-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Chemistry

p-ISSN: 2165-8749 e-ISSN: 2165-8781

2025; 15(3): 76-80

doi:10.5923/j.chemistry.20251503.03

Received: Jul. 22, 2025; Accepted: Aug. 10, 2025; Published: Aug. 13, 2025

Effects of Natural Convection Gas Drying on the Bioactive Compounds of Five Varieties of Mango Grown in Senegal

Mouhamadou Fofana 1, Ibrahima Ba 1, Ndiak Ndiaye 1, Bédié Mbow 1, Baye Dame Cissé 1, Alioune Fall 1, Nicolas Cyrille Ayessou 2

1Department of Chemistry, Technologies and Sciences, University Cheikh Anta Diop of Dakar, Dakar, Senegal

2Department of Chemical Engineering and Applied Biology, Polytechnic School, University Cheikh Anta Diop of Dakar, Dakar, Senegal

Correspondence to: Mouhamadou Fofana , Department of Chemistry, Technologies and Sciences, University Cheikh Anta Diop of Dakar, Dakar, Senegal.

| Email: |  |

Copyright © 2025 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

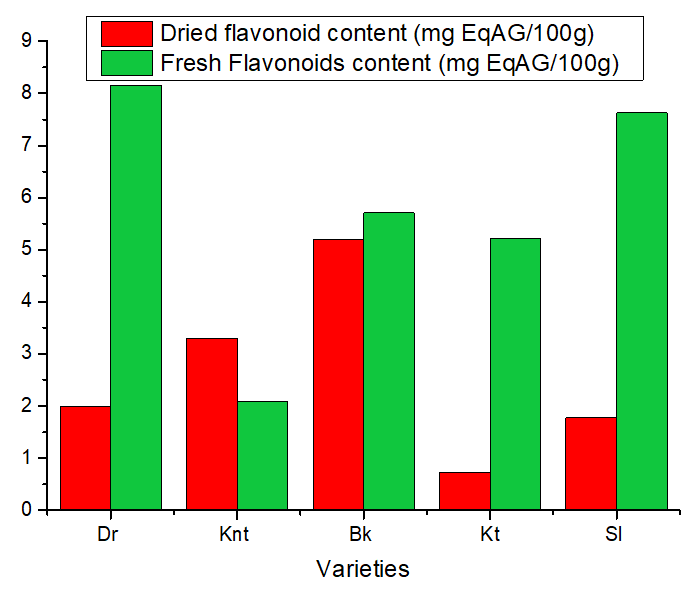

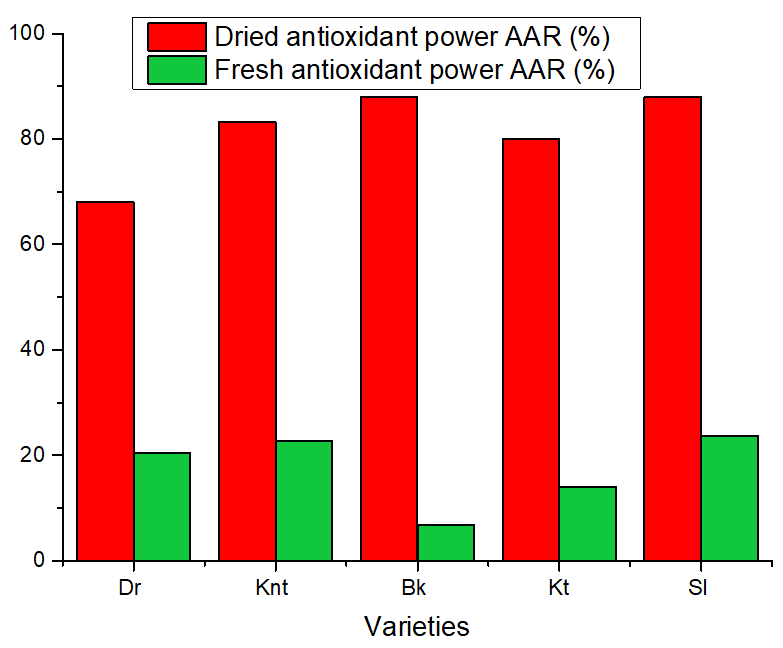

The effects of natural convection gas drying on bioactive compounds were monitored in this study. The results reveal that the Sl, Bk, and Knt mango varieties have the lowest moisture content, at 11.27%, 11.31%, and 11.43%, respectively. In contrast, Kt and Dr have the highest moisture content, at 12.07% and 12.48%. This difference in moisture content between these varieties can be explained by the fact that some contain more water than others. The drying process causes a significant decrease in total polyphenol and flavonoid levels in all varieties, due to the degradation of heat- and light-sensitive compounds. Notably, the Bk variety stands out for its total polyphenol content before drying, while Kt and Bk show the highest levels after treatment. Fresh varieties retain higher levels of flavonoids than dried varieties, with Dr and Sl showing the highest levels, respectively 8mg EqAG/100g and 7mg EqAG/100g among local varieties. After drying, the antioxidant capacity of all varieties increases significantly, partly due to the concentration of antioxidant compounds. For fresh mangoes, the Dr, Sl, and Knt varieties have twice the antioxidant capacity of Kt, while after drying, Bk and Sl have the highest values, reaching 83%.

Keywords: Bioactive compounds, Mango varieties, Fresh and dried

Cite this paper: Mouhamadou Fofana , Ibrahima Ba , Ndiak Ndiaye , Bédié Mbow , Baye Dame Cissé , Alioune Fall , Nicolas Cyrille Ayessou , Effects of Natural Convection Gas Drying on the Bioactive Compounds of Five Varieties of Mango Grown in Senegal, American Journal of Chemistry, Vol. 15 No. 3, 2025, pp. 76-80. doi: 10.5923/j.chemistry.20251503.03.

Article Outline

1. Introduction

- Senegal is undeniably a major player in mango production, boasting a remarkable diversity of cultivated varieties. Among these, the Kent variety stands out for its high export volume, followed by Keitt, which is highly appreciated by consumers. However, a persistent challenge remains: the significant loss of local varieties, often caused by rotting [1]. To address this issue, the processing of mangoes into by-products has been implemented in recent years, with drying being the preferred preservation method [2]. This process offers a promising solution for limiting post-harvest losses. Processing is mainly carried out in artisanal units, often managed by women's groups, as well as in semi-industrial facilities, although industrial units remain rare [3]. This study aims to explore the effects of drying on the bioactive compounds of five mango varieties grown in Senegal. It is important to note that foods subjected to prolonged heat can lose their organoleptic qualities and valuable bioactive compounds [4]. By analyzing the variation in biochemical composition during drying, we will be able to identify the varieties best suited to this process. Based on previous work [5], it should be noted that this study focuses on the most widely grown and prized mango varieties in Senegal. Among these, two varieties, Kent (Knt) and Keitt (Kt), are mainly intended for export, while the other three, Diourrou (Dr), Boukodiékhal (Bk), and Sierra Leone (Sl), are more geared toward local consumption and domestic marketing [5].

2. Methods and Materials

2.1. Materials

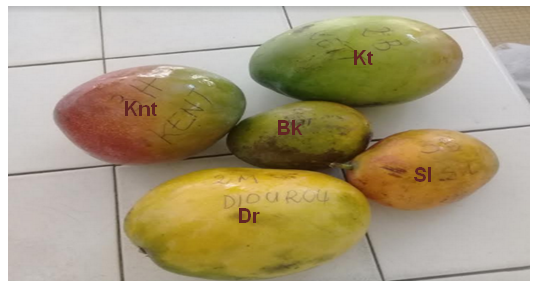

- The mango samples were harvested from an orchard located in the village of Kaguitte, in the Ziguinchor region, Oussouye department. For this purpose, we collected fifteen kilograms of each variety, commercially ripe and without damage. The mangoes were stored at the drying center until they reached the desired level of ripeness.

| Figure 1. Mango samples |

2.2. Drying Equipment

- The technology used is a natural convection gas dryer equipped with forty-two racks. The external dimensions are as follows: length: 6.96 m, width: 2.438 m, height: 2.591 m. Equipment accompanying the dryer includes: a scale, plastic basins, peeling knives, gloves, face masks, and smocks. The drying time is twelve hours.

| Figure 2. Drying shed in Kandialan Diola (in the municipality of Ziguinchor) |

3. Method

3.1. The Drying Stages

- The mangoes are sorted, washed with drinking water, drained, and weighed. After peeling and pitting, they are cut into slices. The skins, pits, and pulp are also weighed. The slices are then laid out on racks, making sure to leave space between them for drying. Finally, the slices are packaged in bags using a vacuum sealer

| Figure 3. Mango slices being processed, mango slices on the rack, and bags of dried mangoes |

3.2. Measurement of Total Polyphenols, Flavonoids, Antioxidant Activity and Determination of Moisture Content

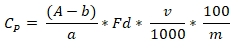

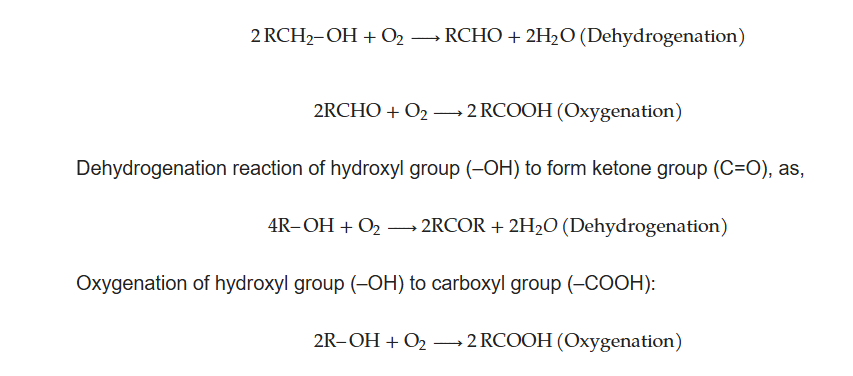

- Ø Measurement of total polyphenols:For polyphenols, the Folin-Ciocalteu method is used, which involves oxidizing the oxidizable groups of phenols in a basic medium. The blue-colored reduction products have an absorption intensity proportional to the amount of polyphenols present. The absorbances are read at 760 nm. The total polyphenol concentration is given by the relationship:

CP: Total polyphenol content expressed in g gallic acid equivalent/100 g;A: Actual absorbance of the sample;a: Slope of the calibration curve = 3.12;b: Y-intercept of the calibration curve = 0.0696;Fd: Dilution factor;v: Extraction volume (mL);m: Test sample (g).Ø Flavonoid dosage:The flavonoid content of the extracts is determined using the colorimetric method described by (6). The results are expressed in g catechin equivalent per 100 g of product.

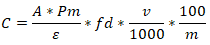

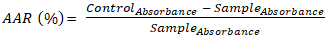

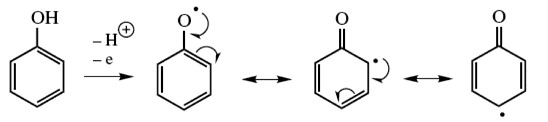

CP: Total polyphenol content expressed in g gallic acid equivalent/100 g;A: Actual absorbance of the sample;a: Slope of the calibration curve = 3.12;b: Y-intercept of the calibration curve = 0.0696;Fd: Dilution factor;v: Extraction volume (mL);m: Test sample (g).Ø Flavonoid dosage:The flavonoid content of the extracts is determined using the colorimetric method described by (6). The results are expressed in g catechin equivalent per 100 g of product. C: Total flavonoid content expressed in g catechin equivalent/100 g;A: Absorbance of the sample;Pm: Molar mass of catechin = 290.26 g/mol;ε: Molar extinction coefficient = 10,332 L/mol;Fd: Dilution factor;v: Extraction volume (mL);m: Test sample (g).Ø Antioxidant activity:It was evaluated with 2,2-diphenyl-1-picrylhydrazyl (DPPH.) according to the method described in [6]. In addition, some adjustments were made to this protocol. That HAT mechanism is reported and followed by phenolic antioxidants. The antiradical activity is expressed as a percentage of reduced DPPH. according to the equation...

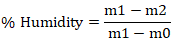

C: Total flavonoid content expressed in g catechin equivalent/100 g;A: Absorbance of the sample;Pm: Molar mass of catechin = 290.26 g/mol;ε: Molar extinction coefficient = 10,332 L/mol;Fd: Dilution factor;v: Extraction volume (mL);m: Test sample (g).Ø Antioxidant activity:It was evaluated with 2,2-diphenyl-1-picrylhydrazyl (DPPH.) according to the method described in [6]. In addition, some adjustments were made to this protocol. That HAT mechanism is reported and followed by phenolic antioxidants. The antiradical activity is expressed as a percentage of reduced DPPH. according to the equation... Also, the concentration reducing 50% of DPPH. (IC50) is determined graphically on the antiradical activity (ARA) curve as a function of pulp concentration.Ø Determination of moisture content.A quantity of 2g of samples is placed in a pre-dried and tapped capsule. The sample is then placed in an oven maintained at a temperature of 130°C for 90 minutes. After the drying period, the capsule is immediately removed and transferred to a desiccator to cool. Once cooled, the sample is weighed accurately. The moisture content is expressed as a percentage and is given by the following equation:

Also, the concentration reducing 50% of DPPH. (IC50) is determined graphically on the antiradical activity (ARA) curve as a function of pulp concentration.Ø Determination of moisture content.A quantity of 2g of samples is placed in a pre-dried and tapped capsule. The sample is then placed in an oven maintained at a temperature of 130°C for 90 minutes. After the drying period, the capsule is immediately removed and transferred to a desiccator to cool. Once cooled, the sample is weighed accurately. The moisture content is expressed as a percentage and is given by the following equation: 𝑚0 = the mass in g of the test capsule (sample).𝑚1 = the mass in g of the test sample + the mass of the capsule before drying. 𝑚2 = the mass in g of the test sample + the mass of the capsule after drying.

𝑚0 = the mass in g of the test capsule (sample).𝑚1 = the mass in g of the test sample + the mass of the capsule before drying. 𝑚2 = the mass in g of the test sample + the mass of the capsule after drying.3.3. Text Font of Entire Document

- The entire document should be in Times New Roman. The font sizes to be used are specified in Table 1. The size of a lower-case “j” will give the point size by measuring the distance from the top of an ascender to the bottom of a descender.

4. Results and Discussions

4.1. Water Content of Dried Mangoes

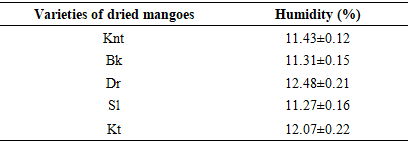

- Table 1 shows the results for the relative humidity of our dried mango samples.

|

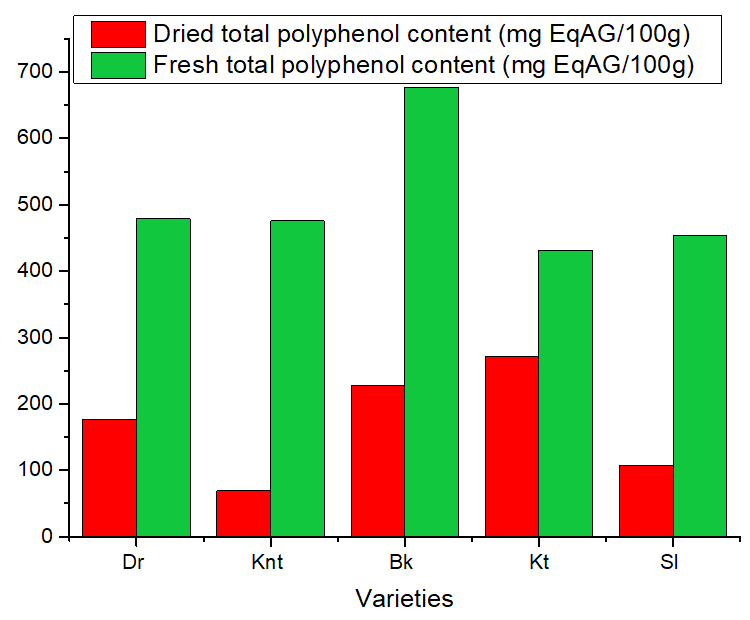

4.2. Total Polyphenol Content of Fresh and Dried Mango Varieties

- Figure 4 illustrates the total polyphenol content of different mango varieties, both fresh and after drying.

| Figure 4. Total polyphenol content of fresh and dried mango varieties |

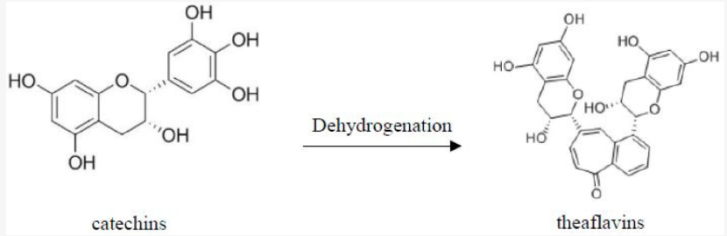

| Figure 5. Formation of theaflavins from catechins by dehydrogenation |

| Figure 6. Formation of theaflavins from catechins by dehydrogenation |

4.3. Flavonoid Content of Fresh and Dried Mango Varieties

- Flavonoids act primarily as primary antioxidants, stabilizing peroxide radicals, but they can also deactivate reactive oxygen species (superoxide ion, OH- radical, singlet oxygen), inhibit lipoxygenase, or chelate metals [2].

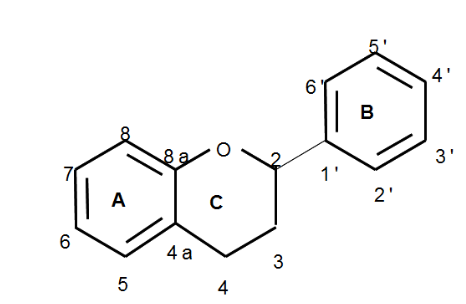

| Figure 7. Generic structure of flavonoids |

| Figure 8. Flavonoid content of fresh and dried mango varieties |

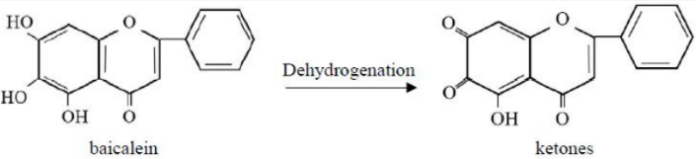

| Figure 9. Chemical structure of baicalein and its oxidation products |

4.4. Antioxidant Capacity of Fresh and Dried Mango Varieties

- Antioxidants are generally referred to as “free radical fighters” because they generously give up electrons to free radicals without turning into electron-trapping substances. Free radicals are therefore also more susceptible to oxidation [10].

| Figure 10. Single-electron oxidation of a phenol |

| Figure 11. Antioxidant power of fresh and dried varieties |

5. Conclusions

- This study highlights significant differences in moisture content, polyphenol, and flavonoid levels among various mango varieties, both fresh and after drying. The Sl, Bk, and Knt varieties have the lowest moisture content, while Kt and Dr have higher levels, which directly impacts their storage potential. Although drying is effective in reducing moisture and concentrating certain compounds, it causes significant degradation of polyphenols and flavonoids, thereby affecting the bioactive properties of the fruit. The results also highlight the importance of variety in preserving antioxidant compounds, with Bk standing out for its high polyphenol content before drying, and Kt and Bk retaining significant levels after processing. Despite a general decline in flavonoids after drying, certain varieties, such as Bk, retain relatively high levels. Finally, the increase in antioxidant power after drying is a positive aspect of processing, suggesting that the remaining compounds may offer increased nutritional benefits. This research opens up promising prospects for the promotion of mangoes, both for local consumption and for export, with an emphasis on the varieties best suited to processing.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML