-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Advances in Life Sciences

p-ISSN: 2163-1387 e-ISSN: 2163-1395

2014; 4(3): 178-183

doi:10.5923/j.als.20140403.14

Hospital Wastewater Treatment by Integrated Fixed Film Activated Sludge, Using Rice Husk as Fixed Media

Mehrdad Farrokhi1, Davood Ashrafi2, Esmaeil Roohbakhsh2, Azad Yoonesi2

1Dept. of Environmental Health, school of public health, Alborz University of Medical Sciences, Karaj, Iran

2Dept. of Environmental Health, school of public health, Giuliani University of Medical Sciences, Rash, Iran

Correspondence to: Mehrdad Farrokhi, Dept. of Environmental Health, school of public health, Alborz University of Medical Sciences, Karaj, Iran.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Hospitals generate a significant amount of wastewater in a day from 400 to 1200 L by bed. These effluents are loaded with microorganisms, heavy metals, toxic chemicals and radioactive elements. Activated sludge process is commonly used for hospital wastewater treatment in Iran. The main objectives of this study were the performance assessment of integrated fixed film activated sludge using rice husk (Rice Husk Activated Sludge-RHAS) for hospital wastewater treatment and comparison of the efficiency of RHAS with conventional completely mixed activated sludge (CMAS). In this study the RHAS has been used in pilot scale for hospital wastewater treatment for one year and its performance was compared with (CMAS). The minimum effluent BOD5 occured in RHAS with 18 hr hydraulic retention time, where BOD5 reached to less than 15 mg/L. In CMAS howewere the minimum BOD5 at 18 hr HRT was about 45 mg/L. In RHAS system HRT has no significant effect on BOD5 removal efficiency (p<0.01) while in the CMAS system HRT has significant effect on BOD5 removal efficiency (p<0.01). comparatively, removal efficiency of RHAS was significantly greater than CMAS for all studied HRT (p<0.01). The RHAS had more ability in the degradation of slowly biodegradable or recalcitrant compounds in hospital wastewater in comparison to CMAS. The VSS concentration in RHAS in all HRTs was more than 2 time greater than CMAS and reaches to 4008 mg/L at the maximum concentration. It is concluded that Rice Husk can be used as fixed media in IFAS system and it can be improved the performance and efficiency of hospital wastewater treatment without any additional costs.

Keywords: Hospital wastewater, Rice husk, Activated sludge, Fixed film

Cite this paper: Mehrdad Farrokhi, Davood Ashrafi, Esmaeil Roohbakhsh, Azad Yoonesi, Hospital Wastewater Treatment by Integrated Fixed Film Activated Sludge, Using Rice Husk as Fixed Media, Advances in Life Sciences, Vol. 4 No. 3, 2014, pp. 178-183. doi: 10.5923/j.als.20140403.14.

Article Outline

1. Introduction

- Hospitals generate a significant amount of wastewater in a day from 400 to 1200 L by bed.These effluents are loaded with microorganism, heavy metal, toxic chemicals and radioactive elements [1]. Hospital waste could be dangerous to the ecological balance and public health. Pathological and infectious wastes, if left untreated could lead to outbreaks of communicable diseases [2, 3].In countries that do not experience epidemics of enteric diseases and that are not endemic for intestinal helminthiasis, it is acceptable to discharge the wastewater from health-care establishments to municipal sewers without pretreatment, provided that the following requirements are needed: 1- the municipal sewers are connected to efficiently operated sewage treatment plants that ensure at least 95% removal of bacteria, 2- the sludge resulting from sewage treatment is subjected to digestion, leaving no more than one helminthes egg per liter in digested sludge, 3- the waste management system of the health-care establishment maintains high standards, ensuring the absence of significant quantities of toxic chemicals, radionucloids, cytotoxic drugs and antibiotics in the discharged wastewater, 4- excreta from patients being treated with cytotoxic drugs may be collected separately and adequately treated [4, 5]. The absence of efficient sewage treatment plant in many cities of Iran and national discharge standards for hospital wastewater results in the necessity of hospital wastewater treatment to be a.Activated sludge processes are commonly used for hospital wastewater treatment in Iran, as more than 78% of hospitals use different modification of that process for wastewater treatment [6, 7].One of the most important limitations of this process for hospital wastewater treatment is the effect of toxic substances on microbial populations which leads to many difficulties in operation of activated sludge processes and may result in unsatisfied discharge standard becomes unsatisfied.Integrated fixed film activated sludge combines the advantages of attached growth and suspended growth processes, therefore resistance against toxic material shocks will be increase in this treatment system [8, 9] and can be more efficient for hospital wastewater treatment than activated sludge. There is a limitation about using IFAS for wastewater treatment in developing countries by importing of fixed media wich is so expensive and build up the cost of wastewater treatment.Searching for natural matters as fixed media for supporting microbial growth and replacement with synthetic media to decrease the cost of treatment is considered as an important act in low income communities.Rice husk with specific surface of

by-product of rice cultivation (consist of

by-product of rice cultivation (consist of  of the seed weight) is a wonderful product with multifunctional features. It has many capabilities in water and wastewater treatment [10] The potential of rice husk for adsorption of many environmental pollutants was reported by many researchers [11, 12]. It can be a hypothesis that rice husk can improve the activated sludge processes for hospital wastewater by adsorbing toxic substances and supporting microbial growth as fixed media and increasing microbial population.With attention to the above-mentioned problems the present study was conducted in pilot scale and on real hospital wastewater. The main objectives of this study were the performance assessment of integrated fixed film activated sludge using rice husk for hospital wastewater treatment and comparison of the efficiency of IFAS with conventional completely mixed activated sludge at the same operational conditions. Finally the operational parameters such as: hydraulic retention time, organic loading and return sludge ratio for IFAS (rice husk Activated sludge- RHAS) system in hospital wastewater treatment were optimized and the corresponding results were discussed.

of the seed weight) is a wonderful product with multifunctional features. It has many capabilities in water and wastewater treatment [10] The potential of rice husk for adsorption of many environmental pollutants was reported by many researchers [11, 12]. It can be a hypothesis that rice husk can improve the activated sludge processes for hospital wastewater by adsorbing toxic substances and supporting microbial growth as fixed media and increasing microbial population.With attention to the above-mentioned problems the present study was conducted in pilot scale and on real hospital wastewater. The main objectives of this study were the performance assessment of integrated fixed film activated sludge using rice husk for hospital wastewater treatment and comparison of the efficiency of IFAS with conventional completely mixed activated sludge at the same operational conditions. Finally the operational parameters such as: hydraulic retention time, organic loading and return sludge ratio for IFAS (rice husk Activated sludge- RHAS) system in hospital wastewater treatment were optimized and the corresponding results were discussed. 2. Materials and Methods

2.1. Hospital Wastewater Characteristics

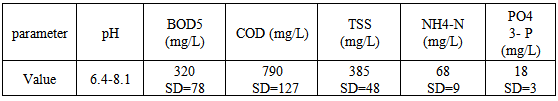

- The wastewater used in this study was taken from the final manhole for Resalat hospital wastewater network before discharging in a septic tank in the city of Masal located in Guilan province, Iran. This hospital with 50 beds generates of about 30 m3 wastewater per day.The results of 3 months survey on hospital wastewater quality are given in Table 1. All samples were collected as 8-hour cumulative sampling method for wastewater analysis.

|

2.2. Analytical Methods

- All chemicals were purchased from MERK company (Germany) and the purity of chemicals were 98% and higher. pH in equalization tank monitored with 826 Metrohm pH meter. Dissolved oxygen concentration in aeration tank was determined with a HQD (4od) probe DO meter from HACH Company.All other analysis include: COD, BOD5, TSS, PO4 3- P, NH4-N and MLVSS were conducted according to standard methods for water and wastewater examination [13]. The biomass was estimated by measurement of volatile suspended solids (VSS) according to the method of 2940E in standard method. For determining the attached biomass, the dry rice husk was weighed before placing it in aeration tank and at the end of experiments and then was tested the same as VSS according to standard method. The differentiation between dry rice husk’s weight and tested VSS was considered as attached biomass. Total volatile solid (attached and suspend) in RHAS reactor reported as sum of suspended and attached volatile solids.

2.3. Experimental Set up and Methods

- In this study the Integrated Fixed Film Activated Sludge using rice husk as fixed media (Rice Husk Activated Sludge-RHAS) was used in pilot scale for hospital wastewater treatment for one year and its performance was compared with Completely Mixed Activated Sludge (CMAS). Figure-1 shows the experimental set up consisting of Integrated Fixed Film (Rice Husk) Activated Sludge (RHAS). A Completely Mixed Activated Sludge (CMAS) with same dimensions as RHAS was used as control and operated in parallel with RHAS with same operational condition.

| Figure 1. The experimental set-up of Rice Husk Activated sludge for hospital wastewater treatment |

| Figure 2. Picture of rice husk package with attached biomass after 3 months operation |

3. Results and Discussion

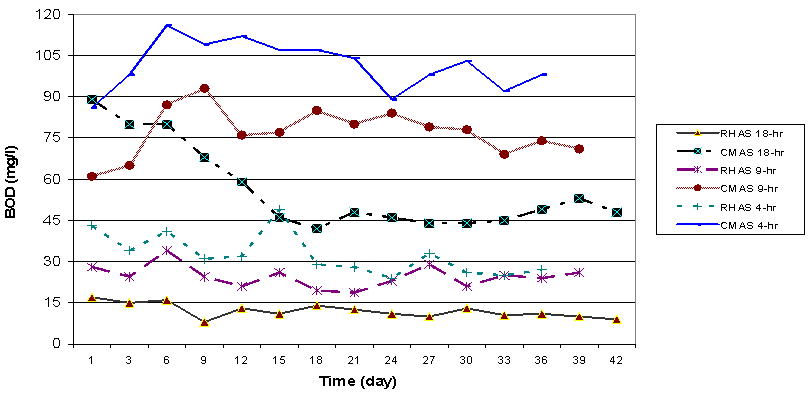

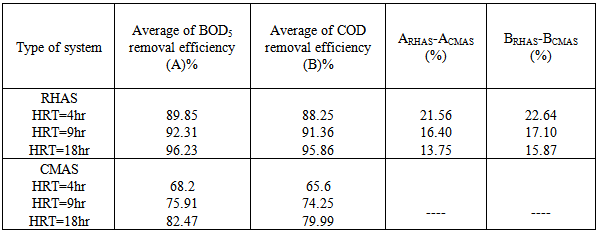

- Figure-3 shows the effluent BOD5 concentration of RHAS and CMAS at different hydraulic retention times. It can be seen that the minimum BOD5 occurs in RHAS with 18 hrHRT, where BOD5 reaches to less than 15 mg/L. In CMAS, however the minimum BOD5 at the corresponding HRT was about 45 mg/L.

| Figure 3. Effluent BOD from RHAS and CMAS in different Hydraulic retention time after steady state |

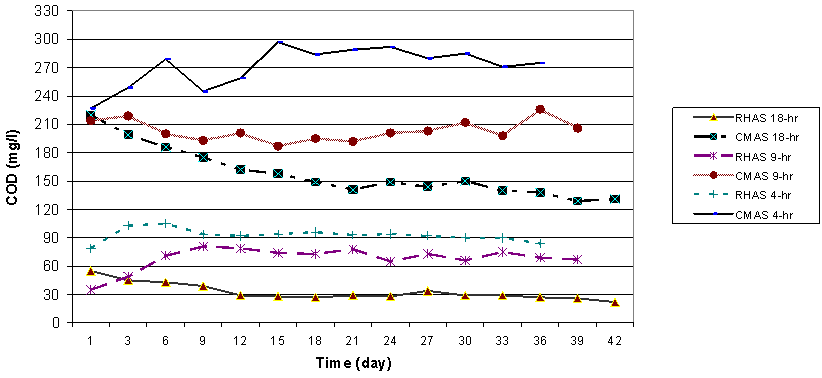

| Figure 4. Effluent COD from RHAS and CMAS in different Hydraulic retention time after steady state |

|

|

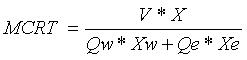

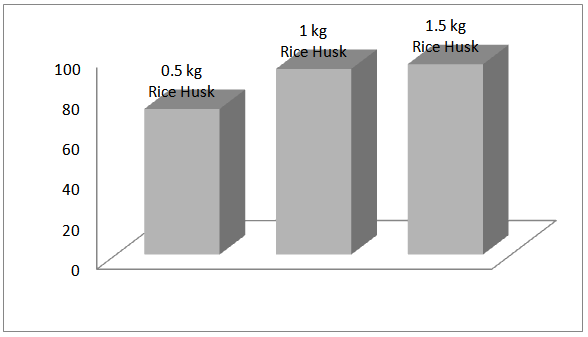

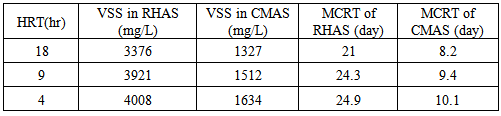

Where: V, reactor volume; X, average biomass concentr ation of the reactor (mgVSS/l); Qw, excess sludge (l/d); Xw, concentration of the excess sludge (mgVSS/l); Q, wastewater flow rate (l/d); Xe effluent concentration (mgVSS/l).MCRTs at different HRT are given in table 3 it can be seen that sludge age at all HRTs of RHAS is greater than CMAS. It must be considered that with changing the wasted sludge amount the MCRT can be change and this is an important point.However the increasing of VSS by Rice Husk is less than synthetic media such as Rope-Type,Sheet Media and Polypropylene Finned Cylinder [17], but from economical point of view it can be better choose because its price is approximately zero while for example 1 m3 of Polypropylene Finned Cylinder media has price about 1000 $ in Iran.To determine the optimum rice husk weight as an important parameter for design and operation of this system, different weight of rice husk (o.5, 1 and 1.5) kg were used in pilot and BOD5 removal at different weight was evaluated. Figure 5 shows the averages BOD5 removal efficiencies at different weight of rice Husk. Operation of the system with

Where: V, reactor volume; X, average biomass concentr ation of the reactor (mgVSS/l); Qw, excess sludge (l/d); Xw, concentration of the excess sludge (mgVSS/l); Q, wastewater flow rate (l/d); Xe effluent concentration (mgVSS/l).MCRTs at different HRT are given in table 3 it can be seen that sludge age at all HRTs of RHAS is greater than CMAS. It must be considered that with changing the wasted sludge amount the MCRT can be change and this is an important point.However the increasing of VSS by Rice Husk is less than synthetic media such as Rope-Type,Sheet Media and Polypropylene Finned Cylinder [17], but from economical point of view it can be better choose because its price is approximately zero while for example 1 m3 of Polypropylene Finned Cylinder media has price about 1000 $ in Iran.To determine the optimum rice husk weight as an important parameter for design and operation of this system, different weight of rice husk (o.5, 1 and 1.5) kg were used in pilot and BOD5 removal at different weight was evaluated. Figure 5 shows the averages BOD5 removal efficiencies at different weight of rice Husk. Operation of the system with  of (rice husk) in the retention time of

of (rice husk) in the retention time of  hours, showed the moderate BOD5 removal of

hours, showed the moderate BOD5 removal of percent.

percent.  the same condition, the reactor with 1 and

the same condition, the reactor with 1 and  (rice husk) showed average BOD5 removal of 92.3 and 94.6percent respectively.

(rice husk) showed average BOD5 removal of 92.3 and 94.6percent respectively. | Figure 5. Comparison of the averages of BOD5 removal efficiencies in the systems with different weights of rice husk (Aeration time of 9 hours) |

4. Conclusions

- One of the most important limitations of activated sludge process for hospital wastewater treatment is the effect of toxic substances on microbial populations which makes many problems in operation of activated sludge processes and decreases the removal efficiency. Integrated fixed film activated sludge is more resistant against toxic material than conventional activated sludge. It can be a hypothesis that rice husk can improve the activated sludge processes for hospital wastewater by adsorbing toxic substances and supporting microbial growth as fixed media and increasing microbial population. Results from this study indicate that removal efficiency of RHAS is significantly greater than CMAS. Optimum conditions for performance of this system for hospital wastewater treatment are 9 hr of HRT and 3.125 of kg Rice Husk / volume of Aeration Tank. It is concluded that Rice Husk can be used as fixed media in IFAS system and it can be improved the performance and efficiency of hospital wastewater treatment without any additional costs.

ACKNOWLEDGMENTS

- The authors gratefully thank chancellor of Guilan University of Medical Sciences for supporting this research and all employees of Resalat hospital for their valuable contribution.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML

“The History of Fixed-Film Wastewater Treatment Systems”, Article-Biofilmhistory. html.

“The History of Fixed-Film Wastewater Treatment Systems”, Article-Biofilmhistory. html.