-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Architecture Research

p-ISSN: 2168-507X e-ISSN: 2168-5088

2015; 5(3): 97-101

doi:10.5923/j.arch.20150503.02

Analyzing the Impact of Air Leakage on the Wall (Case Study: Concrete Brick Wall)

Ahmad Ekhlassi1, Saeed Shiri Germi2, Hamideh Karamat3

1School of Architecture and Environmental Design, Iran University of Science and Technology, Iran

2MS of architecture, Iran University of Science & Technology, Iran

3MA of Urban Design, PNU Tehran, Tehran, Iran

Correspondence to: Saeed Shiri Germi, MS of architecture, Iran University of Science & Technology, Iran.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

One of the main problems that can be addressed in the building is air infiltration or exfiltration in the wall which can lead to the serious problems in the structures. Another is moisture problems in the cavities of the exterior walls and roofs which are often caused by the exfiltration of humid indoor air. This article examines the problems of air leakage in the wall. The simulation and evaluation of the wall is based on the analysis of the output data by the software WUFI®pro. The results show that serious building envelope problems are caused by moisture condensation (due to air exfiltration) within exterior walls. They include efflorescence on brick and stone, spalling of brick and stone, corrosion of anchors and brick ties, paint peeling, icicles on the exterior facade, the rotting of sheathing and the production of mold and mildew and more.

Keywords: Air leakage, Moisture, Wall Modeling, Concrete Brick

Cite this paper: Ahmad Ekhlassi, Saeed Shiri Germi, Hamideh Karamat, Analyzing the Impact of Air Leakage on the Wall (Case Study: Concrete Brick Wall), Architecture Research, Vol. 5 No. 3, 2015, pp. 97-101. doi: 10.5923/j.arch.20150503.02.

Article Outline

1. Introduction

- Air leakage consists of air infiltration from the exterior into the conditioned spaces of buildings and/or exfiltration of conditioned interior air out of buildings. Although under a pressure differential air can pass directly through many materials, air leakage occurs primarily through a myriad of cracks, gaps, improperly designed or constructed joints, utility penetrations, junctions between wall and window and door frames, junctions between wall and roof assemblies, and other avenues. It has long been recognized that the control of air flow is a crucial and intrinsic part of heat and moisture control in modern building enclosures [13] [3]. That this statement is true for all climates has been a more recently developed awareness [8]. A large fraction of a modern, well-insulated building's space conditioning energy load is due to uncontrolled air leakage. Wintertime condensation of water vapor in exfiltration air (or summertime condensation of infiltrating air) within assemblies is one of the two major sources of moisture in the above-grade enclosure (driving rain being the other). Air flow through the enclosure can also carry, exhaust gases, odors, and sounds through enclosures as well as mold spores and off gassing generated within the enclosure. Uncontrolled air leakage through the enclosure is therefore often a major cause of performance (e.g. comfort, health, energy, durability, etc.) problems.Air infiltration and exfiltration in the exterior wall can lead to the serious problems in the structures. These problems are relevant to the efflorescence, crushed materials, freezing under ceilings and pipes, condensation in the cavity, and at the same time it can lead to rainwater infiltration [1]. Moisture due to air leakage is one of the factors which have a negative effect on the building's sustainability. The wall’s U-value can significantly be increased or decreased due to the water content in a building’s construction, and consequently, the building’s energy consumption could also be increased or decreased [10]. Condensation in such a construction can cause serious damages. Also, the mold growth under high moisture has a negative effect on the building's sustainability and human’s health [12]. An important requirement to design the components in a building’s envelope is to limit the risks of this phenomenon [9]. In the field of the healthcare construction, these problems are more sensitive because of the production and the transmission of bacteria, fungi and the spread of infection, as well as increase the building maintenance costs. In Europe, the history of air and moisture modeling goes back to 1932, when Hiresch published his book on drying technology [6]. That book was reworked in 1956 by Krischer and Kroll [7]. The chapter on moisture transport sees the water vapor resistance factor and the moisture diffusivity introduced as main material properties that govern drying by vapor diffusion and capillary suction. Krischcr anyhow was not the only one digging in the field of knowledge [12]. In 1958-1959.Glaser advanced a simple method to control interstitial condensation in cold store walls [2-4]. As most materials used in cold stores are no capillary, as the walls are airtight and as the temperature and vapor pressure difference are close to constant, steady state vapor diffusion remained as the only moisture transport mechanism involved [5]. Thus, the method gave quite good results for those types of envelopes. That motivated the other author to extend the Glaser rationale to building envelope, which was a step too far [13]. One of the conditions fulfilled by cold store walls, in fact, is typical for building envelopes. Transiently loaded, air-tightness not guaranteed. Many materials capillary active, gravity not negligible, etc., Though the Glaser approach was charming in its simplicity. In North America, a method analogous to the Glaser rationale was adopted, based on research done during the 1930s [11].

1.1. Moisture Condensation Due to Air Exfiltration

- Air exfiltration through the walls in a cold climate connecting with paper insulation can lead to the formation of dew and making frost on it. The repetition sequentially and melting frost can damage the insulation. On the walls with enough insulation, the dew point temperature of the interior air will be lower than the air temperature of the insulation. Therefore condensation due to air infiltration can’t occur inside [14]. So if the wall be designed properly, the condensation due to air infiltration doesn’t occur, even though no vapor resistance is considered in the materials assembly. When the outside condition gets colder, the existing humidity level in cold weather as the most of its moisture comes down, because the interior humidity is diluted by increasing the interior dry air which can be effective in the prevent of the condensation. The interior humidity level is usually defined by a combination of the temperature and relative humidity. The condensation will not occur if the insulation temperature is more than the dew point of the interior air [12].

2. Objectives

- The main object of this research is attention to the building durability against the air leakage into the wall assembly. Therefore, the main purpose of the study is to control the problems due to the influence of air and moisture in the buildings. There are three primary classes of reasons why the control of air flow is important to building performance:

2.1. Moisture Control

- Water vapor in the air can be deposited within the envelope by condensation and cause serious health, durability, and performance problems.

2.2. Energy Savings

- Air leaking out of a building must be replaced with outdoor air which requires energy to condition it. Approximately 30% to 50% of space conditioning energy consumption in many well-insulated buildings is due to air leakage through the building enclosure. Convective circulation and wind washing both reduce the effectiveness of thermal insulation and thus increase energy transfer across the envelope.

2.3. Comfort and Health

- Cold drafts and the excessively dry wintertime air that results from excessive air leakage directly affect quality, airborne sound transmission control requires good airflow control, and odors and gases from outside and adjoining buildings often annoy or cause health problems.

3. Methodology

- The theoretical basics of research are based on the study of journal’s articles and investigative reports which have been published in the building journals. In this study to analyze and evaluate the wall details and the influence of air into the wall, the software WUFI® pro has been used. This software is capable to analyze the wall layers and also the whole structure for air and moisture. In this method, the concrete brick wall is simulation, graphically analyzed and determined the weaknesses against air leakage. In this research the multilayer walls have been analyzed. These layers have been listed in the outdoor-indoor direction. The data of materials were obtained from WUFI®pro and used in the simulation. The interior of the enclosure promote condensation which supports biological human comfort, wind-cooled portions of growth which in turn affects indoor air.

3.1. Properties of Materials

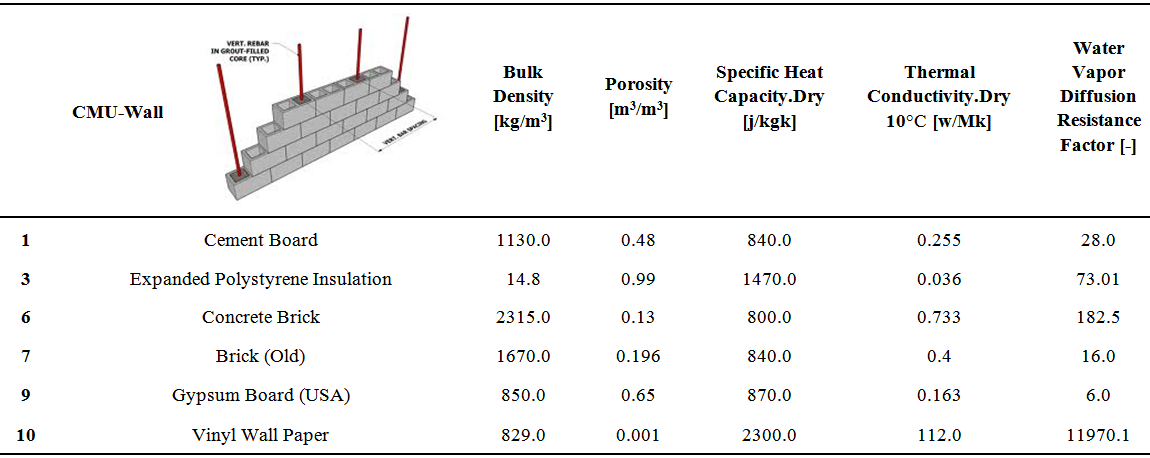

- The studied wall in this research is the concrete block which is widely used in the construction. The materials obtained from WUFI®pro considering the properties of usable materials in the exterior wall in cold climate. The factors have been considered in the selection of the materials are: Bulk density, porosity, specific heat capacity, thermal conductivity and resistance against the water vapor diffusion, which are very important in the increase of the wall performance. The properties of the materials have been specified at the table 1.

| Table 1. The used materials in the analysis (extracted from WUFI®pro software) |

4. Results

- The results show, the influence of air into the wall can lead to the irreversible harm in the buildings. In addition to air leakage can lead to the serious problems in the building envelope which are caused by moisture condensation (air exfiltration) within exterior walls. They include efflorescence on brick and stone, spalling of brick and stone, corrosion of anchors and brick ties, paint peeling, icicles on the exterior facade, the rotting of sheathing and the production of mold and mildew and more.

5. Case Study

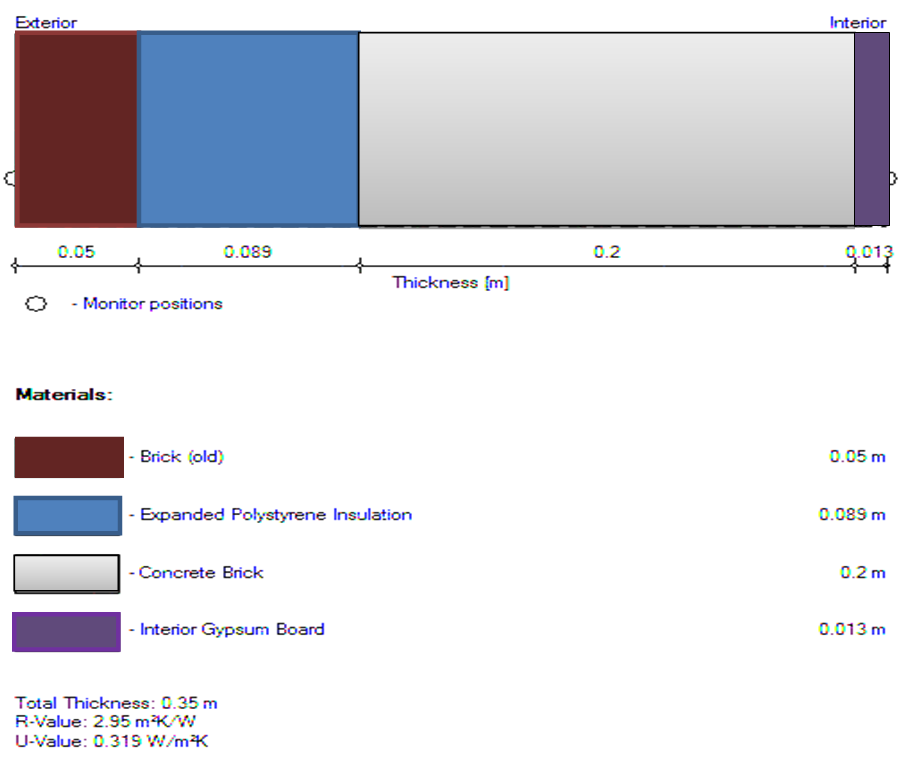

- The main structure in the wall is the Concrete Brick. Other materials are; Expanded Polystyrene Insulation, brick as a cladding and gypsum board. In the simulations, the typical wall of concrete brick was analyzed through WUFI. Outside climate was considered based on cold climate and inside climate was based on standard EN15026 (normal moisture load). The calculation time is one year, see Fig. 1.

| Figure 1. Wall without air & vapor barrier |

6. Analysis and Conclusions

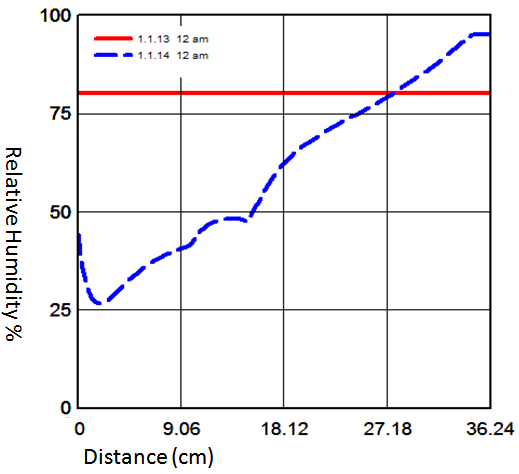

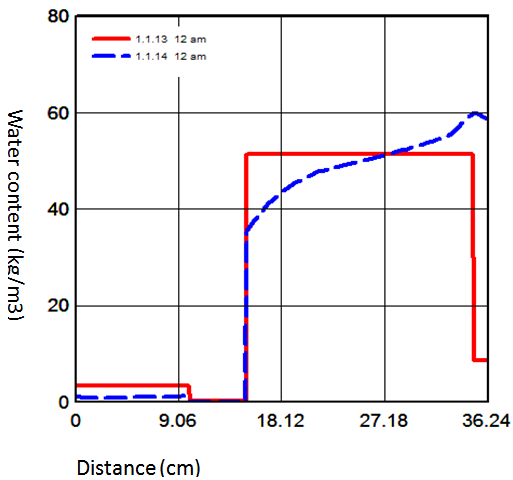

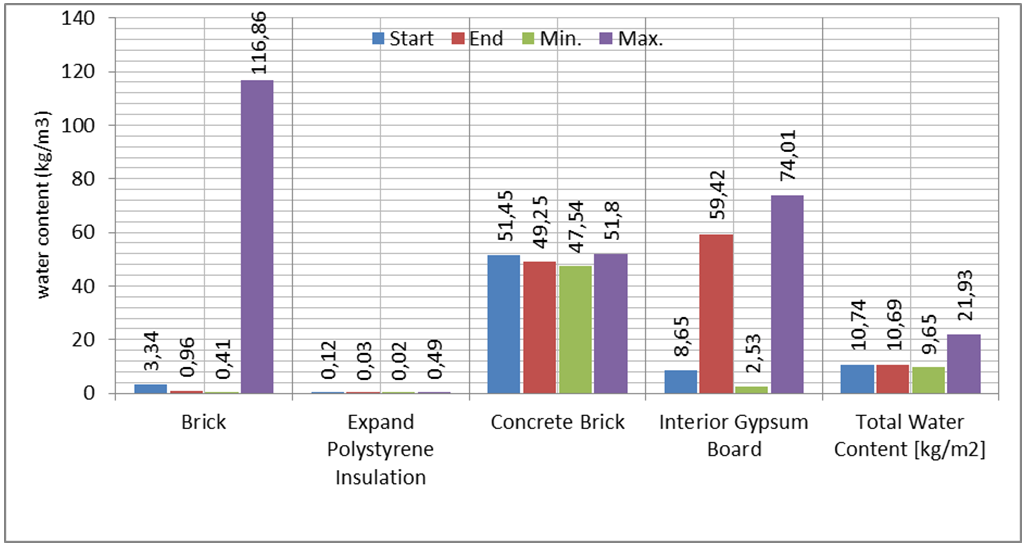

- Studies show the influence of air with water vapor leads to the increase water absorption and moisture into the walls. Increased humidity can cause malfunctions of the walls as well as HVAC system. The most impact of the air influence occurs in the layers of walls and between them, Such as: reducing the materials longevity and corrosion of anchors and brick ties, reducing the thermal resistance as well as the growth of fungi and mold. As can be seen in Figure 2 and 3, the air influence leads to a dramatic increase in the relative humidity as well as an increase in the water absorption into the materials. The rate of the increase has passed from the most permissible levels of 51.45kg/m3 at a distance 27.18 cm (concrete block) of the wall and has reached to 51.8 kg/m3. Also in the gypsum board it has passed from 8.65 kg/m3 and reached to 74.01 kg/m3, which is 9 times of the permissible level (Figure 4). According to Fig. 2 and 3 can be seen that in the range of thermal insulation the air influence leads to the increase of the relative humidity and water absorption. In this section, the amount of the water absorption has passed from 0.41 kg/m3 and reached to 0.49 kg/m3. This can lead to cause the loss of thermal insulation performance and as a result it leads to malfunctions of the wall. Also in the brick section, the amount of the water absorption has increased from 3.34 kg/m3 to 116.86 kg/m3, which leads to the efflorescence and the destruction of the brick. Therefore, according to the above analysis it can be concluded, the influence of air and moisture in the walls can lead to the increased water absorption in the materials. It also leads to a reduction in the materials longevity and the growth of fungi and mold in the building as well as increasing the energy consumption in the buildings through malfunctions in HVAC system. Therefore, Air flow control is important for several reasons: to control moisture damage, reduce energy losses, and to ensure occupant comfort and health.

| Figure 2. Relative humidity |

| Figure 3. Amount of the absorbed water in the materials |

| Figure 4. The amount of the absorbed water due to air leakage in the materials during a year [kg/m3] |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML