Ahmed N. Awad , Shahad S. Mohammed

Chemical and Petrochemical Engineering Department, University of Anbar, Iraq

Correspondence to: Shahad S. Mohammed , Chemical and Petrochemical Engineering Department, University of Anbar, Iraq.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

The aim of this study is to make enhancements on the lubricant oil properties because of its importance in the industry, many methods can enhance the lubricant oil, in this study additive was used at different temperatures to observe effects on the properties of lubricating oil. Three types of stocks were used from Al-Doura oil refinery/Iraq, (40, 60,150)℃, and the experiments were carried out in the chemical and petrochemical engineering department. At conditions atmospheric pressure and temperature range between (20-80)℃. Additive (isobutylene 3%) was used to enhance the efficiency of lubricant oil density and the thermal expansion. Experiment was done on a stock 40 with and without additive to measure its thermal expansion at different temperatures and the other stocks in the same procedures. We concluded that the increasing in temperature cause to decreasing the density of stocks, but with additive the increasing was higher than that without additive. The thermal expansion was increased with increasing temperature, but its increasing with additive was of higher percentage than that without additive.

Keywords:

Lubricant Oil, Enhancement, Viscosity, Additive

Cite this paper: Ahmed N. Awad , Shahad S. Mohammed , A Study of Enhancement of the Properties of Lubricant Oil, American Journal of Chemistry, Vol. 4 No. 1, 2014, pp. 68-72. doi: 10.5923/j.chemistry.20140401.11.

1. Introduction

A lubricant (also referred to as lube) is defined as a substance introduced between two surfaces in relative motion to prevent friction, improve efficiency and reduce wear. They can be in the form of gas, liquid or solid. A lubricant prevents the direct contact of rubbing surfaces and thus reduces wear. It keeps the surface of metals clean and also prevents failure due to seizure. Lubricants can also act as coolants by removing heat effects and also prevent rusting and deposition of solids on close fitting parts. One of the single largest applications for lubricants, in the form of motor oil, is to protect the internal combustion engines in motor vehicles and powered equipment[1].Lubricants were at one time almost exclusively animal or vegetable oils or fat, but modern requirements in both nature and volume have made petroleum the main source of supply. Fatty oils still have their uses although generally in ancillary role.The main function of a lubricant is to reduce the friction between the moving surface and so facilitate motion. Its second most important function is to remove heat generated in the equipment being lubricated, such as piston engine, enclosed gears and machine tools. It has also to remove away debris from the contact area.The main project of lubrication is to replace this solid friction between the two interlockingsurfaces by the much lower internal friction in a film of lubricant maintained between them and keeping them apart so that the asperities no longer touch. The viscosity is the measure of its internal friction. The lubricant oil can be produced by modern methods of refinery crude. They may distillates or residues derived from vacuum distillation of the primary distillate with a boiling range above that of gas oil[2].The inherent problems of vegetable oils, such as poor oxidation and low-temperature properties, can be improved by attaching functional groups at the sites of unsaturation through chemical modifications. In this article, you will see how functionalization helps overcome these disadvantages.Onyeji, 2012: The effects of four different additive formulations namely 5748, 801, 264 and 261 on the viscosity index of two lubricating oils (base oils) namely 150N and 500N at two temperatures 400C and 1000C were investigated. The base oils were blended with the additives in three different proportions of 100/4. 100/8 and 100/12. The results gave a viscosity index of 96 and 98 respectively for 150N and 500N without additives. On the other hand, the addition of 12g of 261 additive formulations to 100cm3 of both base oils gave about 180% increase in kinematic viscosity at 400C, about 161% increase and 146% increase at1000C for 150N and 500N respectively. About 60% in viscosity index was achieved by 100/12 blend of 261 additives in 150N. The results revealed that 261 additive formulations gave the highest increase in viscosity in all proportions increasing as the weight of the additive increases. This work has improved the viscosity of two base oils, 150N and 500N, by blending them in different properties with four additives formulations, 5748, 801, 264, 261. All the four additives improved both base oil to very high viscosity index since viscosity index values higher than 110 were achieved in all the base oil/additives mixtures investigated.Omar, 2007: studied the effect of additive (poly isoprene) on stocks oil properties (density and thermal expansion), was taken from the refinery. He concluded that the rate of changing density with temperature depends largely on the type of basic oil, and blending the type of oil –stocks with additives results in a noticeable increase in thermal expansion coefficient of the mixture and he found that the addition of poly-isoprene increase the thermal expansion coefficients of basic stocks and make decrease of density.

2. Experiment Details

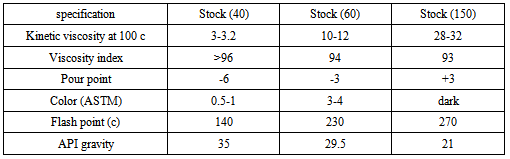

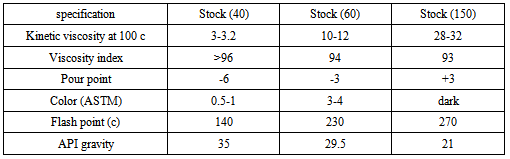

2.1. Properties of Lubrication Oil

Three oil stocks from Al-Dora refinery/Iraq stock (40), stock (60), and stock (150). Their properties are shown in table (1). Stock 40 is the lightest one with API gravity 34.97 while 60 stocks is a middle type and 150 stock is the heaviest one, with API gravity 29.29 and 20.65 respectively. The main properties of oil stocks were measured in Al-Dora refinery laboratories according to API and ASTM specification, as listed in the table (1).Table (1). physical properties of lubrication oil

|

| |

|

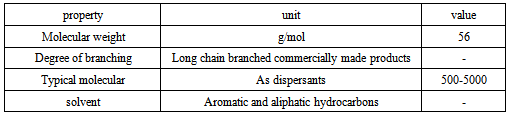

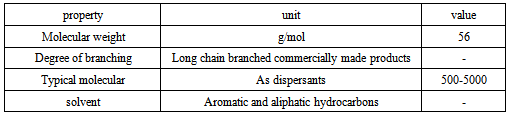

2.2. Additive

Poly isobutylene (3%) was added to the lubricant oil stock, to enhance its physical properties. The thermal expansion was tested to show the effect of Poly isobutylene, table (2) shows some properties of Poly isobutylene.Table (2). properties of Poly isobutylene

|

| |

|

2.3. Procedure

Three types of stocks were used taken from Al-Doura oil refinery/Iraq, (40, 60,160), and the experiments were carried out in the chemical and petrochemical engineering department. Range of temperature used (20-80)℃ under atmospheric pressure. Additive (isobutylene 3%) was used to enhance the efficiency of lubricant oil density and the thermal expansion. After the samples were taken to the laboratory where the experiments were carried out, the first experiment on a stock 40 with and without additive measured its thermal expansion at different temperatures and the other stocks at the same procedure.From thermal expansion[8] equation (1): | (1) |

The density can be calculated at a standard temperature, whereas the density at different temperatures (20-80)℃ was calculated by using (pycnometer, water bath, electrical balance, solvent), and as the following relation:The density of oil = (weight of bottle when it is fulls- weight of a bottle when it is empty) /weight of the bottle.To calculate the density at different temperatures after the steps above, where the temperature of the bath water was fixed and start (20-80)℃ and calculate the weight of the bottle after a change in temperature each 10℃. The additive was diluted with solvent (reformate) and after that it was added to the stock oil with good mixing.

3. Results and Discussion

3.1. Effect Temperature and Additive on Density

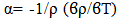

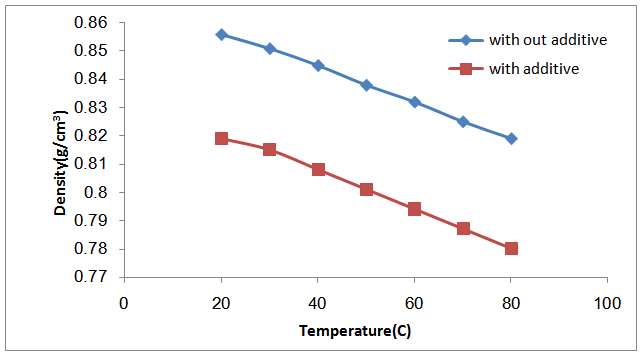

From the results obtained we noted that the density of the stock oil (40,60,150) at atmospheric pressure, and temperature (20-80)℃, decreases with increasing temperature. These results agree with (onyeji, 2012), so, achieving the right viscosity depends on selecting the right base oil and blending it with additives to obtain desired characteristics for a better functional performance. Fig. (1, 2, 3) shows the change in density with temperature. Where fig. (1) The density versus temperature was graphed of stock oil 40, resulted with a linear relation, from the same figure we obtained the coefficient (a, b) of the equation (2): | (2) |

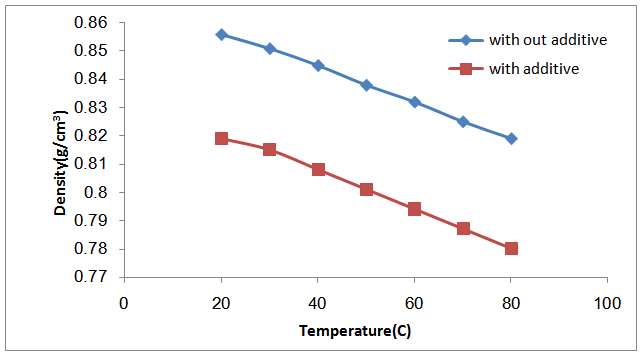

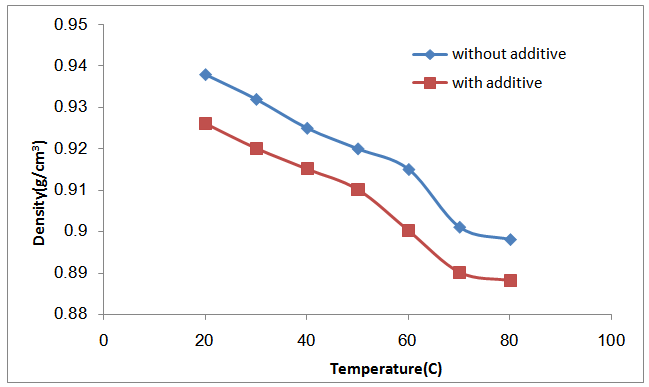

Figure (2), shows the effect of temperature on the density of the stock (60). We obtained good behavior for stock (60), as shown before with stock (40) in figure(1).Where, the effect of the additive (poly-isobutylene) as shown in the figures above gives a clear decrease in values of density for each type of stocks used at different temperatures compared with the values of density before adding additive and the average of decreasing was fixed during a long heating period (20-80℃), thus decreasing have good effect on the performance of stock oil during lubrication. | Figure (1). The density of stock( 40) without additive at different temperatures, Y=-0.000655X+0.869 |

| Figure (2). The density of stock (60) with and without additive at different temperatures, Y=-0.000658X+0.951, Y=-0.00071X+0.94 |

| Figure (3). The density of stock (150) with and without additive at different temperature, Y=-0.00065X+0.976 |

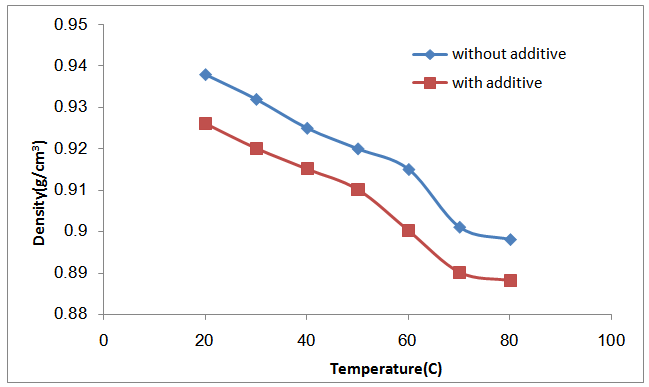

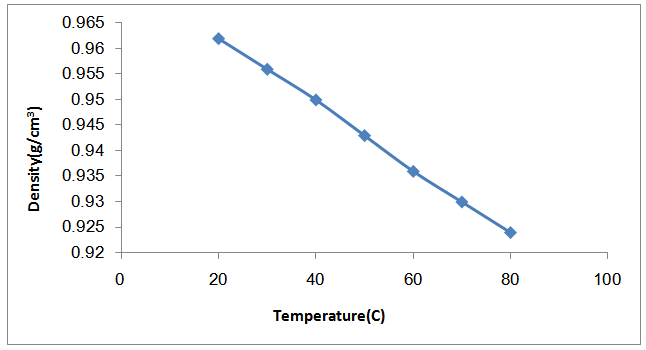

Figure (3) shows the relationship between temperature and density of stock 150 without additive, it is also the same behavior of stocks 40, 60. When using the additive with the stock 150 we did not carry out easily because the environment was very cold less than 20℃ and we did not get results in this sample.

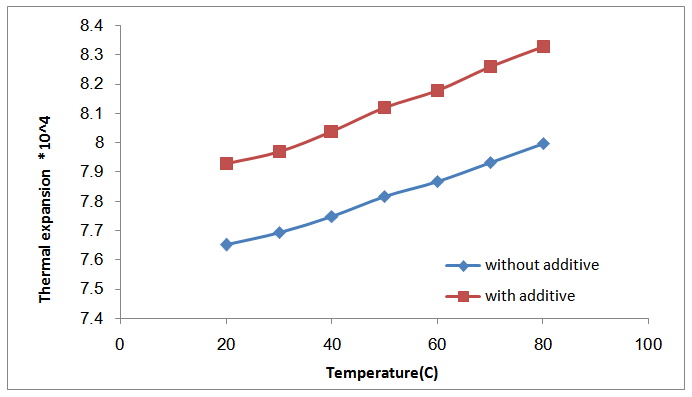

3.2. Effect of Temperature and Additive on Thermal Expansion

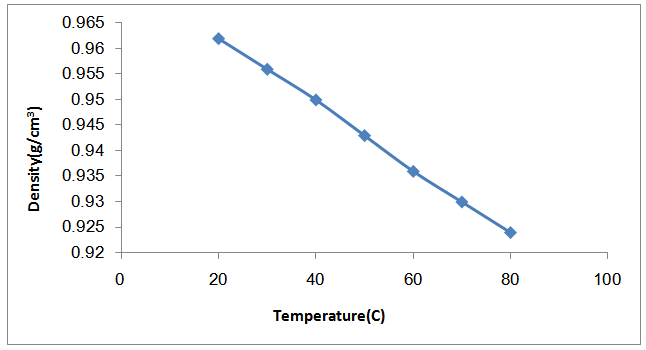

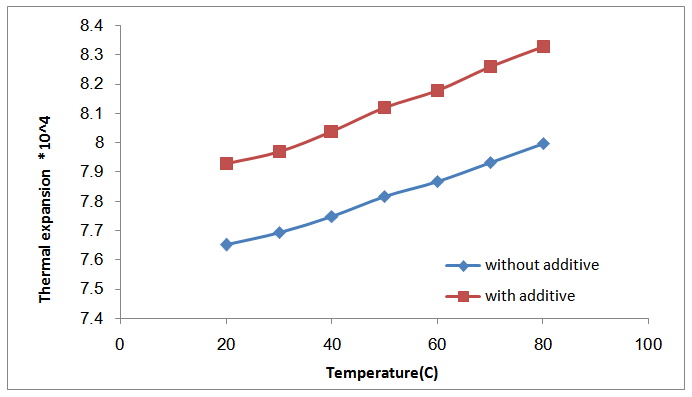

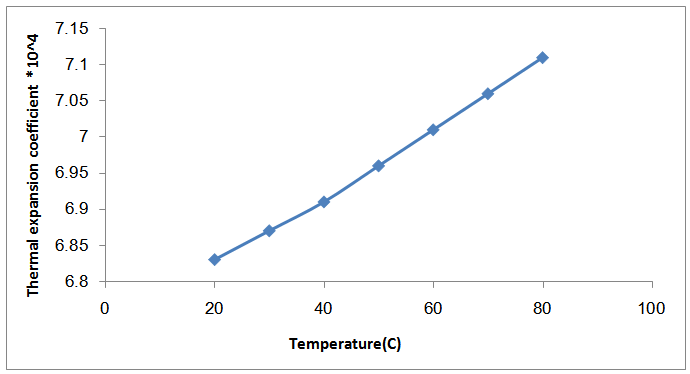

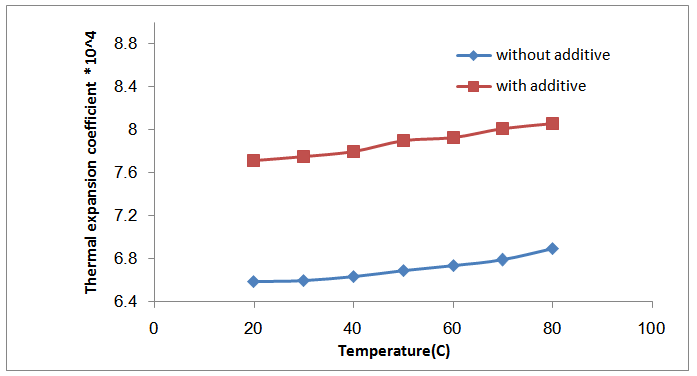

From the results of experiments and after calculating the value of thermal expansion coefficient of stocks, we found that the stocks (40) having a higher thermal expansion coefficient compared with stocks (60, 150). From figure (4) we found that there is a good relation identical to the relation (3): | (3) |

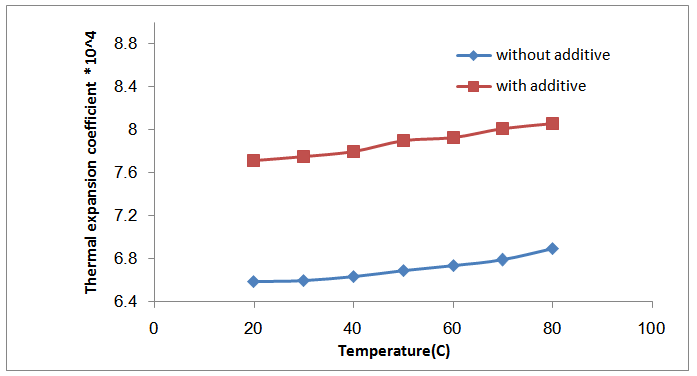

Where the value of thermal expansion coefficient at room temperature was 7.937 and increased with increasing temperature.So, after adding additive we obtained increasing in thermal expansion coefficient of stocks (40,60) and this increasing was fixed with increasing temperature, the increasing in thermal expansion coefficient is a good property of lubricant oil when used in equipments, devises and internal combustion engines, where this increasing led to increasing in surface area to contact the oil with the internal part of devises and to reduce the friction between moving parts and to increase the viscosity index and to reduce density with increasing temperature.The properties of thermal expansion give an important note to transportation and storage of lubricants at different temperatures and this gives us safety side from the fire and during storing or transportation of this material.Figure (4,5) show the relationship of temperature with the thermal expansion of stocks (40,60). We noted that the results obviously increased the thermal expansion with temperature when adding the additive, so these results agree with work done by Omar, 2007. | Figure (4). Thermal expansion of stock (40) with and without poly-isobutylene at different temperatures, Y=0.00068X+7.78, Y=0.0057X+7.52 |

| Figure (5). Thermal expansion of stock (60) with and without additive at different temperatures, Y=0.006X+7.5, Y=0.0048X+6.51 |

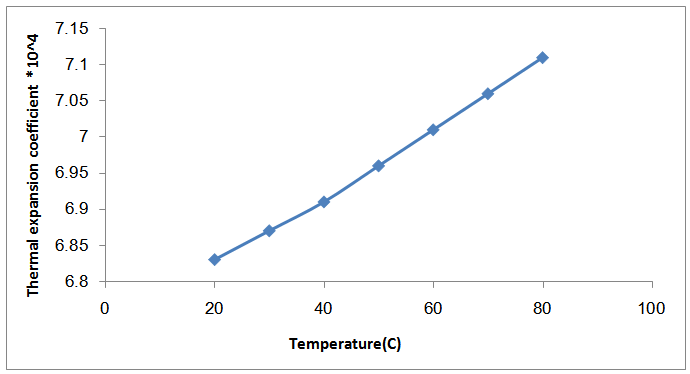

| Figure (6). Thermal expansion of stock (150) without poly-isobutylene at different temperatures, Y=0.0048X+6.722 |

4. Conclusions

From the results above we can conclude that the increasing in temperature results in decreasing the density of stocks, but with additive the increasing was higher than that without additive. The thermal expansion was increased with increasing temperature, but its increasing with additive was higher than that without additive.

5. Notification

α  Thermal expansion coefficient ρ

Thermal expansion coefficient ρ  density (gm/cm3)T

density (gm/cm3)T  Temperature (Co)

Temperature (Co)

References

| [1] | API 1509, Engine Oil Licensing and Certification System, 15th Edition, 2002. Appendix E. |

| [2] | Brouwer, L.E.J., "The Petroleum Handbook", Fifth Edition, PP.116-235,1966. |

| [3] | S.Z. Erhan B.K. Sharma K.M. Doll, 2012," Improving Vegetable Oil Properties for Lubrication Methods", Trade Journal, article 28510, P(1-2). |

| [4] | ONYEJI, LAWRENCE IBE; ABOJE, A. AUDU,2011, "THE EFFECT OF ADDITIVE ON THE VISCOSITY INDEX OF LUBRICATING OIL (ENGINE OIL),International Journal of engineering scince and technology, vol. 3, issue,3, page 1846-1869. |

| [5] | Ahmed Ghafil Alibrahemi, Naser Nassif Gassim, Dr. Adel Sharif Hamadi" EVOLUTIONARY OF EXTRACTING BASE OILS UNIT'S EFFICIENCY UTILIZING MIXED SOLVENT", univercity of technology, Iraq. |

| [6] | Udonne J. D.," A comparative study of recycling of used lubrication Oils using distillation, acid and activated charcoal with clay methods", Journal of Petroleum and Gas Engineering Vol. 2 (2), pp. 12-19, February 2011. |

| [7] | Drotining W.D, "Thermal expantion of molten dioxide", Maryland, Jane 15-18, 1981. |

| [8] | Omar M. Hussein, 2007, "Thermal expansion coefficient of lubricant oils", MSC Thesis, Nahrain University, Iraq. |

Thermal expansion coefficient ρ

Thermal expansion coefficient ρ  density (gm/cm3)T

density (gm/cm3)T  Temperature (Co)

Temperature (Co) Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML