Hicham Lotfi, Ali Moudden, Bouazza Faiz

Laboratory of Metrology and Information Processing, Ibn Zohr University, Faculty of Sciences, B.P. 8106, Agadir, Morocco

Correspondence to: Hicham Lotfi, Laboratory of Metrology and Information Processing, Ibn Zohr University, Faculty of Sciences, B.P. 8106, Agadir, Morocco.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

This paper presents results of studies application of ultrasonic in civil engineering. The measurement has been performed by ultrasonic reflection technique using a transducer with central frequency 0,5MHz. The objective of the study is to determine reflection coefficient, Shear module and Young’s module. The samples investigated consists in six mortar mixtures with ratio Cement / Sand (mc/ms=0,5) and Water / Cement (mw/mc=0,5). The paper is composed of two parts. The first one presents coefficient of reflection obtained for each mortar in function of sand particles size and environment temperature, and the second shows the Shear and Young’s modulus of mortar.

Keywords:

Reflection Technique, Reflection Coefficient, Mortar, Shear Modulus G, Young's Modulus E

Cite this paper: Hicham Lotfi, Ali Moudden, Bouazza Faiz, Processing of Reflection Coefficient of Signals Backscattered by Mortar Using an Ultrasonic Technique, American Journal of Signal Processing, Vol. 3 No. 2, 2013, pp. 17-24. doi: 10.5923/j.ajsp.20130302.01.

1. Introduction

This paper presents an experimental method used to characterize the setting and hardening of different mortars during their hydration and change of their state. The ultrasonic reflection method (Methods of echoes) chosen and the experimental protocol are described in[1]. The effect of the microstructure of the sand and environment temperature on the evolution of the reflection coefficient will be exposed. The technique of reflection of ultrasonic waves, is the process used by several authors to characterize the hydration of some cementitious materials. Feylessoufi et al.[2] investigated the hydration of Portland cement with ultrasonic measurements in transmission mode and reflection by using shear waves. Morin et al.[3] studied the behavior of cementitious materials. The modules shear determined by Morin showed that behavior of cementitious materials is similar to that determined by the parameter heat of hydration.The paper discusses two objectives. The first objective is to assess the response of ultrasound signal used to interpret the change of reflection coefficient of ultrasonic wave backscattered by mortar during hydration, and the second to investigate the response of mortars varying the size of sand particles and effect of environment temperature.

2. Materials and Methods

2.1. Choice of Container

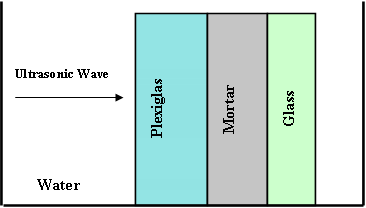

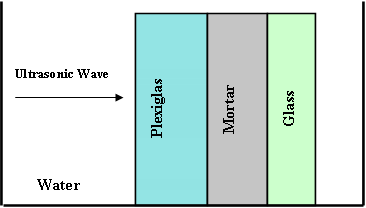

The vessel enclosed mortars are containers with parallel faces (parallelepiped), the choice of materials (plates) formed parallel faces of these containers passed through by study the ultrasonic response of different thicknesses of Plexiglas, steel, Aluminium and Glass used. We verified experimentally that the Plexiglass transmits more power ultrasound and its thickness should be as large as possible to avoid overlap of echoes. To improve the sensitivity of measurement by ultrasound we verified also that the Glass is a good reflector and given its low cost. Therefore, we have chosen containers of a front Plexiglas plate with thickness equal to 20mm, and the rear plate is Glass with a thickness equal to 3mm and the thickness enclosing the mortar is 15mm.

2.2. Sample Preparation

The mortar is a material obtained by mixing cement, water and sand. Mortar ensures the integrity of a masonry wall, so it must be strong, durable and keep the wall intact. The cement used for the preparation of samples is Cement CPJ 45 produced by factory of Agadir, Morocco. Sand used is extracted from the Oued Souss River. The water used for hydration is the water of the city of Agadir.For each size of sand grains (0,200; 0,250; 0,315 and 0,500 mm) is mixed with cement and water. These constituents have mass ratios Cement / Sand (mc/ms=0,5) and Water / Cement (mw/mc=0,5), the sample mixture was introduced into a container, then emerged in a tank filled with water and maintained at a temperature. The container is then excited by the transducer of central frequency equal to 0,5 MHz, and put in at a distance of 10cm from the container. Table 1 presents the characteristics of the water and the plates constituting the faces of the container. Figure 1 shows the schema of the geometry problem.| Table 1. Water, Plexiglass and Glass characteristics |

| | | Density ρ(Kg/m3) | Longitudinalvelocity (m/s) | Acoustic impedance106 kg/m2.s | | Water | 1000 | 1480 | 1,48 | | Plexiglas | 1200 | 2 680 | 3,216 | | Glass | 3134 | 4250 | 13,317 |

|

|

| Figure 1. Geometry problem |

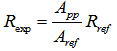

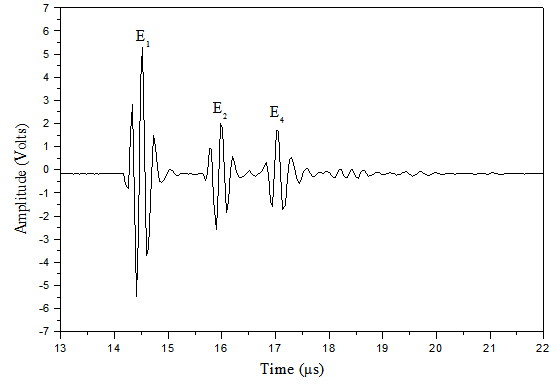

Figure 2 presents the signal composed of echoes E1, E2 and E4 reflected by the vessel enclosing the mortar. The first E1 echo reflected on the bottom surface of plate 1 is not important because it is not used in this study. The second echo E2 corresponds to the reflection on the interface between the second Plexiglas face and the mortar sample enclosed in the vessel. The last echo E4 corresponds to the reflection on the interface between the mortar and the first face of plate 2.

2.3. Measurement of Reflection Coefficient R

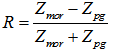

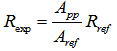

The application of the reflection method using ultrasonic waves, to characterize cementitious materials, has been developed by Stepisnik et al.[4] in 1981, and Lasic and Stepisnik[5] in 1984. To study the applicability of this method we follow the setting and hardening of mortar during the hydration time. The reflection coefficient measured by this technique informs us about the nature of microstructural mortar and the time during which the mortar structure changes phase from viscous state to the solid state.In general, the reflection coefficient can be calculated from the amplitudes A1 and A2 of the echoes of a reflected signal between two interfaces with different acoustic impedance. These amplitudes determined from the representation of the reflections in the time domain or in the frequency domain.Measurement of reflection coefficient of the wave reflected by a mortar specimen is necessary to know the state of the mortar in interface with Plexiglas. The peak to peak amplitude of the echo reflected at the interface Plexiglas / mortar (difference between the maximum and minimum value A2) is measured after isolation of echo A2 using a temporal filtering program. The reflection coefficient R related to acoustic impedance of Plexiglas mortar, which is expressed by the relation (1). | (1) |

By measuring the peak to peak amplitude reference noted Aref from echo reflected at the interface between the Plexiglas and a medium whose acoustic impedance is known, the value of R is then determined by the relation (2). | (2) |

| Figure 2. Reflected echoes by the mortar, time domain |

is the reflection coefficient at the interface between the second face of Plexiglas plate and the reference medium, it is given by. | (3) |

In our study we have taken as reference the middle Air with its acoustic impedance Zref is close to 0 Zref ~0. What gives Rref ~1. Then relation (3) becomes: | (4) |

3. Results and Discussions

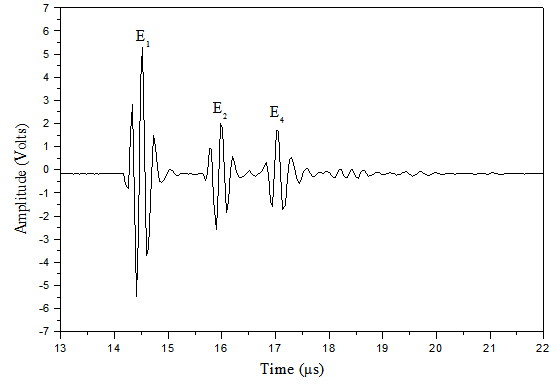

3.1. Effect of Microstructure Sand

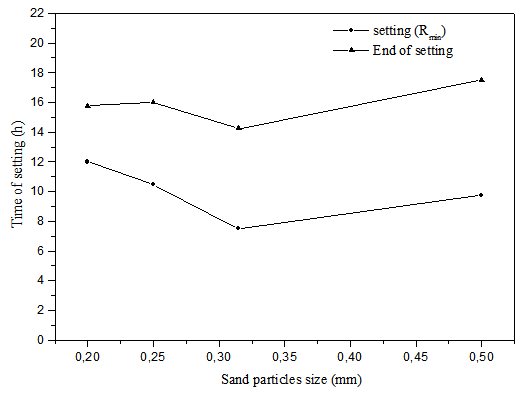

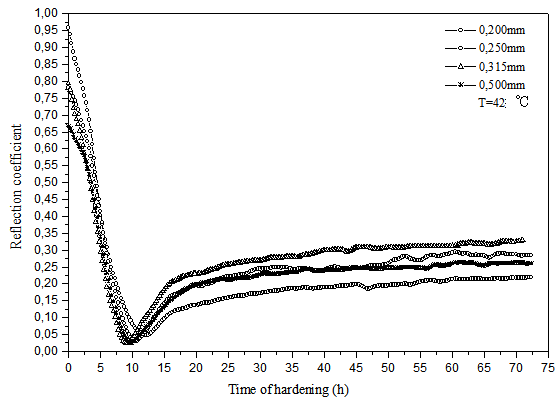

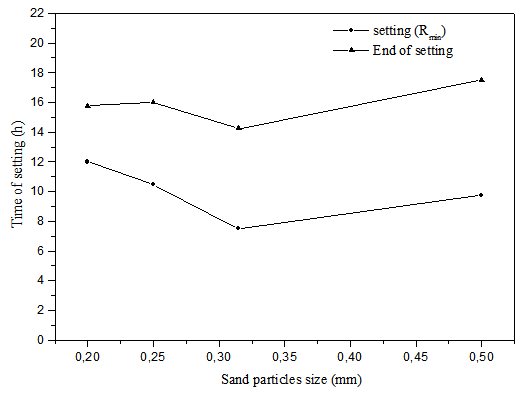

The propagation of ultrasonic waves is directly related to the mechanical properties of cementitious materials. The ultrasonic attenuation allows determining small and large cracks and the degree of heterogeneity of the material, and the ultrasonic velocity gives information about the rigidity and strength of mortar[1]. To obtain a good formulation of mortar we choose the appropriate proportions of each component with the desired properties. We present below different experimental results for four mortars made with sand extracted from Oued Souss River, and for sand particles 0,200; 0,250, 0,315 and 0,500 mm, and for a temperature maintained at 42℃.Figure 3 shows the evolution of reflection coefficient in function of hardening time. We remark that the reflection coefficient for different samples have similar gaits, and the effect of grain diameters on the reflection coefficient R is clearly seen during time of setting of mortar (R becomes minimum) and the hardening phase (R becomes constant). We can distinguish four main periods.The first period is the initial period which occurs when mixing water with cement; it is characterized by a significant release of heat caused by dissolution of cement components in water.The second step in the evolution of the reflection coefficient is the dormant period during which there is decrease of reflection coefficient which means that the acoustic impedance of mortar increase, this period is characterized by the agglomeration of the constituents of mortar. It is interpreted as the time of contact between the particles of cement, water and sand.The third period is the period of setting which is marked by a sharp decrease of reflection coefficient (R minium), during this stage the transmission of ultrasonic wave in the mortar is also important, therefore the acoustic impedance of mortar begins to increase and greater than this of Plexiglass.The fourth stage is the period of hardening during which the reflection coefficient becomes constant which means that all the particles constituting the mortar are interconnected.Figure 4 illustrates the representation of time of hardening for each sand particles size when the reflection coefficient is minimum. The analysis of this figure shows that the mortar prepared with diameter equal 0,315 mm has a low time of hardening compared to other mortars. However sample produced by the grain 0,315 mm has a compressive strength important.

3.2. Effect of Environment Temperature

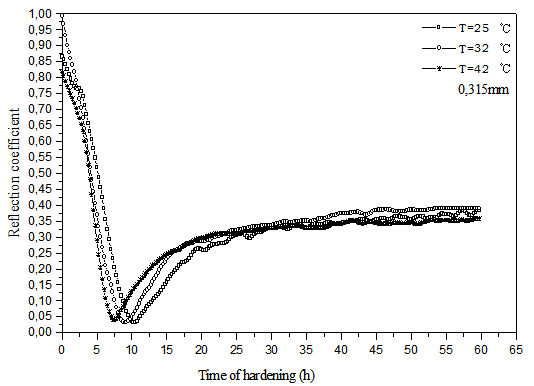

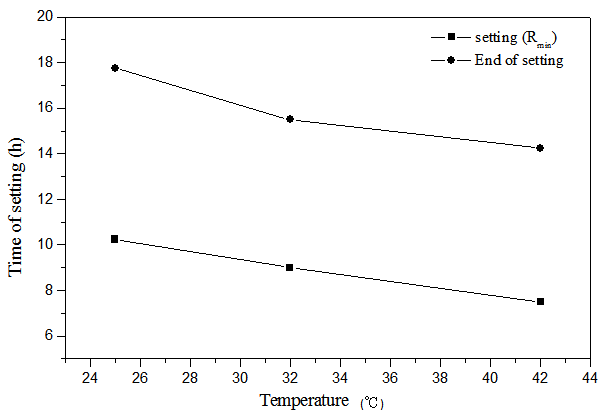

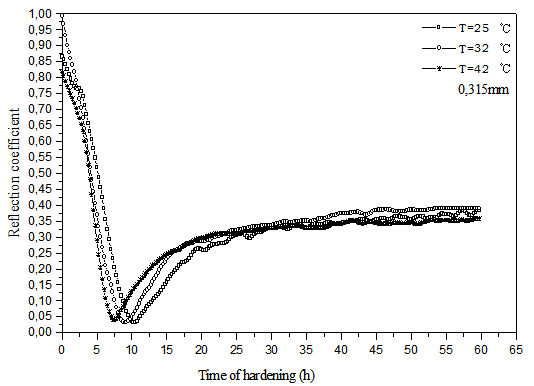

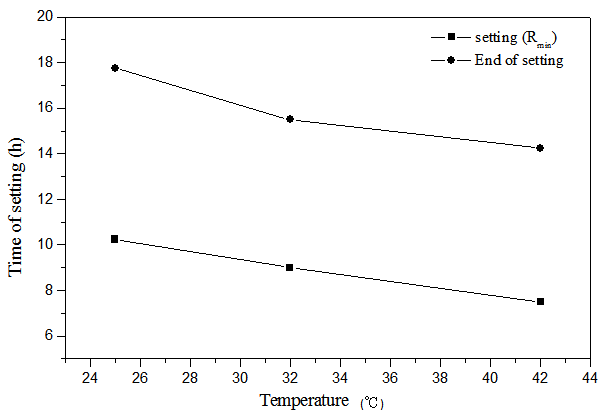

In figure 5 we have plotted the evolution of reflection coefficient in function of time. We note that the increase in temperature has an effect on the reflection of the ultrasonic wave at the interface mortar / plexiglass, which mainly accelerate the chemical reactions of cement components. The increase in temperature causes the accelerated maturity of the mortar during the age of 2 days, or a lower mechanical strength. In Figure 6 we represent the time of setting of the following three temperatures 25, 32 and 42℃. From this figure we deduce that the mortar realized at 42℃ has a time of setting at a young age compared with 25℃ and 32℃. Therefore the temperature has a significant effect on the reactions and kinetics of hydration of the components contained in mortar, thus on the time of setting of mortar. This result is identical to the conclusions that have been found by Pinto et.al[6] and Turcry et al.[7].

4. Variation of Elastic Constants of Mortar

An integrated approach to analyse the relations between cement hydration and the evolution of mechanical properties of cement-based materials was presented by Boumiz et al.[8]. It was also possible to directly evaluate the development of the dynamic Young’s and shear modulus in function of time and degree of hydration. It was concluded that the elastic modulus (Young’s and shear) are governed primarily by the connectivity of the cement particles and compressive strength. Nagy[9] has investigated the relationship between the Young’s modulus derived from static and resonant frequency tests. The measurements, which were started as early as five hours after casting, were used to derive an empirical relation between static and dynamic Young’s modulus. This formula was shown to produce good prediction results for the static Young’s modulus for concretes with two different cement types and w/c-ratios. To describe the durability of mortars by the effect of the microstructure of the sand, we determined the changes in mechanical properties namely the Young's modulus E and the shear coefficient G. | Figure 3. Evolution of the reflection coefficient, different sizes at T = 42℃ |

| Figure 4. The setting time in function of size of sand |

| Figure 5. Evolution of the reflection coefficient at different temperatures |

| Figure 6. The setting time in function of temperature (0,315 mm) |

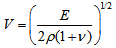

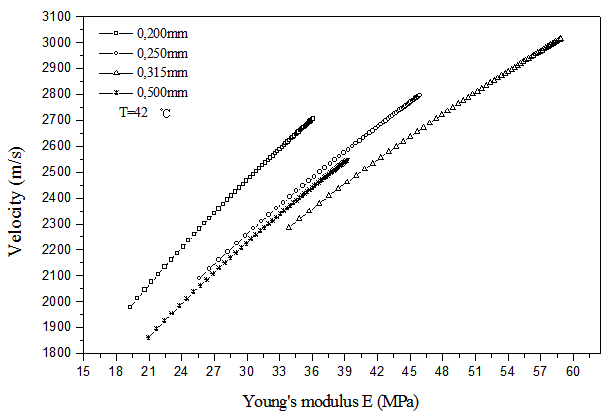

4.1. Young's Modulus E

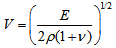

It is possible to express the ultrasonic velocity with other elastic constants such as Young's modulus E and Poisson's ratio ν by the following equation[10]. | (5) |

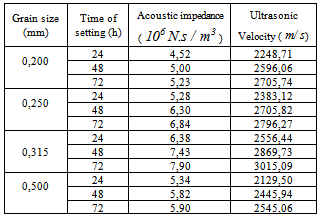

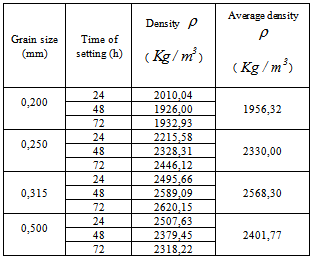

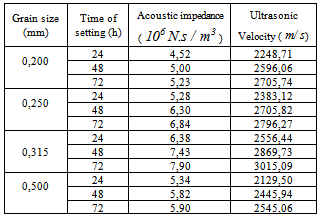

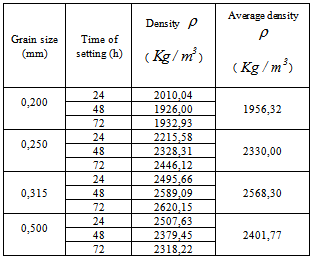

ρ mean the density of the material. The assumptions made in the calculation of the velocity take into account elasticity and isotropic materials, but this term is more or less valid in the case of real materials. The densities of different mortars are calculated and presented in Table 2.Table 2. Acoustic impedance and ultrasonic velocity of mortars at 24, 48 and 72[1]

|

| |

|

Table 3. Density of mortars at 24, 48 and 72

|

| |

|

The influence of ν is relatively low, for mortars is between 0,20 and 0,30[11]. Keeping the Poisson coefficient unchanged we note that the Young's modulus has an influence on the ultrasonic velocity in mortars. For the structure of mortar produced by the size of 0,315mm, the variation of E equal to 2,5 GPa varies the ultrasonic velocity for 84m/s, accordingly the mortar (0,315mm) at a large Young's modulus which results in that the mortar have an important compressive strength (Figure 7). | Figure 7. Influence of Young's modulus of mortar on ultrasonic velocity |

| Figure 8. Influence of the shear modulus of mortar on ultrasonic velocity |

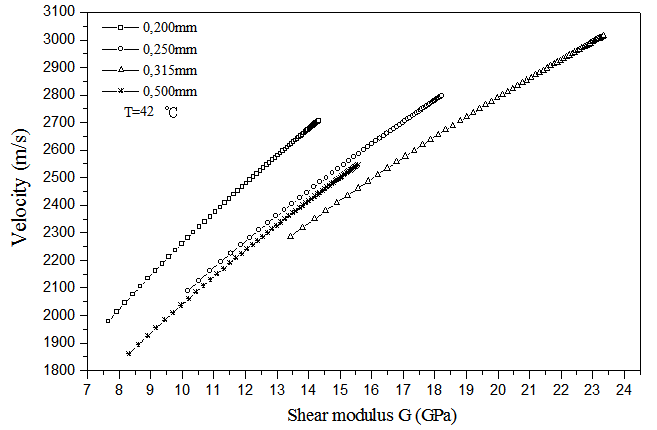

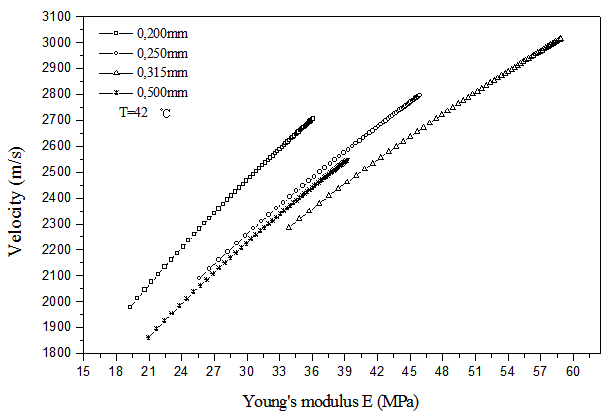

4.2. Shear Modulus G

The shear modulus is used to characterize the concrete and mortar, but it significantly influences the propagation of ultrasonic waves[12]. The shear modulus G is linked to the Young's modulus E and the Poisson coefficient ν by the following relation: | (5) |

The variations of shear modulus in function of the ultrasonic velocity are shown in Figure 8. Always keeping the Poisson's ratio unchanged and equal to 0,26[11], a variation of G equal 1GPa varies the velocity for 84m/s, where the ultrasonic velocity propagated in mortars is more sensitive to change shear modulus.

5. Conclusions

From the results presented in this paper, we noticed that the hydration of mortar is divided into four periods, the initial period, the dormant period, the period of setting and the period of hardening. We also concluded that the presence of impurities in small sizes of the sand, and their mineral composition inhibits the hardening of mortar. For large sizes the reflected amplitude is low which due to the interconnection between the grains of sand then formation vacuum and cracks in the mortar. It was also shown that the setting of mortars depends on the temperature. For high temperatures up to 42℃ the hardening is faster, however mortar is less rigid in comparison with a temperature 25℃. Therefore, the best quality and rigidity of the mortar is achieved with medium grains and temperatures close to 25℃.

References

| [1] | H.Lotfi, B.Faiz, A.Moudden, D.Izbaim, A.Menou, G.Maze and D.Decultot "Ultrasonic Characterization and Hardening of Mortar Using the Reflection Technique” ,journal High Temperature and Process, 2009. |

| [2] | Feylessoufi, A., F. Cohen-Tenoudji, V. Morin, P. Richard ." Early ages shrinkage mechanisms of ultra-high-performance cement-based materials ". Cement and Concrete Research, vol. 31, no. 11, pp. 1573–1579. ( 2001). |

| [3] | Morin, V., F. Cohen-Tenoudji, C. Vernet . "Study of the viscoelastic behaviour of cement pastes at early ages with ultrasonic waves in echographic mode". In Nonat, A. (Ed.), Proceedings of the Second International RILEM Workshop on Hydration and Setting. pp.317–327. (2000). |

| [4] | Stepisnik, J., M. Lukac, I. Kocuvan. "Measurement of cement hydration by ultrasonics". American Ceramic Society Bulletin, vol. 60, no. 4, pp. 481–483, (1981). |

| [5] | Lasic, D. D., J. Stepisnik ."An investigation of the osmotic model of cement curing by ultrasonics". Cement and Concrete Research, vol. 14, no. 3, pp. 345–348. (1984). |

| [6] | R. C. A. Pinto ,S. V. Hobbs ,K. C. Hover. "Relationship Between Nonevaporable Water Content and Hardened Properties of High Performance Mixtures" International Concrete Research & Information Portal .(2000). |

| [7] | Turcry, P., Loukili, A., Barcelo, L., Casabonne, J. M. " Can the maturity concept be used to separate the autogenous shrinkage thermal deformation of cement paste at early age" Cement and Concrete Research, vol. 32, n° 9, p. 1443-1450. (2002). |

| [8] | Boumiz, A., C. Vernet, F. Cohen-Tenoudji (1996). Mechanical properties of cement pastes and mortars at early ages. Advanced Cement Based Materials, vol. 3, no. 3-4, pp. 94–106. |

| [9] | Nagy, A. (1997). Determination of e-modulus of young concrete with nondestructive method. Journal of Materials in Civil Engineering, vol. 9, no. 1, pp. 15–20. |

| [10] | F.F. Graff ." Wave motion in elastic solids”. Courier Dover Publication, (1991). |

| [11] | H.Renaud, "Dessin technique et lecture de plan: bâtiment, gros œuvre, Collection ": Foucher, (1995). |

| [12] | K. Aki and P.G Richards. "Quantitative Seismology : theory and methods” . Freeman and co., S.Francisco, (1980). |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML