-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Advances in Life Sciences

p-ISSN: 2163-1387 e-ISSN: 2163-1395

2025; 13(1): 1-8

doi:10.5923/j.als.20251301.01

Received: Sep. 29, 2025; Accepted: Oct. 21, 2025; Published: Oct. 25, 2025

Processing and Rheological Behavior of Sudanese Mango Cultivars under Vacuum Concentration

Fatima Mohi eldin Mohammed Ahmed1, Fatima Fadul Ali2, Najlaa Siddig Nasir3, Waheeba E. Ahmed4, Ammar AL-Farga5, Islam Ragab6

1Dept. of Food Science and Technology, College of Agriculture, Al-zaiem Al-azhari University-Khartoum, Sudan

2Dept. of Health Education and Promotion, College of Public Health, Al-zaiem Al-azhari University-Khartoum, Sudan

3Dept. of Medical Entomology, College of Health, Al-zaiem Al-azhari University-Khartoum, Sudan

4Department of Food Science and Human Nutrition, College of Agriculture and Food, Qassim University, Buraydah, Saudi Arabia

5Department of Biochemistry, Faculty of Science, University of Jeddah, Saudi Arabia

6Department of Chemistry, College of Science, Qassim University, Buraidah, Saudi Arabia

Correspondence to: Islam Ragab, Department of Chemistry, College of Science, Qassim University, Buraidah, Saudi Arabia.

| Email: |  |

Copyright © 2025 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Background: The success of mango cultivation in Sudan can be attributed to the potential for extending the fruiting season to eleven months a year, thanks to diverse environmental conditions. This presents Sudan with a significant opportunity for export in the global market. Mango pulp, characterized by its high moisture content, is highly perishable and has a short shelf life. Both marketers and consumers desire an extended shelf life, necessitating the concentration of the pulp. This study aimed to evaluate the impact of vacuum concentration on the physicochemical and rheological properties of mango pulp and its concentrates. Methods: The physicochemical and rheological properties of four mango cultivars (Kitchener, Alphonso, Shendi, and Neelum) were analyzed before and after processing. These cultivars were concentrated under vacuum using a closed kettle pan at a temperature of 50°C and a pressure of 24 inches Hg. The resulting concentrates were 26%, 26%, 26%, and 22%, respectively. Rheological parameters were measured using a rheometer at 30°C and a shear stress range of (0-1000 s⁻¹). The Bingham model was employed to determine the relationship between shear stress and shear rate. Results: The analysis of physicochemical and rheological properties, conducted both before and after processing, revealed significantly higher values of total soluble solids (TSS), viscosity, and total sugars. Furthermore, there were notable differences in rheological parameters, such as yield stress, consistency coefficient, and behavior index, among the different mango varieties. Conclusion: Kitchener and Neelum mango concentrates exhibited thixotropic behavior with yield stress. In contrast, Alphonso concentrate demonstrated a mixed behavior of pseudoplastic and thixotropic characteristics. Shendi concentrate displayed pseudoplastic behavior with yield stress. Recommendation: It is advised to apply physical treatments to Kitchener and Neelum mango concentrates to reduce fiber content, thereby enhancing heat transfer and improving pumping characteristics.

Keywords: Mango, Pulp, Concentrate, Physiochemical properties, Rheological properties

Cite this paper: Fatima Mohi eldin Mohammed Ahmed, Fatima Fadul Ali, Najlaa Siddig Nasir, Waheeba E. Ahmed, Ammar AL-Farga, Islam Ragab, Processing and Rheological Behavior of Sudanese Mango Cultivars under Vacuum Concentration, Advances in Life Sciences, Vol. 13 No. 1, 2025, pp. 1-8. doi: 10.5923/j.als.20251301.01.

Article Outline

1. Introduction

- Mango is one of the most significant tropical fruit trees globally, renowned for its high yield, consumption, and exceptional nutritional value. It is rich in bioactive compounds such as vitamin C, carotenoids, and polyphenols, which contribute to its antioxidant activity [1]. Mango fruit have attractive color, pleasant aroma and taste . Fruit pulp and concentrate play a crucial role in health. They are dietary sources of essential nutrients, micronutrients, and vitamins, which are vital for human health and well-being. A well-balanced diet rich in fruits is particularly valuable for its ability to prevent deficiency diseases and has been reported to reduce the risk of several other diseases [2]. Mango (Mangifera indica L) is commonly cultivated in mainly tropical and subtropical regions and is Worldwide distributed [3]. It belongs to the family Anacardiaceae and the genus Mangifera [4,5]. It has been cultivated for more than 4,000 years [6]. Mango provides an excellent flavor, attractive odor and delicious taste [7] it also has high nutritional value [8]. The physico-chemical characteristics of mango fruits and the technological qualities of their processed products vary among different mango varieties, with some being more suitable than others for specific applications [9]. Mango processing can solve the problem of accumulation of fresh mango fruits and it is highly perishable and has a short shelf life [10,11]. Concentrating the juice through evaporation reduces transportation costs and extends shelf life by achieving high Brix levels. [12].Physical properties, such as density and viscosity, are influenced by the solid content and temperature of mango products. Therefore, it is essential to understand these physical properties as a function of temperature and solid content during the manufacturing process to ensure excellent quality. Developing a comprehensive database of these values is crucial for optimizing the transformation process [13]. Rheology is the science that studies the deformation and flow behavior of matter. The consistency of a Newtonian fluid, such as water, milk, or clear fruit juice, can be described by its viscosity. However, the viscosity of a non-Newtonian fluid changes with varying shear rates and therefore must be characterized by multiple parameters [14]. Numerous studies have been conducted to determine the rheological properties of fruit purees, fruit juices, vegetable purees, and vegetable suspensions [15].The viscosity characteristics of food products significantly impact various aspects of fluid performance during processing [16,17], such as pumpability, droplet breakup in spray drying, emulsion formation, flow into molds, and formability. Additionally, viscosity affects the quality of liquid products, including texture, flavor release, stability, and appearance. Viscosity is correlated with composition and molecular distribution, thereby influencing the material’s overall characteristics [18]. The rheological behavior of fruit juices and pulps is significantly influenced by their quantitative and qualitative composition, which depends on the fruit type and the treatments applied during the manufacturing process. Factors influencing the rheological behavior of fruit pulps encompass temperature, total solids, concentration, and particle size [19]. The inclusion of pulp solids in the dispersed phase of fruit juice contributes to its non-Newtonian characteristics [20].The rheological properties of fruit juice are crucial for quality control, designing process engineering applications, and selecting appropriate equipment such as heat exchangers, transport systems, evaporators, and pumps. They also play a vital role in calculating energy usage and power requirements for mixing, determining flow in processing operations like pasteurization, concentration, dehydration, aseptic processing, and ensuring consumer acceptability of the product [21-23]. The rheological behavior of fruit juices and concentrates can be characterized by various rheological models, depending on the specific nature of the juices [21]. Various rheological models have been employed to describe the flow behavior of food, including the Newtonian model (one parameter), the power law model (two parameters), the Bingham and Casson models (two parameters), and the Herschel-Bulkley model (three parameters) [24]. These models effectively characterize the rheological behavior of various fruit juices [21]. Therefore, this study aimed to evaluate the effect of vacuum concentration on the physicochemical and rheological properties of pulp and concentrates from four Sudanese mango cultivars (Kitchener, Alphonso, Shendi, and Neelum). The specific objectives were to determine the changes in key quality parameters—including total soluble solids, acidity, pH, sugars, ascorbic acid, non-enzymatic browning, density, and viscosity—before and after processing, and to characterize the flow behavior using the Herschel-Bulkley model.

2. Material and Methods

- Experiments were conducted at canning section in Food Research Center Shambat, unit operation laboratory of university of Khartoum department of chemical engineering and Central Petroleum Laboratories in Ministry of petroleum, Sudanese petroleum Corporation.

2.1. Preparation of Raw Materials

- Ripe mango fruits from four cultivars (Kitchener, Alphonso, Shendi, and Neelum) were sourced from local orchards in the Gezira and Khartoum states of Sudan during the peak harvest season (June to August 2023). The fruits were selected at a commercially ripe stage based on their skin color, firmness, and aroma. The selection criteria ensured that the fruits were free from visual defects, mechanical injuries, and fungal infections. Upon receipt at the laboratory of the Food Research Center, Shambat, the fruits were sorted, washed, peeled, and sliced with a stainless-steel knife before being pulped using a fruit pulper. The extract pulp of four varieties (Kitchener, Alphonso, Shendi and Neelum) were heated at 80°C in jacketed kettle for 10 minutes [25,26] with continuous stirring. After pasteurization, the samples were quickly cooled to room temperature in ice water.

2.2. Vacuum Concentration

- The concentration process was performed under vacuum using a jacketed kettle pan (Pilsen, 10 L capacity, stainless steel). The process was carried out at 50°C and an absolute pressure of 24 inches of Mercury (inch Hg), which is equivalent to approximately 61 kPa or 0.61 bar. This level of vacuum was maintained using a vacuum pump [25,26]. The pan was heated using water bath connected to thermostat and pump. After process was stopped, the physiochemical characteristics were evaluated.

2.3. Physiochemical Analysis

- TSS, PH, Total sugars, and Ascorbic acid content of the mango pulp and concentrates were determined according to AOAC [27]. The total titratable acidity was determined using the method outlined by [28].

2.4. Non Enzymatic Browning

- The method commonly applied to evaluate non–enzymatic browning is generally known as "soluble color”. Non-enzymatic browning was determined using spectrophotometric method [29]. 10 grams of sample were extracted with 100 ml ethanol (60%) for 12 hours and centrifuged at 1260 rpm for 5 minutes. The absorbance of the extract was then measured with spectrophotometer (model: uv-1800.Shimadzu) at 420 nm with 60% ethanol as blank.

2.5. An Apparent Viscosity

- The apparent viscosity of mango pulp and concentrates was measured using a concentric cylinder Brookfield rheometer (DV-III ULTRA; Brookfield Engineering Laboratories, USA). A Brookfield (TC-502) thermostatic bath was utilized to adjust the sample temperature to 30°C for each test. The filled sample cup (10 ml) and spindle (LV4) were equilibrated at this temperature for approximately 20 minutes [19]. The apparent viscosity data were obtained using Rheocalc software (version V3.3 build 49-1; Brookfield Engineering Laboratories, MA, USA) at 50 rpm. The averages of ten readings were recorded for each material.

2.6. Density of Mango Pulp and Concentrates

- The density of mango pulp and concentrates were determined by digital density meter (Model DMA 5000, ANTON PAAR). According to D4052-96. American National standard method. A small volume of approximately 0.7 ml of the liquid sample was introduced into an oscillating sample tube. The change in oscillating frequency, caused by the alteration in the tube’s mass, was used alongside calibration data to determine the sample’s density.

2.7. Rheological Parameter of Mango Pulp and Concentrates

- The rheological measurements were performed in controlled rate using rheometer (Hakke Rheoscope1, Karlsruhe, Germany). Shear stress/rate rotation Ram tests were performed using a cone sensor (C70/10 Tipo; 70mm diameter, 1angle) with 0.026 mm gap and measuring plate cover (MPC70). The sample compartment was controlled at temperature of 30°C Cousin Cryostat /Circulator (Haake Phoenix II P1) ascending and descending flow cruve of shear stress versus shear rate were carried out in the range (0-1000s-1) during 300s. Mathematical model of Bingham was used to calculate the relationship between shear stress and shear rate.

3. Statistical Analyses

- Data generated was subject to statistical analysis (SAS) (2007). A completely randomized design (CRD) was adopted for this study. Analysis of variance and the least significant difference (LSD at 5%) were used to separate the means according to Duncan’s Multiple Range Test (DMRT) [30].

4. Results

4.1. Effect of Vacuum Concentration on the Physicochemical Properties of Mango Pulp

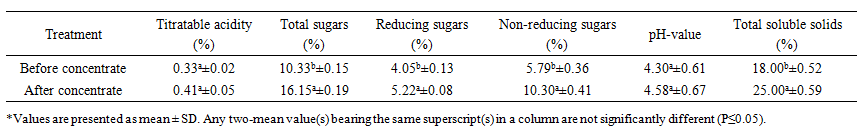

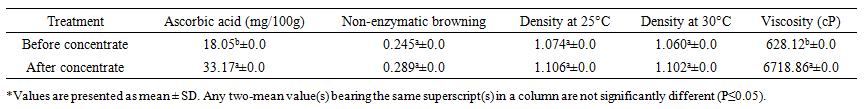

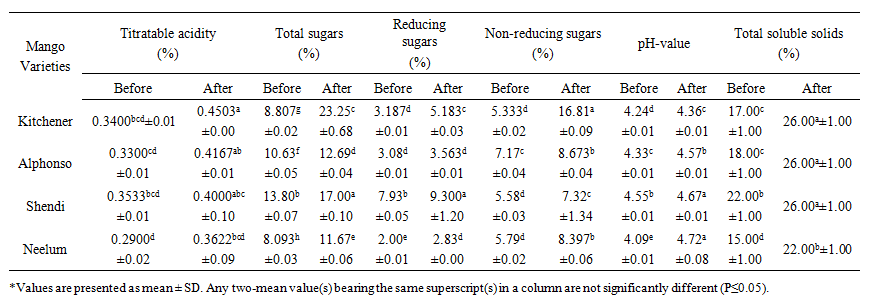

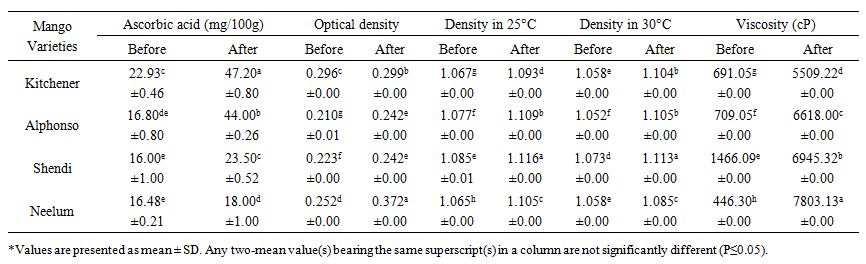

- The impact of vacuum concentration on the physicochemical properties of the mango pulp blends is summarized in Tables 1 and 2. The concentration process led to significant increases (p ≤ 0.05) in total soluble solids (TSS), total sugars, reducing sugars, non-reducing sugars, ascorbic acid content, and apparent viscosity compared to the fresh pulp. Conversely, no significant differences (p > 0.05) were observed in titratable acidity, pH, non-enzymatic browning, or density at 30°C after concentration.

| Table 1. Effect of processing on physicochemical properties of four Sudanese mango varieties* |

| Table 2. Effect of processing on physicochemical properties of four Sudanese mango varieties* |

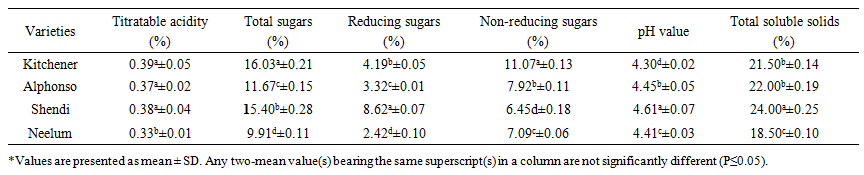

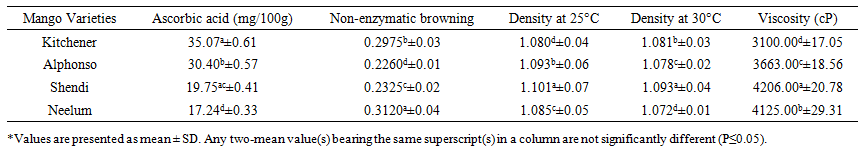

4.2. Effect of Mango Cultivar on the Physicochemical Properties of Concentrates

- Significant variations (p ≤ 0.05) were observed in all measured physicochemical properties among the four mango cultivars after concentration, as detailed in Tables 3 and 4. The Kitchener cultivar exhibited the highest values for total sugars (16.03%), titratable acidity (0.39%), and ascorbic acid (35.07 mg/100g). In contrast, the Shendi concentrate showed the highest pH (4.61), density at 25°C and 30°C, and the highest viscosity (4206 cP). The Neelum cultivar recorded the lowest values for most parameters, including TSS (18.50%), titratable acidity (0.33%), and ascorbic acid (17.24 mg/100g), but exhibited the highest level of non-enzymatic browning.

| Table 3. Effect of varieties difference on physicochemical properties of four Sudanese mango varieties* |

| Table 4. Effect of varieties difference on physicochemical properties of four Sudanese mango varieties* |

4.3. Interaction Effect: Processing and Cultivar

- The combined effect of processing (concentration) and cultivar variation on the physicochemical properties was highly significant (p ≤ 0.05), as presented in Tables 5 and 6. Vacuum concentration consistently and significantly increased the values of titratable acidity, all sugar fractions, pH, TSS, ascorbic acid, non-enzymatic browning, density, and viscosity across all four cultivars compared to their initial state as fresh pulp. For instance, the TSS of the Neelum cultivar increased from 15.00% to 22.00% after concentration. The magnitude of these increases, however, varied depending on the specific cultivar.

| Table 5. Effect of processing and varieties difference on physicochemical properties of Sudanese mango puree before and after concentration* |

| Table 6. Effect of processing and varieties difference on physicochemical properties of Sudanese mango puree before and after concentration* |

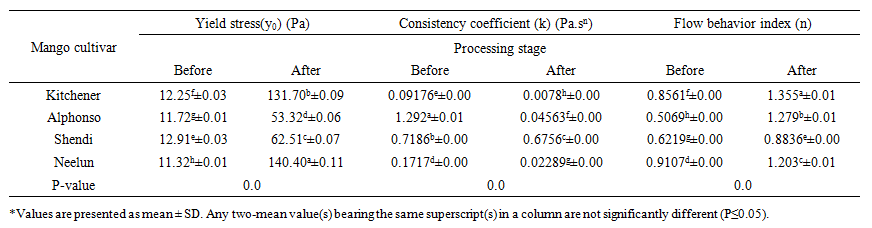

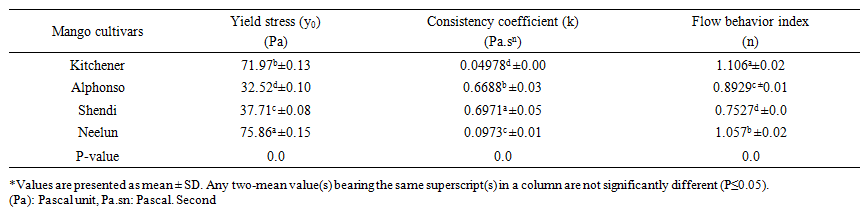

4.4. Rheological Properties

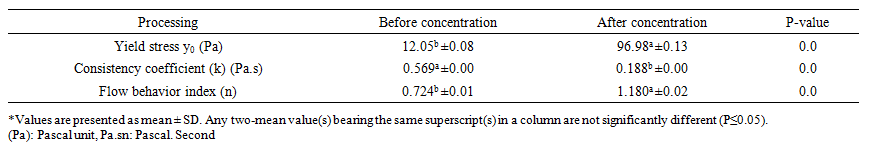

- The rheological behavior of the mango pulps and concentrates was effectively described by the Herschel-Bulkley model. The model parameters yield stress (y₀), consistency coefficient (k), and flow behavior index (n) are presented in Tables 7, 8, and 9.

| Table 7. Effect of processing and Sudanese mango varieties on their Rheological properties on (Herschel-Bulkley Model)* |

| Table 8. Effect of processing and Sudanese mango varieties on their Rheological properties on (Herschel-Bulkley Model)* |

| Table 9. Effect of processing on their Rheological properties on (HB Model)* |

5. Discussion

5.1. Modifications in Physicochemical Properties Following Vacuum Concentration

- The vacuum concentration process induced substantial changes in the physicochemical properties of the four mango pulp varieties. Analysis revealed statistically significant increases (p ≤ 0.05) in total soluble solids (TSS), total sugars, reducing sugars, non-reducing sugars, ascorbic acid content, and apparent viscosity following processing (Tables 1, 2, 5, 6). This phenomenon can be directly attributed to the fundamental principle of concentration through water removal, which effectively increases the concentration of soluble constituents per unit volume. These findings are consistent with previous research on fruit concentration, particularly the work of [31] on Sudanese mango varieties.A noteworthy observation was the significant increase in titratable acidity post-concentration. This aligns with findings by in [32] in grape juice concentrates, who reported acidity ranges of 0.8-2.4 g/100g for white and 0.8-3.4 g/100g for red juice concentrates. The concentration of organic acids through water evaporation provides a logical explanation for this increase. However, this contrasts with results reported by [33] for apricot and peach concentrates, suggesting fruit-specific responses to concentration processes.The significant enhancement in ascorbic acid content, despite thermal processing, underscores the advantage of vacuum concentration. The reduced processing temperature and limited oxygen exposure under vacuum conditions likely minimized degradation, allowing the concentrating effect to predominate, thereby improving the nutritional profile of the final product.

5.2. Rheological Behavior and Model Fitting

- The rheological characterization demonstrated that the Herschel-Bulkley (HB) model effectively described the flow behavior of both fresh pulps and concentrates at 30°C. The model parameters revealed significant alterations in rheological properties due to processing. Specifically, vacuum concentration resulted in a universal increase in yield stress and flow behavior index across all cultivars, while the consistency coefficient decreased significantly (Table 9).Distinct rheological behaviors were observed among cultivars. The Shendi concentrate exhibited pseudoplastic behavior with yield stress, consistent with findings by [34] for mango pulp and [35] for ginger paste. In contrast, Kitchener and Neelum concentrates displayed thixotropic behavior with yield stress, while Alphonso showed mixed pseudoplastic and thixotropic characteristics. These variations can be attributed to differences in fibrous material content and composition among cultivars, supporting the observations of [36] regarding the influence of discontinuous phase substances on rheological behavior.The increase in yield stress values following concentration aligns with the fundamental relationship between solid content and structural strength in food dispersions. As [37] noted, yield stress depends on particle size distribution and interactions, which are inevitably altered by concentration processes.

5.3. Inter-cultivar Variability and Industrial Implications

- The significant differences in both physicochemical and rheological properties among the four cultivars (Tables 3, 4, 7, 8) highlight the crucial role of genetic factors in determining processing behavior and final product quality. This cultivar-specific variability has substantial implications for industrial applications.The distinct rheological profiles observed necessitate customized approaches to process design and equipment selection. For instance, the thixotropic behavior of Kitchener and Neelum concentrates requires consideration of time-dependent viscosity changes in pumping system design, while the pseudoplastic nature of Shendi concentrate demands different handling parameters.These findings provide valuable insights for the Sudanese mango processing industry, enabling strategic cultivar selection based on desired product characteristics and processing requirements. The research establishes a scientific basis for optimizing concentration processes specific to local mango varieties, potentially enhancing product quality and processing efficiency.

6. Conclusions

- The study aimed to assess how vacuum concentration impacts the physicochemical and rheological properties of mango pulp and its concentrates. Physicochemical and rheological traits of four mango cultivars (Kitchener, Alphonso, Shendi, and Neelum) were analyzed before-after processing. The examination revealed increased levels of total soluble solids (TSS), viscosity, and total sugars after processing. Variations in rheological parameters such as yield stress, consistency coefficient, and behavior index were noted across the mango varieties. Kitchener and Neelum concentrates demonstrated thixotropic behavior with yield stress, Alphonso showed a combination of pseudoplastic and thixotropic characteristics, while Shendi exhibited pseudoplastic behavior with yield stress. Physical treatments are recommended for Kitchener and Neelum mango concentrates to reduce fiber content, potentially enhancing heat transfer and pumpability.

CRediT Authorship Contributions Statement

- Fatima M. Mohamed: Conceptualization, writing-original draft, supervision, methodology, data curation and editing. Najlaa Siddig Nasir: Conceptualization, writing-original draft. Waheeba Elfaki: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Supervision, Writing – original draft, Writing – review & editing. Ammar AL-Farga: Methodology, writing-Review, and editing Fatima Fadul Ali: Conceptualization, Methodology, writing-Review, and editing. Islam Ragab: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Supervision, Writing – original draft, Writing – review & editing.

Declaration of Competing Interest

- The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

ACKNOWLEDGEMENTS

- The Researchers would like to thank the Deanship of Graduate Studies and Scientific Research at Qassim University for financial support (QU-APC 2025).

Data Availability

- All data is included within the search.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML