-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Signal Processing

p-ISSN: 2165-9354 e-ISSN: 2165-9362

2012; 2(6): 158-161

doi: 10.5923/j.ajsp.20120206.02

Pellet Size Distribution Using Circular Hough Transform in Simulink

Jagdish Lal Raheja1, Gaurav Sahu2

1Digital systems GroupCentral Electronics Engineering Research Institute (CEERI/CSIR), Pilani

2Department of ElectronicsB K Birla Institute of Engineering & Technology (Bkbiet), Pilani

Correspondence to: Jagdish Lal Raheja, Digital systems GroupCentral Electronics Engineering Research Institute (CEERI/CSIR), Pilani.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

This paper presents fast and effective technique for determining the size of pellets from real-time video stream. The circular Hough transforms had been used by several researches in iris detection for face recognition, automatic ball recognition and detecting fingertips position. Here we used circular Hough transform to determine size of pellets in steel plant. This system consists of five steps i.e., take input image, convert into grey scale image, normalize grey scale image, detect edges & perform circular hough transform and do the size analysis. Initially the real-time RGB image is being read from the webcam, as the image is obtained it is converted to grey scale image following that the light normalization of the image is done, after all the circular hough technique is used to detect the pellets and to determine the size of pellets. Since detection and recognition in noisy and cluttered images is challenging problem in computer vision. Some of the pellets are overlapping each other and some itself noise that make the recognition process challenging. So to get rid from all such difficulties the technique used is circular hough transform. This technique helps in determining the centres of the pellets and to measure the radius of pellets and to mark the pellets which are selected. The system is so fast that any change in the input image causes change in the output.

Keywords: Pellet Size Determination, Circular Hough Transforms Computer Vision

Cite this paper: Jagdish Lal Raheja, Gaurav Sahu, "Pellet Size Distribution Using Circular Hough Transform in Simulink", American Journal of Signal Processing, Vol. 2 No. 6, 2012, pp. 158-161. doi: 10.5923/j.ajsp.20120206.02.

Article Outline

1. Introduction

- We introduce a fast and effective technique for determining the size of pellets from real-time video stream. In the recent past, the Circular Hough Transform (CHT) had been used in several researches for various applications, Some of the application includes iris detection for face recognition, automatic ball recognition and detecting fingertips position[1]. We apply CHT for finding the size of iron ore pellets using images of pellets taken from a CCD camera in real time. These pellets are small spherical iron ore balls used in steel production. The pellets are made and sent to industries. It makes the steel production more reliable and energy efficient when iron ore pellets are used. One of the important factor in pellets is that their size should be within a given limits (≈ 10-16 mm). Any pellets beyond the specified size have to be recycled. Therefore the size of the pellets must be regularly checked in real time during their production. Estimation of pellets is done based on the fact the pellets are spherical. The size will be determined by implementing the mathematical algorithm. Since the production of pellets is in bulk, so it is very difficult to determine the size of pellets by manual sampling, and it is also not possible to take images again and again and feed them to system and get the result, so to get rid of this problem the system developed is the real-time in which we just have to place the camera which gives the input as the real input, as this input is given to system then further processing is done and the desired output is obtained. In the system, inputs which are given to the system are radius range, threshold gradient, filter for local maxima, multi-radii and filter for accumulator. As the RGB input image is given to the system, the radius range and all other parameters are set then the model is simulated, during simulation the various calculation [1] are performed and also various conversions are done to determine the centres and radius of pellets using the technique circular hough transform[2][3], the results obtained are also real time and in the output the pellets which are in the radius range are selected and marked with white color, also centres and radius values are displayed.

2. Methodology

- Pellets size determination algorithm is divided into six subparts:● Take an image frame from live video.● Convert this image to grey scale image.● Light normalization of grey scale image.● Embedded matlab function for circular hough transform.● Embedded matlab function for circling pellets.● Displaying circle centres and radius.

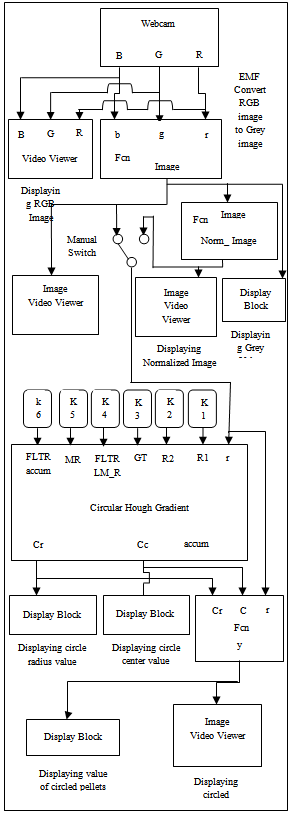

2.1. Video Input Image

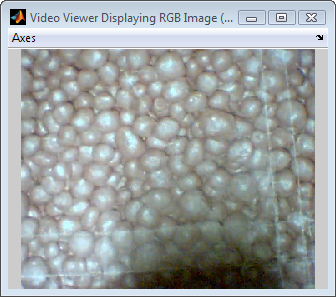

- The live video which is taken as the input image is the RGB image i.e., having red, blue and green component, it forms an array which can be of class double, uint8 or uint16. The RGB image pixels are stored along the three dimension array. Figure 1 shows the RGB input image.

| Figure 1. Input image taken from webcam |

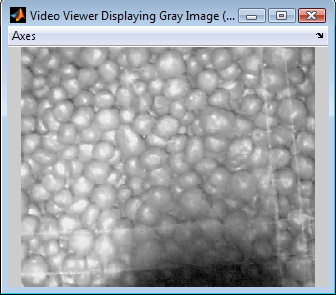

2.2. Conversion to Grey scale image from input RGB image

- As the RGB image is received from the webcam, then we convert it to Grey scale image so that our processing will be fast because it occupy less space. Figure 2 shows the converted Grey scale image.

| Figure 2. Converted Grey scale image |

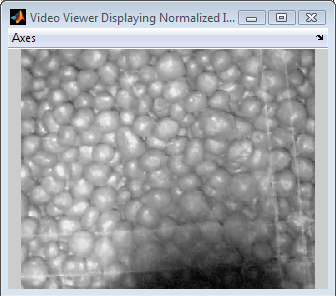

2.3. Normalization of grey scale image

- As the Grey scale image is received, light normalization of image][2][3][4][5][6] is done so as to get rid of the varying light problem on the image. The model is designed so if the normalization is not required then with the help of the manual switch the Grey scale image can also be directly given to main function for detecting the size of pellets. Figure 3 shows the image after performing light normalization.

| Figure 3. Normalized image of Grey scale image |

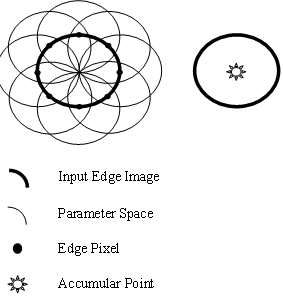

2.4. Circular Hough Transform (CHT)

| Figure 4. The edge points contribution to the accumulator space |

| (1) |

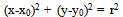

3. The Designed Model

- The details of the designed model are as follows:● The live input image is taken from the webcam.● The embedded matlab function is written which convert the RGB image to the Grey scale image also the RGB image is being viewed with the help of video viewer.● Another embedded matlab function is written to normalize the image, the display block is placed which is displaying the grey values. After normalization the image is viewed with the help of video viewer.● The manual switch is also placed so that if normalization is not required than the grey image will directly give as further input to the system. Whatever image is being given as further input is viewed by video viewer.●The embedded matlab function i.e., the main function for circular hough transform is written which detects the pellets and calculates the centres and radius of the pellets. The inputs to this function are as follows: the normalized image or the un-normalized grey image into r mentioned in the Figure 5, the R1 and R2 are the radius range of the pellets, GT is the threshold gradient, FLTRLM_R is the filter for local maxima, MR is the multi radii and FLTR accum is the filter for the accumulator.● The outputs of the embedded matlab function i.e., for the circular hough transform are as follows: accum which stores all the accumulated data produced during pellet size determination, Cc are the circle centres and Cr are the circle radius. The display blocks are connected to Cc and Cr which displays the values of centres and radius respectively.● Another embedded matlab function is written to mark the pellets which are selected and are within the radius range. The inputs to this embedded function are the image which is given as input to circular hough transform function, circle centres Cc and circle radius Cr. The output of this embedded function is the image circling the pellets which are selected. To this the display block is connected which is displaying the values of the image pixels, and also video viewer is connected which is displaying the image.

| Figure 5. Simulink model for pellet size determination |

4. Experimental Results

| Figure 6. RGB image from webcam |

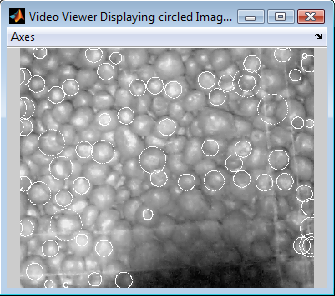

| Figure 7. Pellets which are selected are circled |

5. Conclusions and Results

- To detect the pellets and to determine the size of them the live input image which is taken is of size 288*352 pixels the image is shown in Figure 6, as this image is given to the system then this image is converted to grey scale image having same pixels 288*352. After this the image is normalized if required with the help of manual switch transferring control to the embedded function for normalization. After normalization the image is given to the main embedded matlab function i.e., circular hough transform for detecting pellets and determining centre and radius of the pellets. After this the image is given to the embedded matlab function which is used to mark the pellets which are selected, the image is shown in Figure 7, having the same pixels 288*352.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML