Attar M. Z. 1, Fathi M. M. 2

1PhD, Agricultural Engineering Department., Faculty of Agriculture , Ain-Shams University, P.O. Box 68, Hadayek Shoubra 1124, Cairo, Egypt

2Prof, Poult. Production Department, Faculty of Agriculture, Ain-Shams University, P.O. Box 68, Hadayek Shoubra 1124, Cairo, Egypt

Correspondence to: Attar M. Z. , PhD, Agricultural Engineering Department., Faculty of Agriculture , Ain-Shams University, P.O. Box 68, Hadayek Shoubra 1124, Cairo, Egypt.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Poor eggshell quality has been of major economic concern to commercial egg producers all over the world, with estimated annual losses in the USA of around 247million US dollars. This study suggest using eggshell resonant frequency to estimate egg strength and shell thickness in post-harvest egg sorting, grading, and packing process as non-destructive test method. Experiments was conducted on thirty eggs collected from 44-week-old Fayoumi hen (an Egyptian local strain) with average mass of 60.13 g. The intact eggs were submitted to the acoustical excitation process-represented by this study - to obtain natural frequency for each tested egg. The eggs strength were evaluated in the range 3.6 to 5 kg/cm2 using a distractive compression test method. The eggshell, albumin, and yolk were individually subjected –for second time - to the acoustical excitation process to obtain the natural frequency for each. Results showed that eggshell, albumin, and yolk resonate around 1750 Hz, 3500 Hz, and 3900 Hz respectively. No obvious relation was found between the eggshell thickness and its breakage force. However measured shell resonant values correlated by 0.97 and 0.91 with the eggshell strength and thickness respectively. The results emphasize the suitability for using the acoustic excitation methods for evaluating egg strength in eggs production line as a noncontact test method. Moreover, further investigation on using the selective resonant analysis of the egg albumin and yolk to detect egg pathogen invasion and egg quality are required.

Keywords:

Egg integrity, Non-destructive, Resonant frequency, Stiffness, Egg strength

Cite this paper: Attar M. Z. , Fathi M. M. , Non-Destructive Acoustic Resonance Method for Evaluating Eggshell Strength and Thickness, International Journal of Biophysics , Vol. 4 No. 1, 2014, pp. 9-15. doi: 10.5923/j.biophysics.20140401.02.

1. Introduction

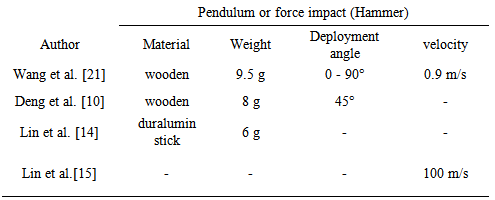

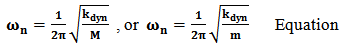

Eggs have always been an important part of the human diet as one of the most complete and versatile food available. On the other hand, eggs are also important source for food poisoning causing human intoxications [11]. Cracked or broken eggshell is vulnerable to invasion by microbial pathogens, creating problems for egg quality and safety. In their journey from the laying cage to shipments out of an egg production operation, table eggs encounter multiple shock events. Shell eggs are particularly susceptible to being cracked or broken during the production operation. A typical egg production facility experiences 2% to 7% checks (a partial mechanical failure to the eggshell) during handling, packaging and transportation of shell eggs. It has been estimated that the total losses to the U.S. egg industry due to checks and breakage of eggs during production amounts to over $247 million per year [18].Various employed methods to determine egg quality such as incubational egg weight loss, eggshell weight per unit of total eggshell surface area, eggshell pore concentration, and relative eggshell vapor conductance have been proven to most accurately describe the eggshell [17]. However, those measurement techniques for predicting the egg strength were slow, often inaccurate, subject to human subjectivity and usually destructive [26], and gave different estimates about egg strength and breakage force [9]. Sinha et al. [19] claimed to be the first on performing acoustical vibration studies on chicken eggs. Coucke [7] developed an acoustic resonance technique to assess eggshell integrity and eggshell strength, defined by the dynamical stiffness (Kdyn). De Keterlaere et al. [9] described the egg dynamic stiffness measurements as a rapid assessment of shell strength, providing a global measure of egg strength, due to the response of the egg as a whole, and stated the possibility to judge the integrity of the eggshell according to its vibration response. Wang et al. [21] and Bamelis et al. [2] established the relationship between the dominant frequency and the egg physical properties like egg strength and shellintegrity. They found that dynamic excitation and response analysis is an acceptable method for determination of physical properties for quality evaluation of table egg.Results of recent studies on using the dynamic stiffness measurement to detect egg strength varied considerably due to complication associated with the mechanical excitation of the tested eggs. Lin et al. [14] stated that the hammer tip and weight of the hammer are two important factors that determine the magnitude and duration of the force pulse. They also observed that the egg frequency response was greatly affected by the selection of the egg support. Table 2 showed variation on material, weight, deployment angle, and velocity of pendulum used to excite the egg to vibrate at its natural frequency.Borille et al. [3] concluded that little information is available about the contribution of the basic material and geometrical properties to the result of the dynamic tests. Moreover, Borille did not find a full explanation for the different effect of size and eggshell thickness on the mechanical behavior.The egg components differ in many aspects; eggshell as a solid structure with different strength and masses. While, albumin and yolk as liquids (differ in viscosities and masses) causing egg multiple resonant frequency values. This study aimed to investigate and measure the resonant frequencies of egg, eggshell, albumin, and yolk in response to acoustical excitation. Moreover, it also intended to investigate the relationship between eggshell strength and its resonant frequency as an eggshell strength evaluator for post-harvest egg grading and sorting processes.

2. Materials and Methods

Experiments were conducted in 2009 in the Agricultural Engineering Department, Faculty of Agricultural, Ain-Shams University, Cairo, Egypt, on 30 eggs collected from 44-week-old Fayoumi hen (an Egyptian local strain). The average egg mass was 60.13 g. All measurements were performed on intact egg within one week from egg collection.

2.1. Determination of Egg Resonant Frequency

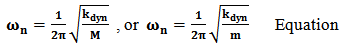

An acoustic measurement configuration was developed to investigate the response of egg, eggshell, albumin, and yolk to acoustical excitations. The following equation estimate the stiffness (Kdyn) of the egg or eggshell, based on egg mass (M) or eggshell mass (m), and resonant frequency  [4, 5].

[4, 5]. | (1) |

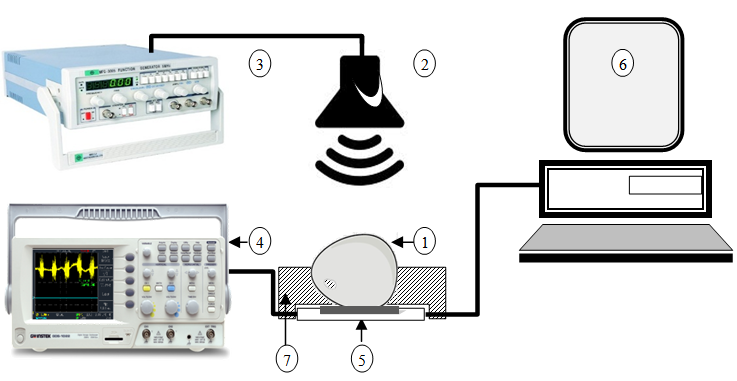

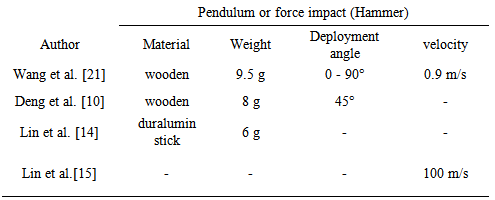

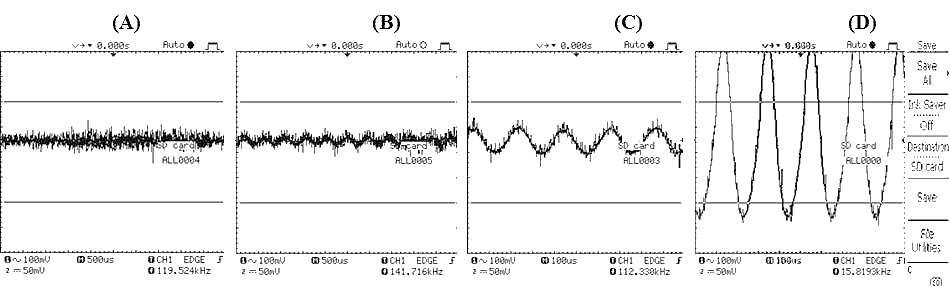

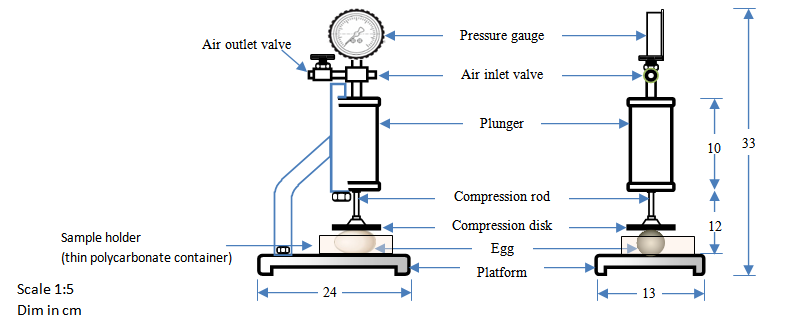

Figure 1 shows the experimental set used to investigate egg resonant frequencies. The tested egg was subjected to an acoustical excitation with the frequency range of 200 Hz ~ 20 kHz emitted from a SWT "8Ω" loudspeaker (model DS2850-08A). This loudspeaker received sinusoidal waves from the function generator (model MFG-3002: 0.1 MHz to 2 MHz, measurement range 1 Hz to10 MHz ≥ 10 VP-P, accuracy less than 0.003% ± 1 digit, sensitivity 100 mVrms , and frequency response 0.1 - 100 MHz.Table 1. Reviewed pendulum characteristics used to calculate egg dynamic stiffness

|

| |

|

| Figure 1. Egg resonance, detection, recording, and analysis system: (1) tested egg, (2) loudspeaker, (3) function generator, (4) digital oscilloscope, (5) piezoelectric sensor, (6) computer, (7) holding sponge |

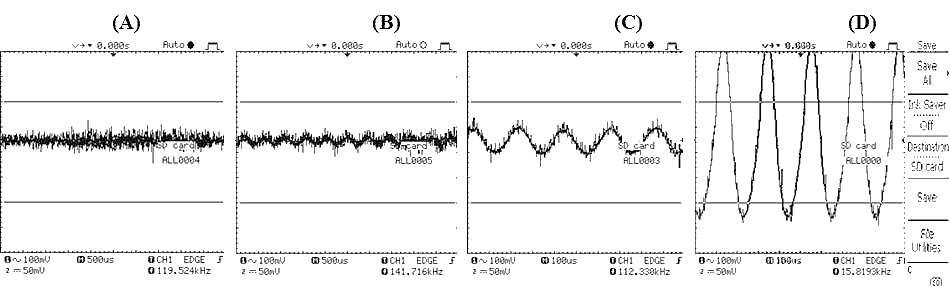

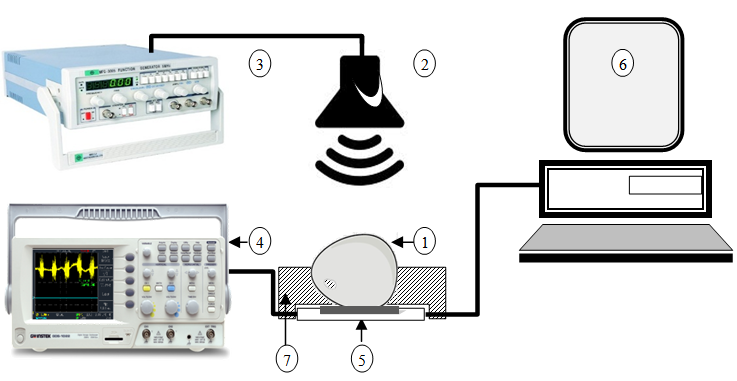

Response from the egg was transmitted to a dual channel digital storage oscilloscope (model GW INSTEK, GDS-1022,sensitivity 5V/div., accuracy ± (3% x |readout|+ 0.1 div. + 1 mV,) by means of the ceramic plate piezoelectric FT-20T-6A1 uncased vibration sensor (resonant frequency: 6.8 ±0.7kHz resonant resistance: 300Ω, capacitance : 15,000 pF ±30%. The acoustic data were recorded, stored and analyzed with a personal computer. Hollow sponge (four centimeters inner The measurements performed on egg at six marked locations: four equally-spaced on the egg’s equator and one at each pole. A loudspeaker, located at five centimeter above the tested egg, produced acoustic excitation signal, which was gradually tuned by the frequency generator until the egg resonance responses were captured by the oscilloscope (figure 2). | Figure 2. Egg vibration response to the gradually tuned acoustic excitation frequencies: (a) egg with no response to the excitation signal, (b, c) egg vibration response and (d) egg vibration with maximum response (resonant frequency) |

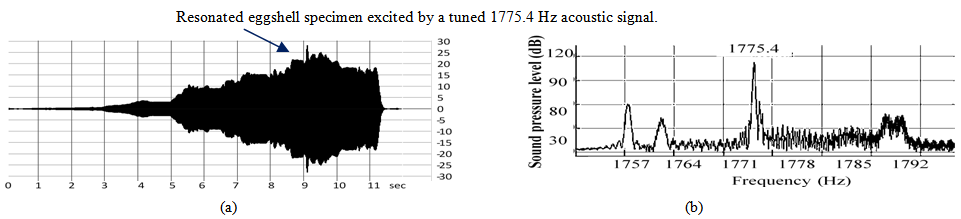

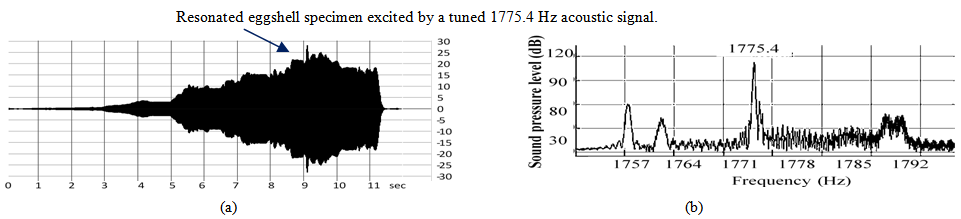

The egg vibration response was recorded and processed by a signal analysis CoolEdit Pro (ver. 2) Adobe Audition Inc. software. Recorded resonance signals at 44100 samples/sec saved to a 16-bit resolution PCM file format (fig. 3). | Figure 3. Vibration response of an egg, subjected to incremental frequencies, recorded in the time (a) and frequency (b) domains |

2.2. Determination of Egg Breakage Force

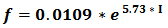

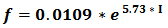

Egg strength to breakage force was determined on its equator with destructive compression test setup (fig. 4). A detailed description of the test set and calculation method [12]. The egg breakage force, Pa, was calculated, to within an accuracy of 0.02 kg/cm2, from the registered gauge reading Pt and the apparatus correction factor f:  | (2) |

| (3) |

where I represents the egg length/width ratio. | Figure 4. An apparatus for measuring eggshell strength [12] |

2.3. Measurement of Weight and Thickness

Egg mass was measured with AcculabV-200 digital scale with the full capacity of 200 g and a repeatability of ±0.01 g to the nearest 0.01 g. All tested eggs were selected according to the USDA [20] standards. After laying, the eggs were stored in room temperature, with approximate 15°C.For weight measurement of eggshell, the broken eggshell resulted from the fracture test was collected and washed by a warm water to remove adhering albumin and dried at 105°C for 24 hours. Shell thickness was measured, using a dial gauge micrometer, for three pieces from egg equator and equidistant from each other on the same half of the shell.

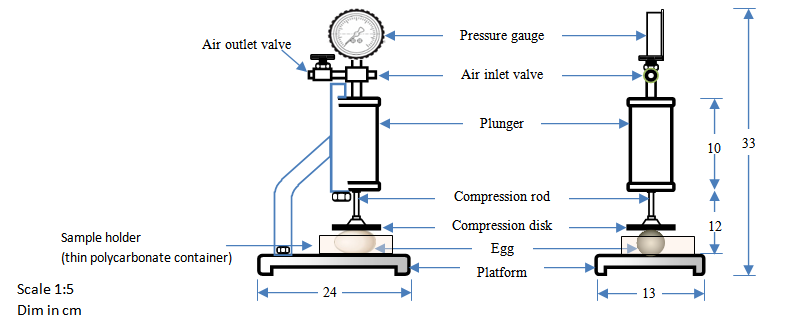

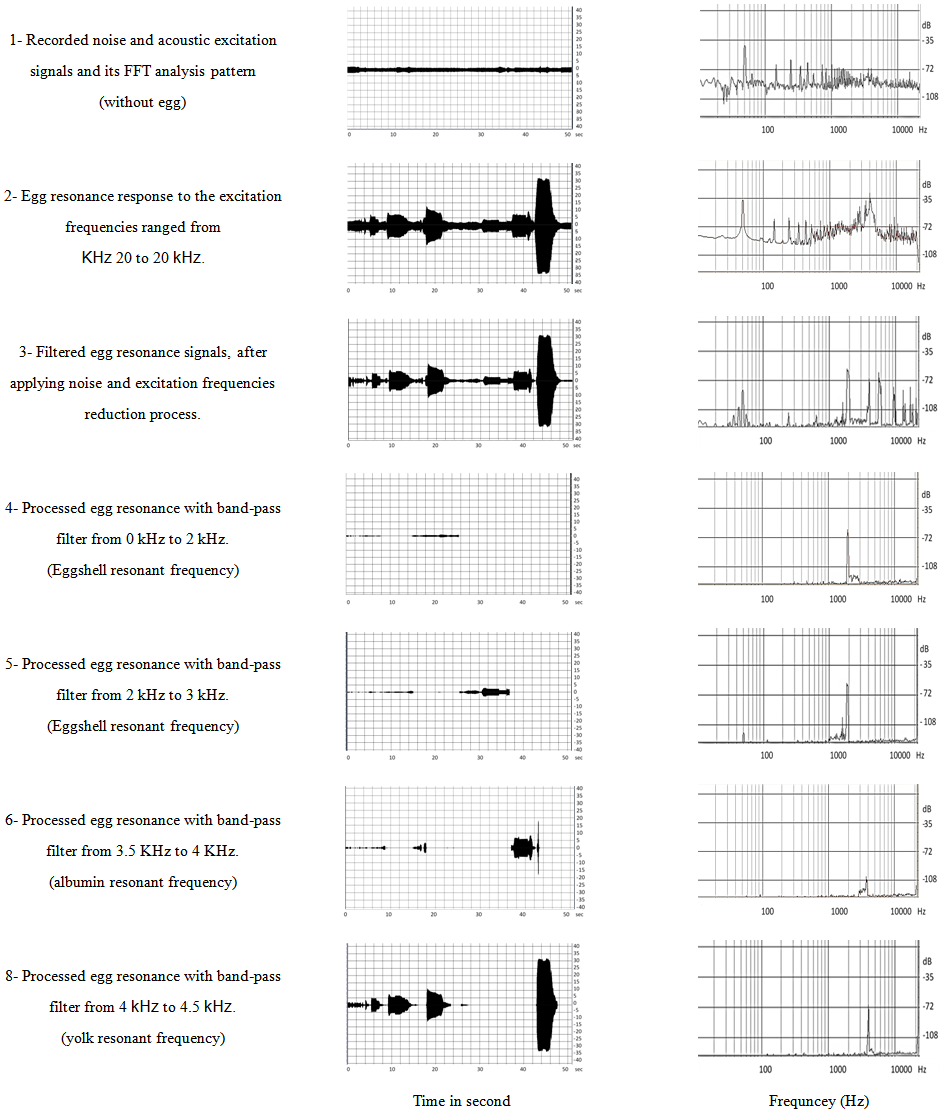

2.4. Signal Noise- reduction and Analysis for the Egg, Eggshell, Albumin, and Yolk Resonance

After obtaining all of the distinct resonant frequencies form the intact eggs. Eggs were subjected to destructive strength test to evaluate its breakage force. Separated and cleaned eggshell, albumin, and yolk preserved in a thin polycarbonate container were subjected to acoustical excitation signals. The frequency generator was tuned gradually to detect the eggshell, albumin, and yolk resonant frequencies to occur on the oscilloscope – maximum signal peak - and data recording.Signals with ambient and electrical noises were recorded and analyzed in the absent of the tested eggs. The recognized noise reduced in all of the recorded eggs vibration signals electronically by 40 dB. According to the primary tests, egg vibration responses were separated and analyzed for eggshell, albumin, and yolk by band-pass filters in range from 0 kHz - 2 kHz, 2 kHz- 3 kHz, 3.5 kHz - 4 kHz, and from 4 kHz - 4.5 kHz (fig. 5). | Figure 5. Vibration response of egg submitted to incremental frequencies to obtain resonance vs. time, recorded with CoolEdit Pro computer software |

3. Results

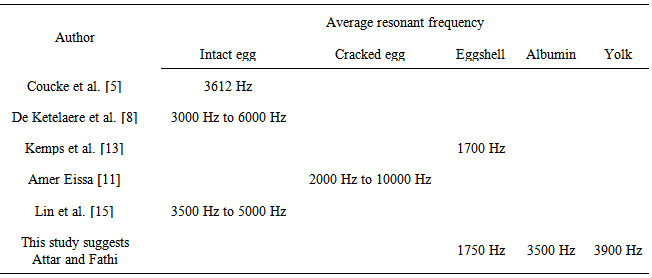

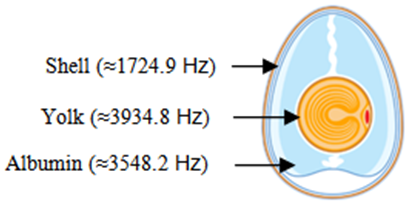

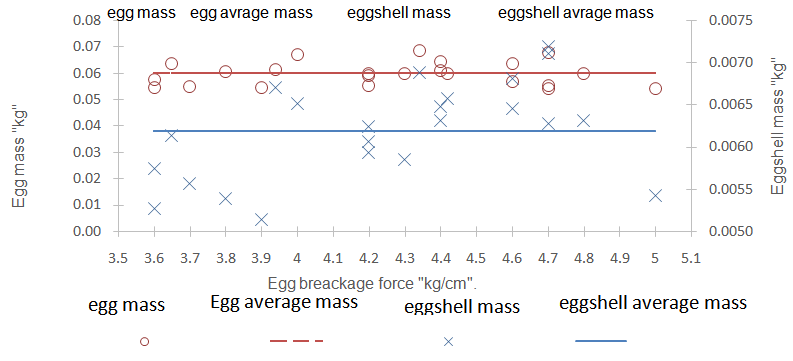

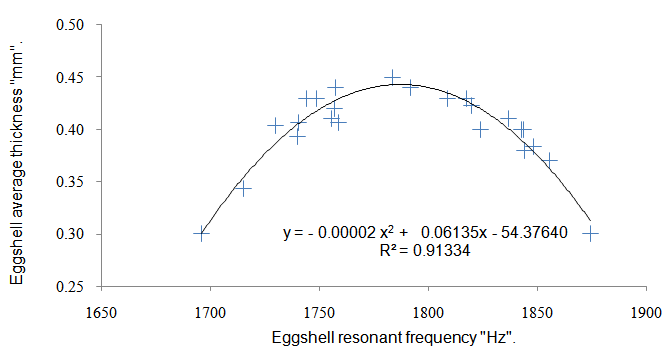

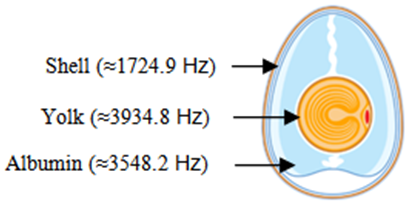

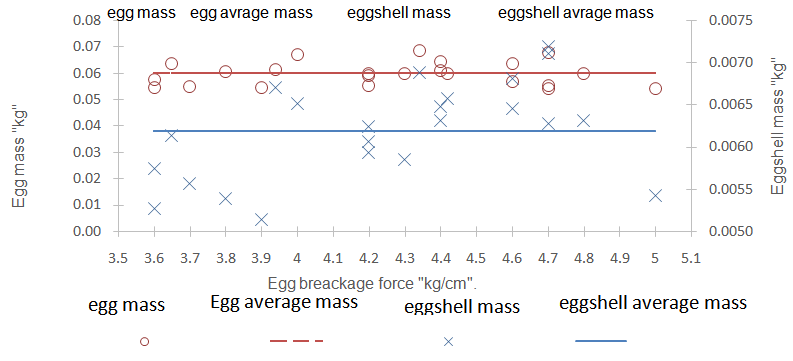

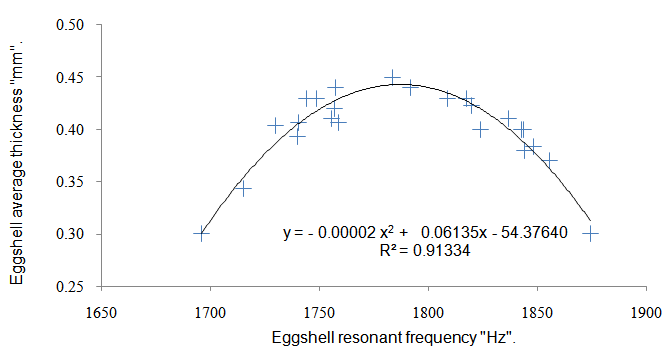

Egg, as a complex structure, can resonate at a multiple degrees of freedom. Eggshell, albumin, and yolk were found to resonate around 1750 Hz, 3500 Hz, and 3900 Hz respectively as shown in figure 6. Variation in the measured resonance values occurred because the egg samples differed in physical and mechanical properties. Results in figure 7 showed that neither the egg nor eggshell mass is indicative of the eggshell strength. Results from the egg’s acoustic response to the sinusoidal excitation (fig. 8) showed that eggshell resonant frequency was highly correlated to its average thickness (R2 = 0.91). | Figure 6. Eggshell, albumin, and yolk measured resonant frequencies |

| Figure 7. Egg and Eggshell mass relationship to eggshell breakage force |

| Figure 8. Relationship between eggshell thickness and eggshell resonant frequency |

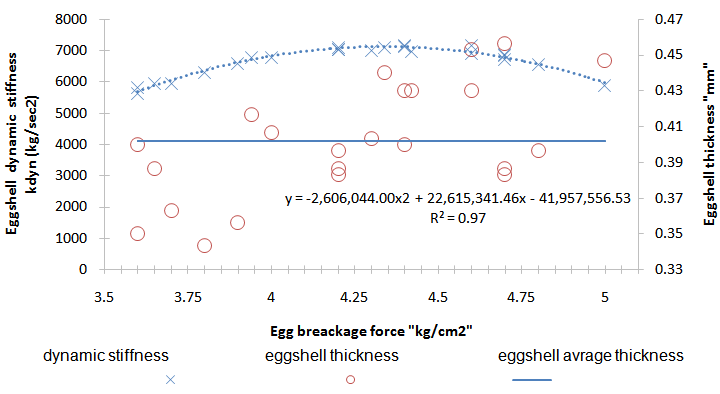

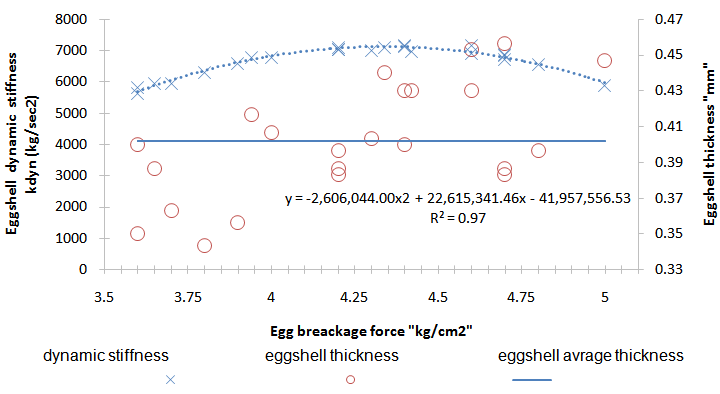

Figure 9 shows no obvious relation between the eggshell thickness and breakage force. However, the calculated dynamic stiffness Kdyn values of the eggshell, calculated from the resonant frequency and eggshell mass (equation 1), highly correlated with the egg breakage force with a correlation coefficient of 0.97. | Figure 9. The eggshell thickness, breakage force and calculated dynamic stiffness |

4. Discussion

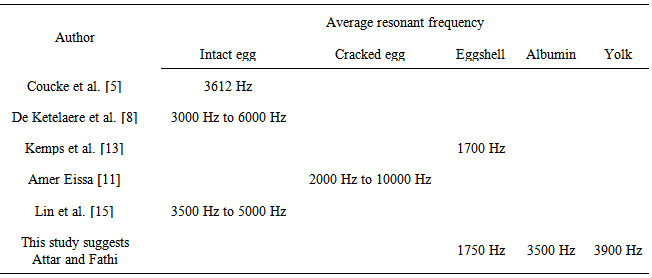

Previous investigation [7] reported that intact egg subjected to impact only exhibited one resonant frequency, while cracked egg produced a number of resonant peaks. Their findings are in disagreement with results presented by Lin et al. [14], where they explained that egg resonant frequency varied from 3500 Hz to 5000 Hz in intact egg, and disappeared in the cracked egg. De Keterlaere et al. [8] showed that resonant frequency of an intact egg varies from 3000 Hz to 6000 Hz. However, only a few confirmatory reports on the egg resonant frequency have been published, as shown in table 2. Reviewing results obtained from different resources, this study suggests that variation in reported egg resonant frequency could be due to two reasons. The first is the non-slandered mechanical excitation method –different methods and tools obtained from reviewed studies. Second, the reported resonances of egg actually represent the acoustic transmissibility in the eggshell, resulting from internal egg components. The physical properties of albumin and yolk change due to the environmental and biological factors, which, in turn, affects their resonant values. Therefore, the intact eggshell can transmit albumin and yolk resonant frequencies, while cracked shell dissipates the energy of these frequencies allowing detection of cracked eggshell. This may explain why resonant frequency could not predict the eggshell strength in this study.Table 2. Resonant frequency record of current and previous studies

|

| |

|

Correlation between eggshell resonant frequency and shell thickness by using present study to determine eggshell resonance frequency increased to R2=0.91 compared with 0.86 obtained by Coucke [5].

5. Conclusions

Egg resonant frequencies provide various clues for non-destructive egg quality measurement. Egg has multiple resonance related to its components. Eggshell resonated at 1500 Hz to 2000 Hz. Results showed a high correlation (R2 = 0.97) between eggshell resonant frequency and its strength by using the acoustical excitation method. Using the acoustical excitation method to measure eggshell resonant frequency and strength is a promising non-destructive egg examination method. More studies are needed for the determination of the possibilities of egg resonant frequencies usage as a non-destructive detection method for biological invasion of eggs.

References

| [1] | Amer Eissa, A.H. 2006. Comparative eggshell stability assessment using three different non-destructive sensing instruments and breakage force strength. Food Eng. J. 93(4):444-452. |

| [2] | Bamelis, F.R., B. De Ketelaere, B.J. Kaemps, K. Mertens, E.M. Decuypere, and J.G. De Baerdemaker. 2006. Non-invasive methods for egg quality evaluation. World’s Poult. Sci. J. Supplement XII Eur. Poult. Conf. (EPC). |

| [3] | Borille, R., Garcia, R., Royer, A., Santana, M., Colet, S., Naas, I., and Caldara, F. 2013. The use of light-emitting diodes (LED) in commercial layer production. Revista Brasileira de Ciência Av’\icola (Sci. ELO Brazil) 15: 135–140. |

| [4] | Cai, C., Zheng, H., Khan, M. & Hung, K. 2002. Modeling of material damping properties in ANSYS in CADFEM users’ meeting \& ANSYS Conf., pp. 9–11. |

| [5] | Coucke, P, E. Dewil, E. Decuypere, Jde Baerdemaeker. 1999. Measuring the mechanical stiffness of an eggshell using resonant frequency analysis. British Poult. Sci. 40:227-232. |

| [6] | Coucke P. 1998a. Assessment of some physical egg quality parameters based on vibration analysis. PhD diss.: Katholieke University, Leuven, Belgium. |

| [7] | Coucke, P., G. Jacobs, P. Sas, and J. De Baerdemaeker. 1998b. Comparative analysis of the static and dynamic mechanical eggshell behavior of a chicken egg. ISMA Inter. Noise and vibration Eng. 23:1497-1502. |

| [8] | De Ketelaere, B., P. Couke, J.De. Baerdemeker. 2000. Eggshell crack detection based on acoustic resonance frequency analysis. J. Agric. Eng. Res. 76: 157-163. |

| [9] | De Ketelaere, B., T. Govaerts, P. Coucke, E. Dewil, J. Visscher, E. Decuypere, and J. De Baerdemaeker. 2002. Measuring the eggshell strength of 6 different genetic strains of laying hens-Techniques and comparisons. British Poult. Sci. 2(43):238 – 244. |

| [10] | Deng, X., Wang, Q., Wu, L., Gao, H., Wen, H. & Wang, S. 2009. Eggshell crack detection by acoustic impulse response and support vector machine. African J. Agric. Res.4(1), 40–48. |

| [11] | EU .2003. Introducing detailed rules for implementing certain marketing standards for eggs. EU J., Reg. No. 2295/2003, L 340/16. |

| [12] | Fathi, M.M., and E.A. El-Sahar. 1996. Determining the strength of eggshell by using an appropriate apparatus and an equation to calculate egg surface depending on its dimensions. Egypt. Poult. Sci. 16(11):285-303. |

| [13] | Kemps, B. , B. De Ketelaere, F. Bamelis, T. Govaerts, K. Mertens, B. Kamers, K. Tona, E. Decuypere, and J. De Baerdemaeker. 2004. Development of a methodology for the calculation of Young’s modulus of eggshell using vibration measurements. Biosystem Eng. 89 (2): 215–221. |

| [14] | Lin, H., J. Zhao, Q.S. Chen, J. Rong Cai, and P. Zhou. 2009. Eggshell crack detection based on acoustic impulse response and supervised pattern recognition. Czech J. Food Sci. 27 (6): 393–402. |

| [15] | Lin, H., Zhao, J., Sun, L., Chen, Q., Sun, Z. & Zhou, F. 2011. Stiffness measurement of eggshell by acoustic resonance and PLS models. J. Food Eng. 103(4): 351–356. |

| [16] | Mertens, K., B. De Ketelaere, F. Bamelis , B. Ostyn , B. Kemps , C. Perianu , I. Vaesen , J. Zoons , E. Decuypere , and J. De Baerdemaeker. 2007. Using the dynamical stiffness (Kdyn) in an egg quality-monitoring scheme. Euro. Symposium on the quality of eggs and egg products, Prague, art. No. 041: Czech Republic. |

| [17] | Peebles, D., and C.D. McDaniel. 2004. A practical manual for understanding the shell structure of broiler hatching eggs, and measurements of their quality. Agric. Comm. Office. Agric. Forestry& Veterinary Medicine: Mississippi State University. (Unpublished) |

| [18] | Singh, J. A., Ferrier, C., and Singh, P. 2007. Measurement and analysis of the shocks generated during egg production. Applied Packaging Research, 2(1): 45–59. |

| [19] | Sinha, D.N., R.G. Johnston, W.K. Grace, and C.L. Lemanski. 1992. Acoustic resonances in chicken eggs. Biotech. Program (8): 240-243. |

| [20] | USDA. 2000. Egg grading manual. Agric. Handbook No. 75:17-19. |

| [21] | Wang, J., R.S. Jiang, and Y. Yu. 2004. Relationship between dynamic resonance frequency and egg physical properties. Food Res. Inter. 37: 45–50. |

[4, 5].

[4, 5].

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML