa, A., Guidi, S., and Cattelan, L., 2016, Ionic liquids as transesterification catalysts: applications for the synthesis of linear and cyclic organic carbonates., Beilstein Journal of Organic Chemistry, 12, 1911-1924. https://doi.org/10.3762/bjoc.12.181. |

| [14] | Kim, S. C., Kim, Y. H., Lee, H., Yoon, D. Y., and Song, B. K., 2007, Lipase-catalyzed synthesis of glycerol carbonate from renewable glycerol and dimethyl carbonate through transesterification., Journal of Molecular Catalysis B: Enzymatic, 49, 75–78. doi: https://doi.org/10.1016/j.molcatb.2007.08.007. |

| [15] | Hervert, B., McCarthy, P. D., and Palencia, H. 2014, Room temperature synthesis of glycerol carbonate catalyzed by N-heterocyclic carbenes., Tetrahedron Letters, 55, 133–136. doi: https://doi.org/10.1016/j.tetlet.2013.10.135. |

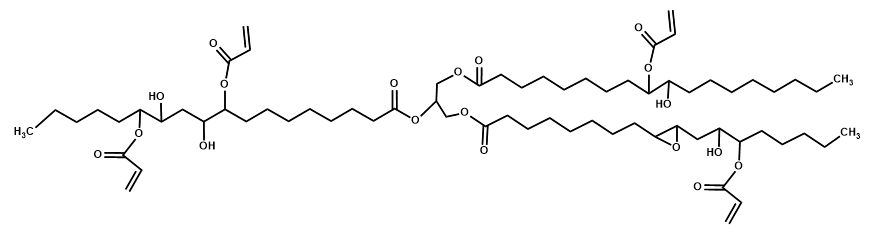

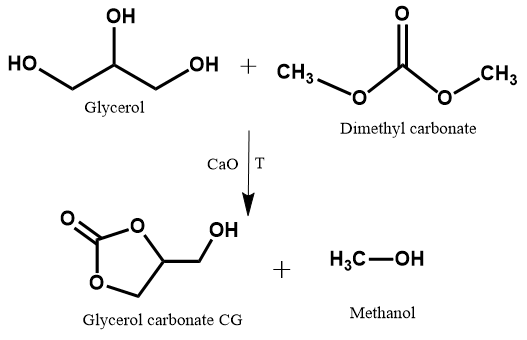

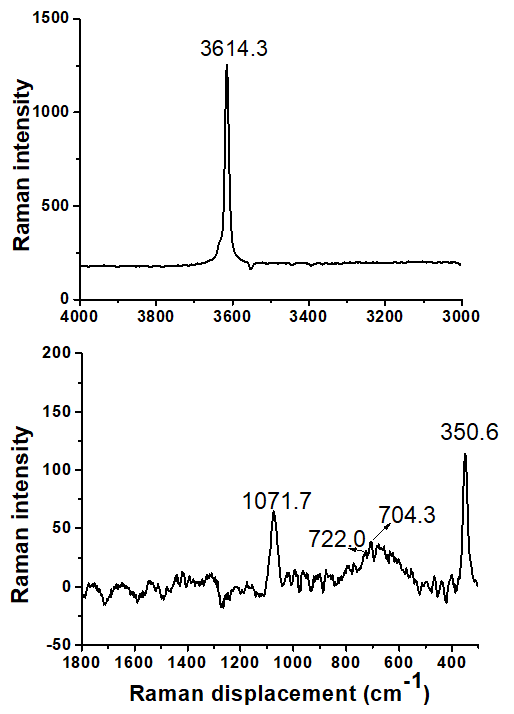

| [16] | Pham, P.D., Monge, S., Lapinte, V., Raoul, Y., and Robin, J.J., 2013, Various radical polymerizations of glycerol-based monomers., European Journal of Lipid Science and Technology, 115, 28–40. DOI: 10.1002/ejlt.201200202. |

| [17] | Rodriguez Herrero, Y., and Ullah, A., 2021, Rapid, Metal-Free, Catalytic Conversion of Glycerol to Allyl Monomers and Polymers., ACS Sustainable Chemistry and Engineering, 9, 9474−9485. https://doi.org/10.1021/acssuschemeng.1c03134. |

| [18] | Ventura-Hunter, C., Lechuga-Islas, V.D., Ulbrich, J., Kellner, C., Schubert, U.S., Saldívar-Guerra, E., Rosales-Guzmán, M., and Guerrero-Sánchez, C., 2022, Glycerol methacrylate-based copolymers: Reactivity ratios, physicochemical characterization and cytotoxicity., European Polymer Journal, 178, 111478, 12 pp. https://doi.org/10.1016/j.eurpolymj.2022.111478. |

| [19] | Beach, E.S., Cui, Z., Anastas, P.T., Zhan, M., and Wool, R.P., 2021, Properties of thermosets derived from chemically modified triglycerides and bio-based comonomers., Applied Science, 3, 684-693. https://doi.org/10.3390/app3040684. |

| [20] | Quirino, R.L., Monroe, K., Fleischer III, C.H., Biswas, E., and Kessler, M.R., 2021, Thermosetting polymers from renewable sources., Polymer International, 70(2), 167–180. https://doi.org/10.1002/pi.6132. |

| [21] | Singhal, P., Kumar, A., Kumar, H., Kumar, V., and Vishnoi, R., 2022, Polymeric Material from Plant Oil and Their Application. In: Baskar, C., Ramakrishna, S., Daniela La Rosa, A. (eds) Encyclopedia of Green Materials. Springer, Singapore. https://doi.org/10.1007/978-981-16-4921-9_120-1. |

| [22] | W. Liu, T. Chen, and R. Qiu, “Soybean oil-based polymers and their composites”., in Green Chemistry and Green Materials from Plant Oils and Natural Acids, ed. Z. Liu and G. Kraus, Royal Society of Chemistry, 2023, vol. 83, ch. 3, pp. 42-58. https://doi.org/10.1039/BK9781837671595-00042. |

| [23] | S. Hernández López, and E. Vigueras Santiago., 2013, “Acrylated-epoxidized soybean oil-based polymers and their use in the generation of electrically conductive”., in Soybean: Bio-Active Compounds, H. El-Shemy ed., Ch. 11., 231. http://dx.doi.org/10.5772/52992. |

| [24] | Lin, F-Y, Hohmann, H.D., Hernandez, N., Shen, L., Dietrich, H., and Cochran, E.W., 2020, Self-assembly of poly(styrene-block-acrylated epoxidized soybean oil) star-brush-like block copolymers., Macromolecules, 53(18) 8095–8107. https://doi.org/10.1021/acs.macromol.0c00441. |

| [25] | Kumar, V., Khan, A., and Rabnawaz, M., 2023, A plant oil-based eco-friendly approach for paper coatings and their packaging applications., Progress in Organic Coatings, 176, 107386. https://doi.org/10.1016/j.porgcoat.2022.107386. |

| [26] | Gapsari, F., Wijatmiko, I., Andoko, A., Diharjo, K., Mavinkere Rangappa, S., and Siengchin, S., 2024, Modification on fiber from alkali treatment and AESO coating to enhance UV-light and water absorption resistance in kapok fiber reinforced polyester composites., Journal of Natural Fibers, 21, 2383970. https://doi.org/10.1080/15440478.2024.2383970. |

| [27] | Kumar, A., Some, D.K., and Kiriamiti, K.H., 2014, Pretreatment of CaO catalyst for transesterification of croton megalocarpus oil., Journal of Sustainable Research in Engineering, 1(2), 57-62. https://jsre.jkuat.ac.ke/index.php/jsre/article/view/17. |

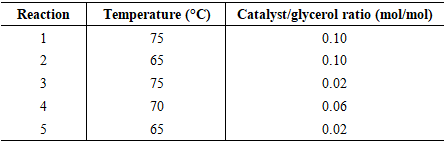

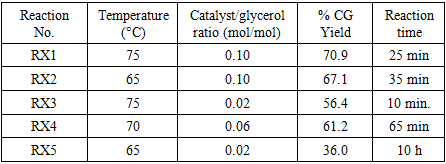

| [28] | Ochoa-Gómez, J.R., Gómez-Jiménez-Aberasturi, O., Maestro-Madurga, B., Pesquera-Rodríguez, A., Ramírez-López, C., Lorenzo-Ibarreta, L., Torrecilla-Soria, J., and Villarán-Velasco, M.C., 2009, Synthesis of glycerol carbonate from glycerol and dimethyl carbonate by transesterification: Catalyst screening and reaction optimization., Applied Catalysis A: General, 366 (2), 315–324. doi: 10.1016/J.APCATA.2009.07.020. |

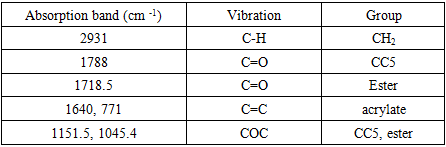

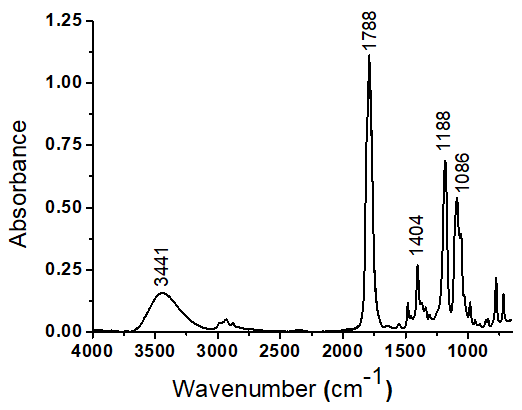

| [29] | Calvino-Casilda, V., Mul, G., Fernández, J.F., Rubio-Marcos, F., and Bañares, M.A., 2011, Monitoring the catalytic synthesis of glycerol carbonate by real-time attenuated total reflection FTIR spectroscopy., Applied Catalysis A: General, 409–410, 106-112. https://doi.org/10.1016/j.apcata.2011.09.036. |

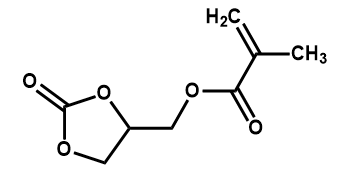

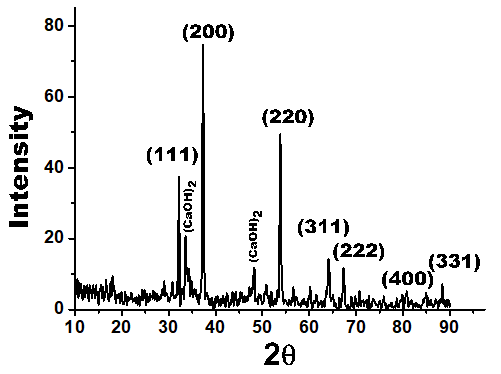

| [30] | Fiquet, G., Richet, P., and Montagnac, G., 1999, Crystal structure data from: High-temperature thermal expansion of lime, periclase, corundum and spinel Sample: PtRh10% heating wire, T = 1222 K., Physics and Chemistry of Minerals, 27,103 - 111. https://www.crystallography.net/9006695.html. |

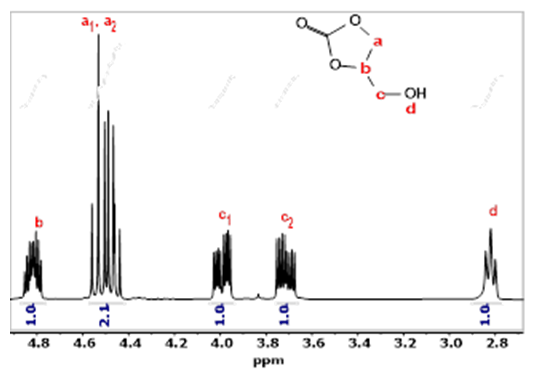

| [31] | Kaur, A., Prakash, R., and Ali, A., 2018, 1H NMR assisted quantification of glycerol carbonate in the mixture of glycerol and glycerol carbonate., Talanta, 178, 1001-1005. http://dx.doi.org/10.1016/j.talanta.2017.08.103. |

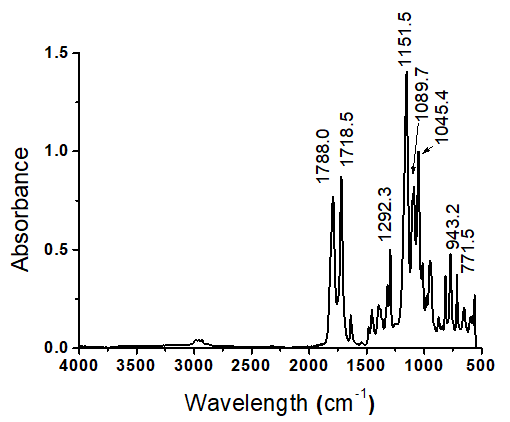

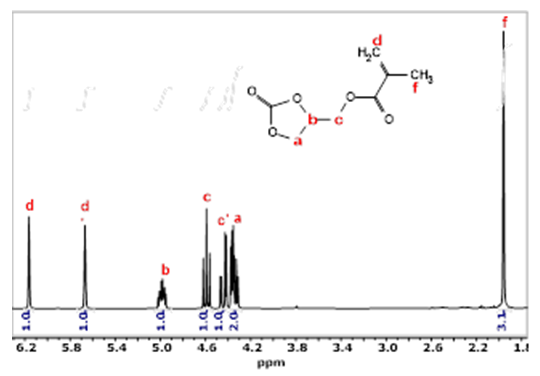

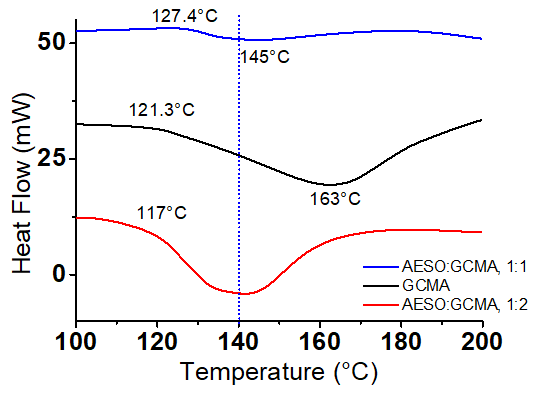

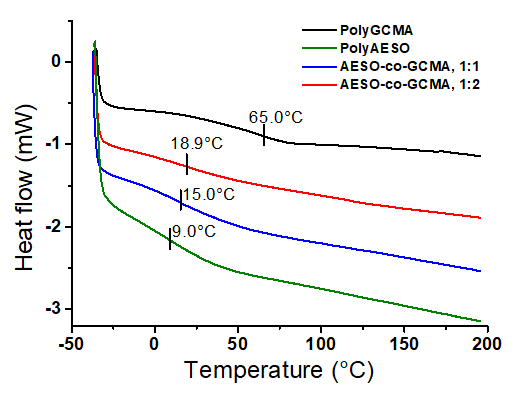

| [32] | Camara, F., Caillol, S., and Boutevin, B., 2014, Free radical polymerization study of glycerin carbonate methacrylate for the synthesis of cyclic carbonate functionalized polymers., European Polymer Journal, 61, 133-144. https://doi.org/10.1016/j.eurpolymj.2014.10.001. |

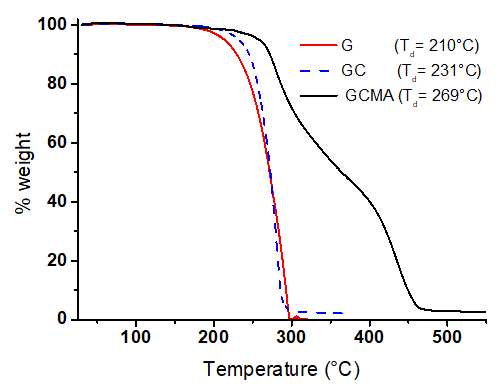

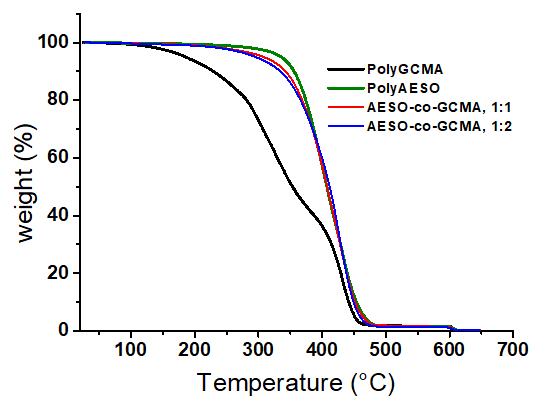

| [33] | Li, R., Liu, J., Tao, H., Sun, D., Xiao, D., Liu, Ch., 2016, The investigation of thermal pyrolysis of glycerol carbonate derivatives by TG–FTIR., Thermochimica Acta, 624, 76-81. https://doi.org/10.1016/j.tca.2015.12.002. |

| [34] | Zhang, D., Cao, Y., Zhang, P., Liang, J., Xue, K., Xia, Y., and Qi, Z., 2021, Investigation of the thermal decomposition mechanism of glycerol: the combination of a theoretical study based on the Minnesota functional and experimental support., Phys. Chem. Chem. Phys., 26(36), 20466-20477. DOI: 10.1039/D1CP01526E. |

| [35] | Britz, J., Meyer, W.H., and Wegner, G., 2007, Blends of Poly(meth)acrylates with 2-Oxo-(1,3)dioxolane Side Chains and Lithium Salts as Lithium Ion Conductors., Macromolecules, 40(21), 7558-7565. https://doi.org/10.1021/ma0714619. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML