-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Archaeology

p-ISSN: 2332-838X e-ISSN: 2332-841X

2021; 9(1): 54-55

doi:10.5923/j.archaeology.20210901.10

Digital 3D Preservation of a Rare Homo Naledi Skull

Konstantinos Naseb1, Petros I. Stavroulakis2, Karim Sadr3, Theodore Ganetsos1, Nikolaos Laskaris1

1Non-destructive Testing Measurement Lab, University of West Attica, Athens, Greece

2Daedalus Research Associates, Athens, Greece

3Archaeology Department, University of Witwatersrand, Johannesburg, South Africa

Correspondence to: Petros I. Stavroulakis, Daedalus Research Associates, Athens, Greece.

| Email: |  |

Copyright © 2021 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In this work the digital preservation of the outer geometry of a rare homo naledi skull is achieved in a quick and semi-automated fashion, using a low-cost commercially-available industrial 3D scanner. Additionally, the replication of the result on a PLA 3D printer is evaluated for educational and tele-research purposes. We show the possibility of preserving the skull digitally and creating a 60% volume replica in under 2 hours.

Keywords: 3D Scanning, 3D printing, Digital preservation, Tele-research, Cultural heritage, Homo naledi

Cite this paper: Konstantinos Naseb, Petros I. Stavroulakis, Karim Sadr, Theodore Ganetsos, Nikolaos Laskaris, Digital 3D Preservation of a Rare Homo Naledi Skull, Archaeology, Vol. 9 No. 1, 2021, pp. 54-55. doi: 10.5923/j.archaeology.20210901.10.

Article Outline

1. Introduction

- The Homo naledi are a distinct lineage of fossil hominins, first discovered in the Dinaledi Chamber of the Rising Star Cave system in South Africa, during an expedition led by Lee Berger [1-3] in beginning of October 2013. In November of 2013 and March of 2014, over 1550 specimens from at least 15 Homo naledi individuals were recovered from this site. This excavation remains the largest collection of a single hominin species that has been found in Africa. Rick Hunter and Steven Tucker found an additional 133 Homo naledi specimens in the nearby Lesedi Chamber in 2013, representing at least another 3 individuals – two adults and a juvenile. In 2017, the Homo naledi fossils were dated to between 335,000 and 236,000 years ago.This therefore a relatively newly discovered hominin species and due to its limitation, it is a rare specimen. It was digitally preserved with a price-effective commercially- available 3D measurement and reproduced with a budget PLA 3D printer in order to test the quality and speed of reproduction and its applicability to hands-on education and artefact dissemination purposes.

2. 3D Measurement

- To measure the object’s 3D structure cost-efficiently and in a fast, high fidelity and automated method, the ‘industrial version’ of the Einscan Pro 2X which includes an automatic rotation table that was used to scan the cranium shown in figure 1.

| Figure 1. Experimental setup used to measure the cranium in 3D |

3. Post Processing

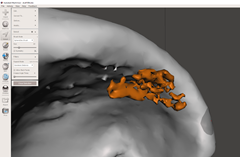

- Most of the post processing steps were streamlined via the Shining 3D software ‘Make watertight’ function. However some errors were identified especially around the eyelobes show in Figure 2.

| Figure 2. Evidence of errors remaining on the model after 3D model was exported from the 3D scanning software |

4. 3D Printing

- In order to 3D print the duplicate, an Einstart-C printer was used. The scanned model was scaled down to 65% of the original dimensions. The layer height of 0.1mm was selected in order to preserve most of the details.

| Figure 3. Homo naledi cranium (left) and 3D printed replica of skull as it was removed from the 3D printer (right) |

5. Results

- The results of the 3D scanning and 3D printing process followed are acceptable for educational purposes and a very close match and high repeatability of the geometry features was possible. Both the real cranium and the replica are visibly indistinguishable. However, a major difference between the two was that the 3D printer creates horizontal ripples across the surface of the 3D-printed object creating a relatively rough surface which might lower the accuracy of distinguishing features.

6. Conclusions

- We show here that it is possible to rapidly scan, post-process and replicate archaeological skull remains in under 2 hours. We find the time required applicable for rapidly replicating rare specimens for educational and research purposes. However, in order to achieve mass digitization, improvements to the autonomy of the 3D scanner and post processing steps are required to make it practical for archaeological sites that would like to digitize large amounts of specimens as requiring 2 hours per specimen is deemed impractical.The 3D scanning software used possessed integrated post processing tools and was able to create models which were 3D printer-friendly, such as the ‘make watertight’ feature which accelerates the procedure greatly. Limited further post-processing in a different license-free software (Meshmixer) was required to remove small remaining errors in the post-processing of the 3D data.Future work will concentrate on identifying which features of the cranium are most important for archaeologists so that a more optimized 3D scan strategy can be implemented in order to minimize the output data file size which in our case was very large (>700MB) whilst simultaneously keeping all the necessary information required for research and educational purposes.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML